After a few iterations, here was my design for a manual one handed solder feeding assistive device. A 3d printed hollow tube forms the base and with a wire ferrule connection at the end for a metal blunt tip near the soldering iron. The body has a cut away area to expose the solder allowing it to be pushed forward by just the thumb and two contours to all holding it like a pencil. Original design used a leur-lock syringe tip but solder would snag up. The wire ferrule terminal may need a bit of super glue to keep it secured in place but provides snag free feeding.

Original design used rounded funnel on the free end to feed the solder. Upgraded design now has integral spool holder with a mini bobbin. For the original funnel design, regular benchtop solder spool holder can be used. By holding the solder secure in the tube with thumb while pulling the whole contraption more solder can be unwound from the spool. Rounded funnel design prevents kinks in the solder from causing snags while feeding. My test prints were printed in PLA+ oriented vertically on print bed, works well but the fit and finish not real smooth. Printed more with SLA resin; nicer feel but the cut away section has more flex than the FDM print.

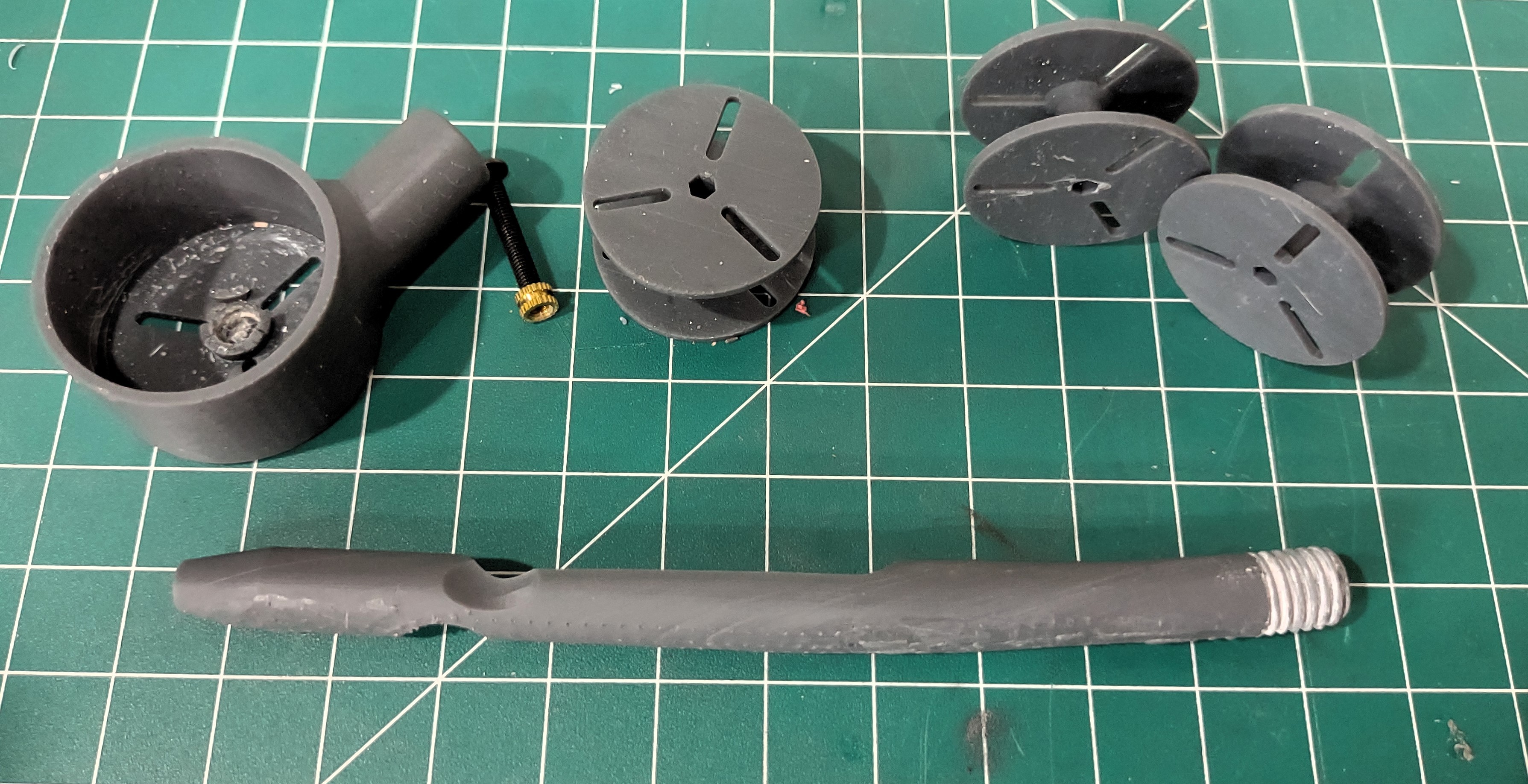

With the original design, there was still a tether to the main spool on the desk. This results in the occasional snag on some other part or getting tangled with another cord. The integral spool holder took a few iterations but dispenses the solder smoothly using a M3 screw as a shaft. Nothing special for the screw and allows for some spare bobbins to be stocked. A few different STL options are provided to accommodate printing the spool design on FDM or with SLA. This eliminates the tether and still provides a robust design without any motors, buttons, or batteries to complicate the operation or build.

The design was modeled with Fusion 360. STL files, exported fusion 360 models, and .STEP files are available on Printables. (https://www.printables.com/model/531387-one-handed-manual-solder-feeder) to build your own. It is released with a creative commons attribution license.

mulcmu

mulcmu

ken.do

ken.do

B K

B K

Ian Hunn

Ian Hunn

SUF

SUF

My personal method is to spool solder wire on empty solder litze spools.

It's not as sophisticated as this, but it's been adequate for 20+ years.