Features:

- very compact - will fit into handle

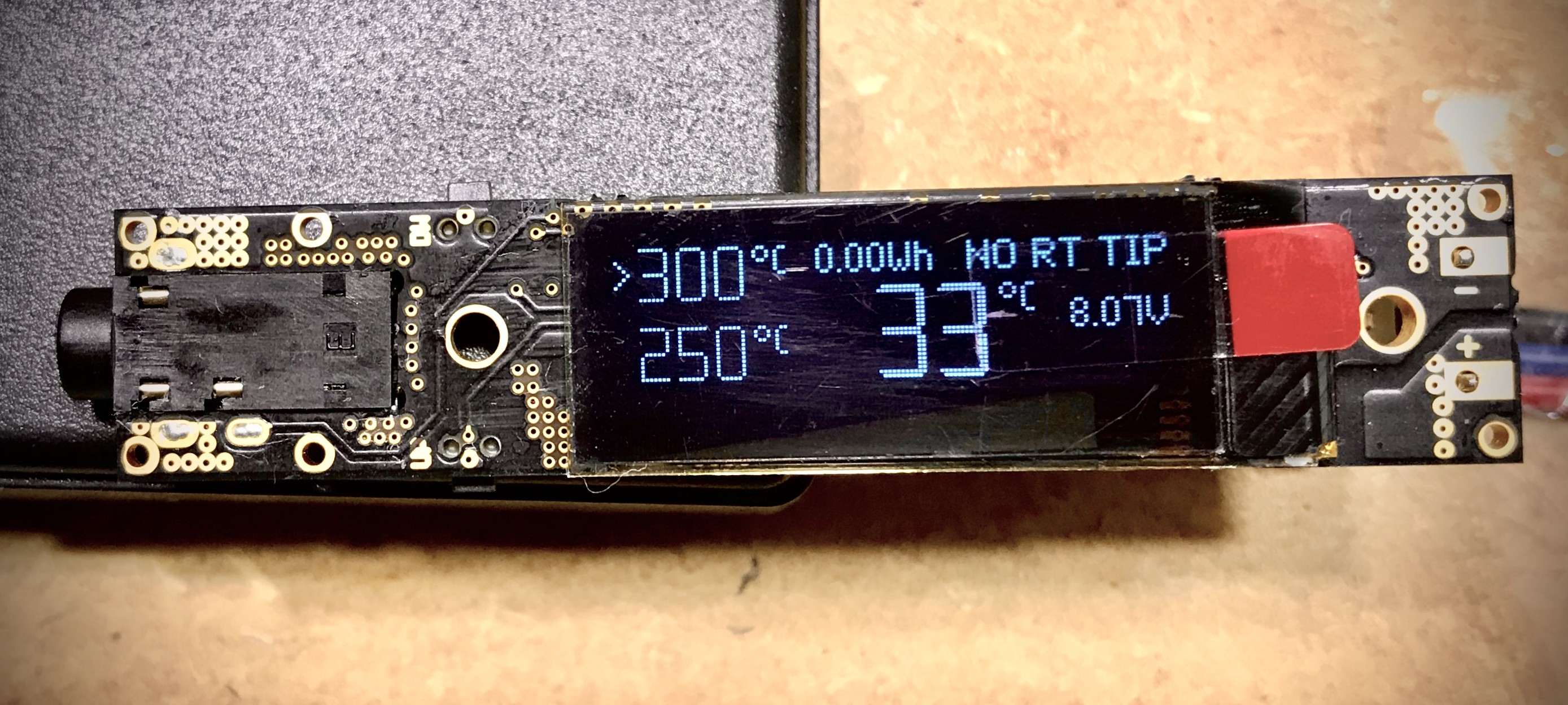

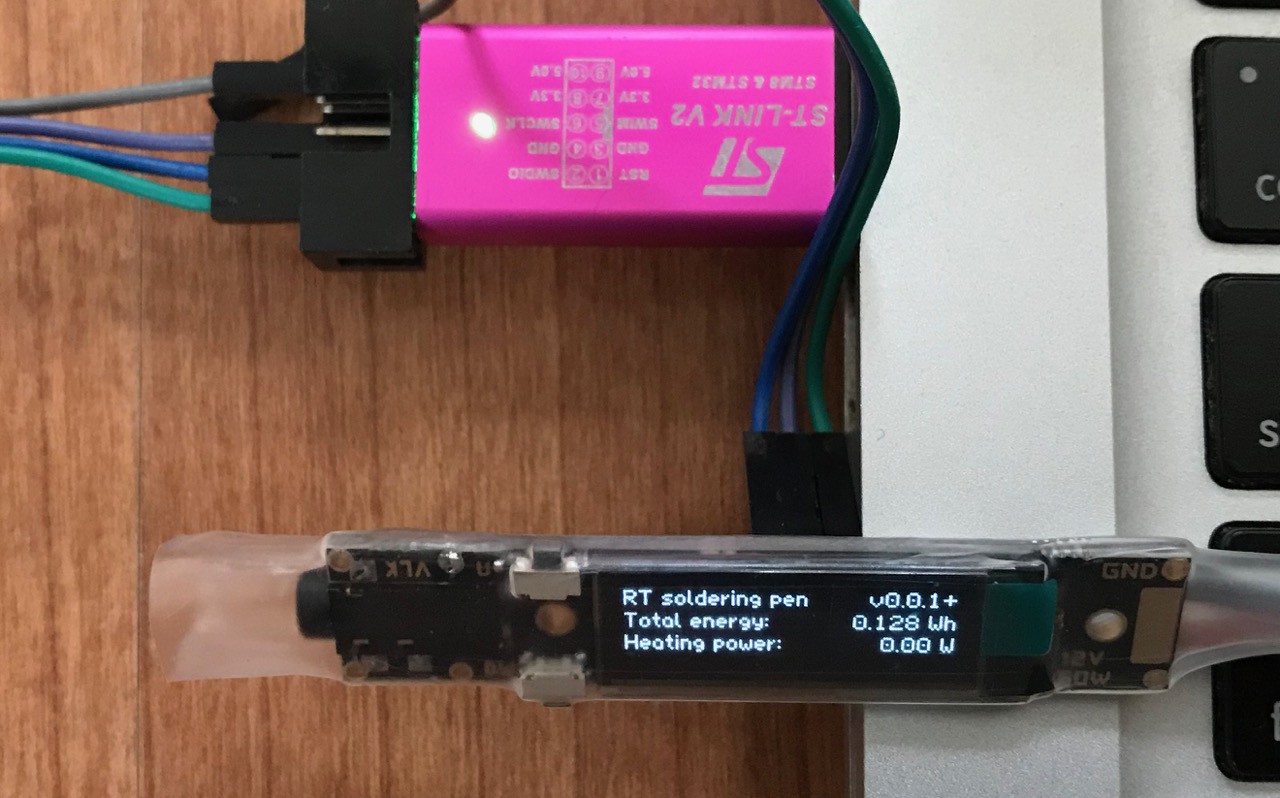

- display show status, preset and tip temperature, power, supply voltage, drop, ...

- two buttons

- automatic standby

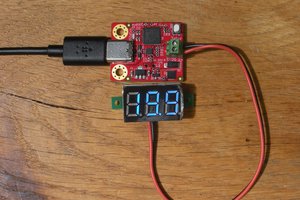

- sensing supply voltage and tip current

- precise regulation with PID (PSD controller with some modifications)

- supply voltage is from 5V to 18V (best is 10-13V)

- designed to supply from LIPO battery 2S (7.4V max is about 18W) or 3S (11.1V max is more than 40W)

- calculating consumed Wh

- heat-up in 5sec from 25 to 400°C (with 40W limit)

- Idle current about 8mA

What is planed:

- case

- battery monitor (warn when battery need charge)

- configuration editor for some constants from PSD controller, power limit, ....

- open-source everything

Videos:

vlk

vlk

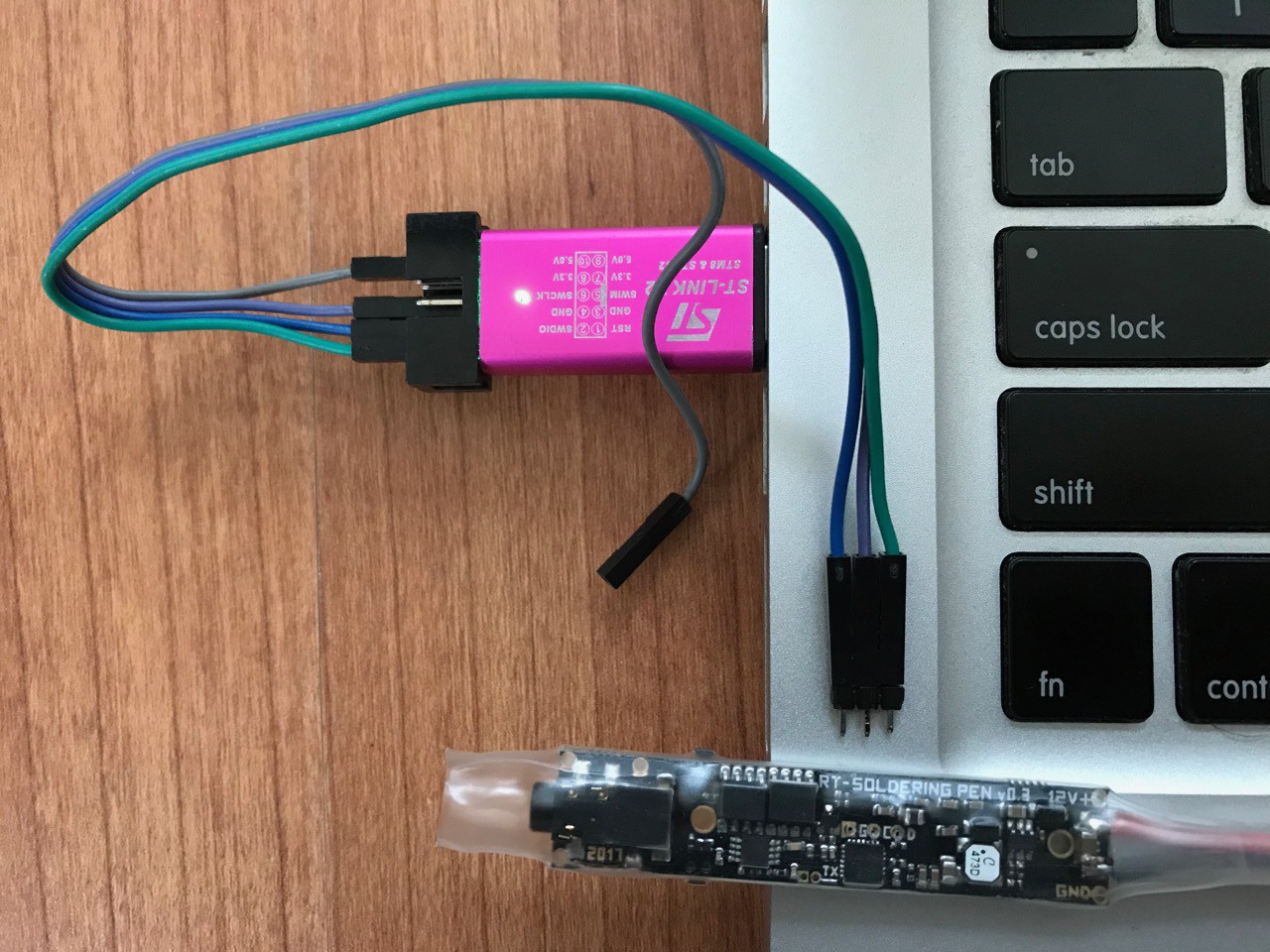

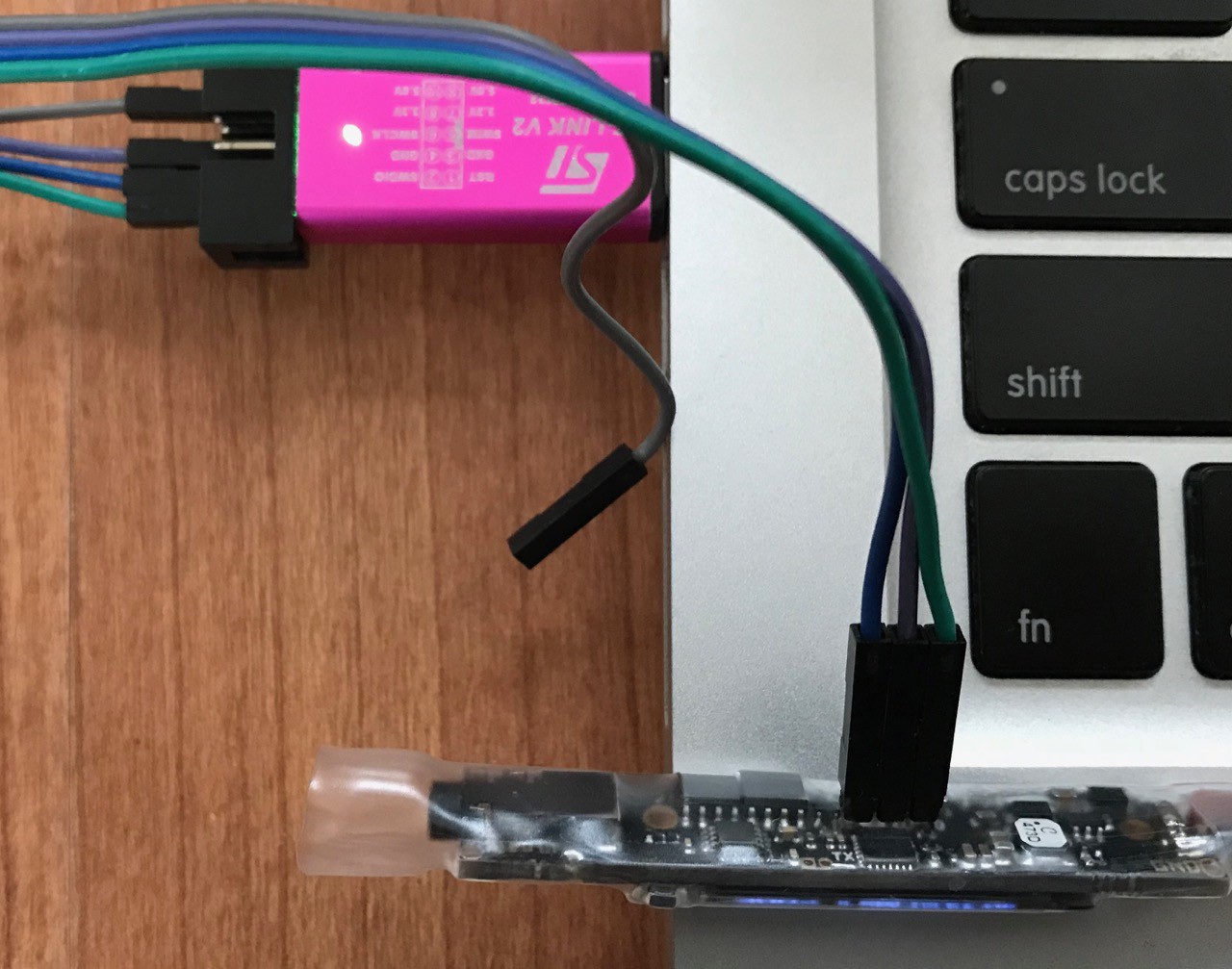

To program, use ST-Link utility from ST, or any other SW for Flashing STM32 micro-controllers (openocd, texane/stlink, pystlink, ...)

To program, use ST-Link utility from ST, or any other SW for Flashing STM32 micro-controllers (openocd, texane/stlink, pystlink, ...)

Markus Loeffler

Markus Loeffler

Clara Hobbs

Clara Hobbs

Otto Winter

Otto Winter

bobricius

bobricius

No, it is not a clone, it is completely created from scratch (HW and SW), it uses different MCU, also have current sensor, for better diagnostic and more precise regulation and also it can operate at lover voltages, faster heating (4s). Also biggest advantage are Weller tips, and is made in EU. On other side there is no USB.