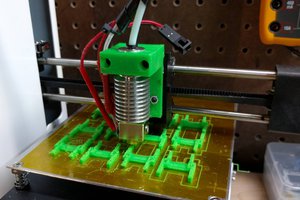

A printer for the people that want to print BIG objects at industrial quality levels with a 200EUR household 3D-printer.

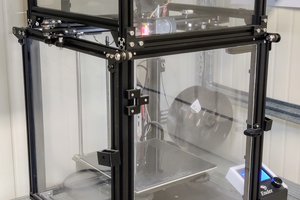

XL Long bed 3D-printer conversion

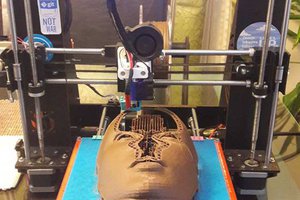

This how-to will show how to fit a longer bed on any flashable 3D-printer. We use the long bed ourselves to print windturbine blades.

Bram Peirs @ FW2W

Bram Peirs @ FW2W

Benchoff

Benchoff

Mateo Miličević

Mateo Miličević

Federico Virdia

Federico Virdia

Gorky

Gorky