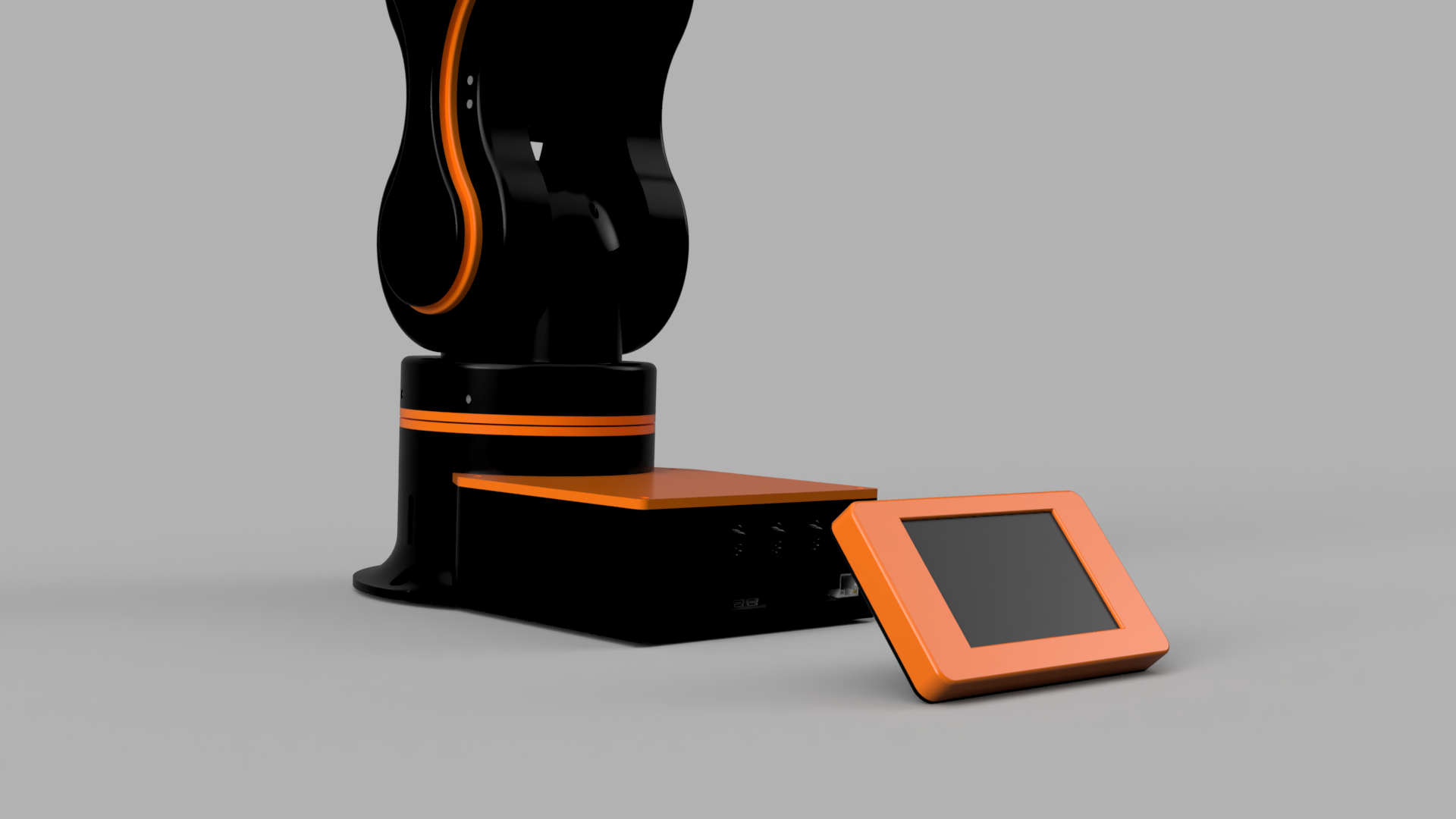

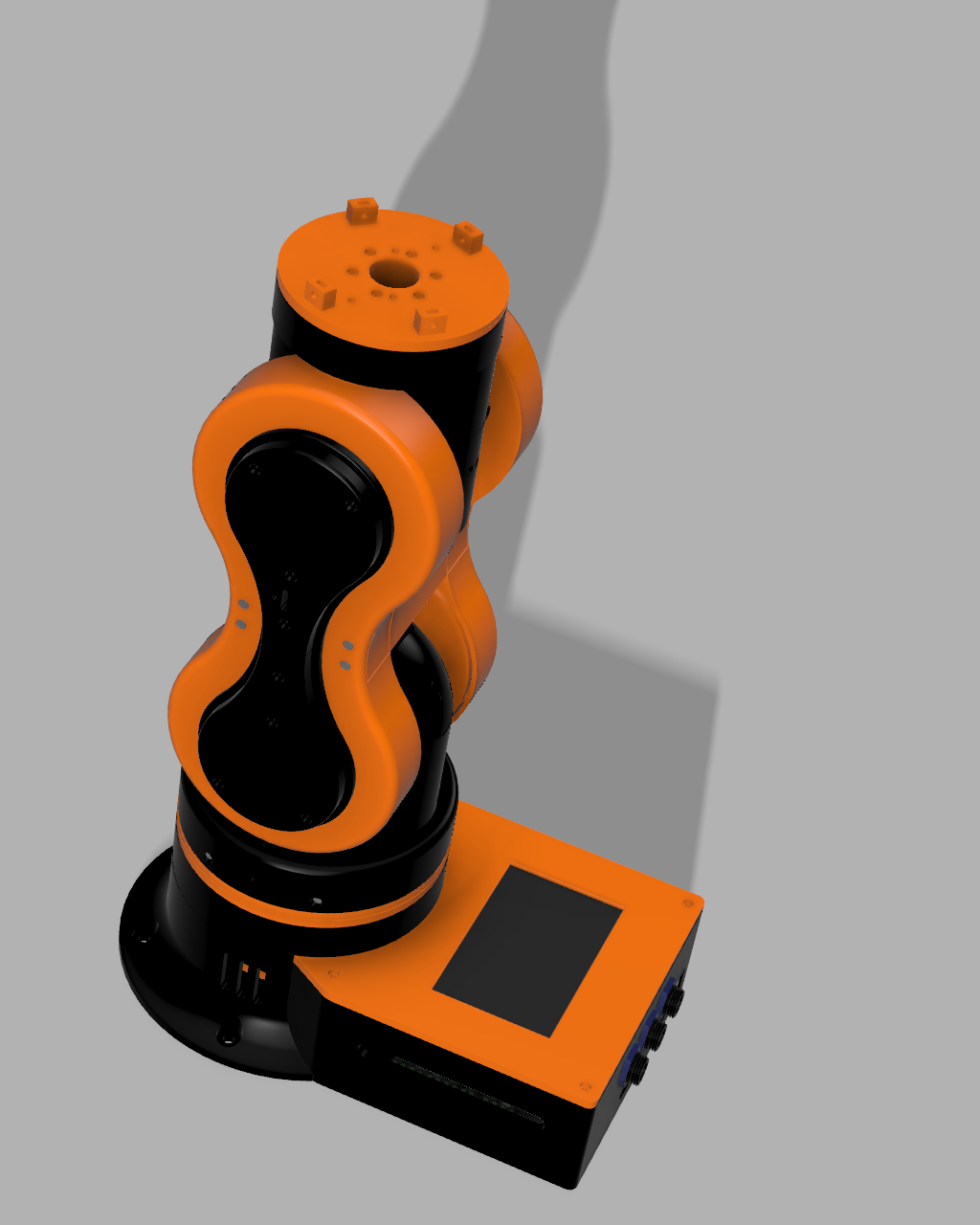

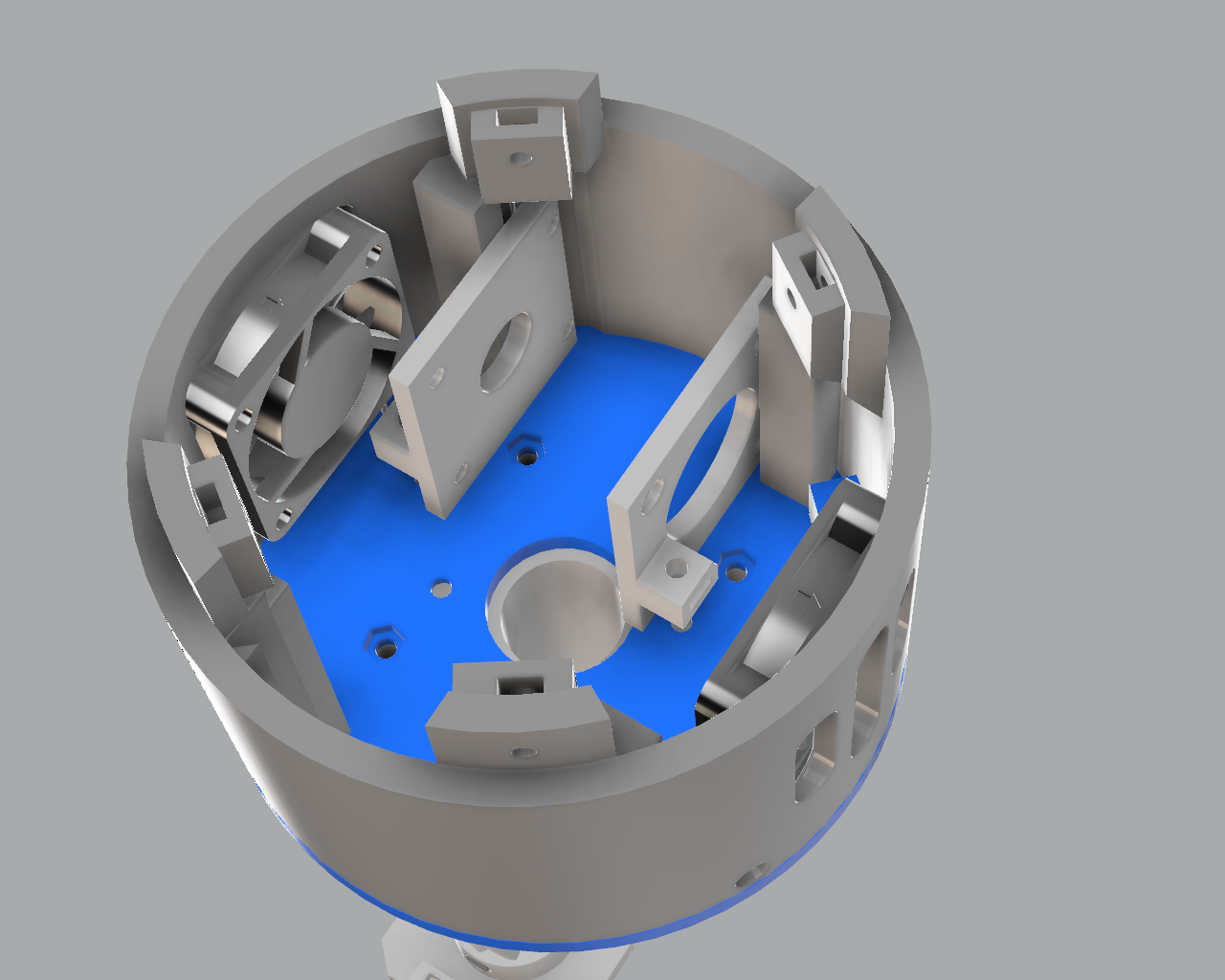

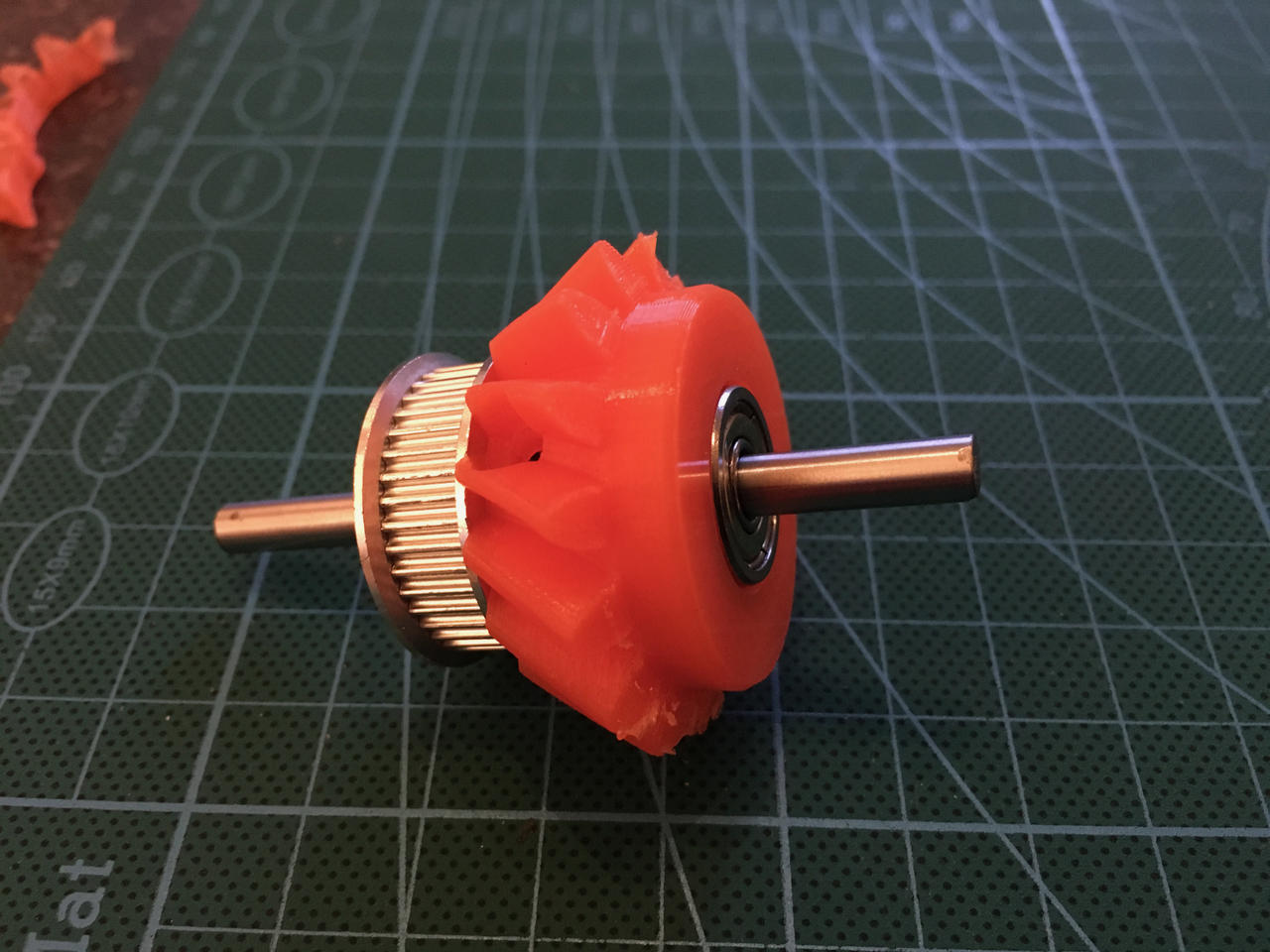

I was looking for a 6DOF robot arm to print.

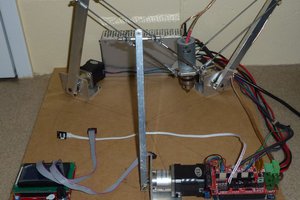

The first project I found was the Mantis Robot Arm. This is a nice robot arm but the project seams to be abandoned.

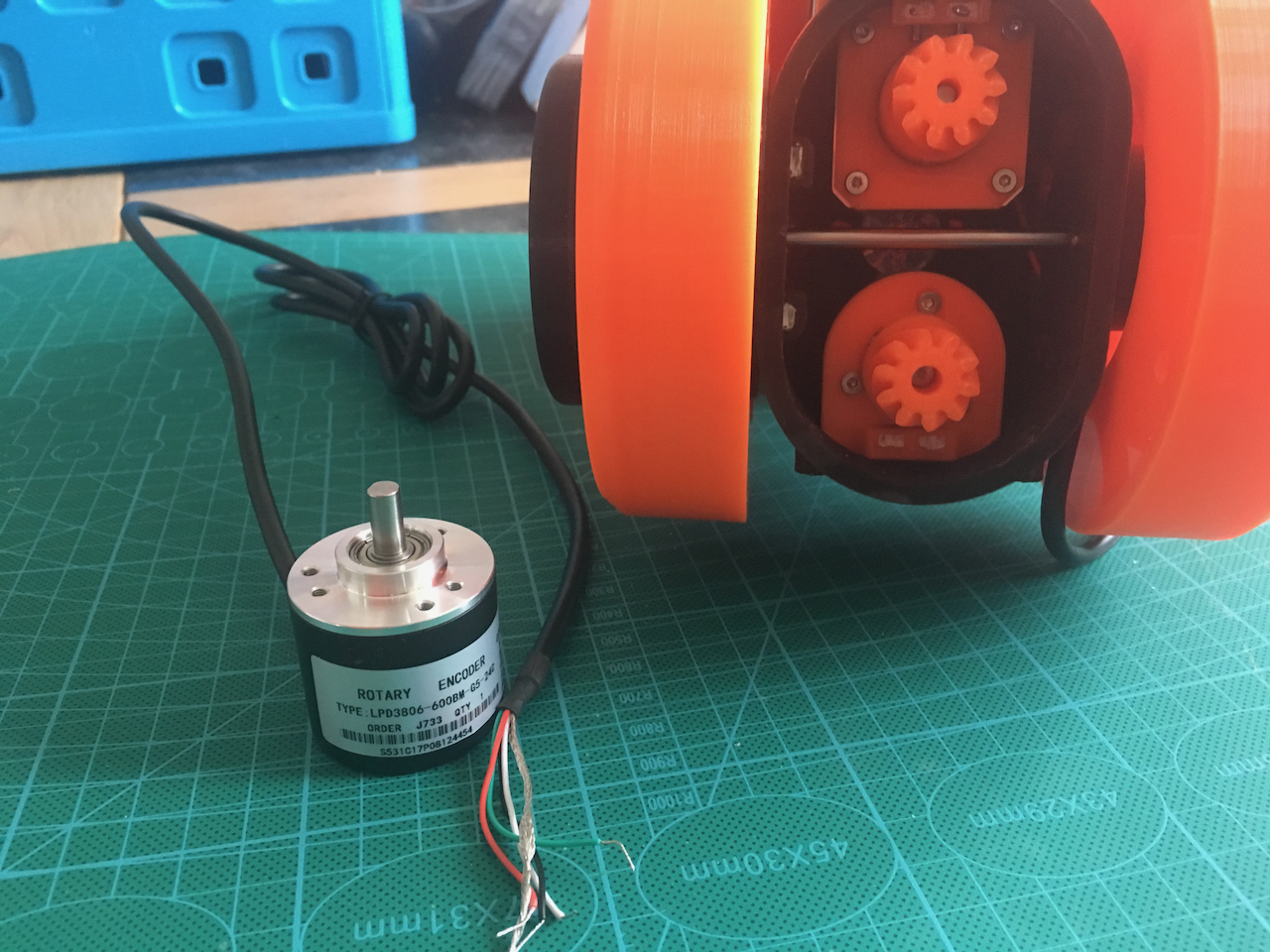

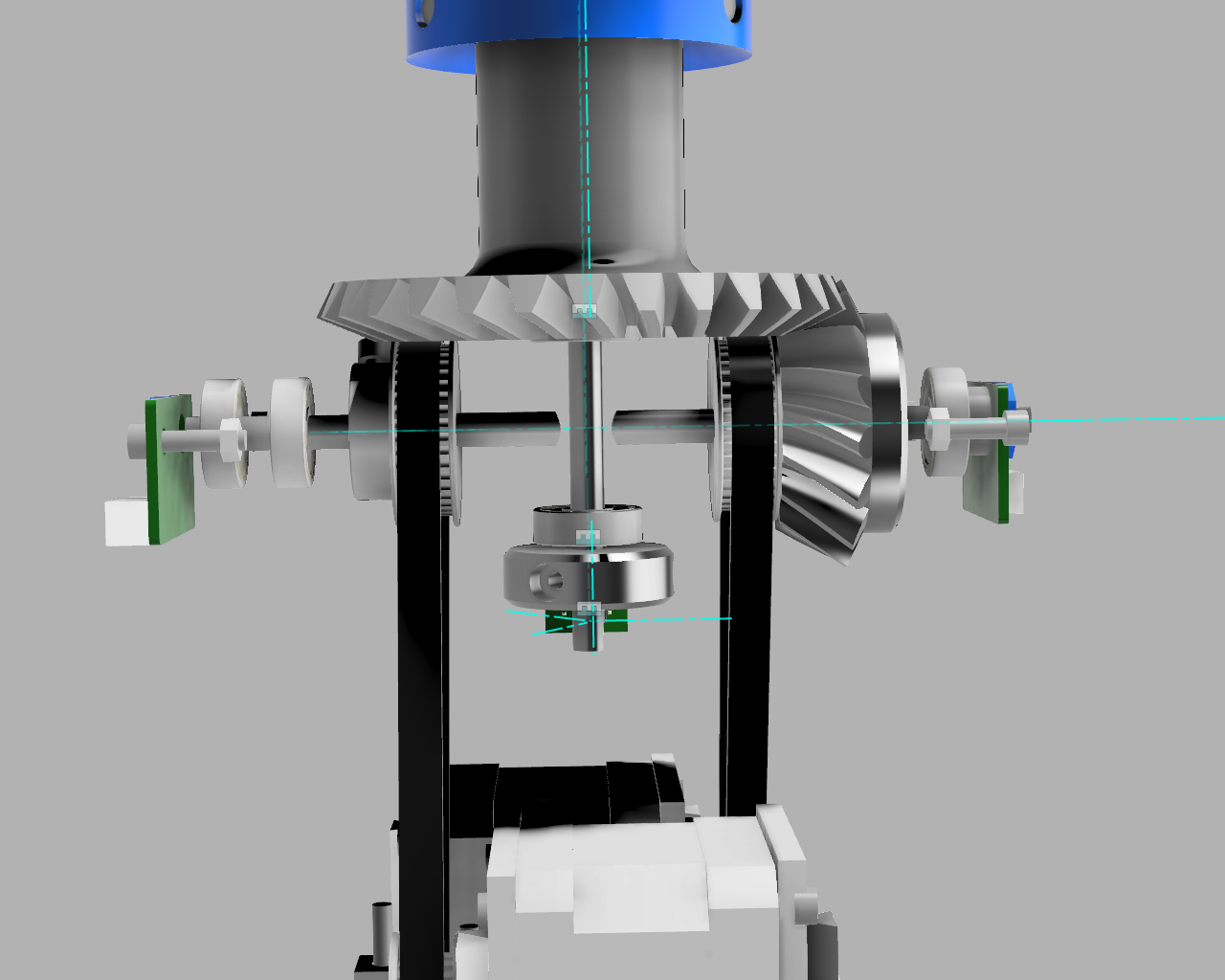

Then somebody pointed me to the Thor OpenSource 3D printable Robotic Arm from Angel LM. I loved this design but I was missing the feedback sensors.

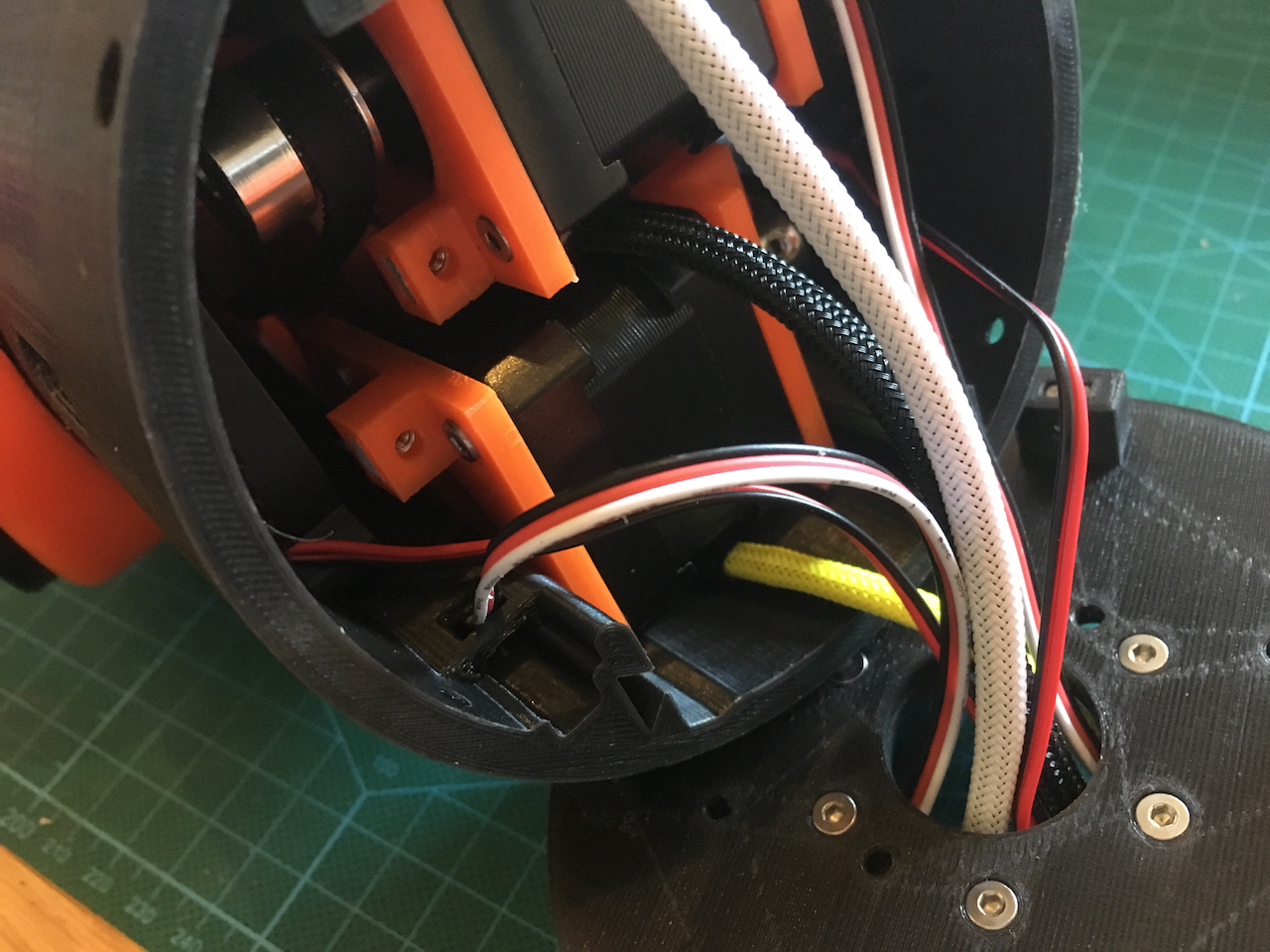

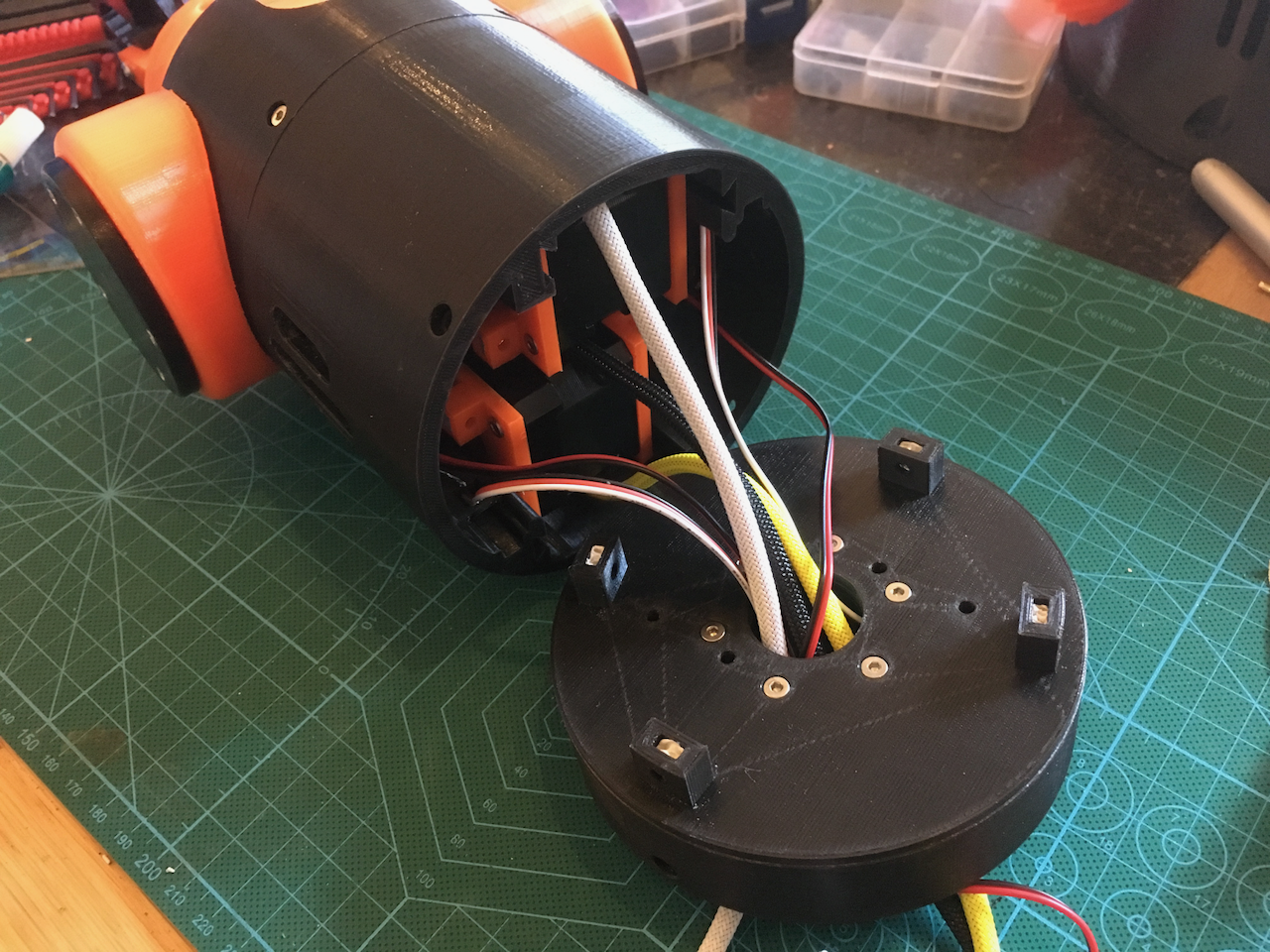

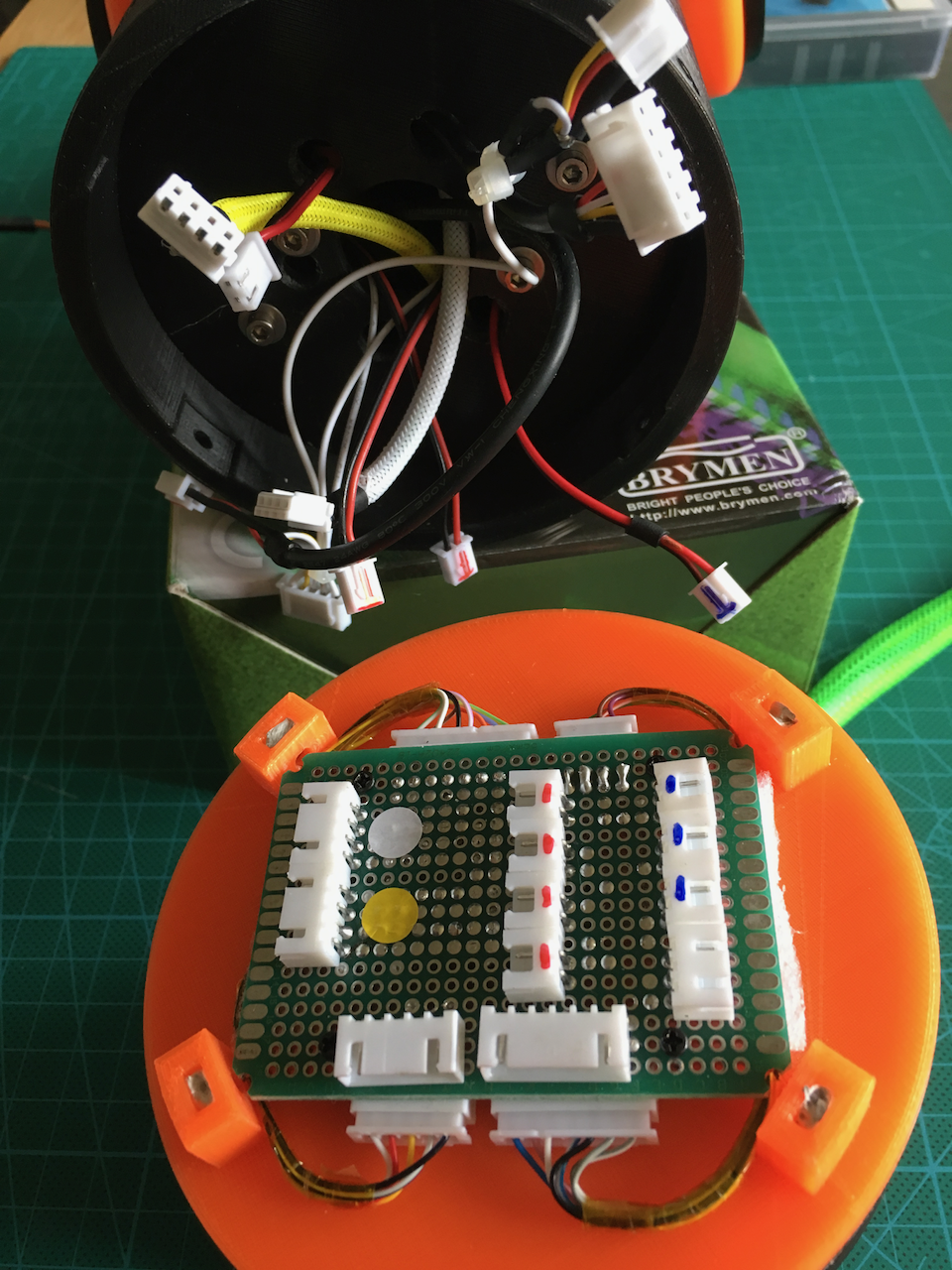

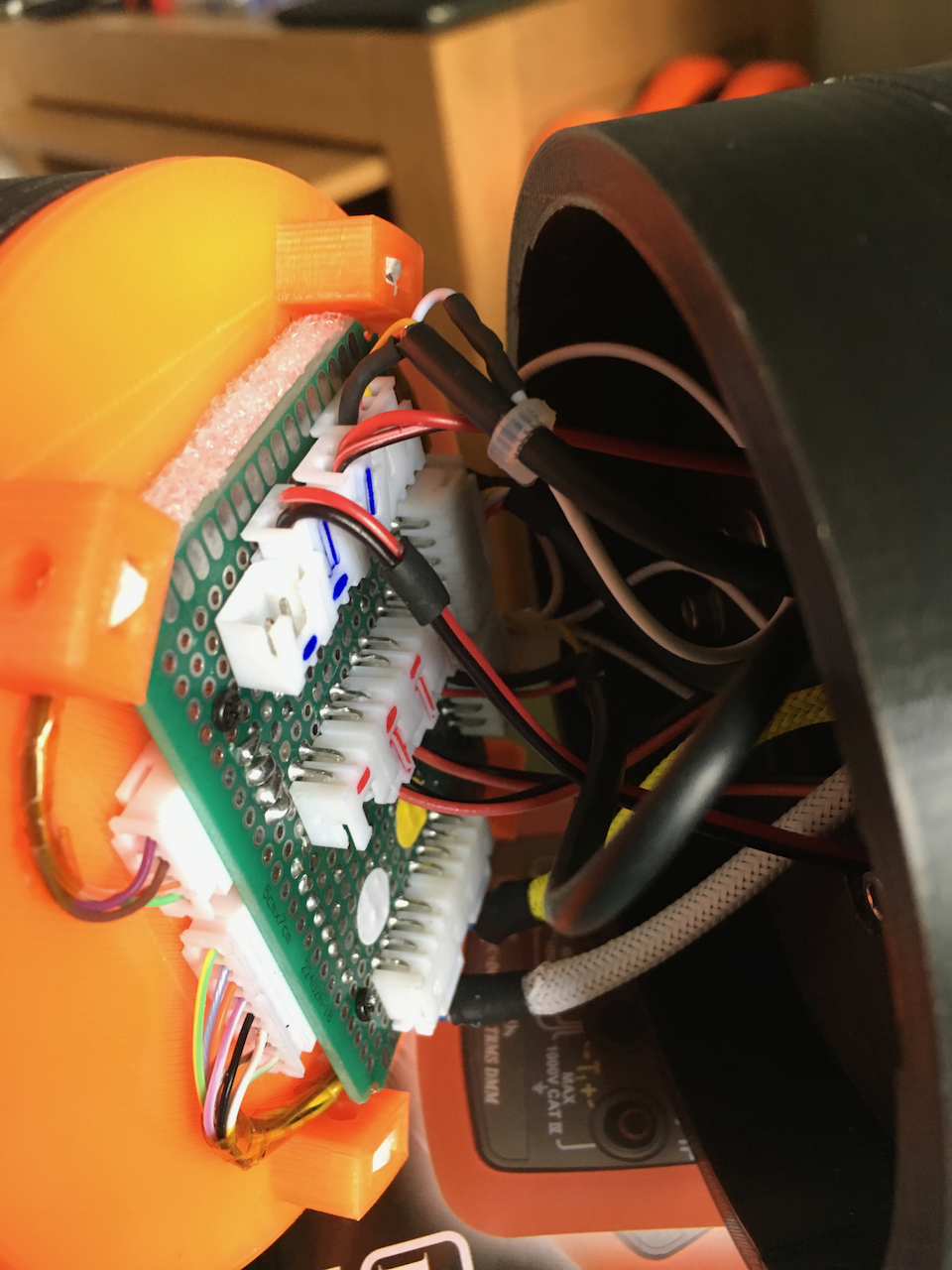

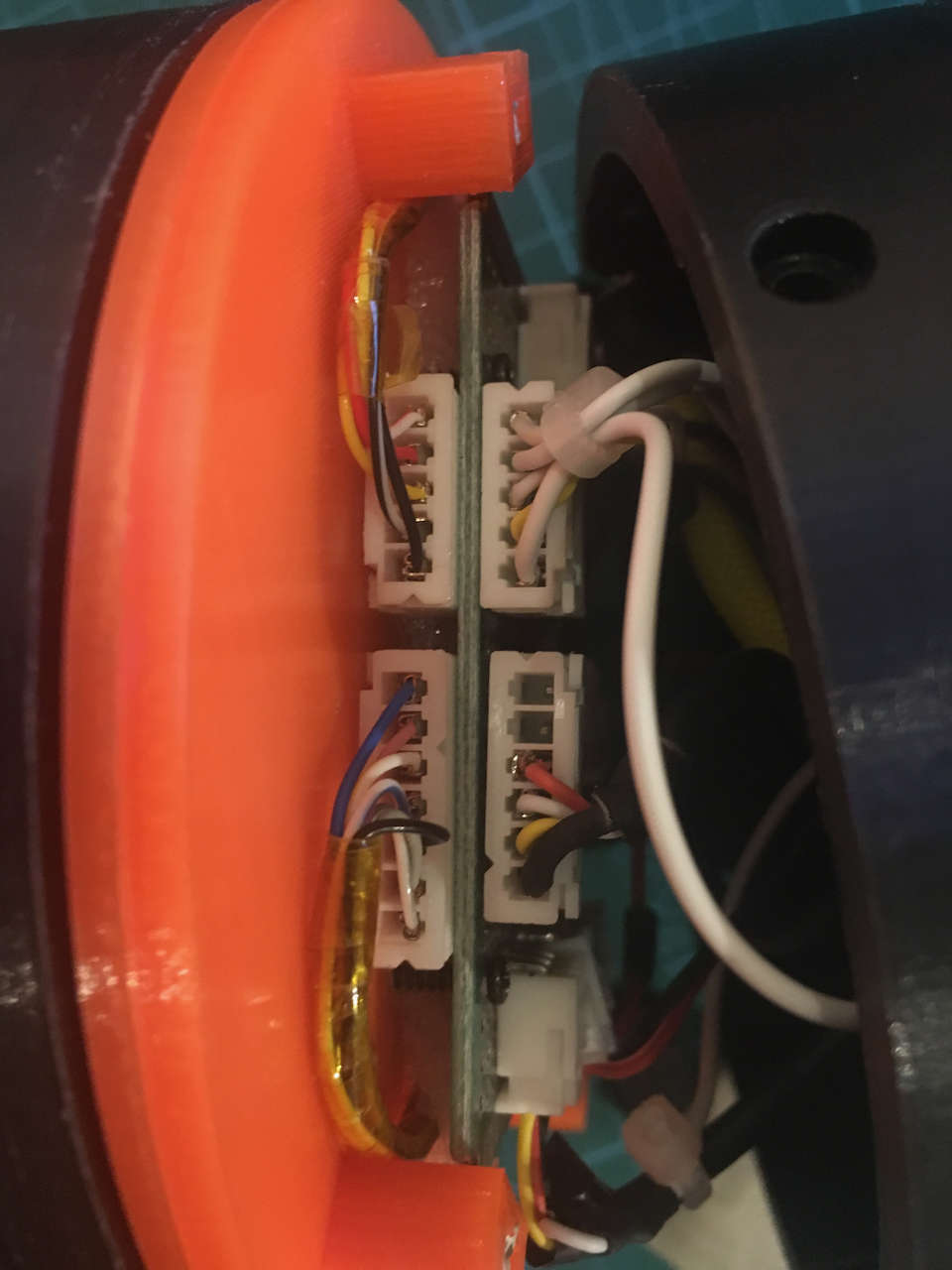

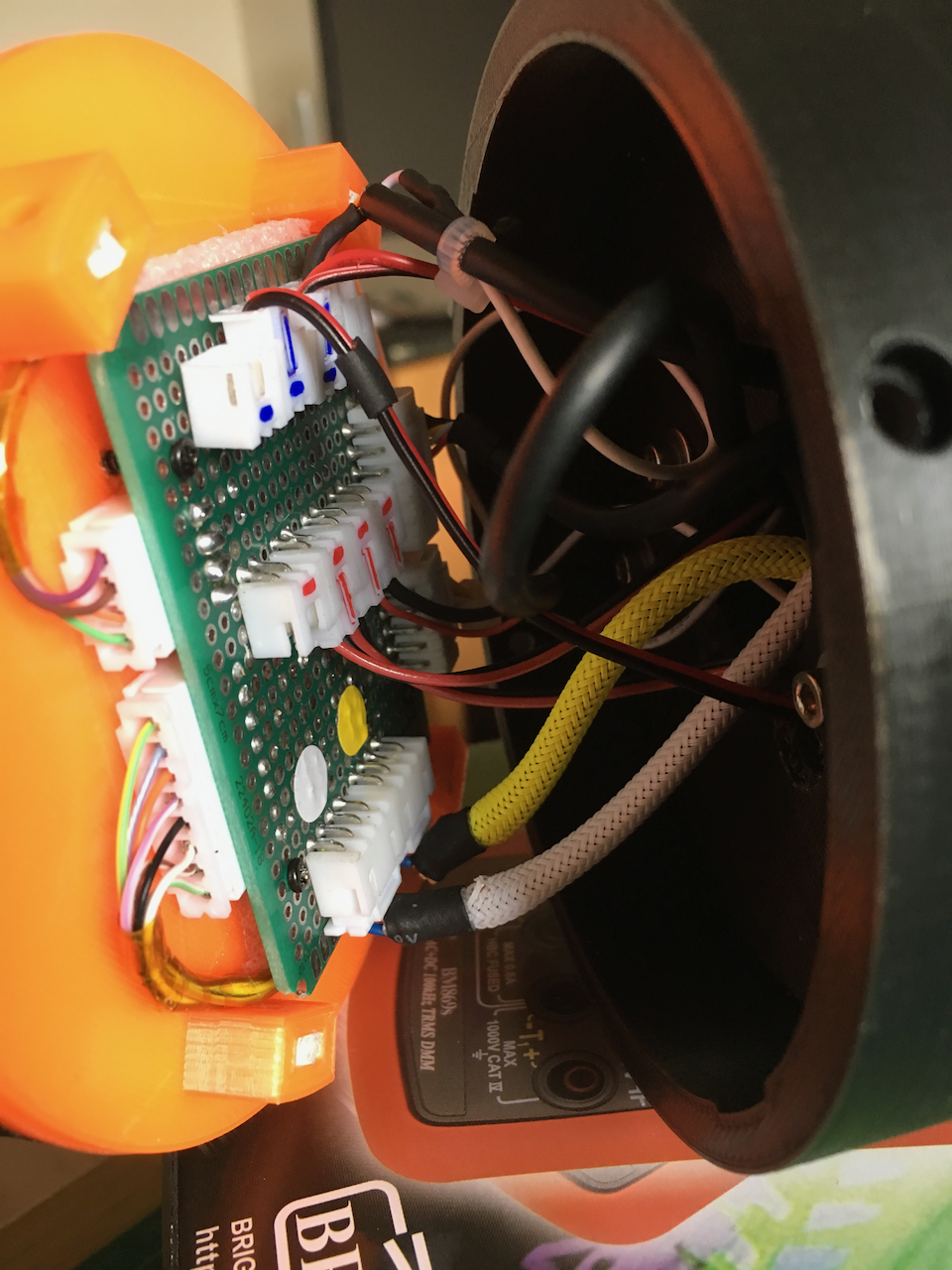

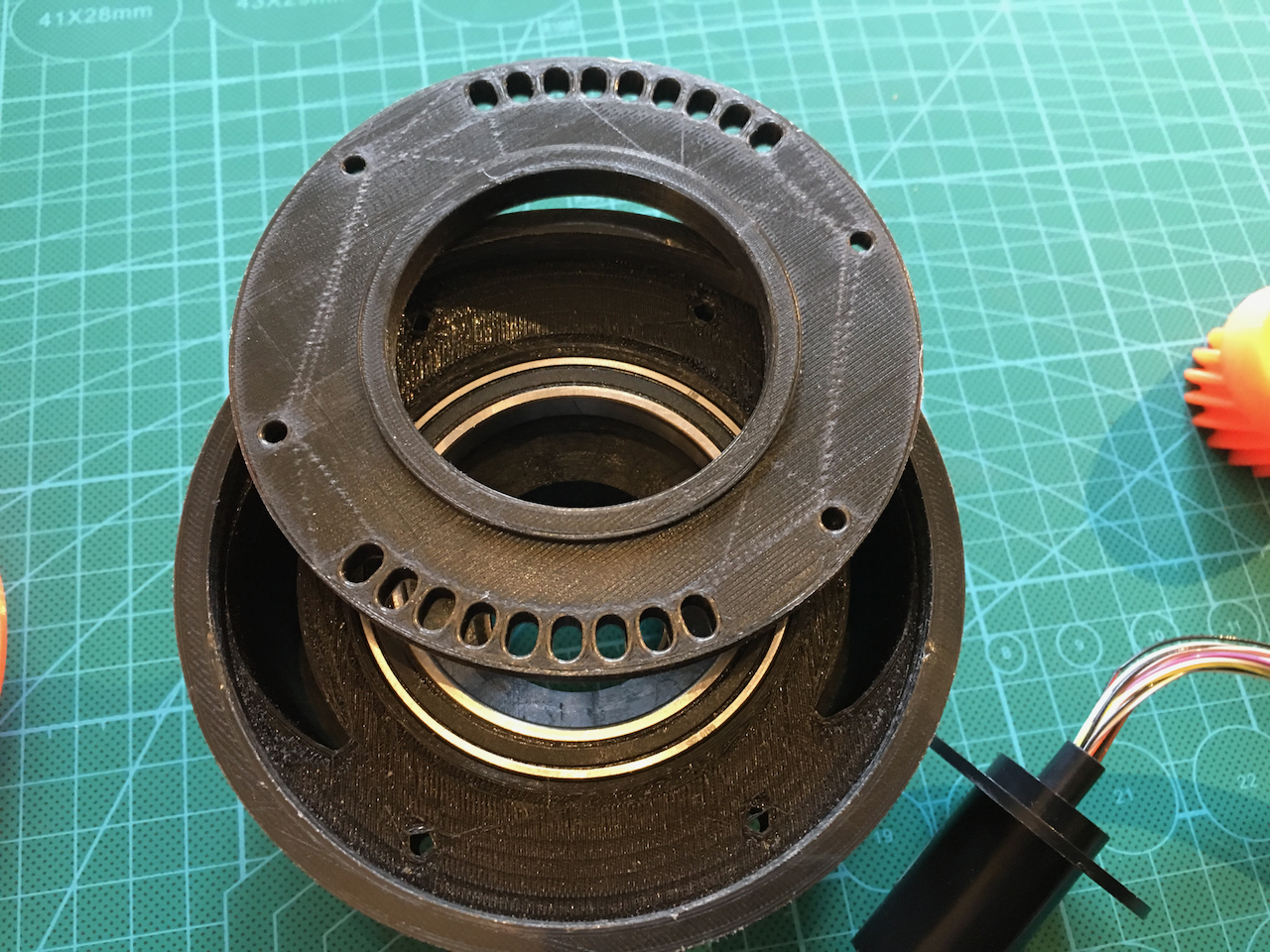

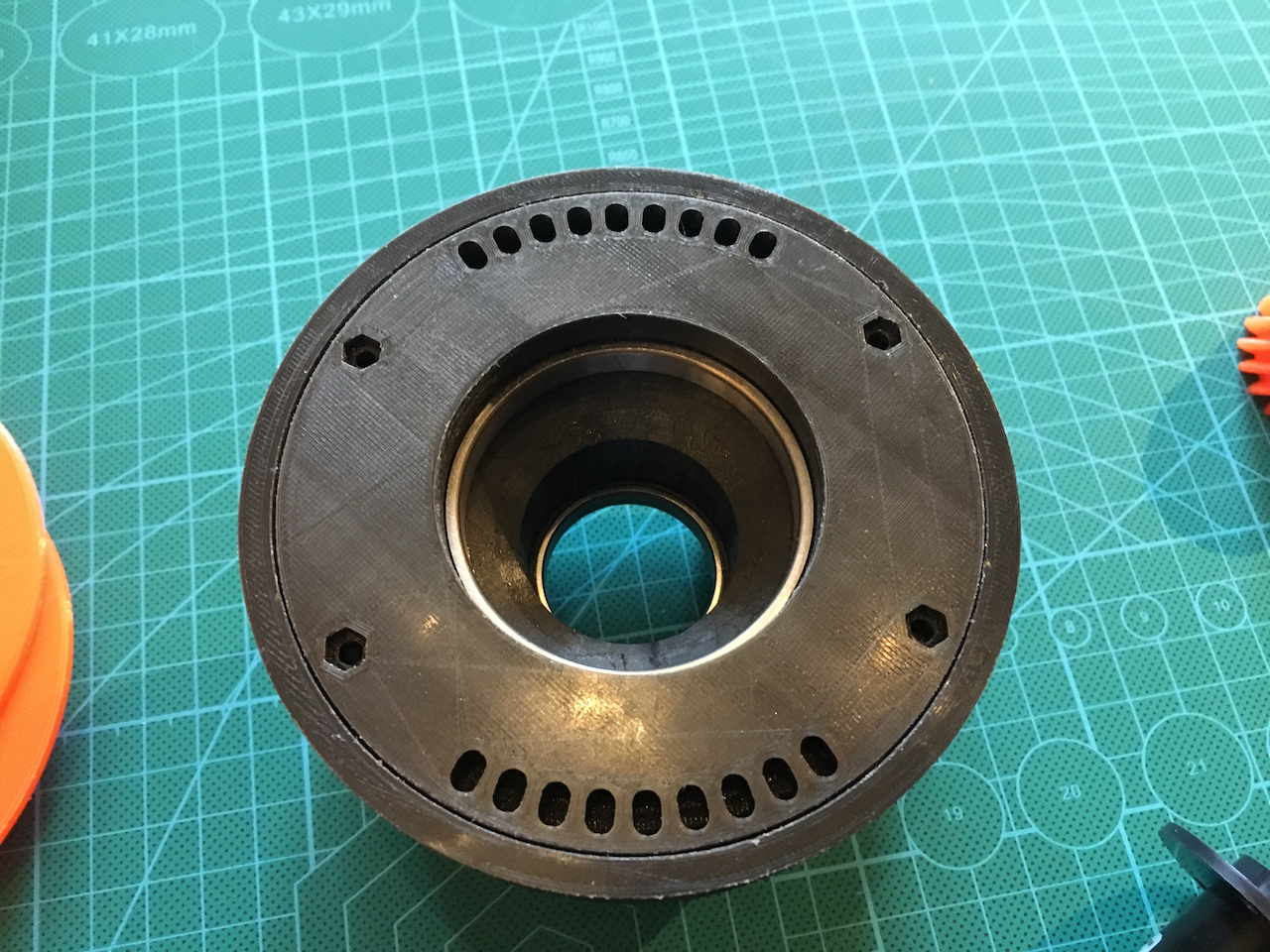

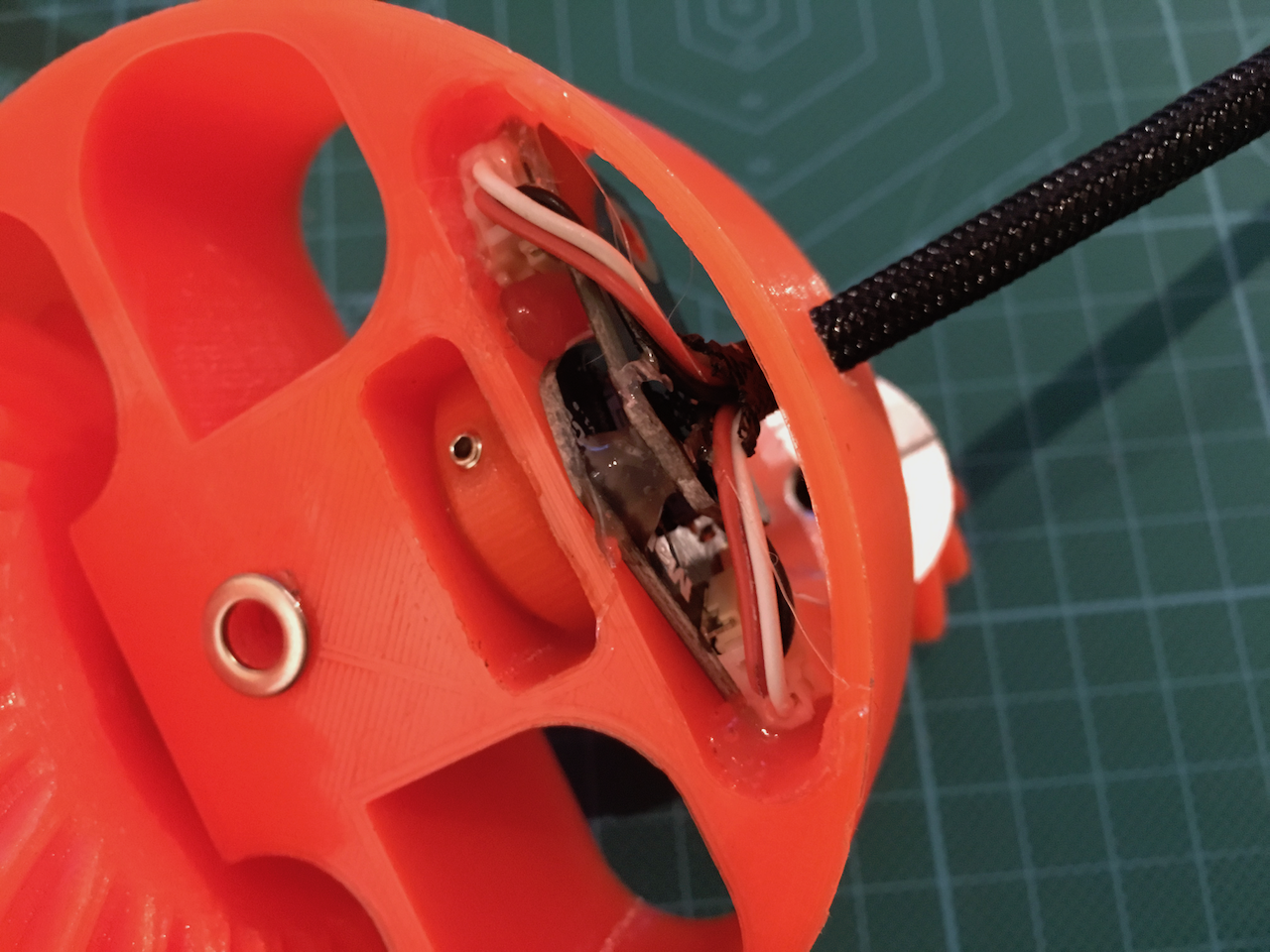

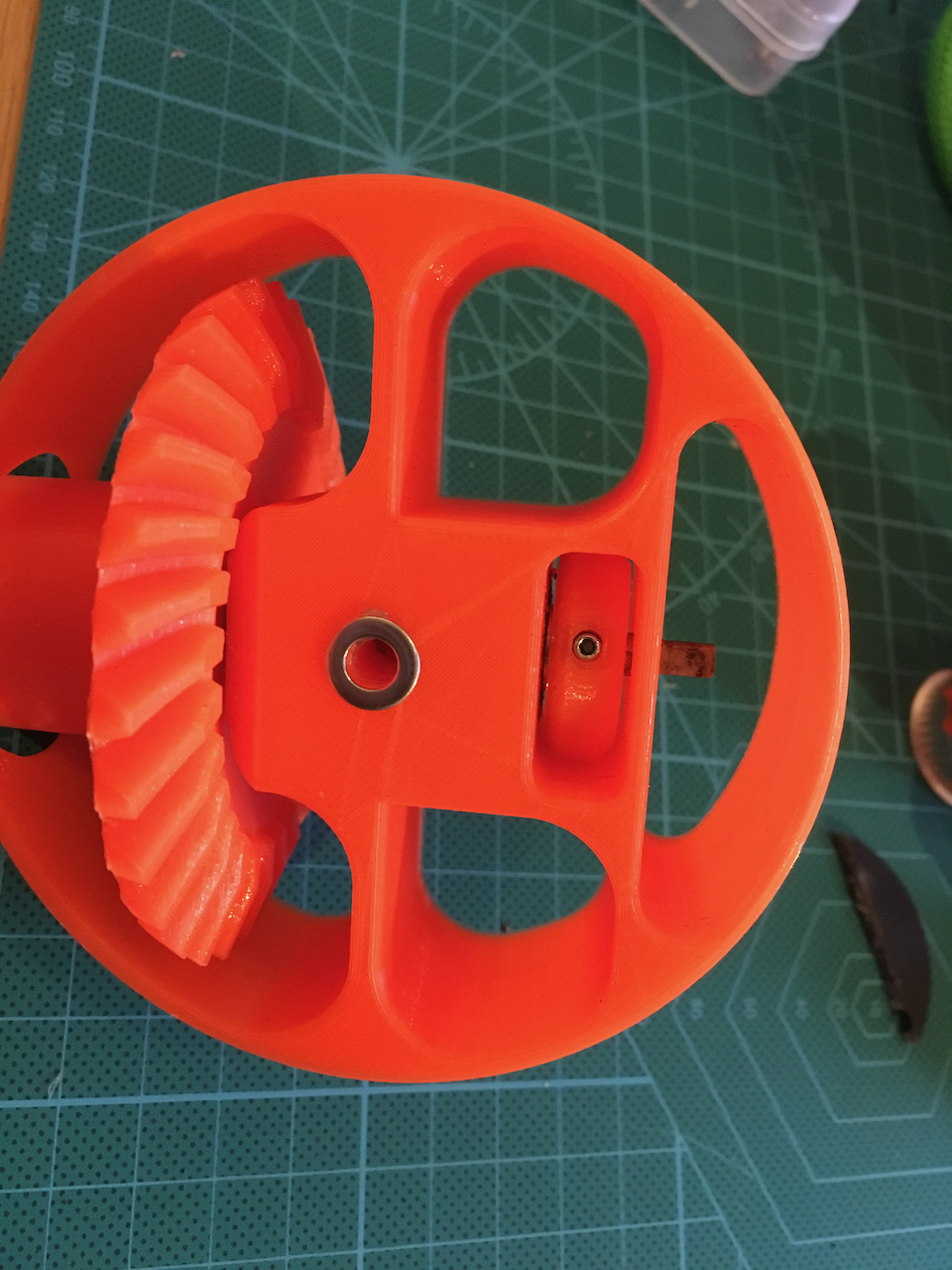

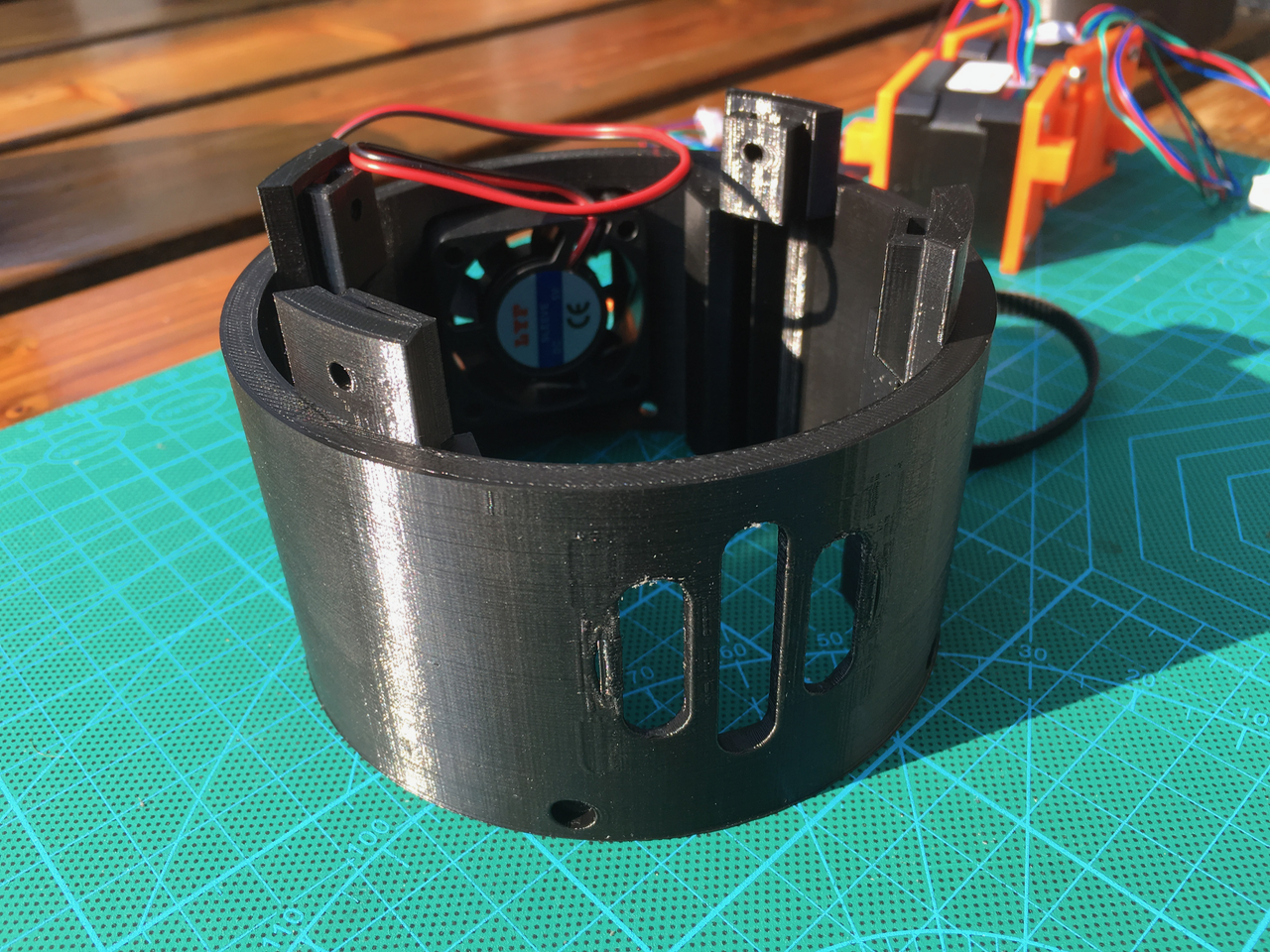

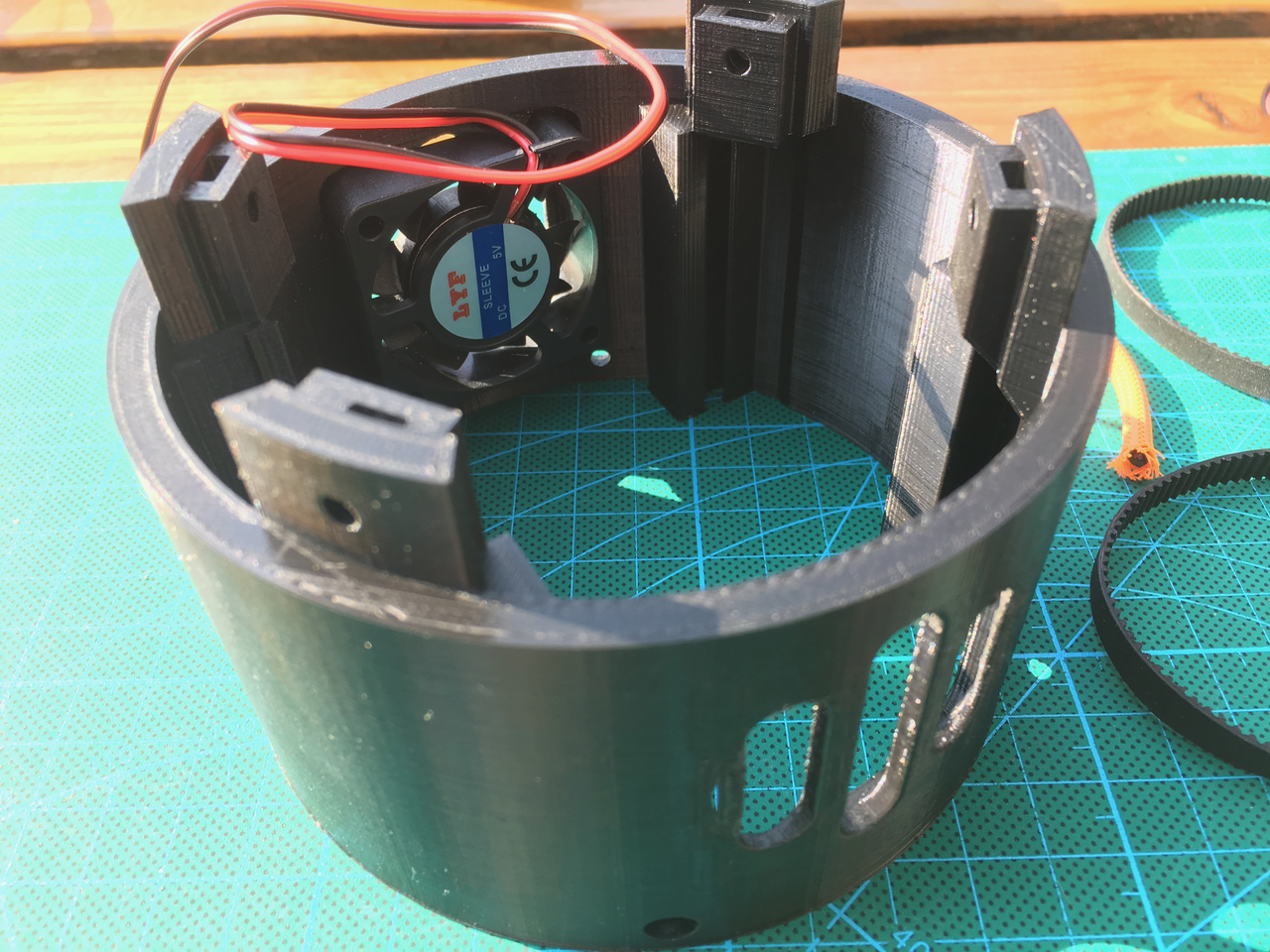

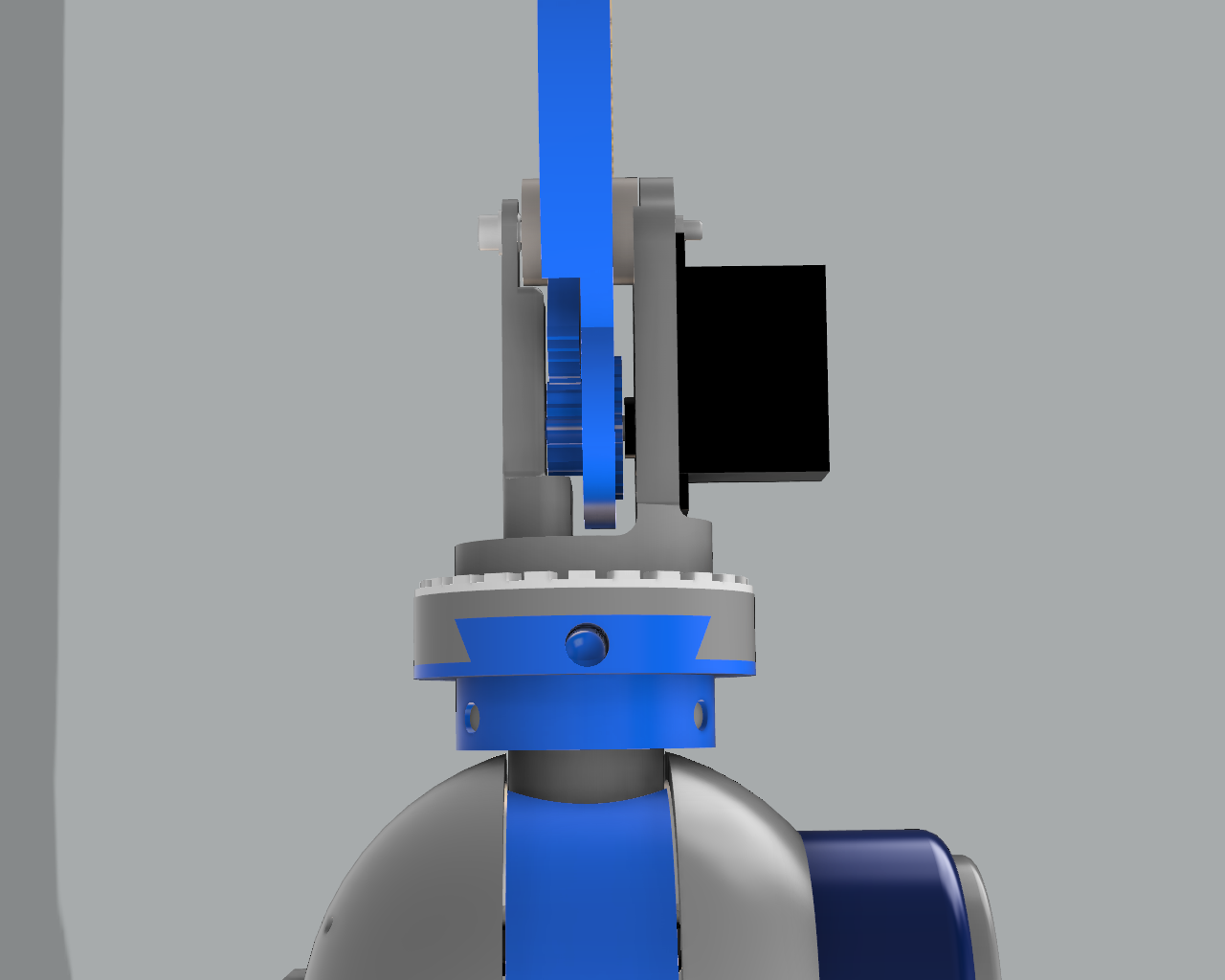

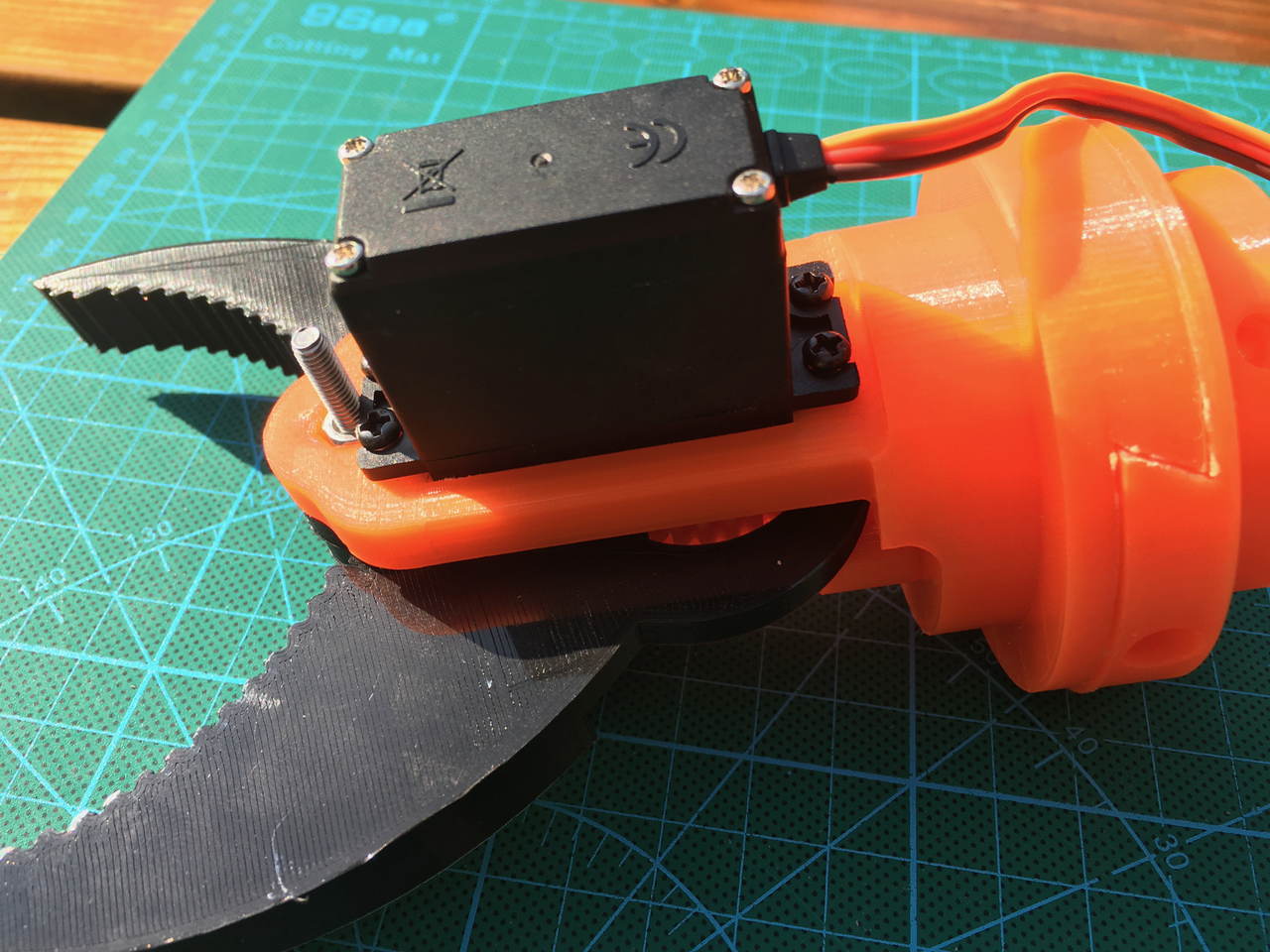

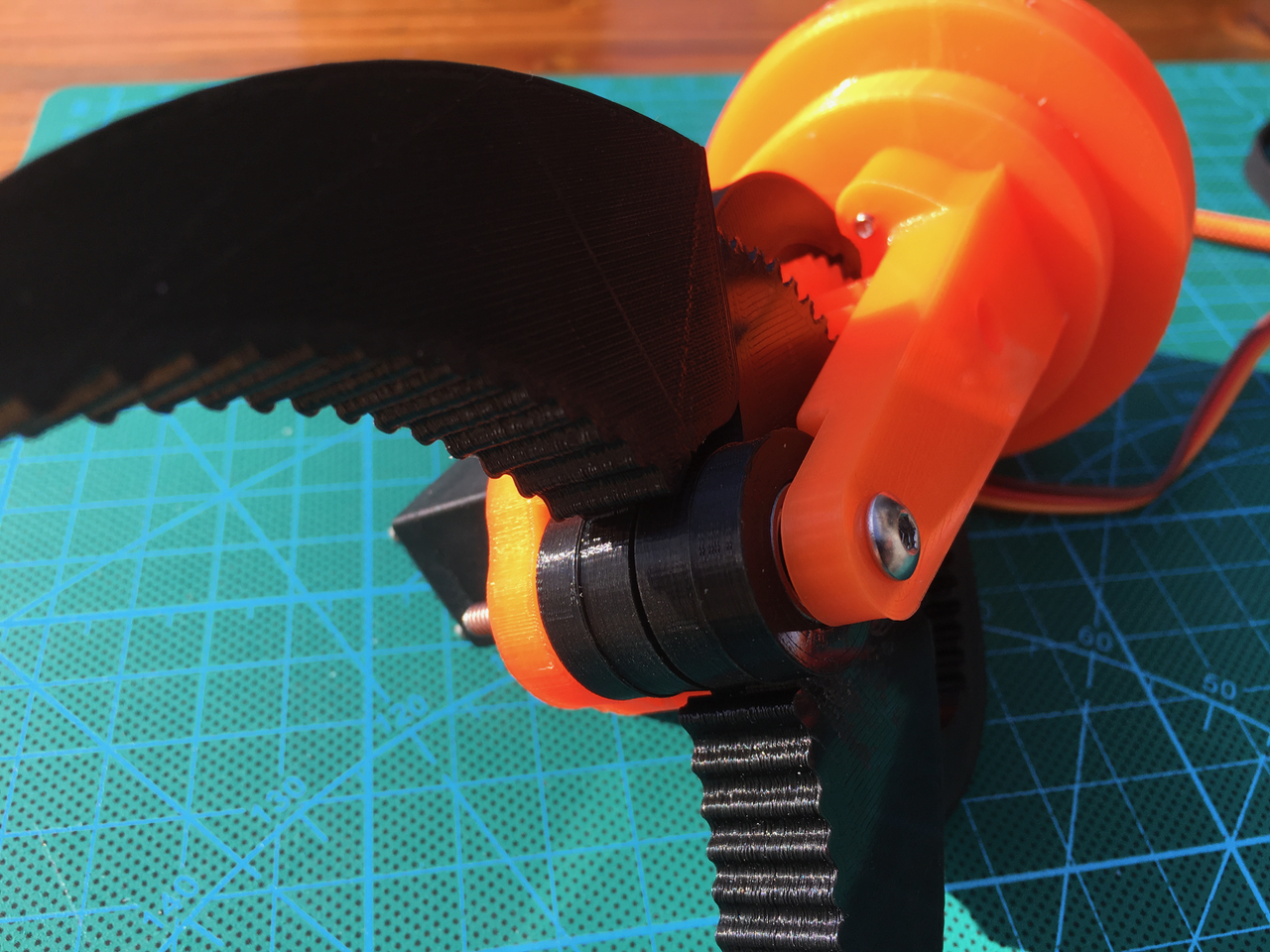

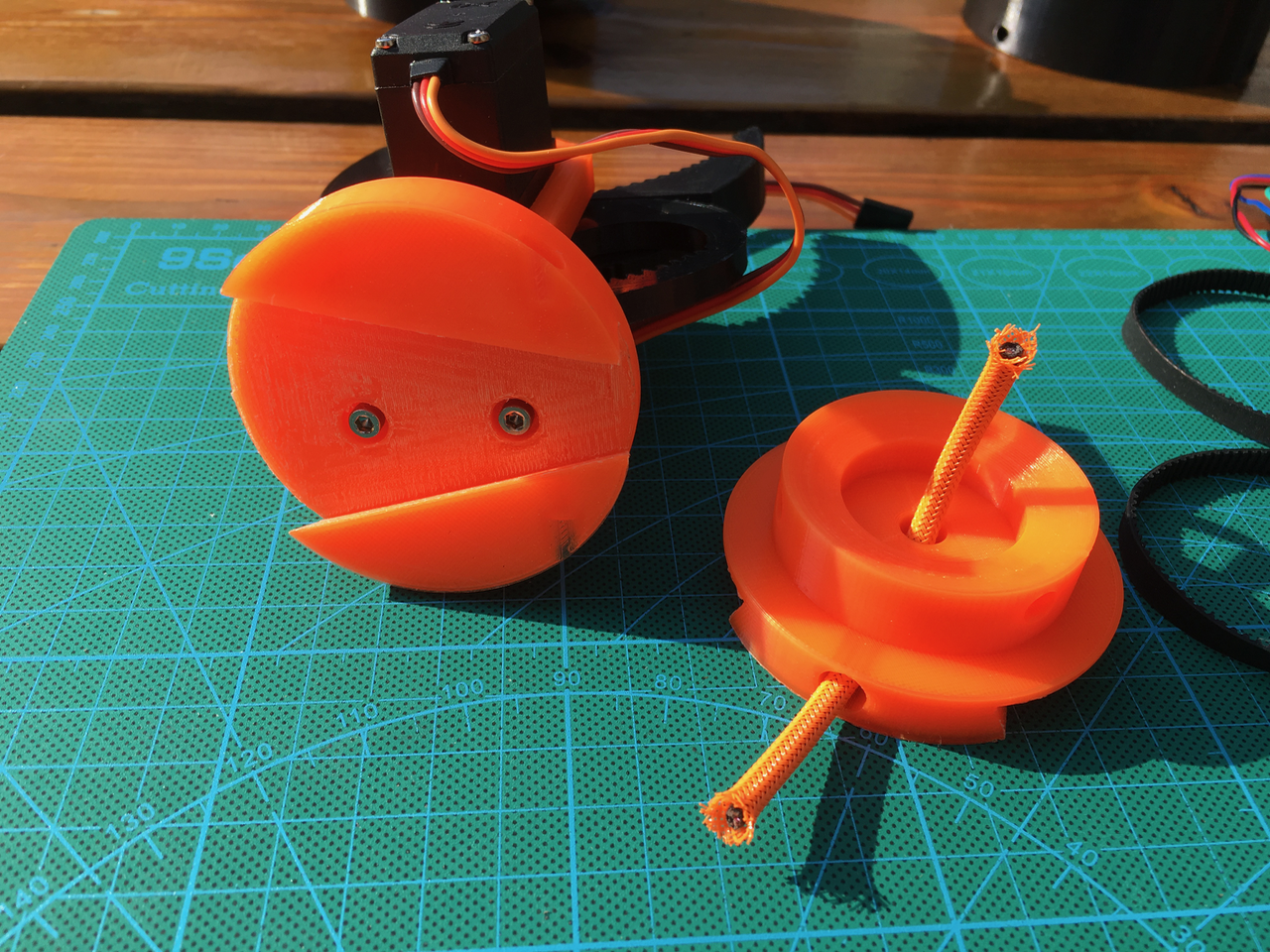

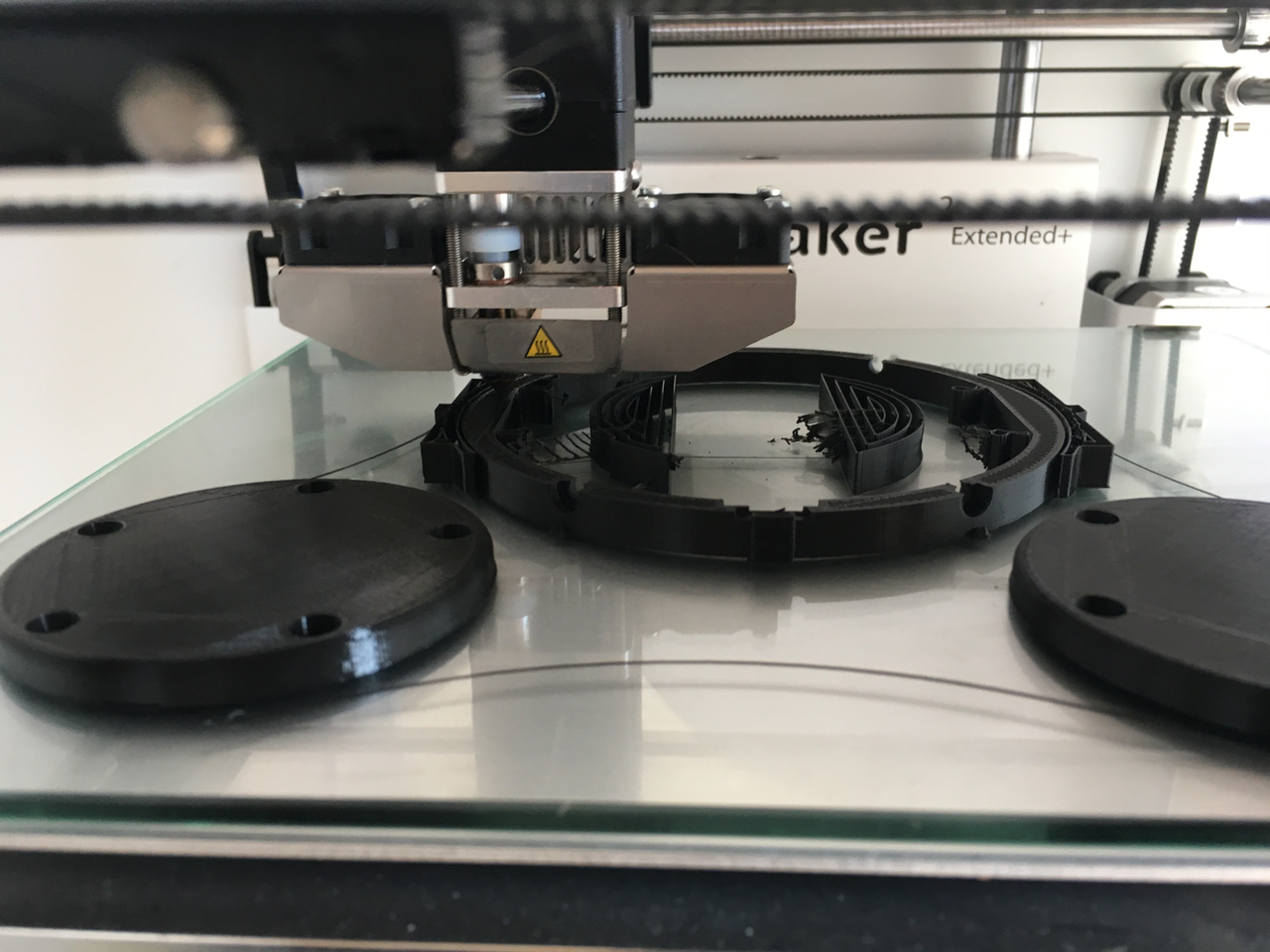

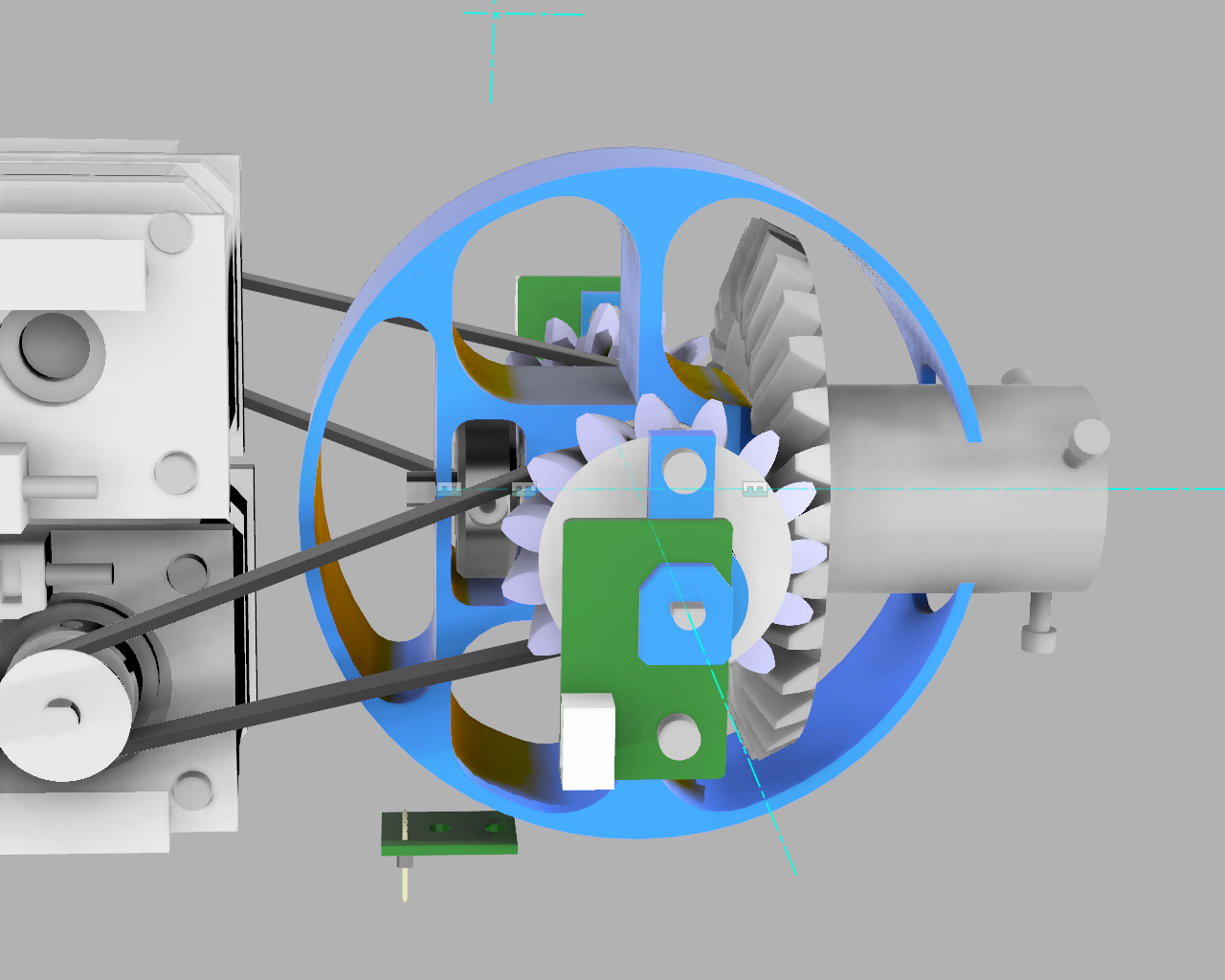

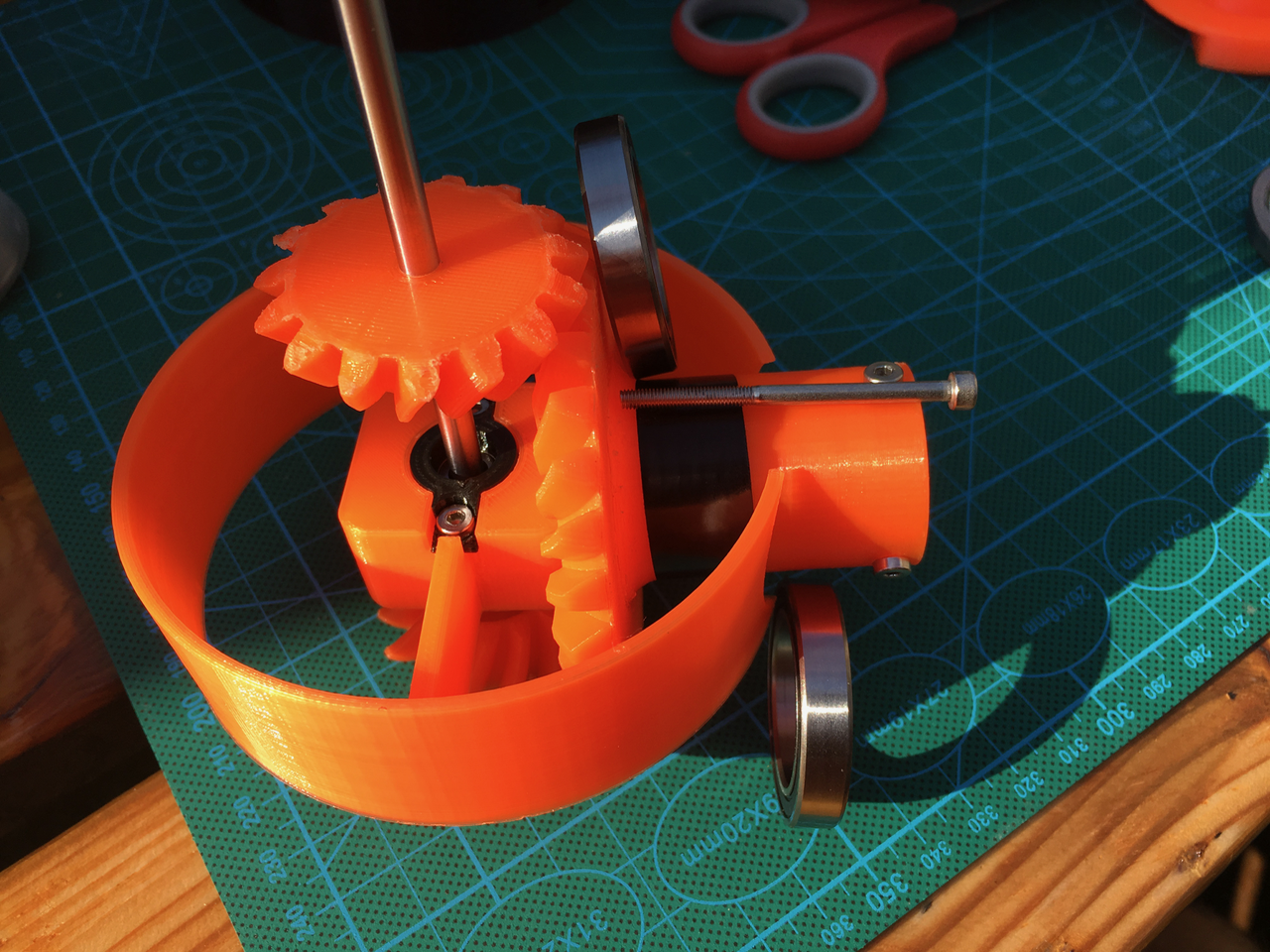

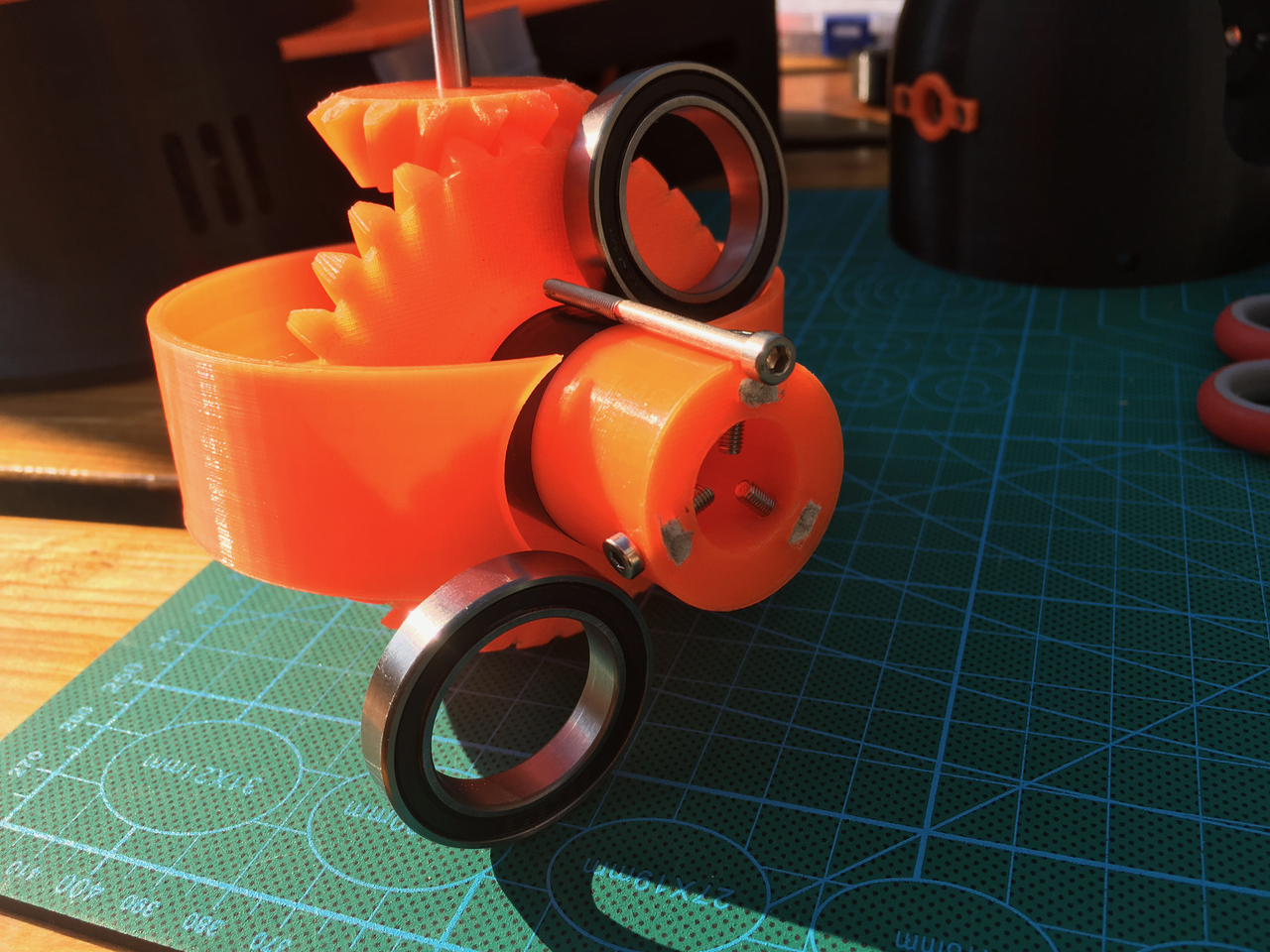

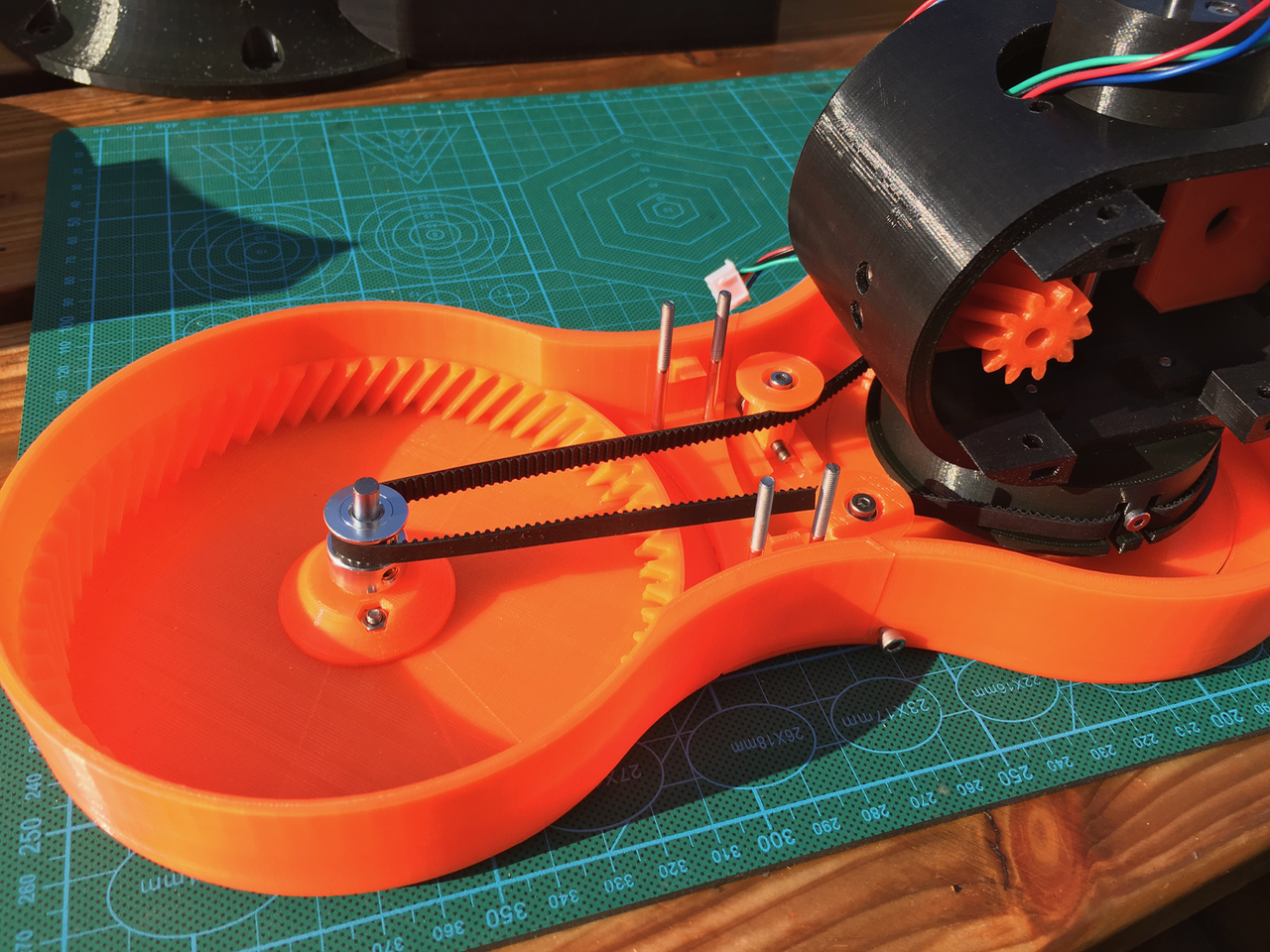

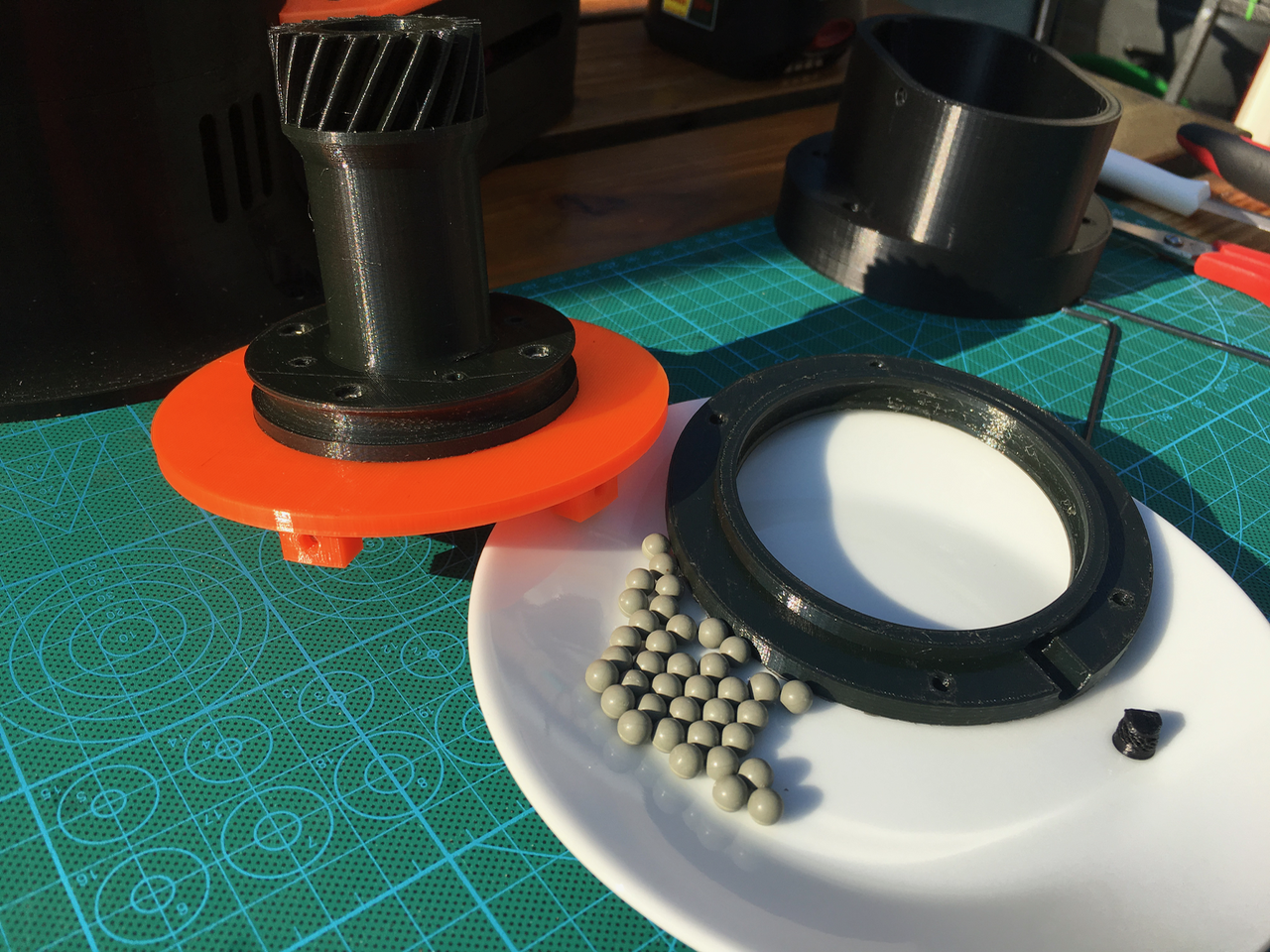

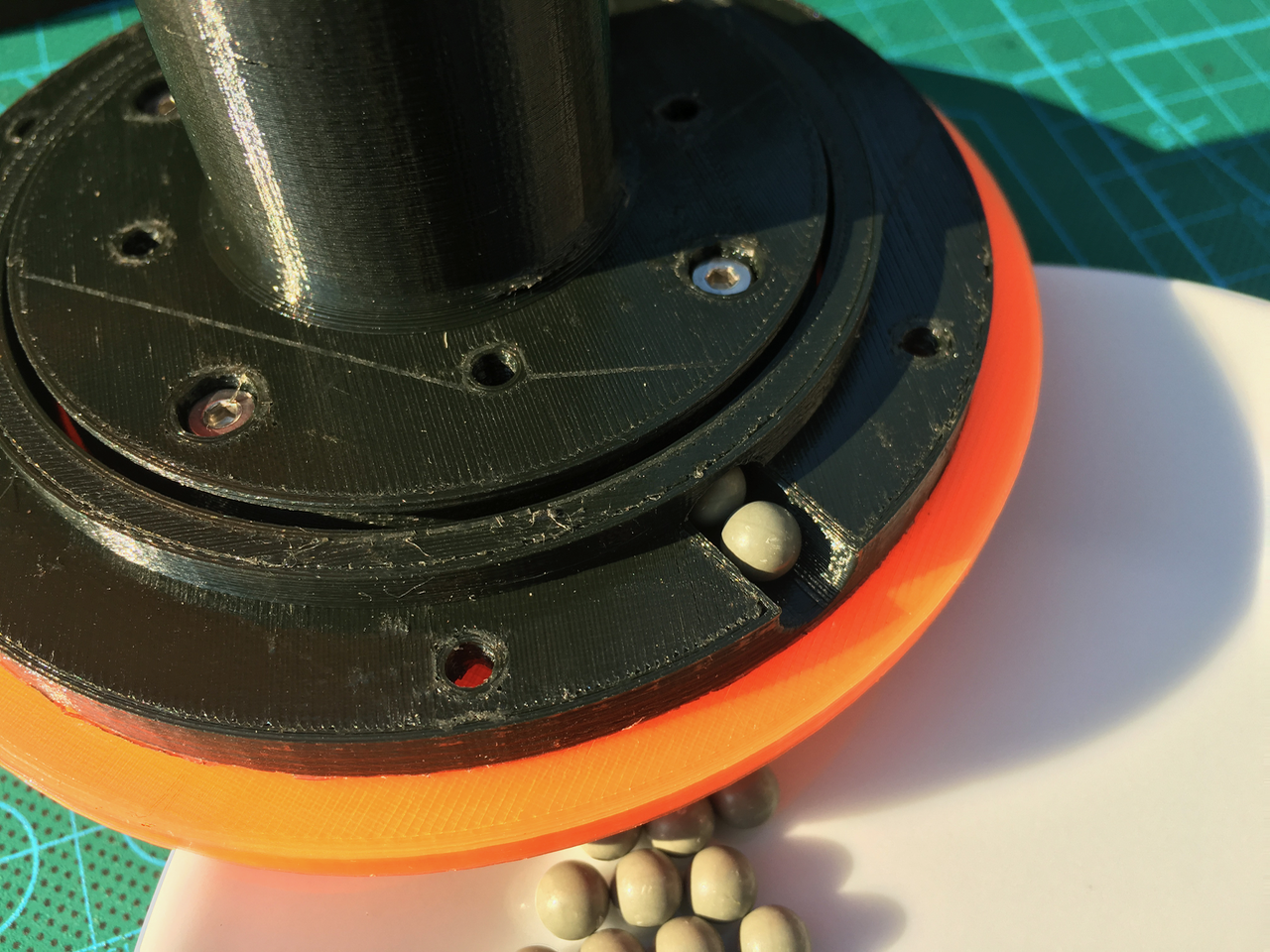

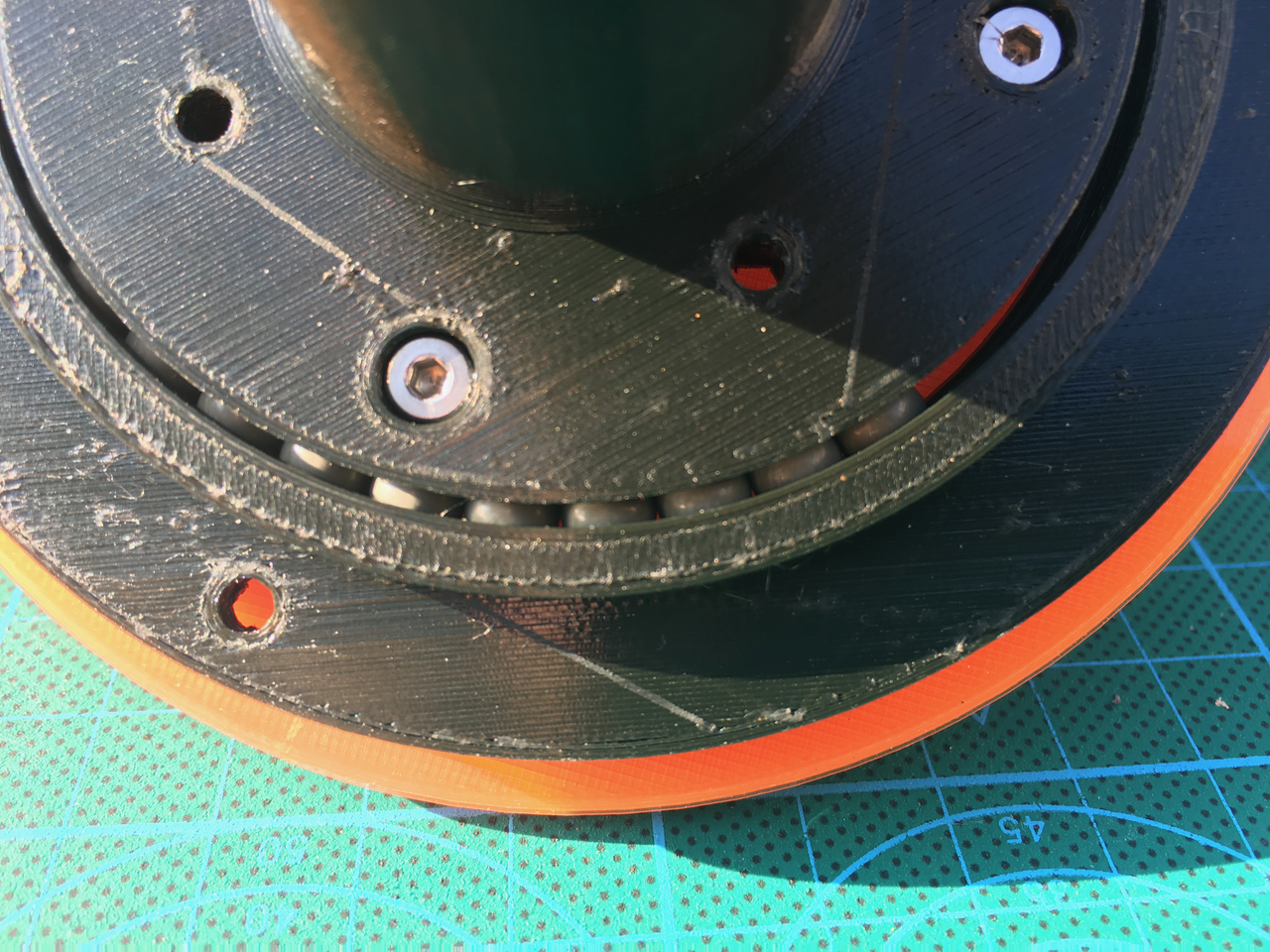

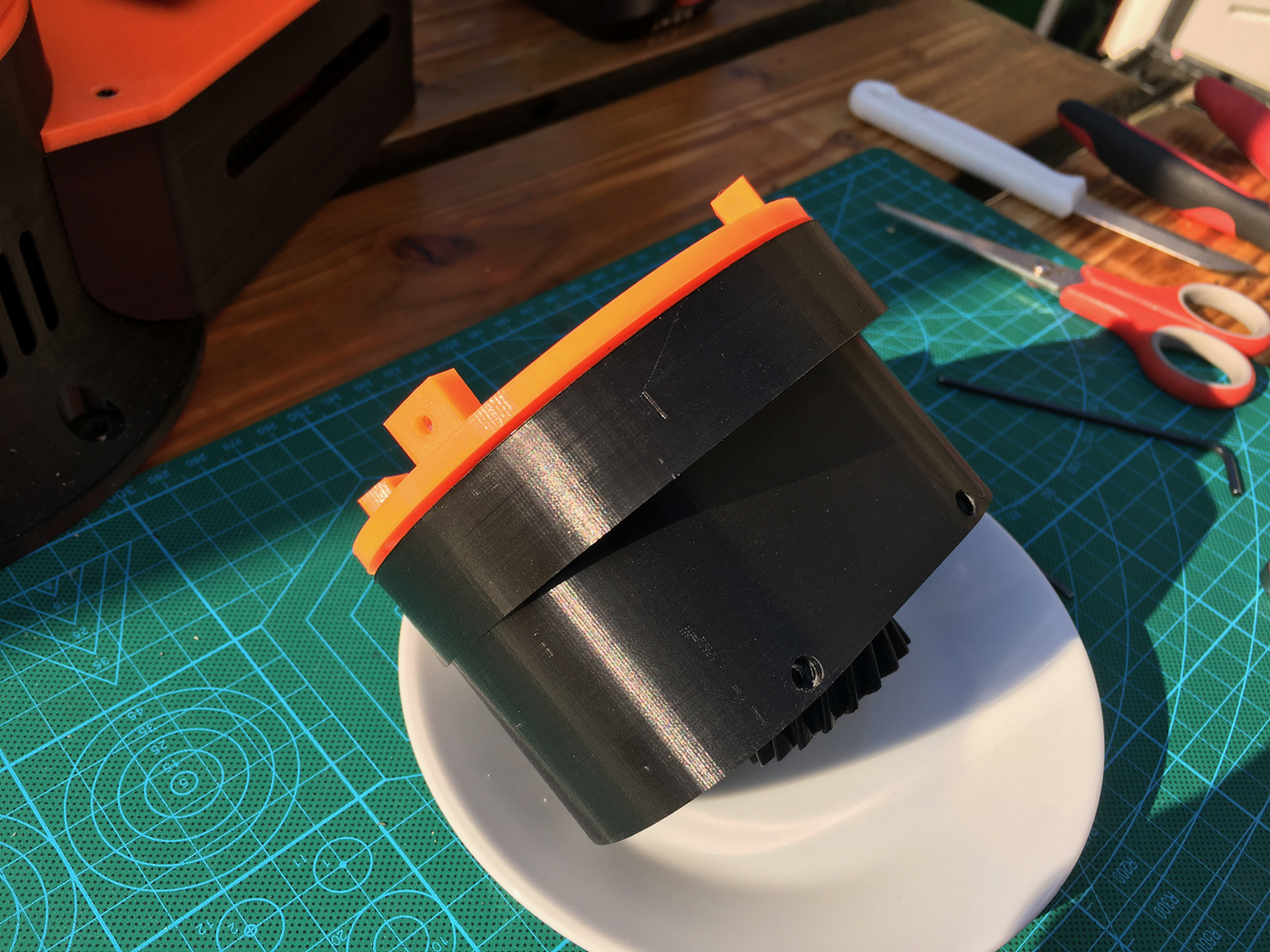

And then I found the 'Thor' robot with addons and GUI from Dannyvandenheuvel. This is the Thor robot arm with a lot of addons and improvements. Danny added the feedback sensors in V2.02.

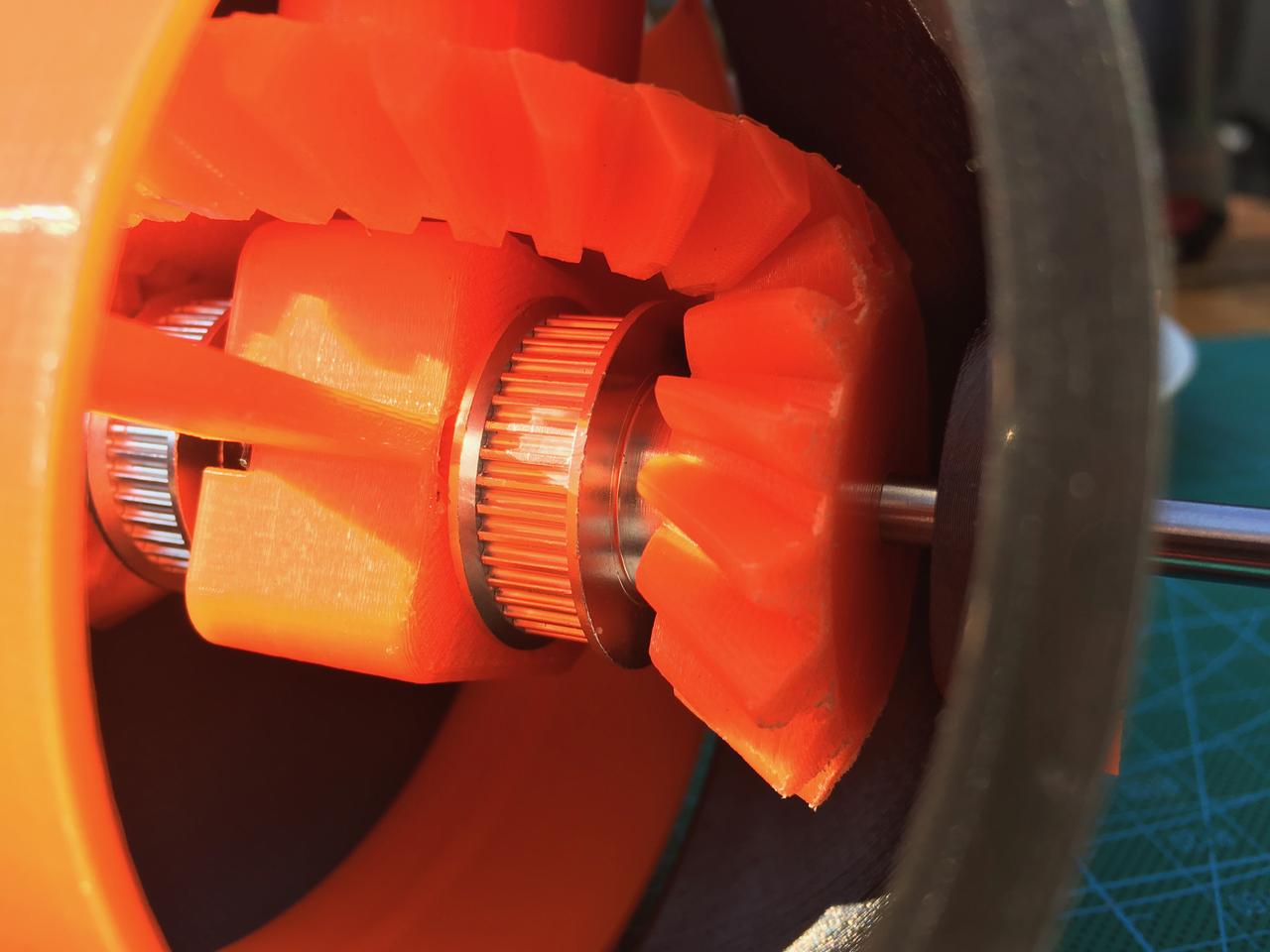

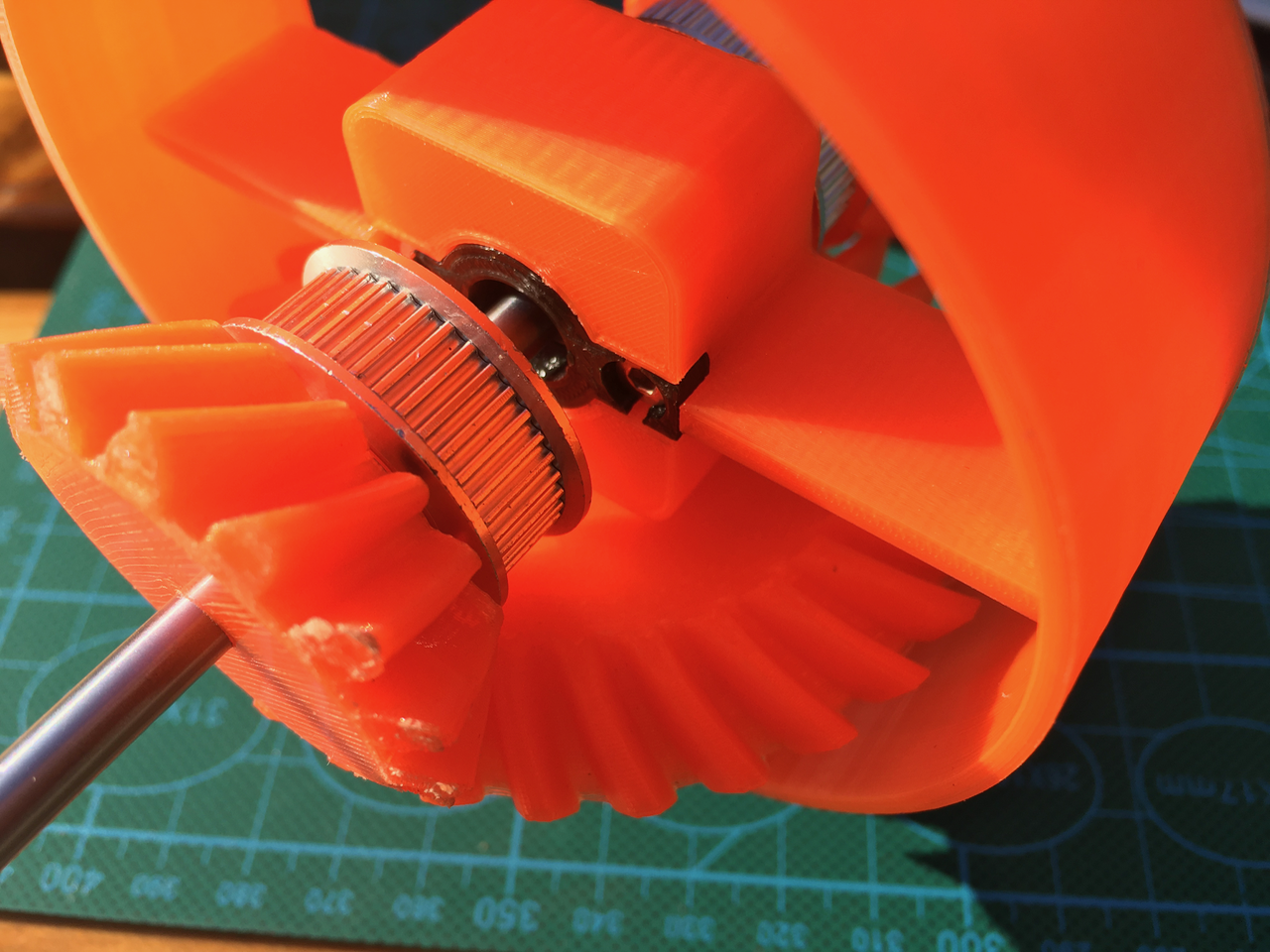

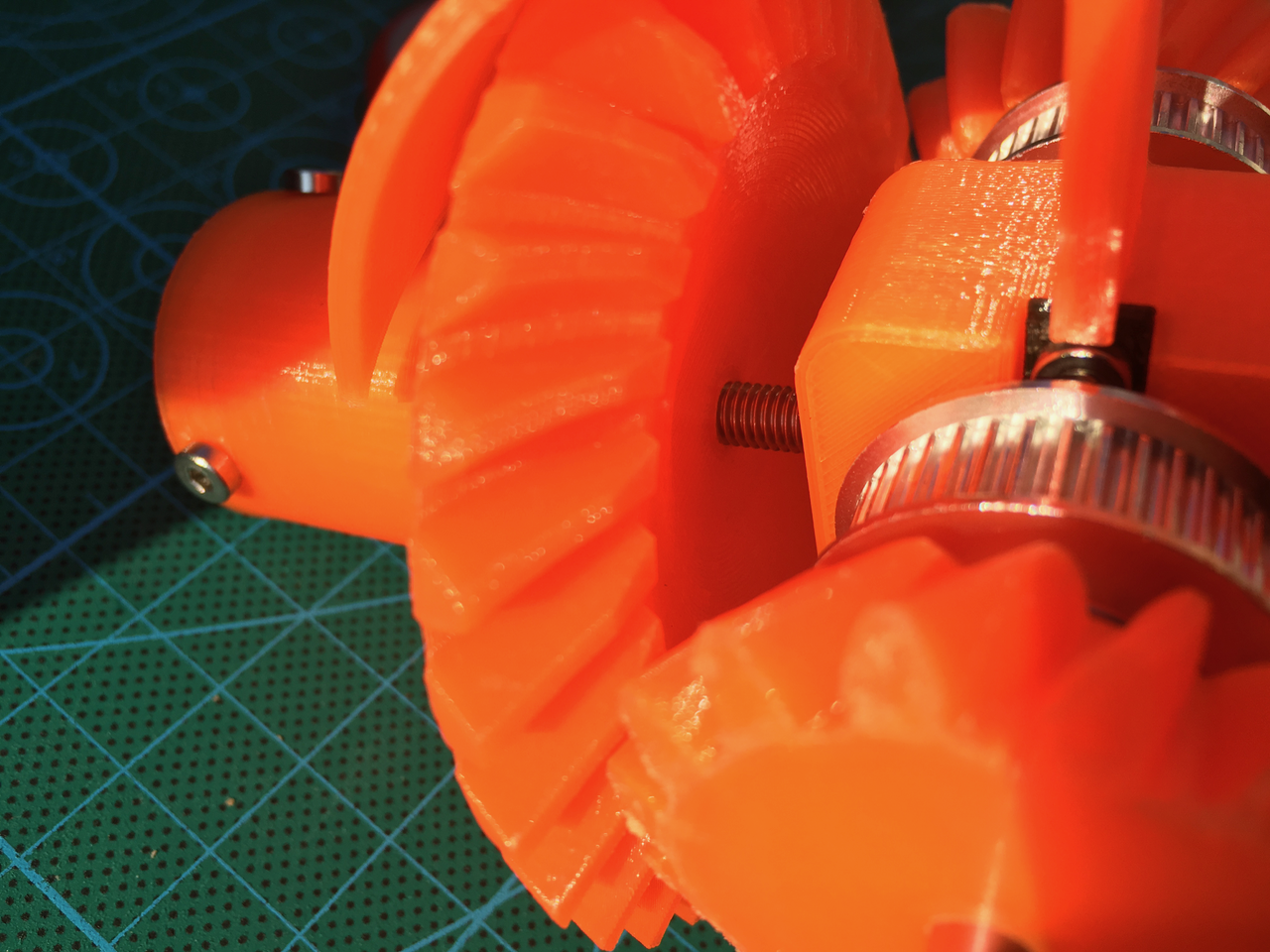

In this project I will share my building of experience of Danny's version of the Thor robot.

Sepio

Sepio

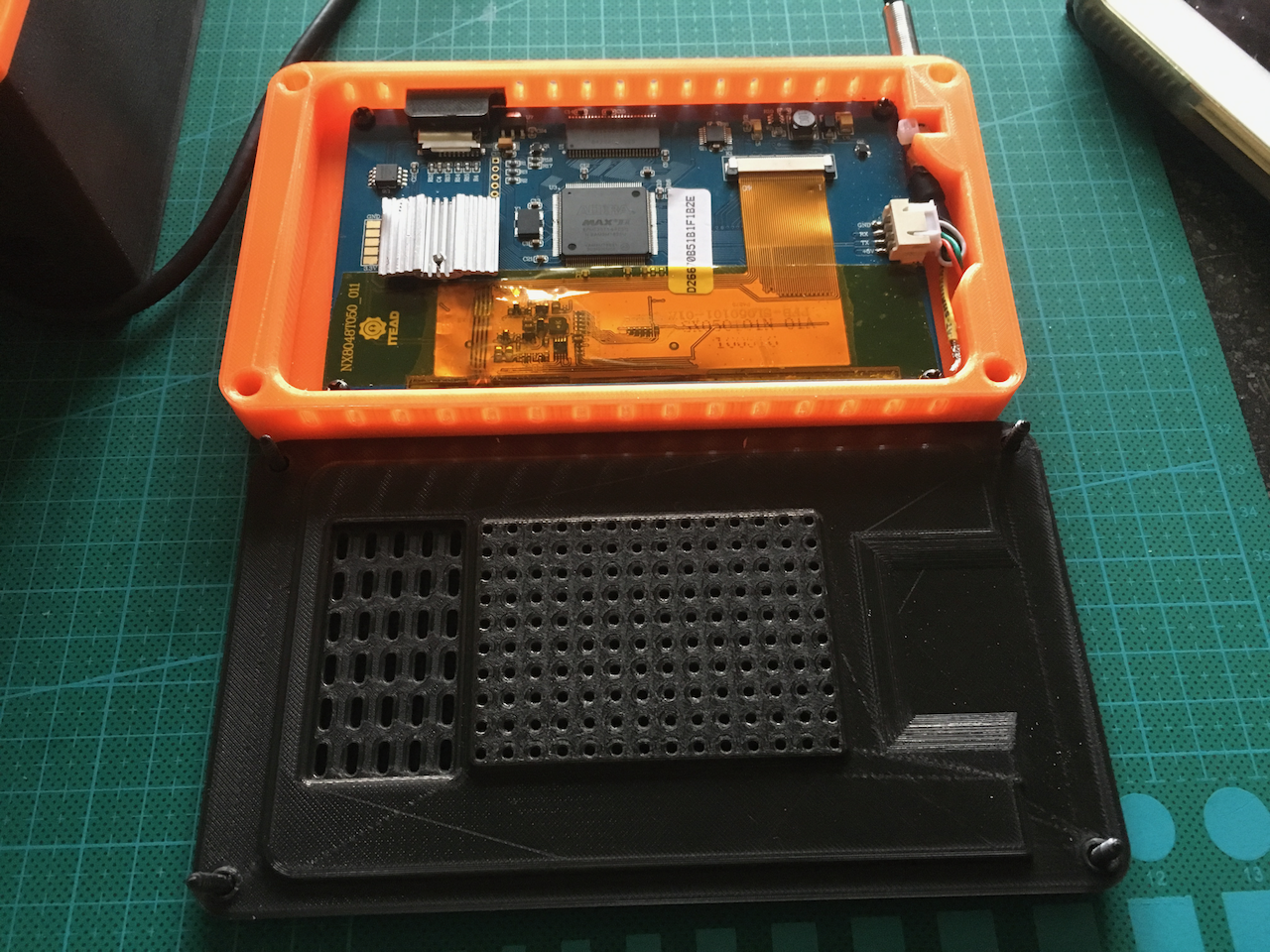

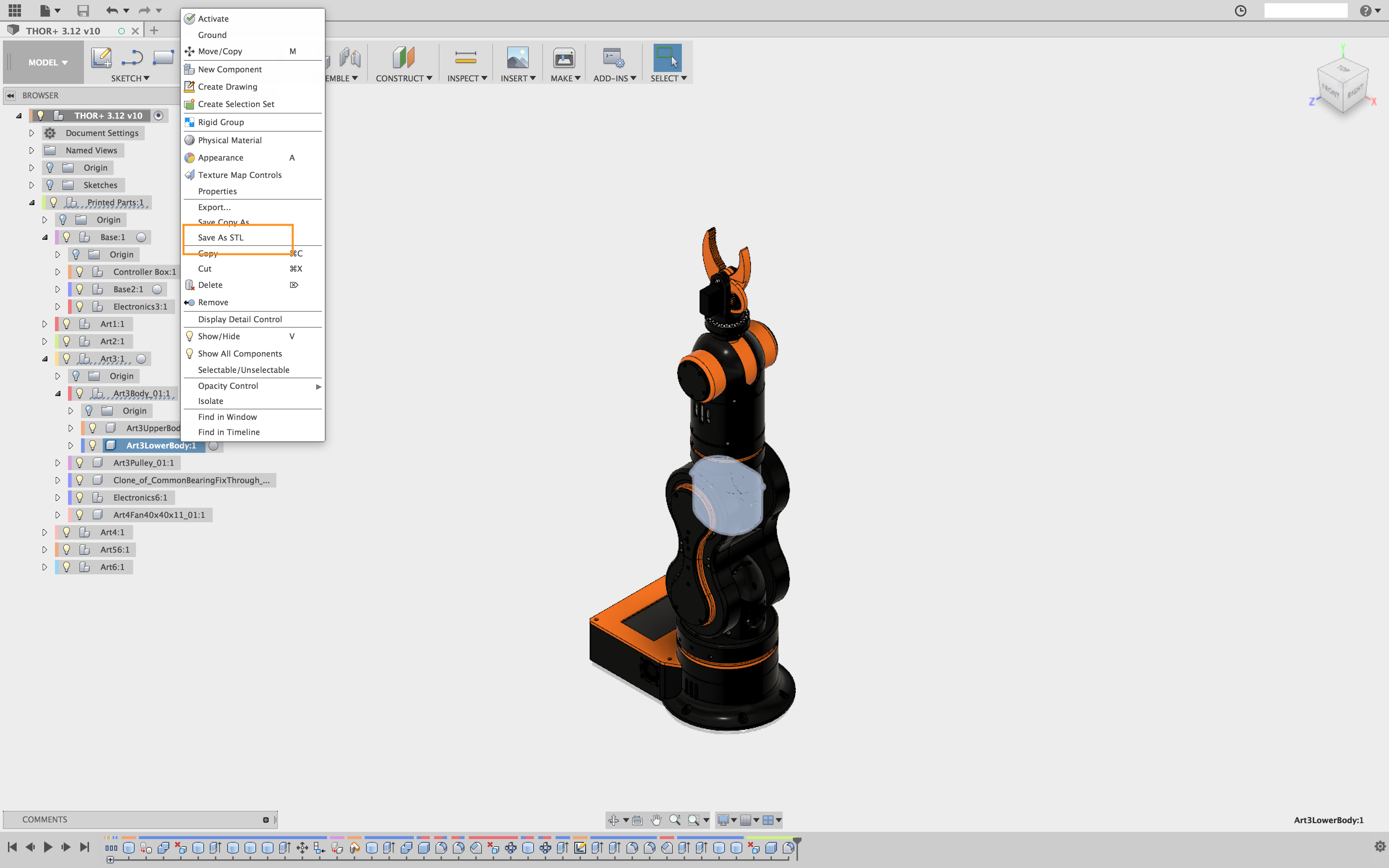

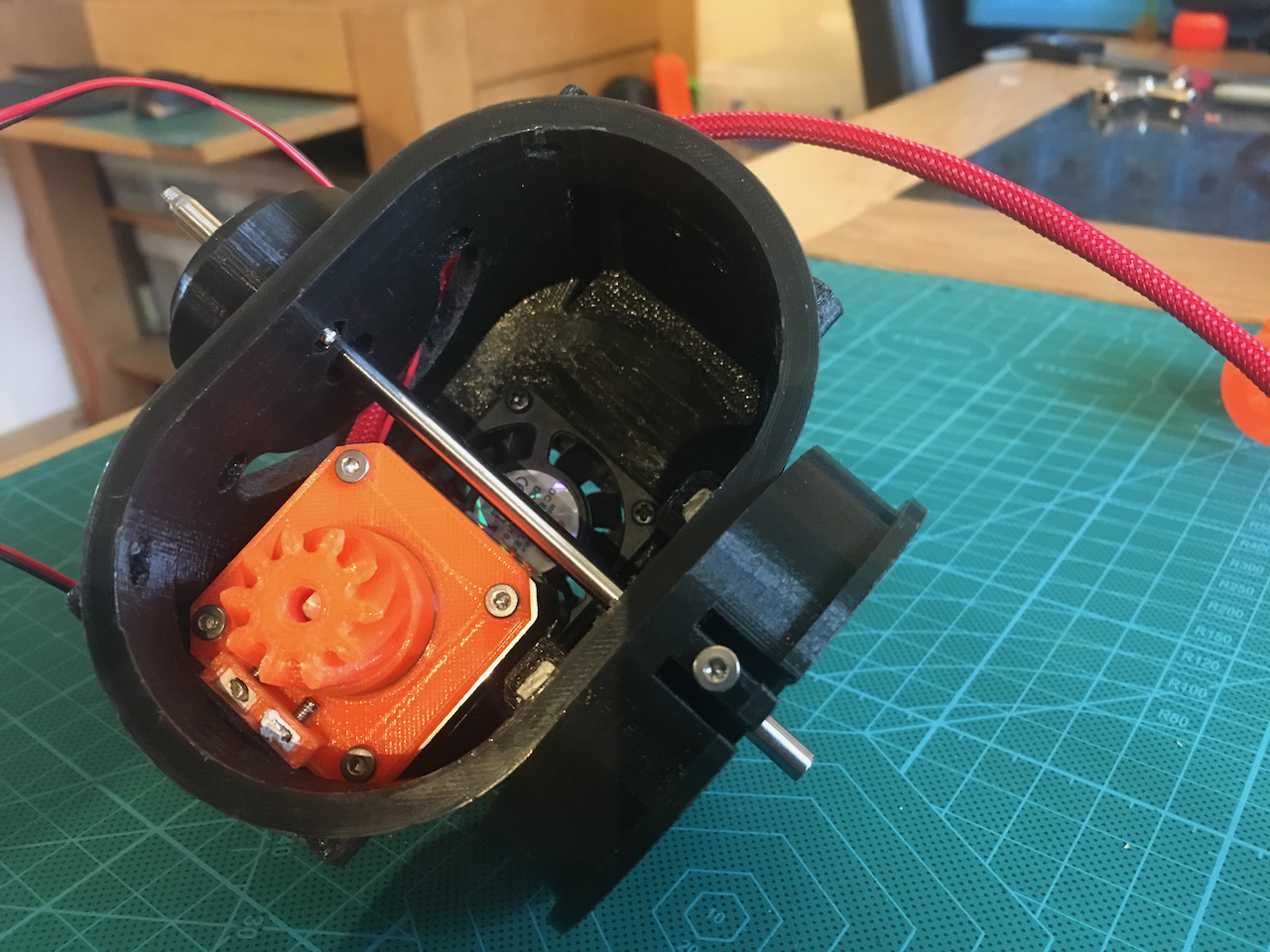

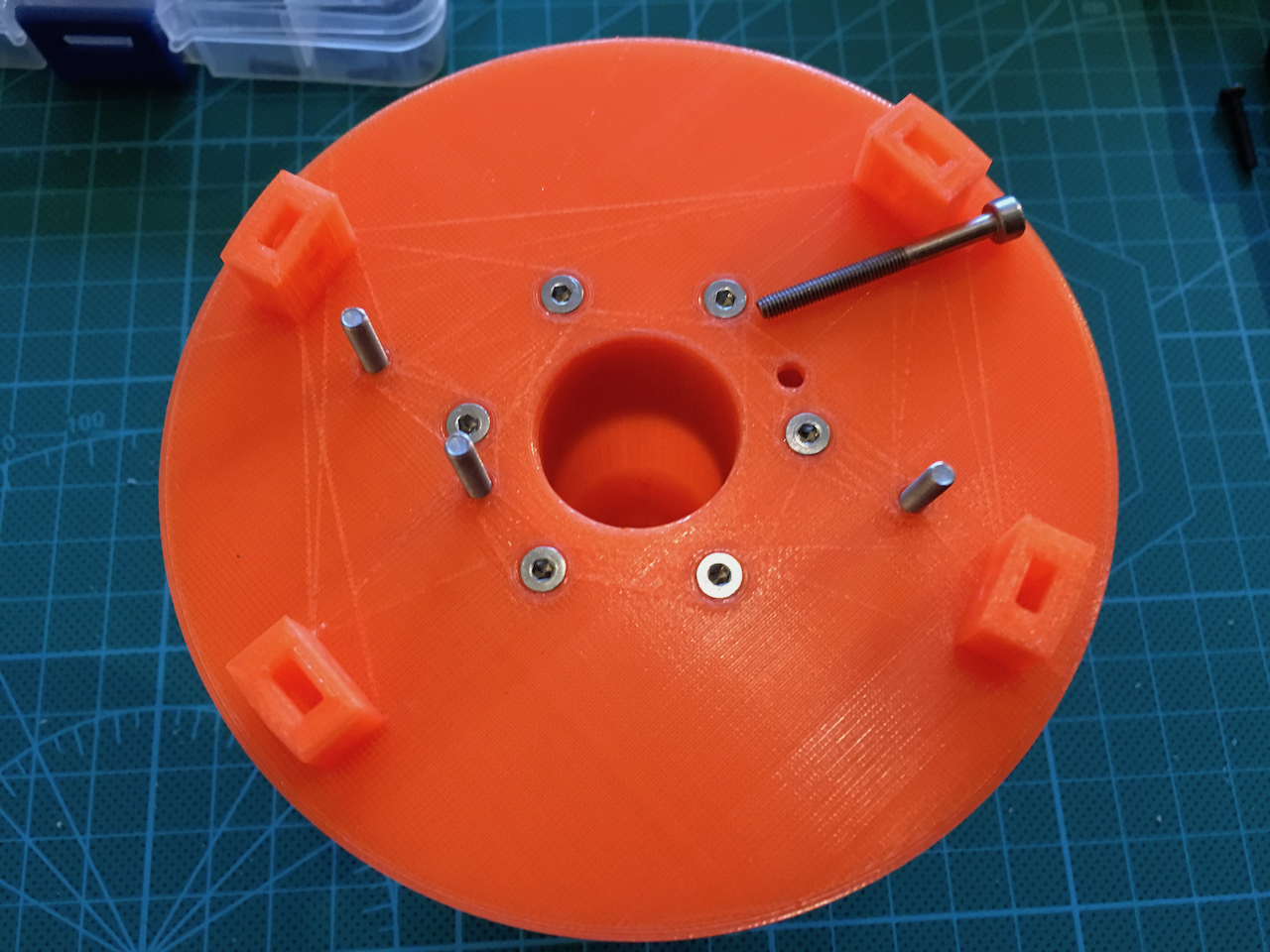

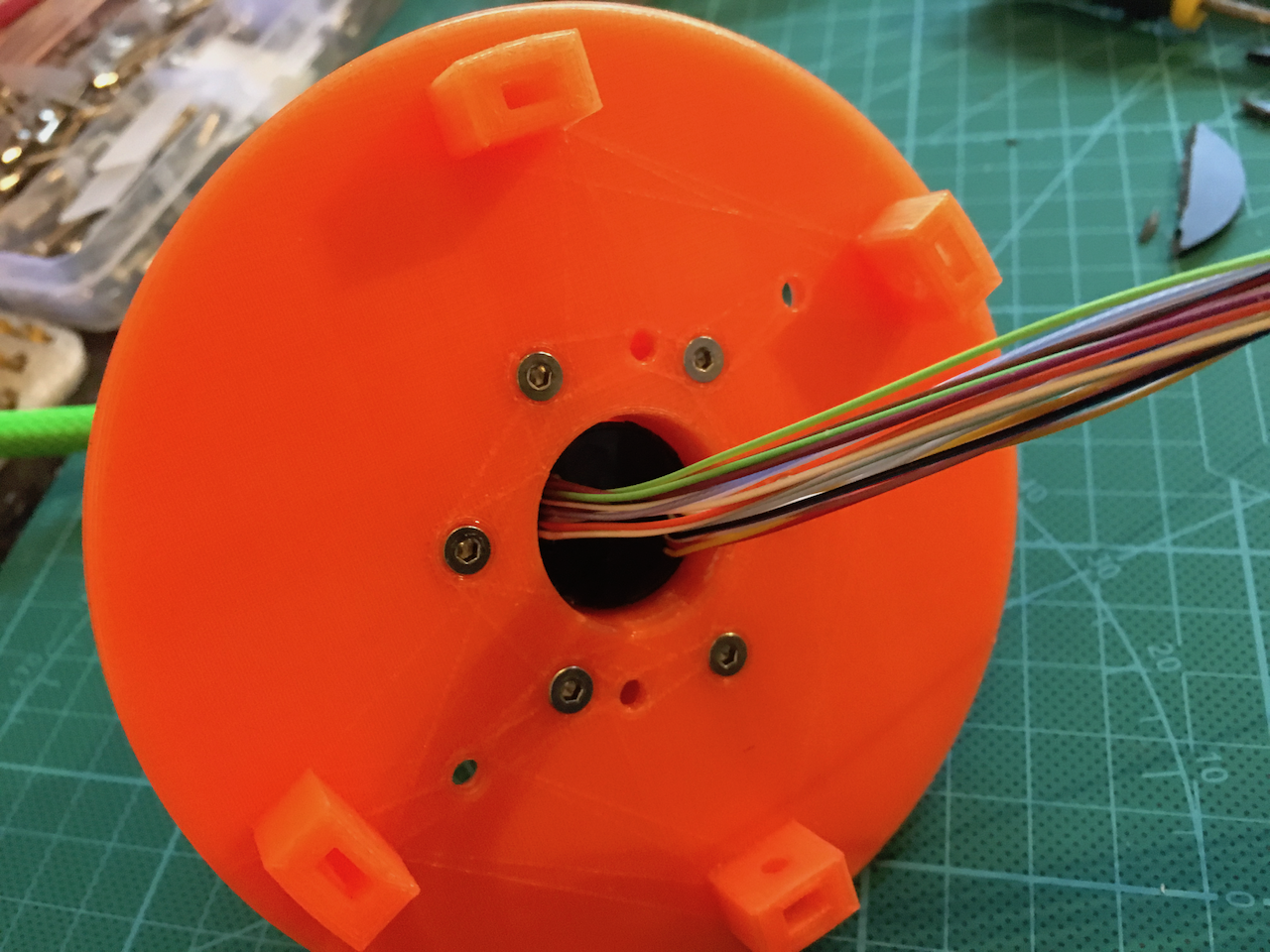

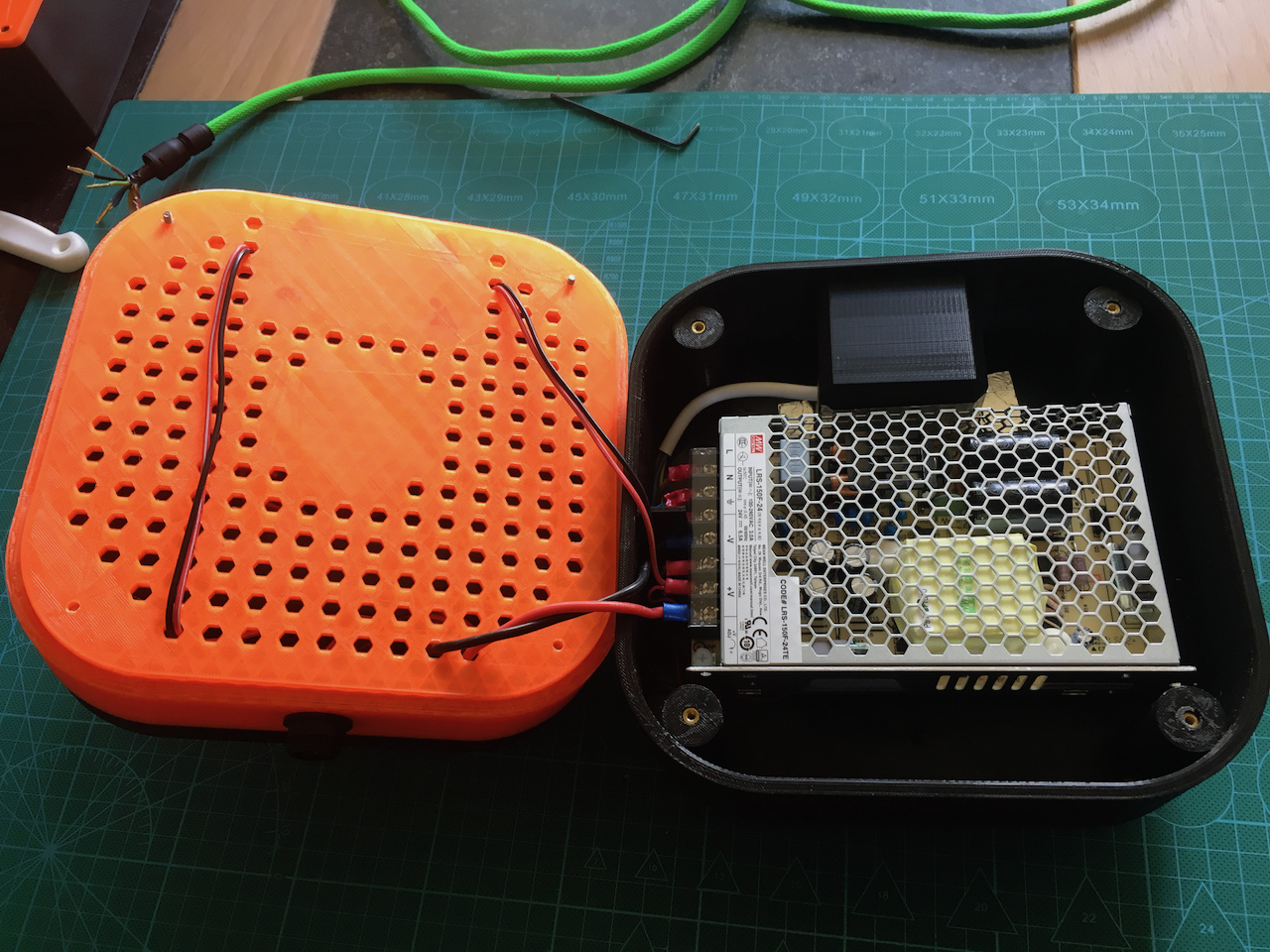

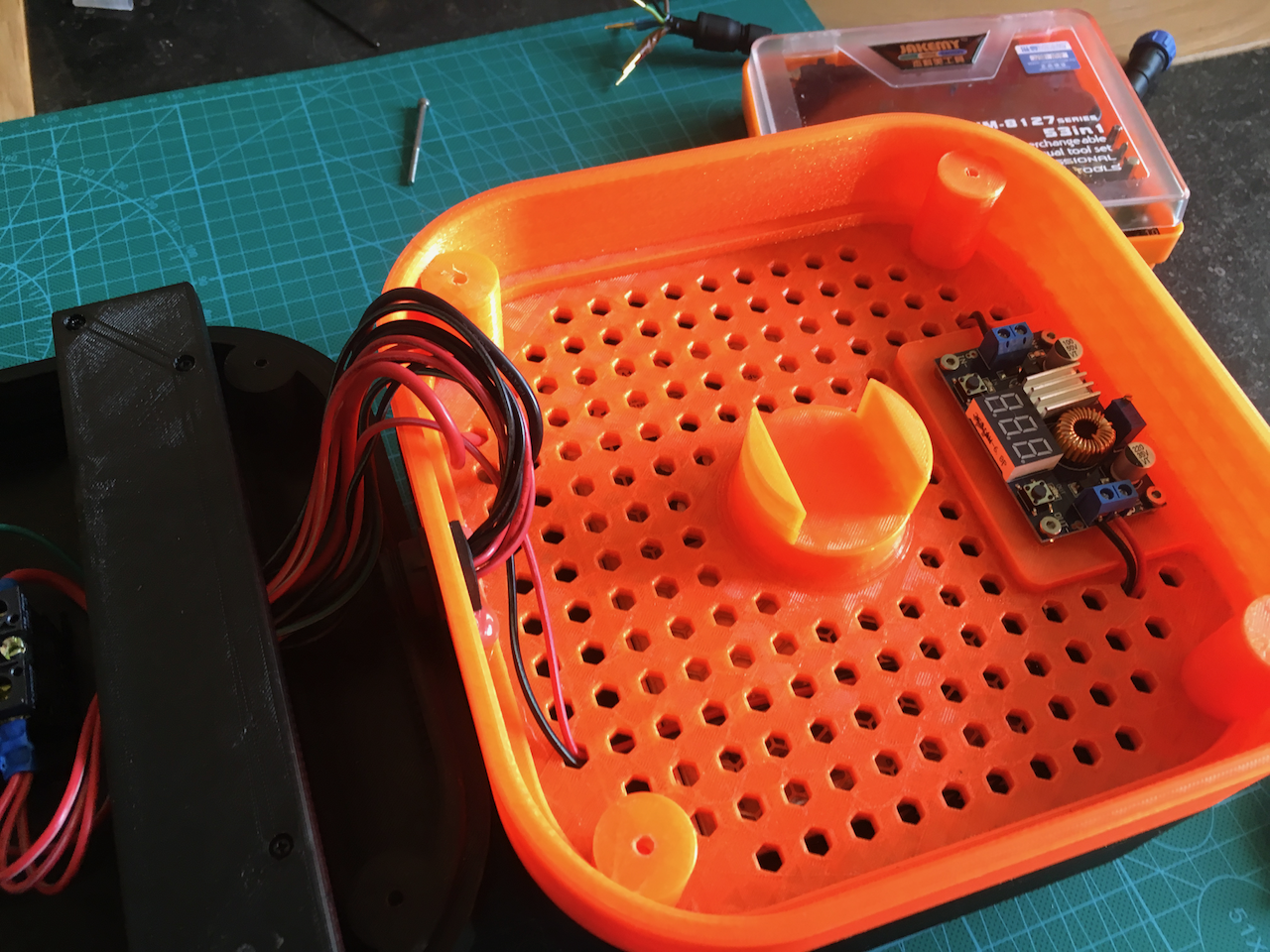

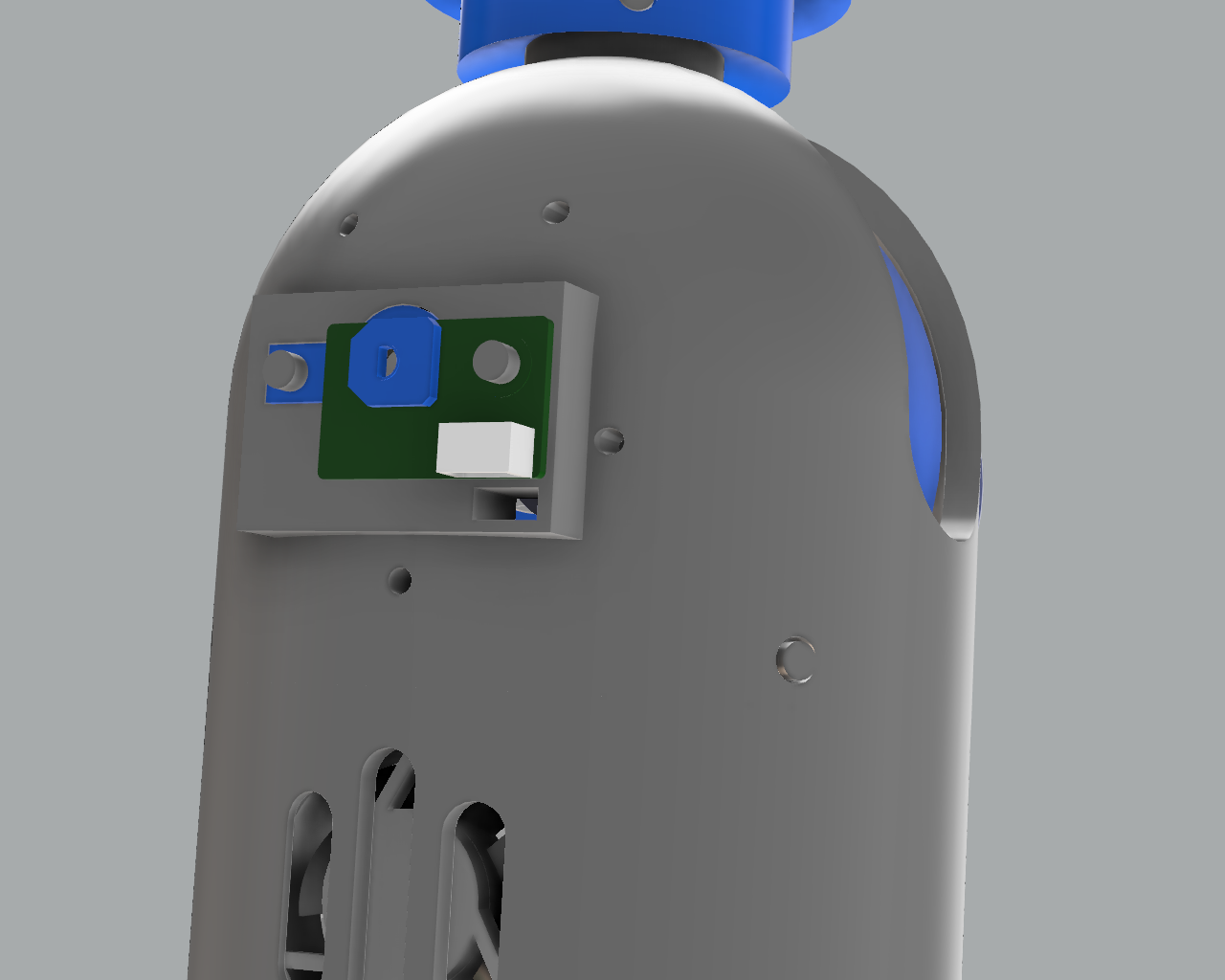

On the back of the back panel there is a square (with all those small holes). This adds some structure and it can also be used to screw a custom mount on the back.

On the back of the back panel there is a square (with all those small holes). This adds some structure and it can also be used to screw a custom mount on the back.

Timescale

Timescale

Hacker404

Hacker404

Love the project. Thank you so much for having such awesome documentation.