I recently acquired a second hand washing machine, and while all the mechanical bits (motor, tub and all rubber parts) were in good shape, the electrical system was not. Some switches were broken and the control timer started failing, causing interrupted cycles that ultimately resulted in damp soapy clothes.

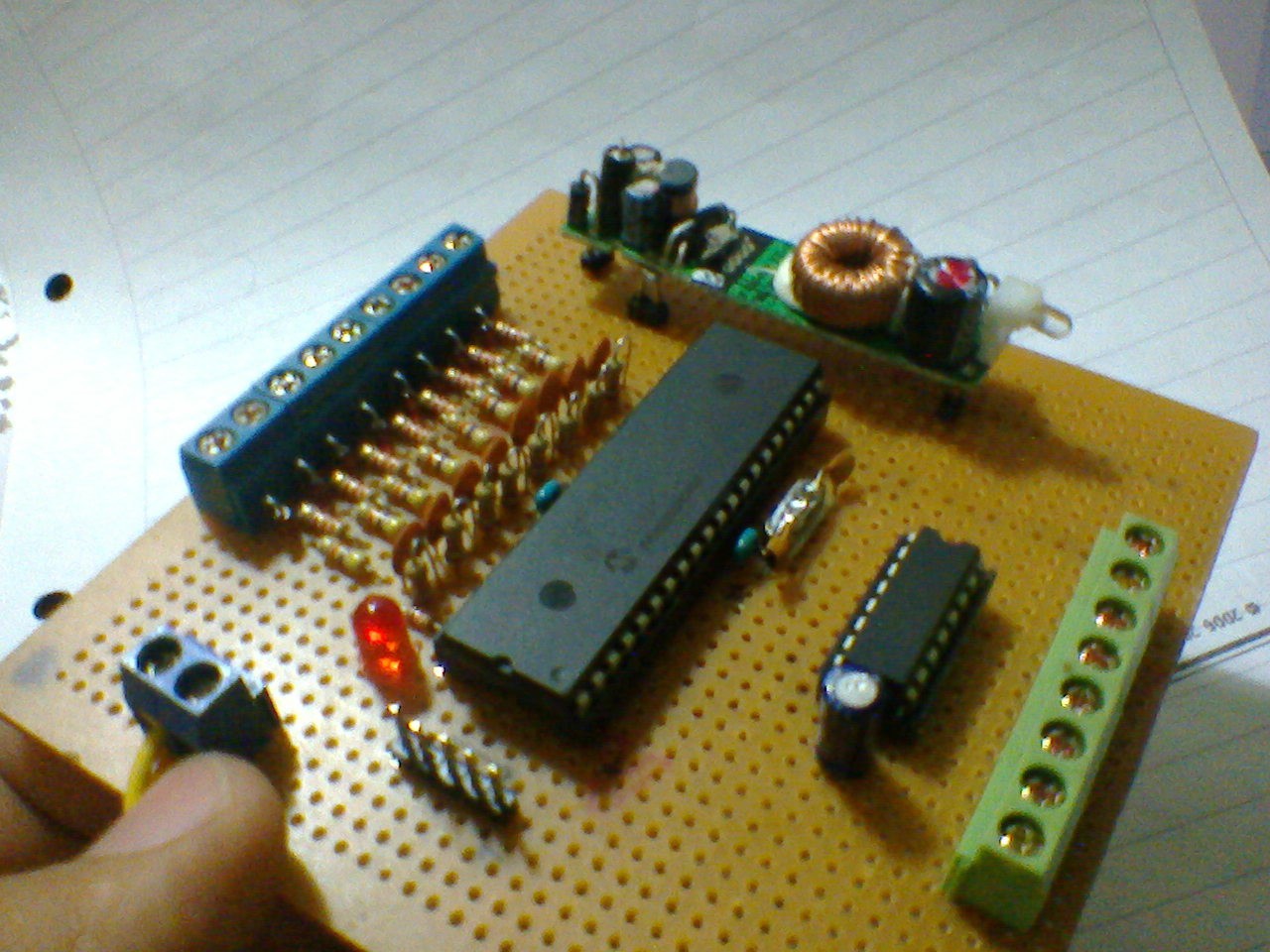

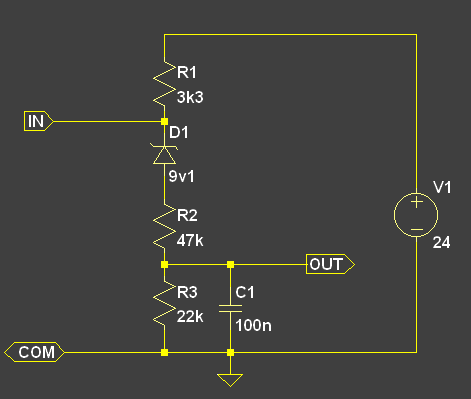

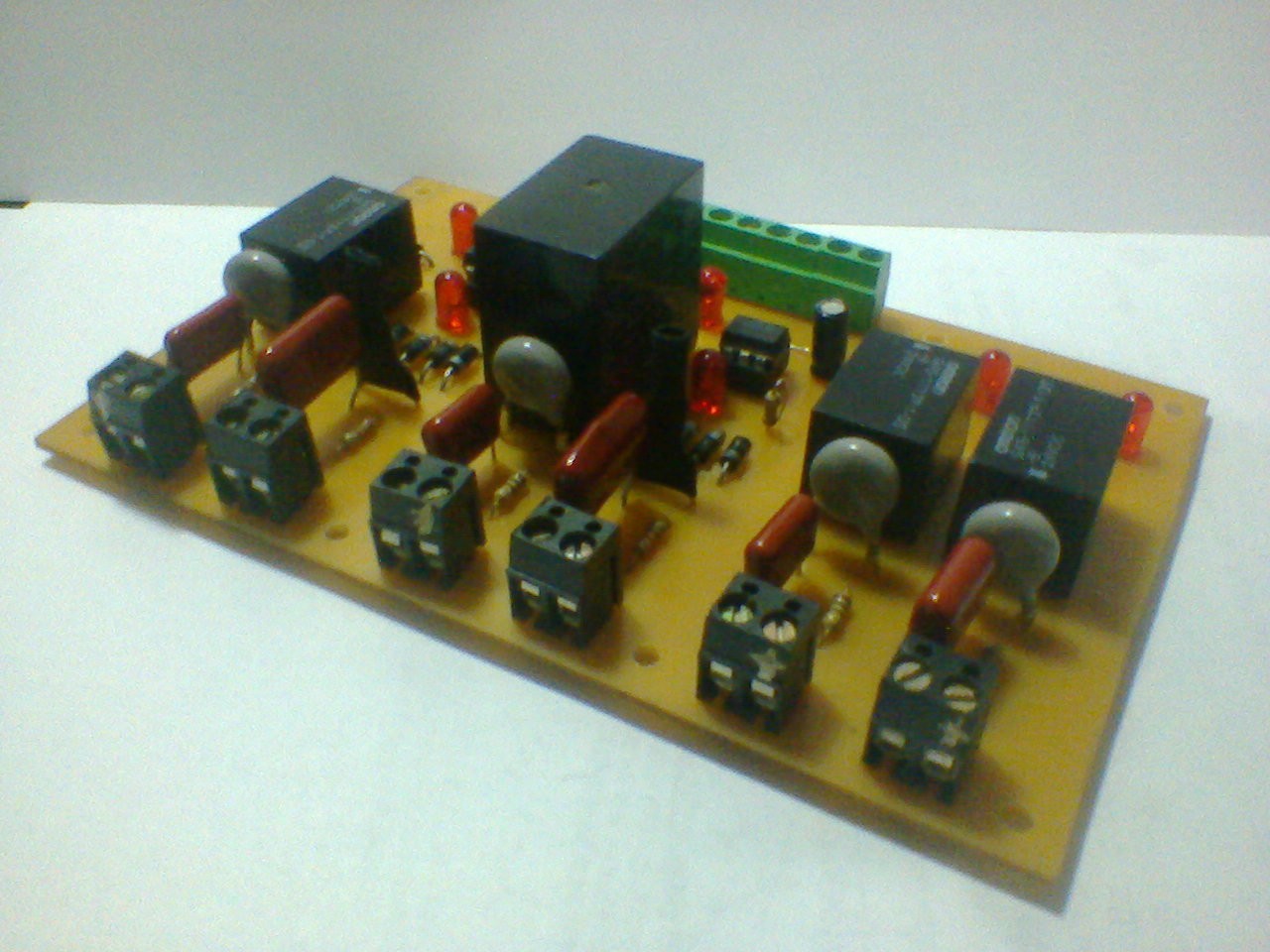

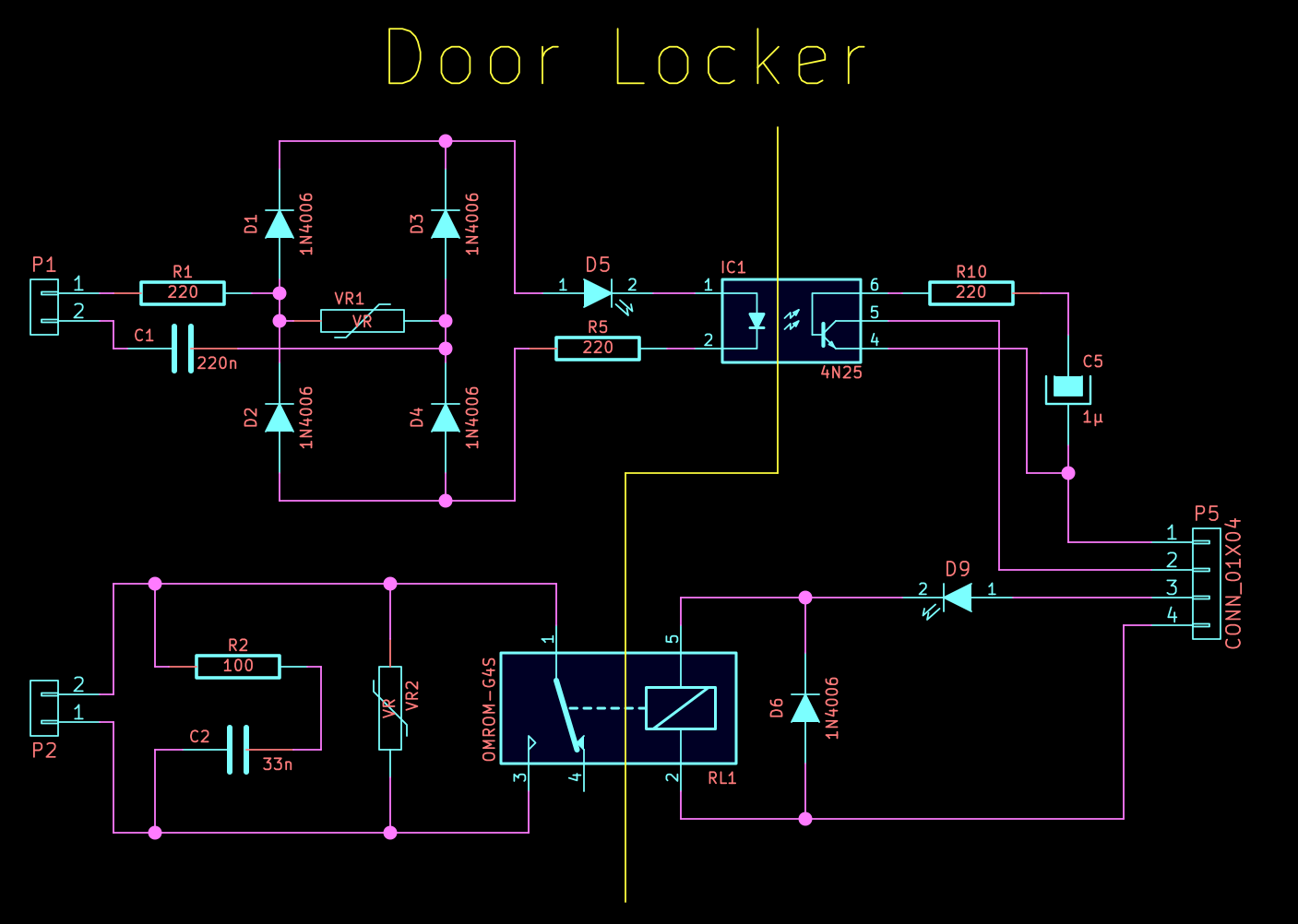

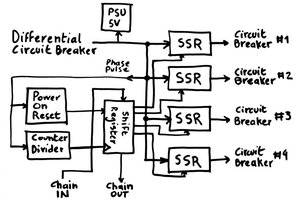

Inspired by a similar project by a fellow Argentinian tinkerer, I decided to replace the whole electrical system outright with my own. My plan was to build something more heavy-duty, backed by my previous job experience working with industrial electronics, interfacing circuits, safety, and ladder logic. This has been a great opportunity to put all that experience together into a personal project.

The guiding principles for this design are:

- Robustness: fail-safe hardware and software.

- Flexibility: to be able to add more features down the line.

- Low cost: use repurposed components and simple designs to keep the build, maintenance and repair costs down for the lifetime of the machine.

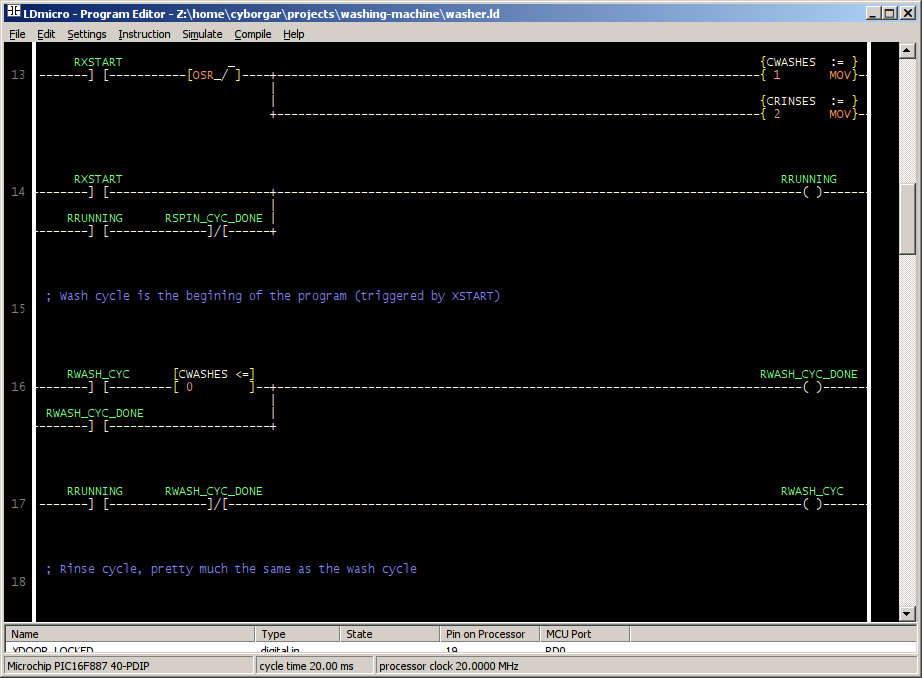

Since I have an abundance of Microchip PIC16F887s lying around, it was an easy choice for the main processor as it offers more than enough power for this application, and I have spares. The firmware design was a harder decision, however. At first I wanted to code a ladder logic interpreter from scratch (and still do), but I ultimately settled on LDMicro to get a prototype done faster since it supported my processor and my clothes wouldn't wash themselves.

I'll continue describing the nitty-gritty details of this project with a series of build logs, so stay tuned.

Jose Ignacio Romero

Jose Ignacio Romero

SUF

SUF

Paul Stoffregen

Paul Stoffregen

Ted Yapo

Ted Yapo

Yann Guidon / YGDES

Yann Guidon / YGDES

greating job