These are compiled from questions that people have asked me at events and makerspace open houses where my bike has been part of a display.

FAQ:

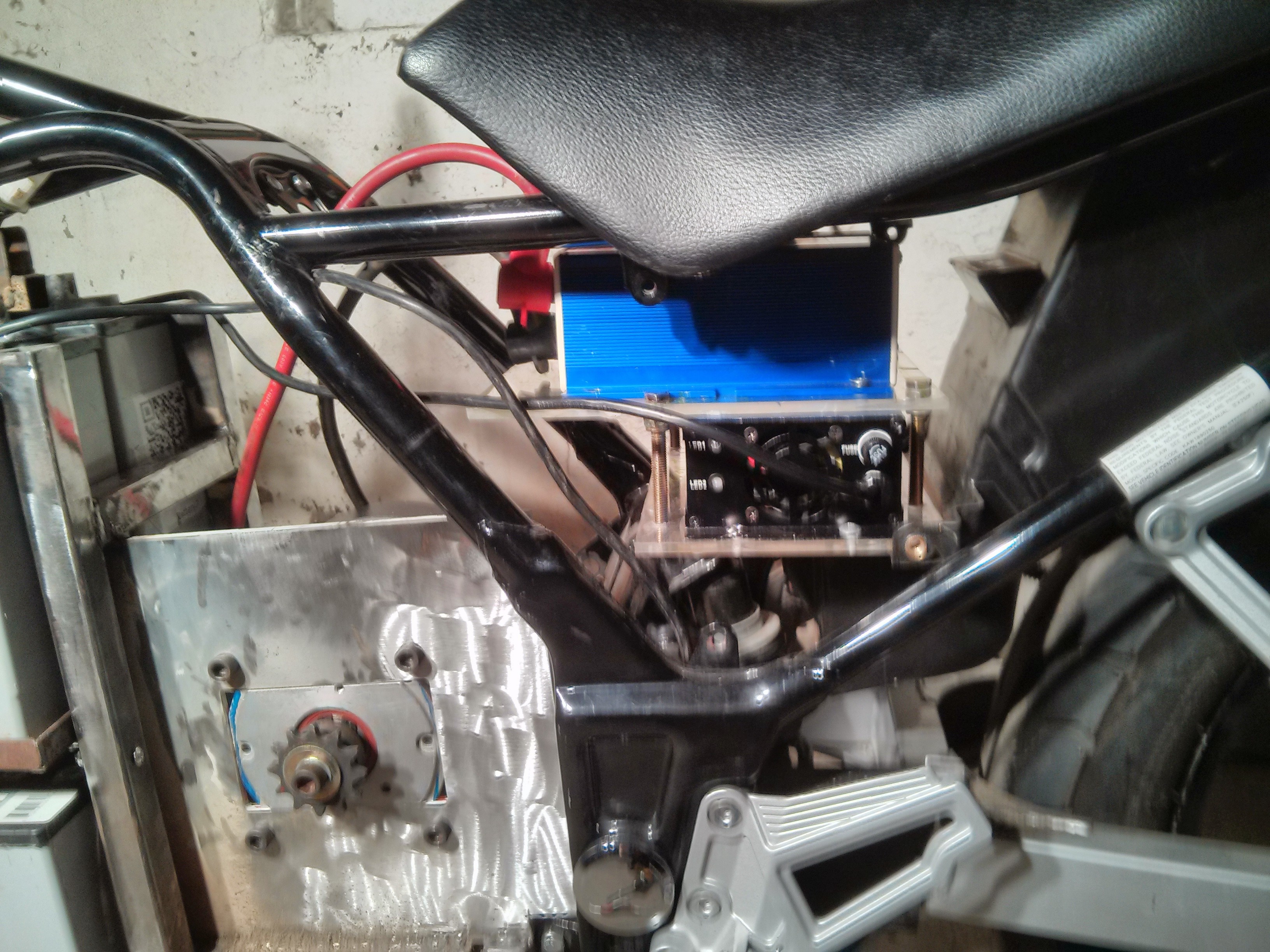

- Is this a hybrid? No, it's purely electric, a hybrid would require having some sort of internal combustion engine still on-board.

- What's the range and top speed? I don't know, I started this project in late summer and haven't had a chance to take it for a proper test ride (excluding doing laps in the makerspace parking lot).

- Why did you use lead acid batteries? I used lead acid batteries because they are cheap and take a lot of abuse, unlike fussy chemistries like Li-ion. I also don't immediately need the range of more expensive Li-ion batteries, I plan on using this as a purely inter-city vehicle. That being said I am working on a drop in replacement (physically) that will be Li-ion based.

- What would you recommend to someone that wants to build an electric vehicle? Just do it, it's so rewarding and it doesn't need to be nearly as complicated as you might think, not to say that can't be, but you can choose your level of complexity based on your skill set.

- Was it hard to get insured, registered, inspected? Insured no, it's listed as a kit bike by my insurance carrier. Registered, no the NYS DMV was more worried about making sure I paid sales tax than about any mods I've made to the drive train. Inspection, not sure about this one yet, as far as I can determine by reading the state and federal inspection guidelines I am complying with all safety regulations (most of these concern lights).

- How long does it take to charge? About 6 hours from completely dead.

- Why don't you add a sidecar full of batteries to the bike so it can go further? Ugh, ok let's tackle this one. First of all batteries add weight and weight reduces range and at some point it's a law of diminishing returns. Two; a side car on a Ninja????? Really? Third, listen I'm already riding an electric motorcycle that I made myself, I would like to occasionally show my face in public again.

- How could you tear apart a perfectly working Ninja and do this? Ummmm... so I don't know about where you live, but in upstate NY you can't throw a rock in the spring/summer without hitting two Ninjas and someone pining for a flat in the city.

ErikL

ErikL

Chris Low

Chris Low

Jorj Bauer

Jorj Bauer

Quinn

Quinn

Sorry if I missed it, but what motor controller are you using?