Print settings

Print in TPU. These need to be a little flexible to be pushed in the collar, and the top actually snaps onto the shaft.

1.2-1.6 mm top/bottom/walls.

25-33% grid or line infill. The sparse infill here helps the part be compliant enough to be pressed into the collar.

250-265C extruder temperature.

60C bed temperature.

30mm/sec for all motion except travel. Keeping the speed constant helps keep the extruder pressure even which helps a lot with printing flexible filaments.

High speed for travel. For me that was 400mm/sec.

Disable retraction.

Enough 'skirt' lines to prime the extruder. Four was enough for me.

45% part cooling.

Installation

Clean out the remaining bits of the old bushing, or if you are like me, just wonder where it disappeared to.

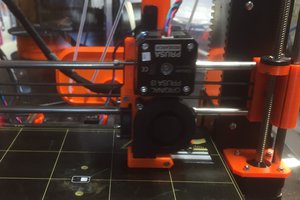

Look at the shaft. The top of the bushing as pictured here is the end which snaps into the groove you see on the shaft. Orient the bushing so that will be the case.

Press the bushing into the collar. Being slightly loose so you can still rotate it in the collar is good.

Press the collar/bushing onto the shaft until the end snaps into the groove.

Daren Schwenke

Daren Schwenke

nfk

nfk

JP Gleyzes

JP Gleyzes

Tim Wilkinson

Tim Wilkinson

this better be for the turbo PT.. which is still a sad replacement for the just as bad and unsafe neon.. I kind of blame the PT for the crossover craze so consider yourself warned.. especially if you are not running a turbo... i mean manuals are a plus but pts need to at least have the power or their is zero excuse...