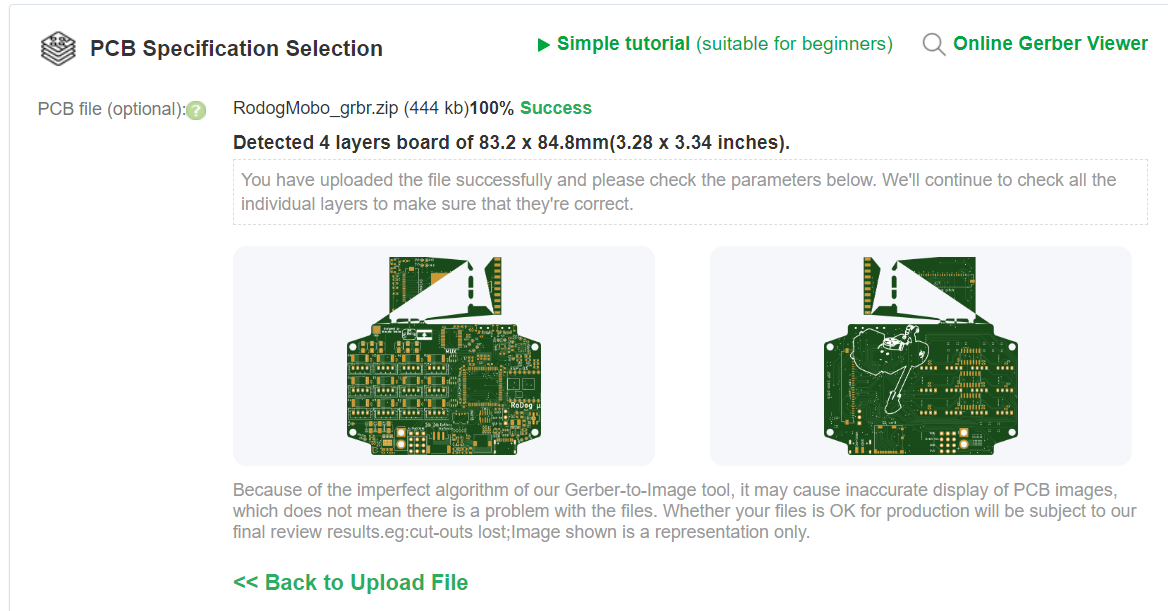

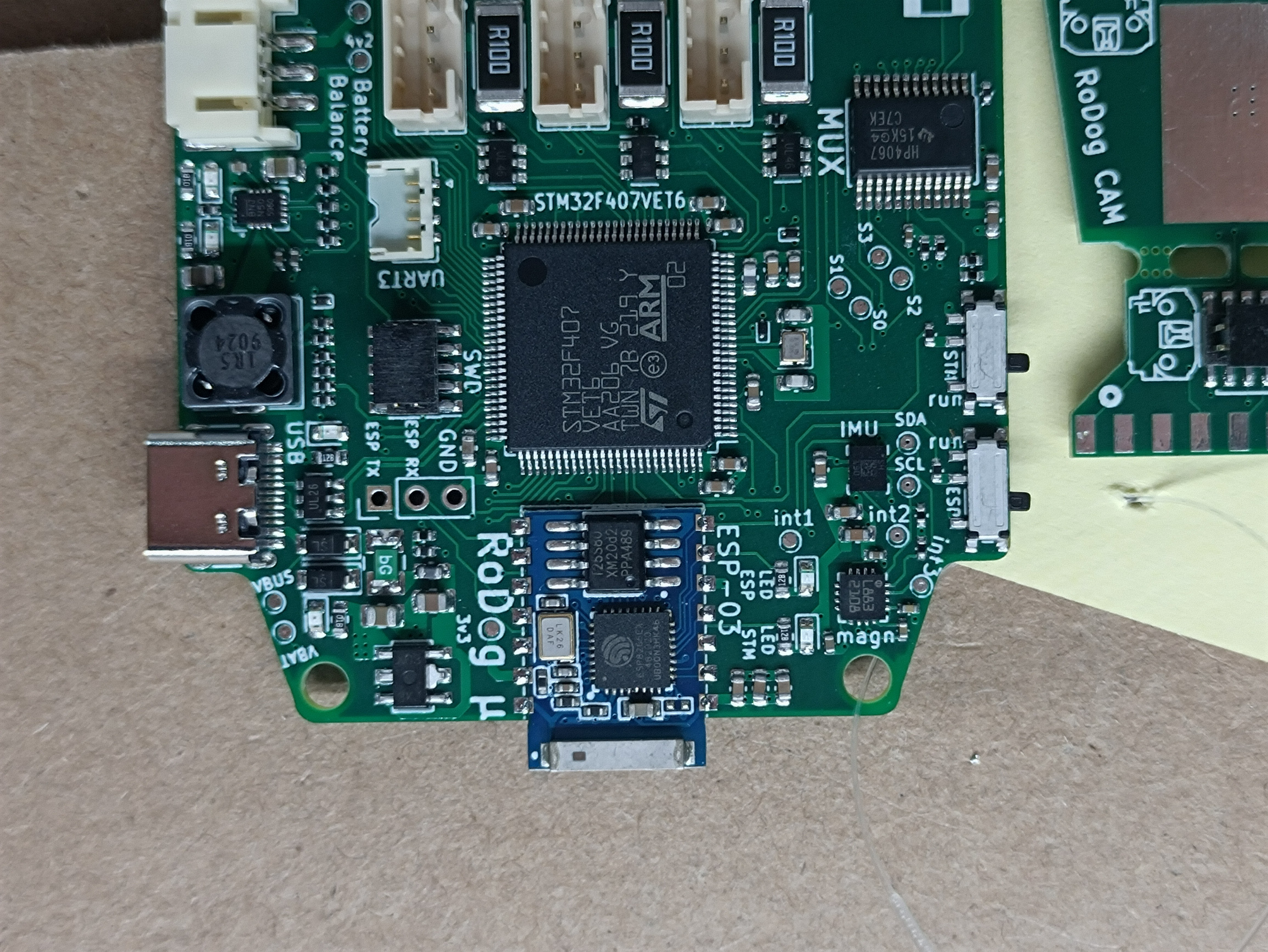

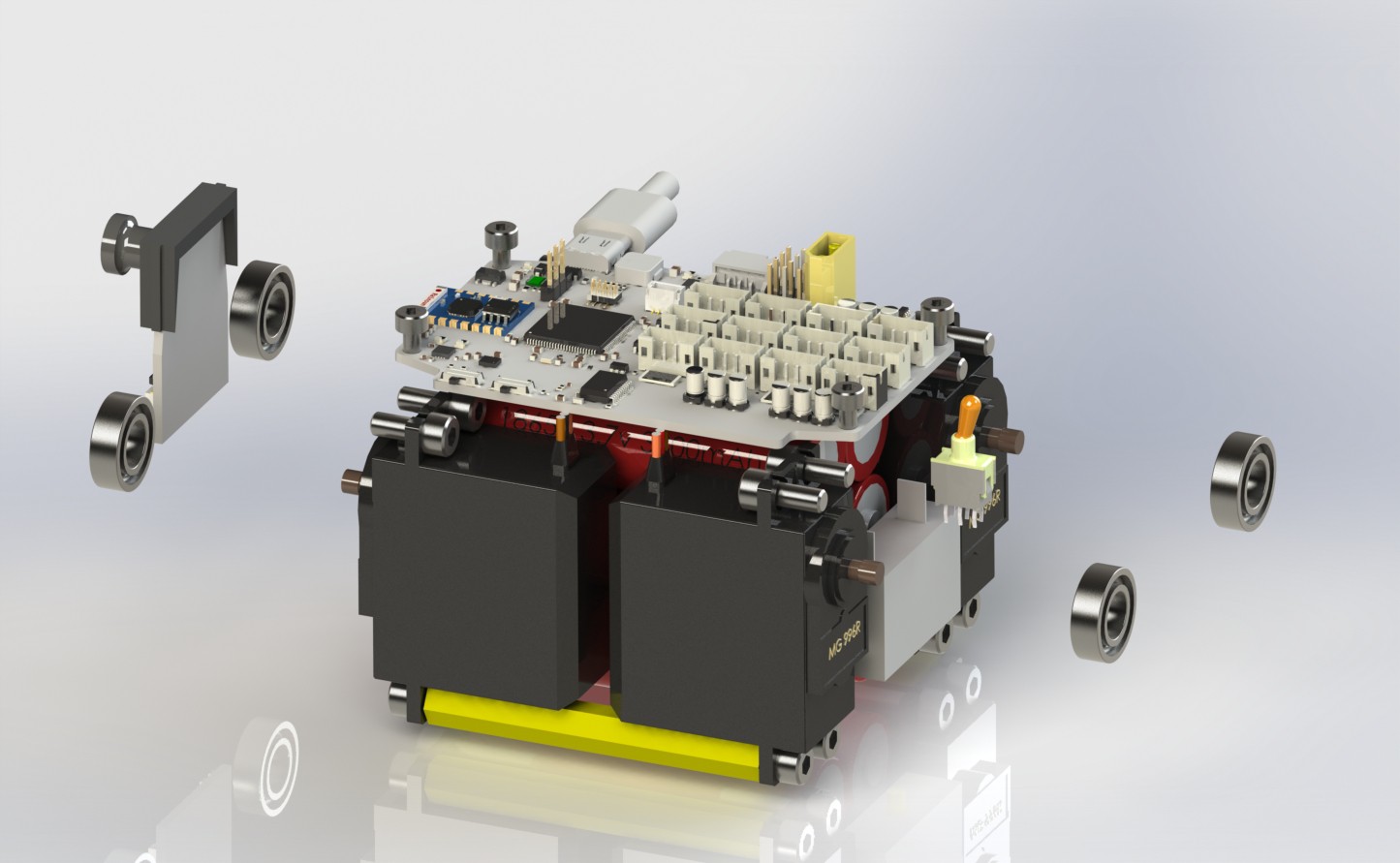

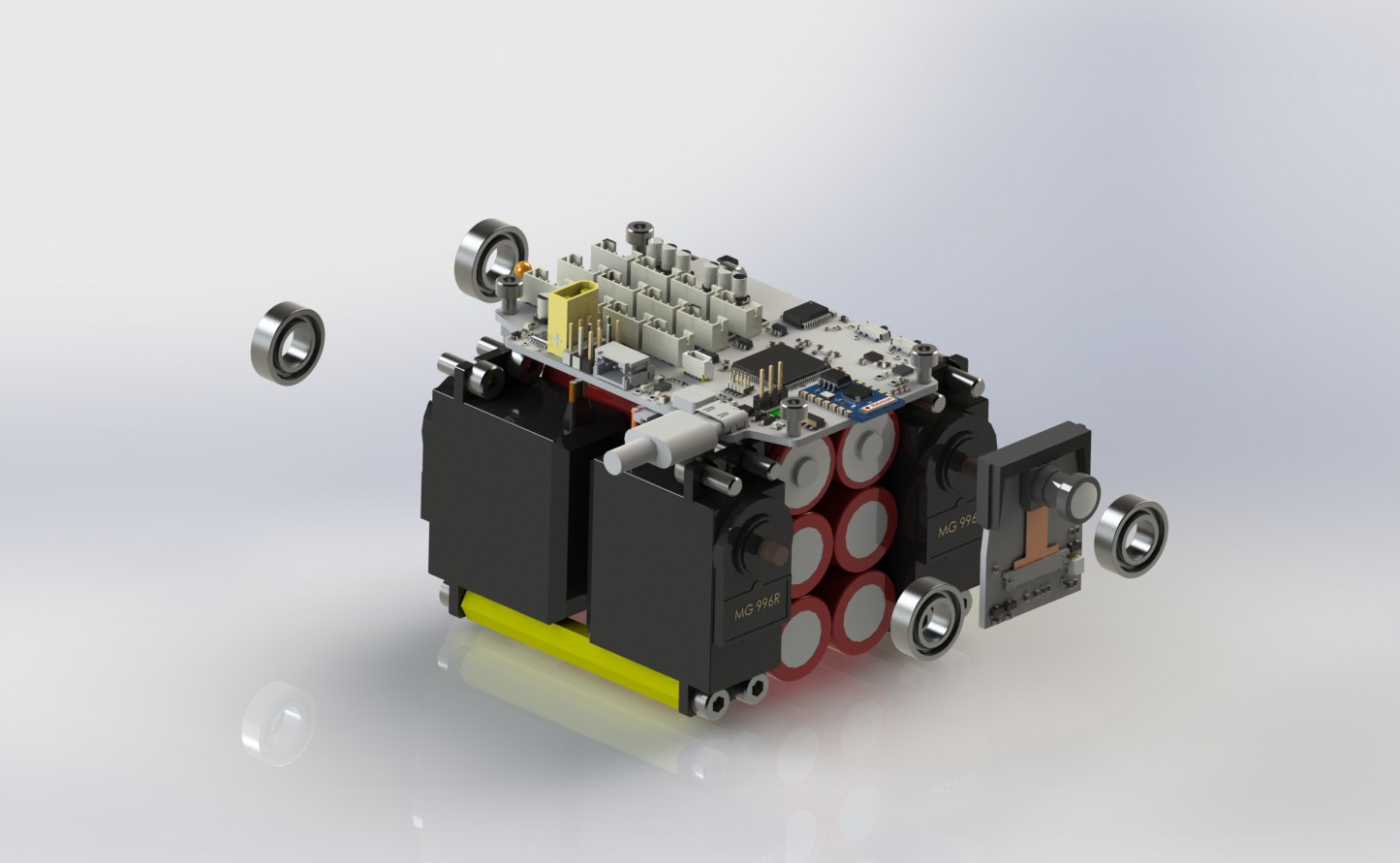

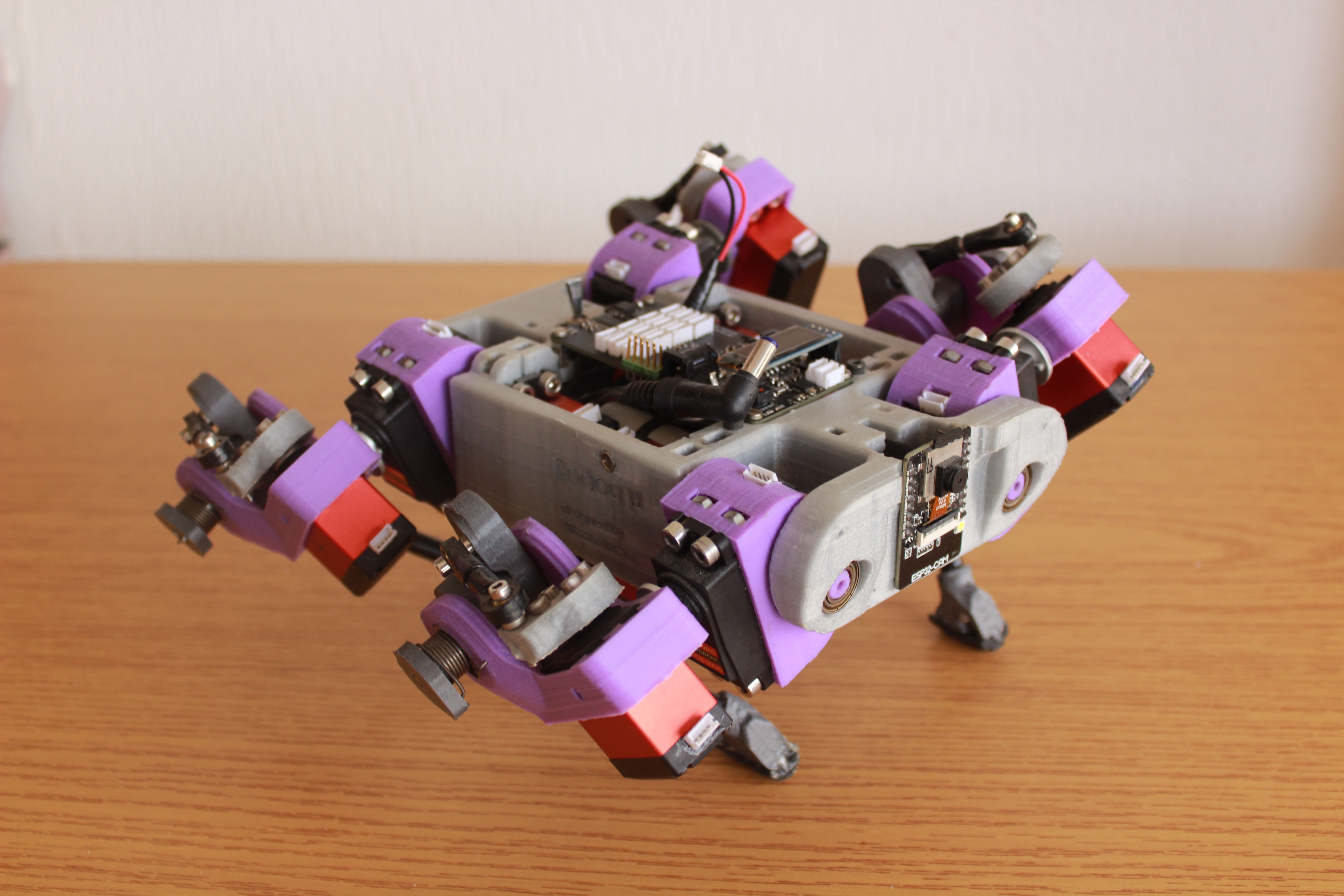

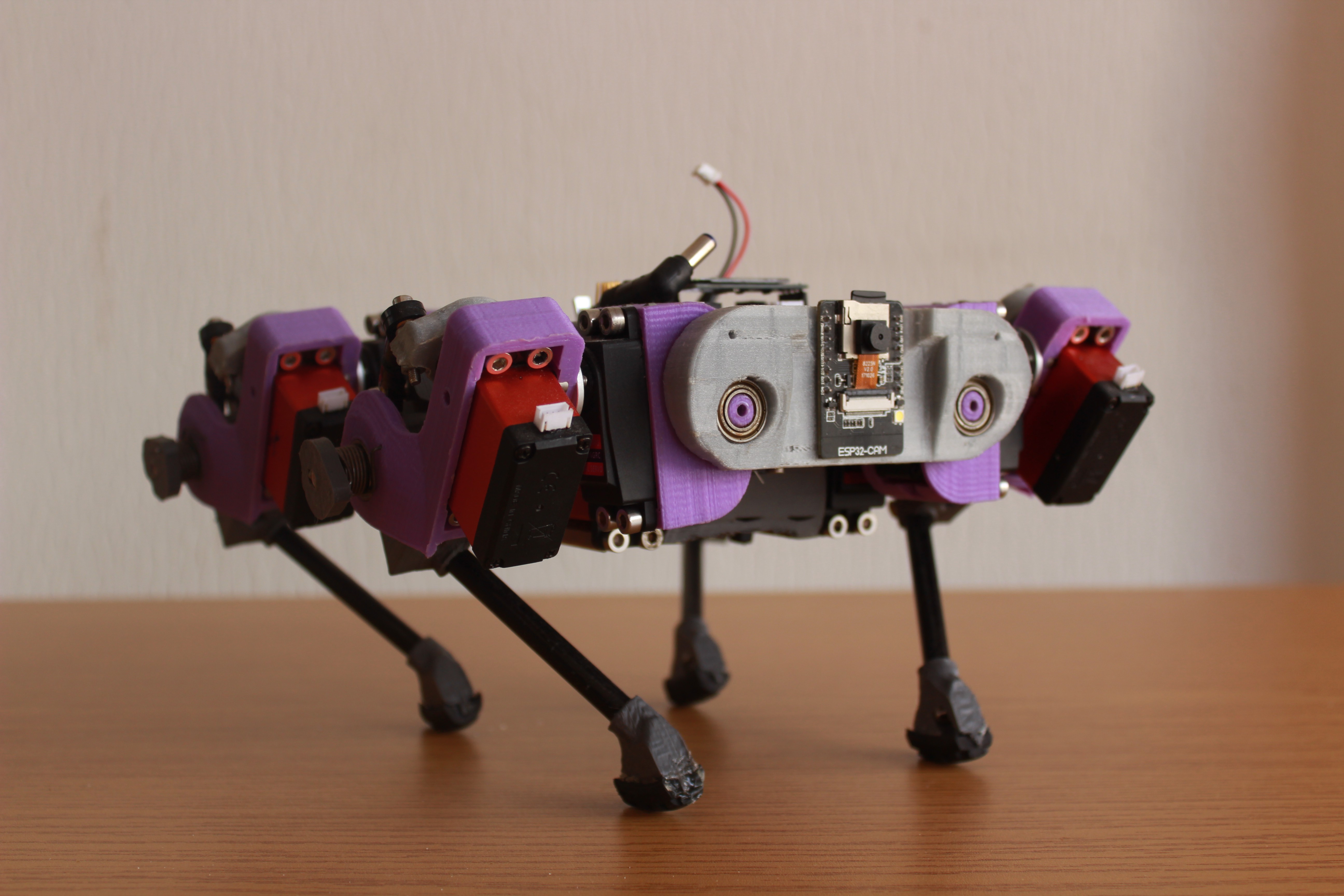

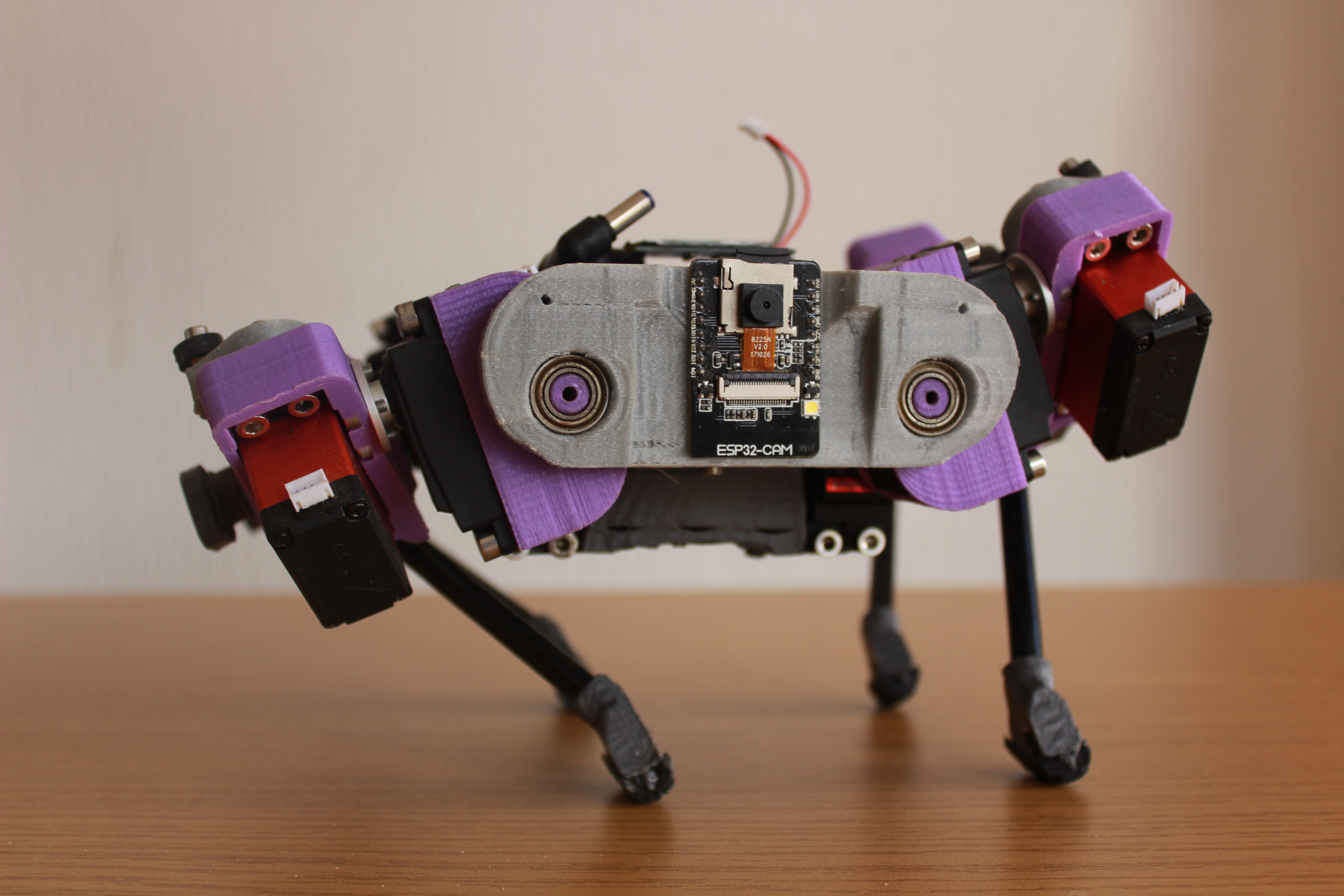

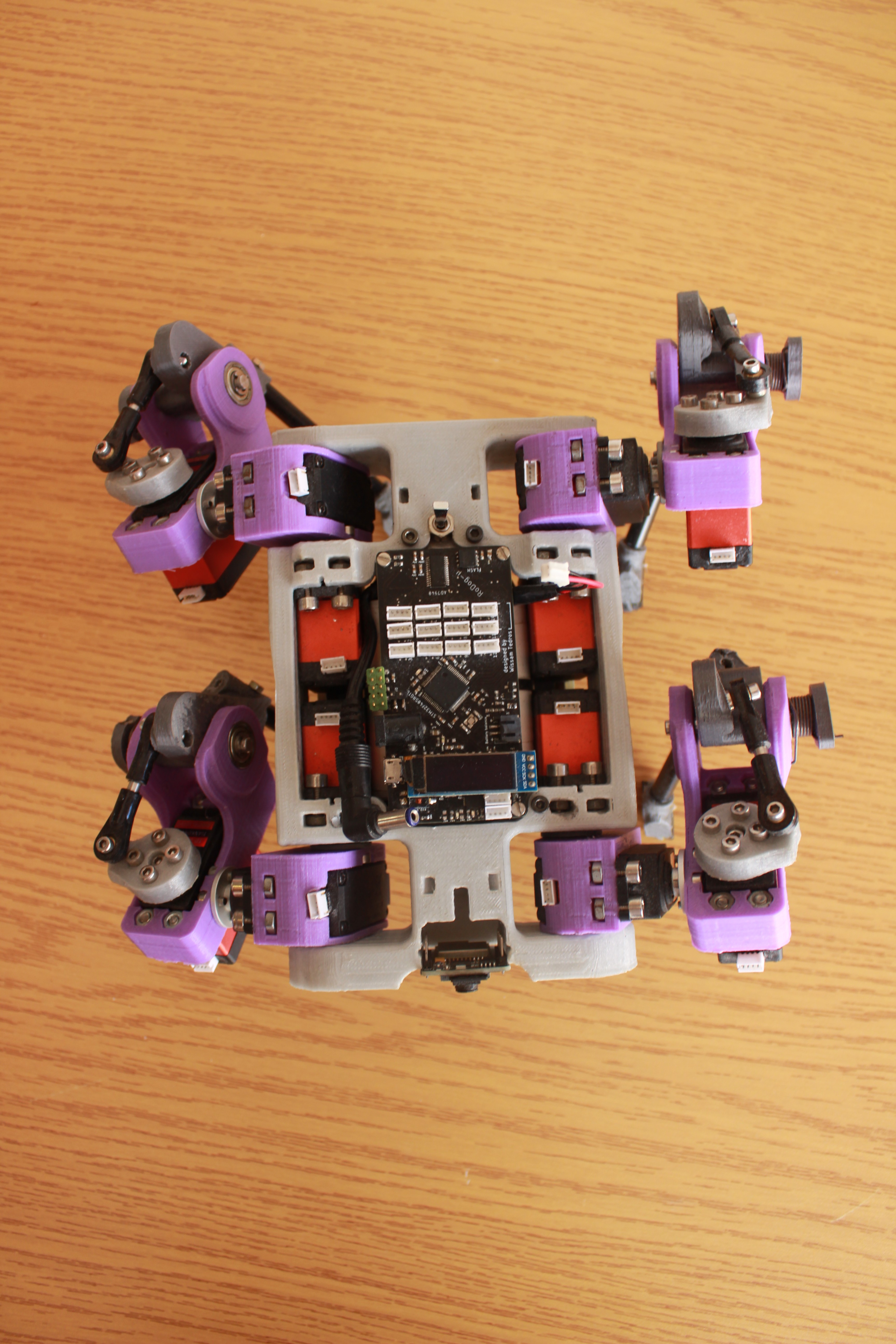

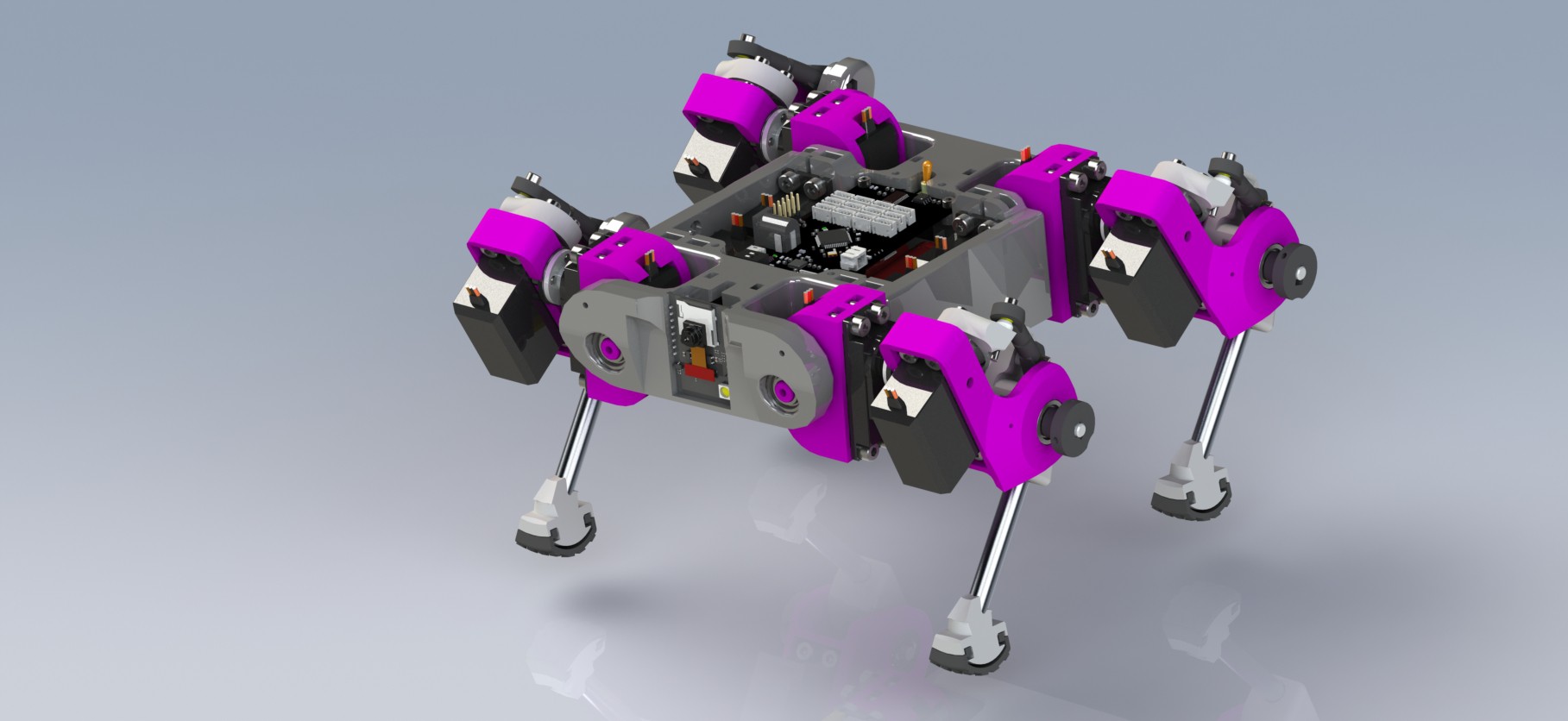

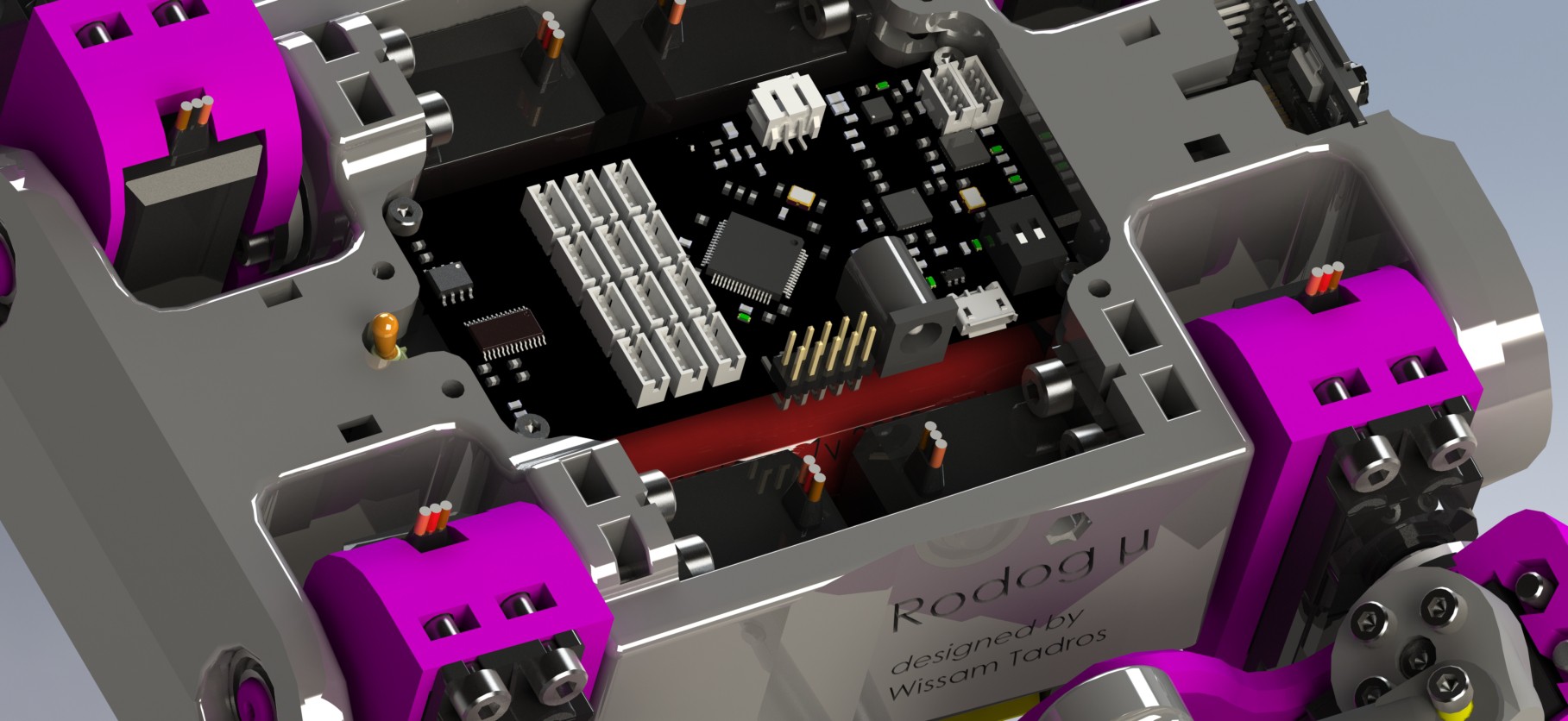

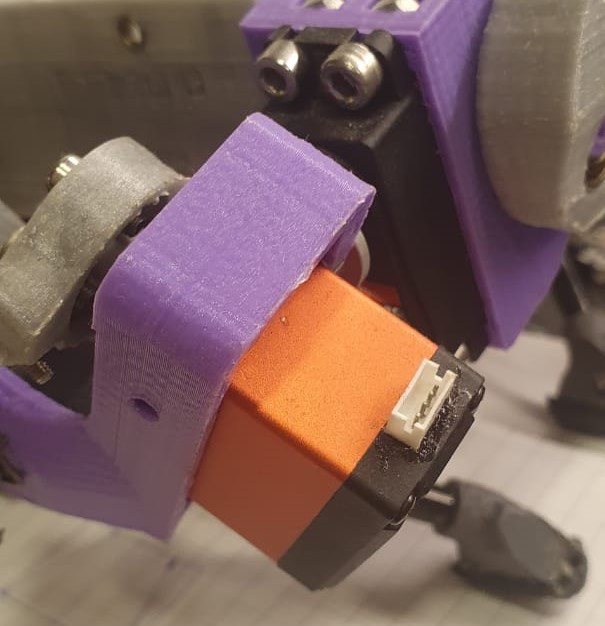

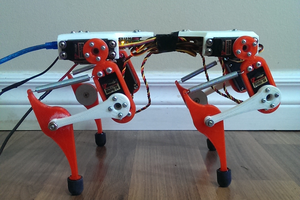

3D printed, Fully accessible!

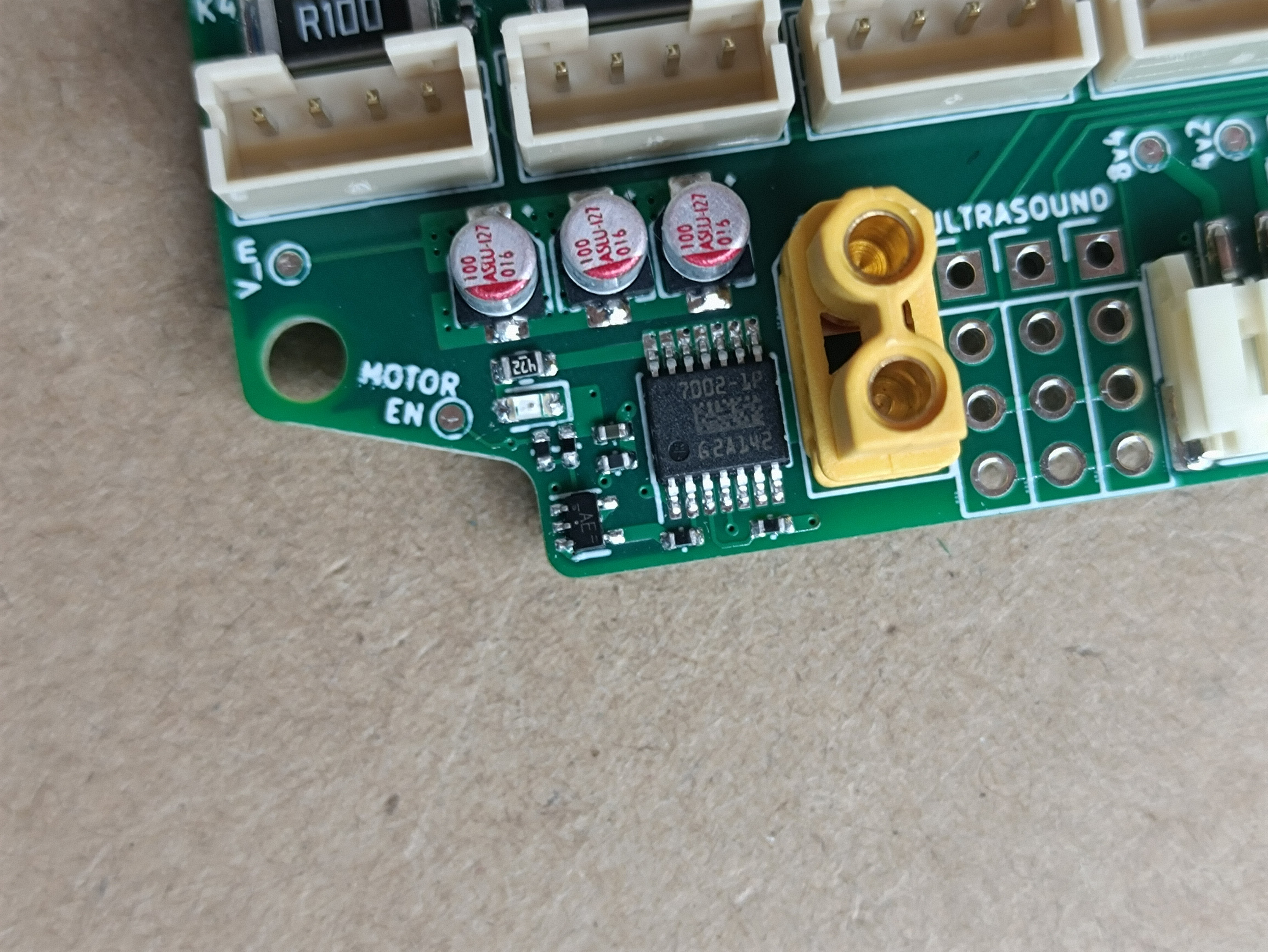

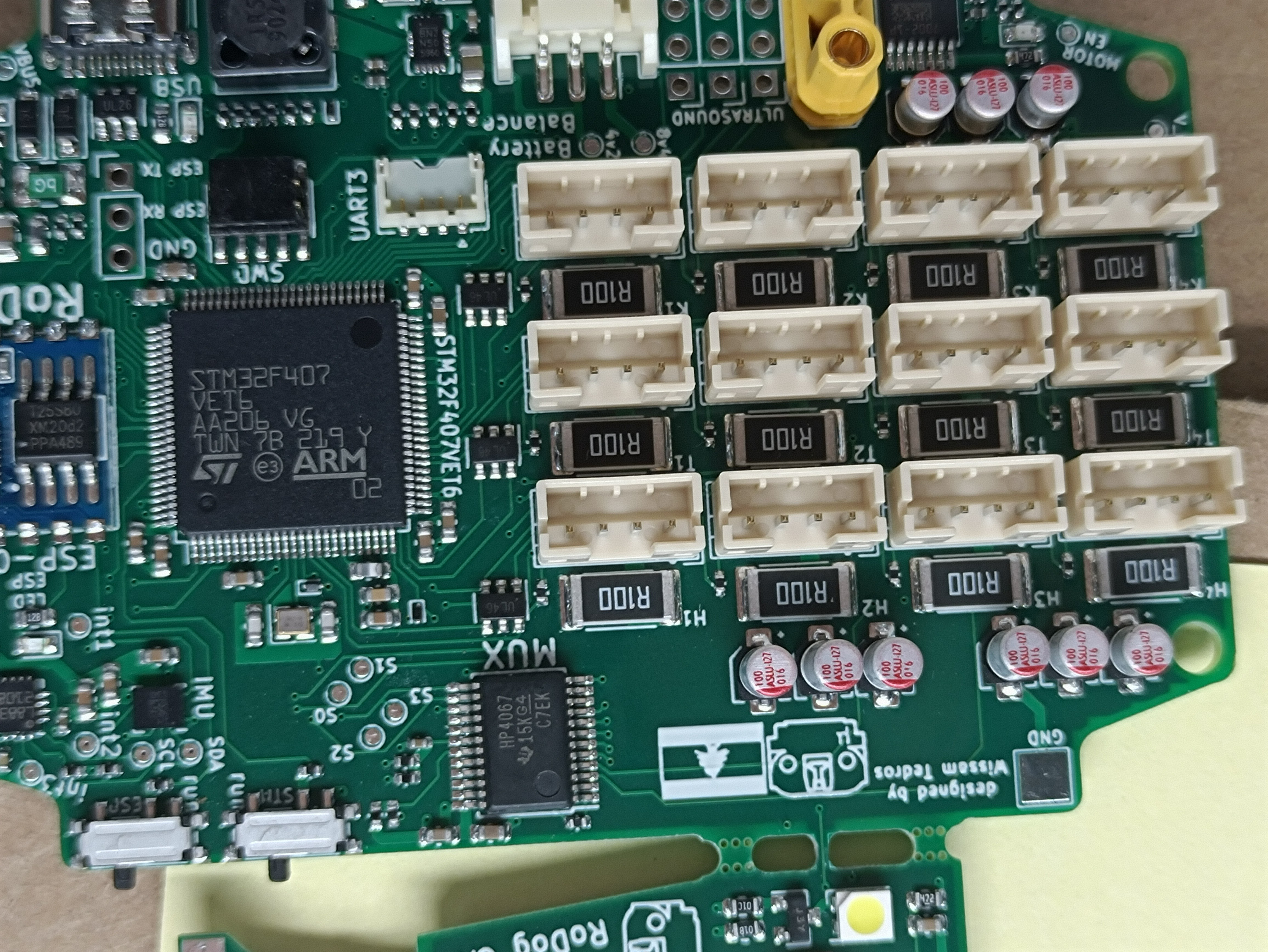

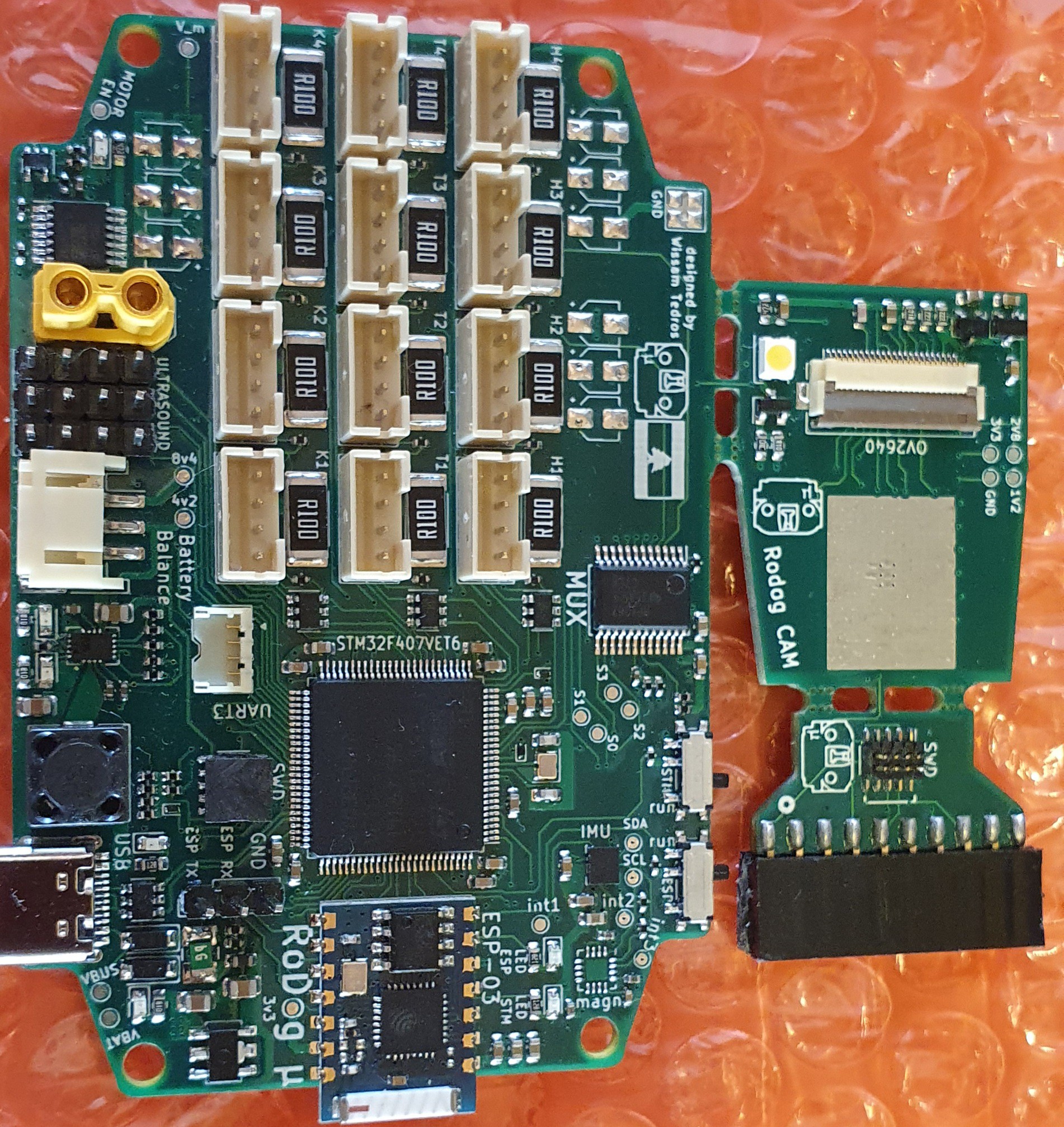

this particular design implements:

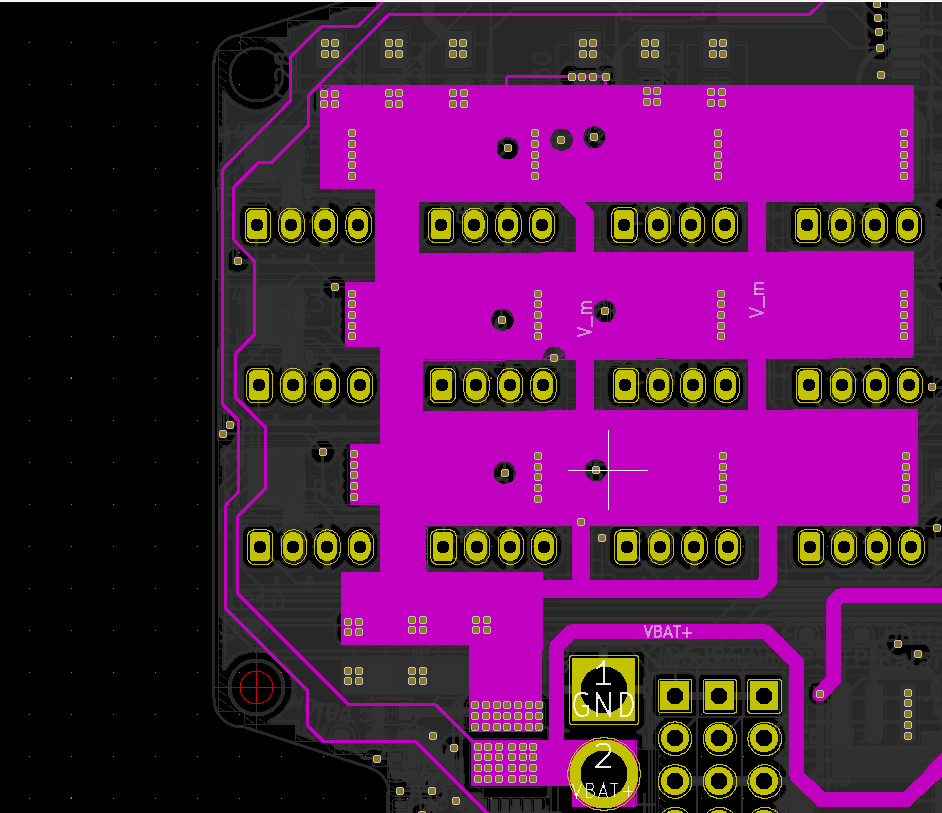

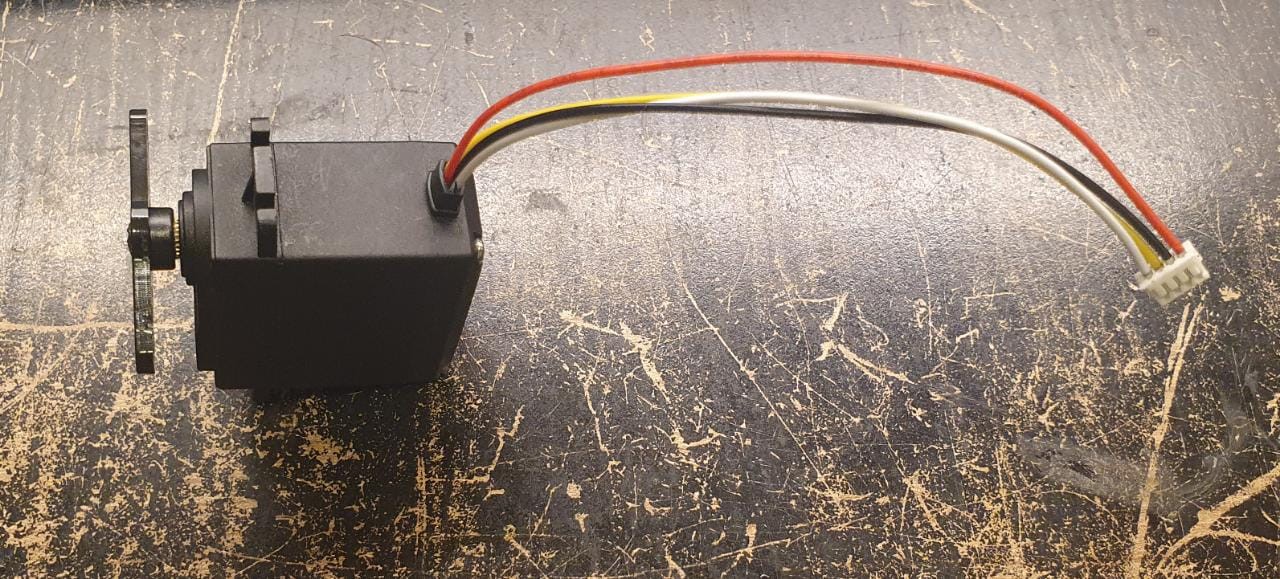

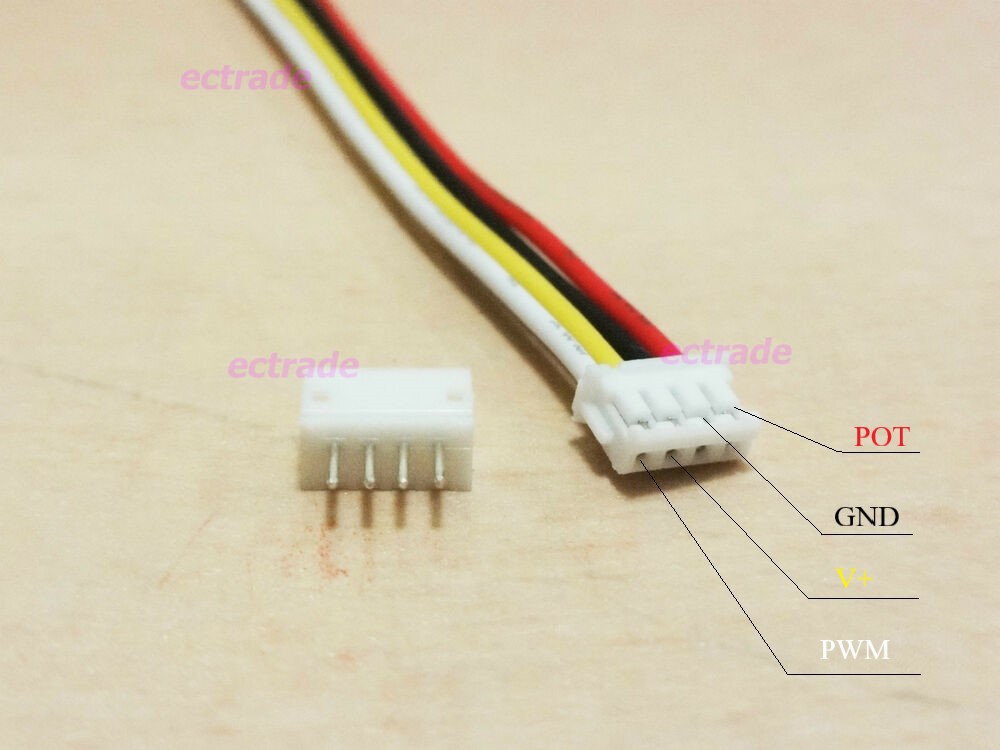

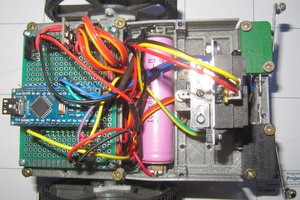

- 12 RC servos actuators, each having position and force feedback.

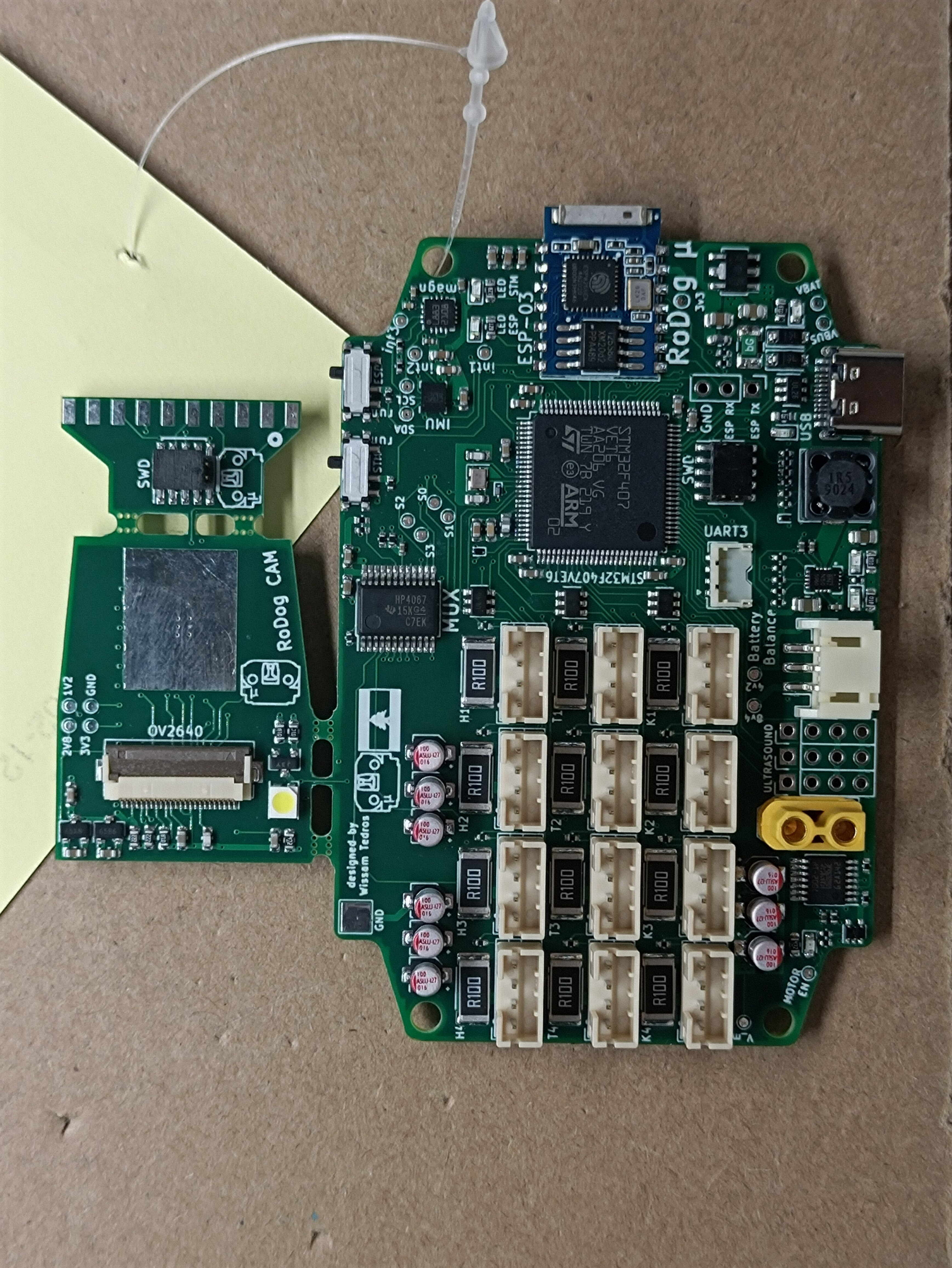

- 9 DOF inertial measurement unit, Gyroscope, accelerometer, magnetometer

- ESP8266 WiFi connectivity.

- 2S Li-ion charging circuit with the USB port

- UART breakout for expansions

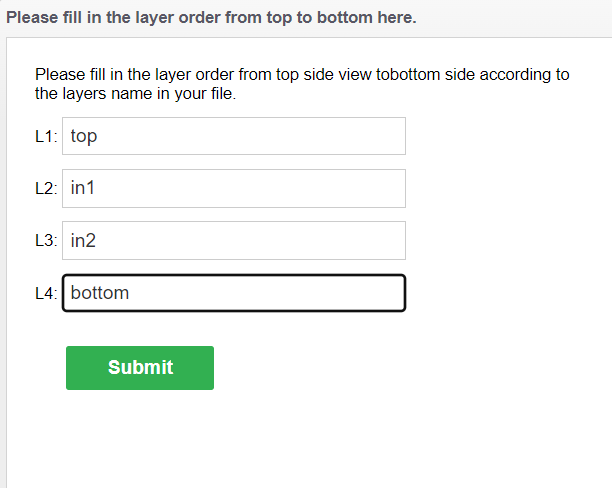

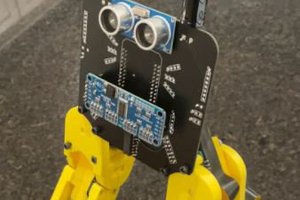

- 3 Ultra-sound interfaces

- DCMI interface

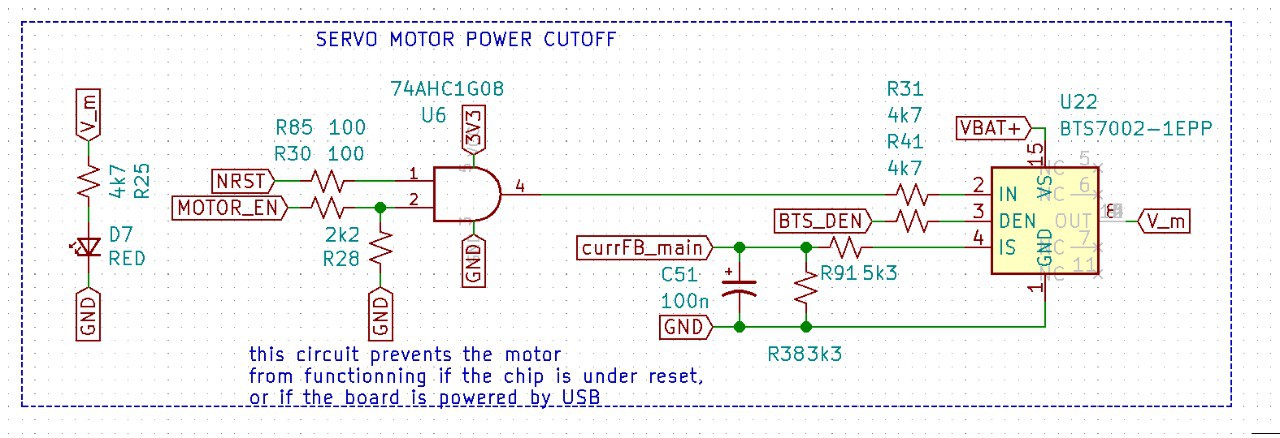

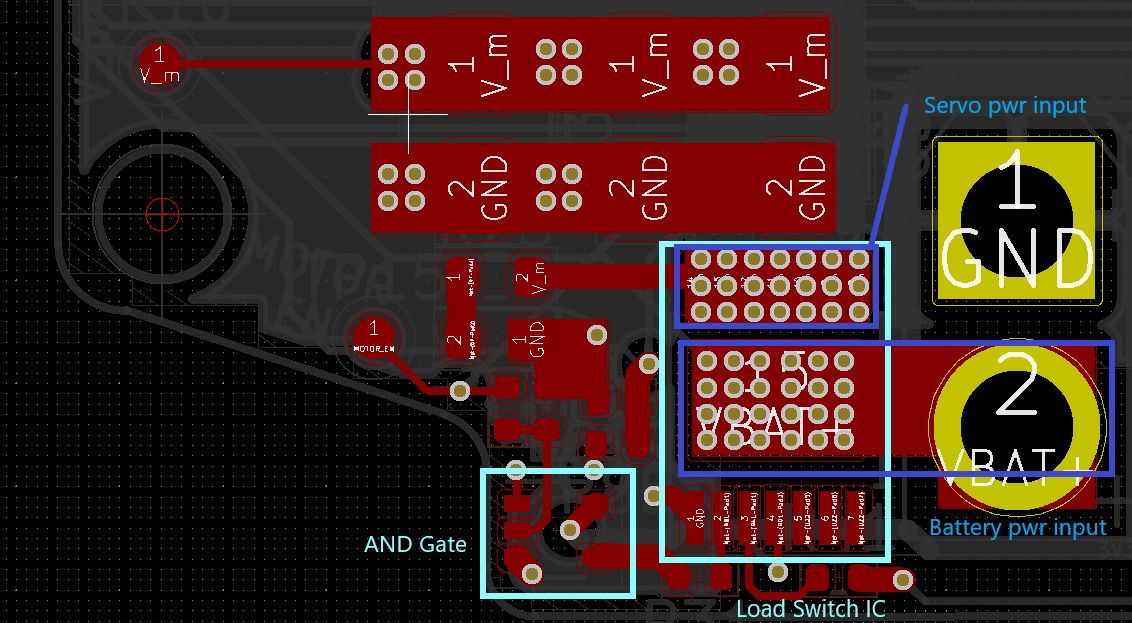

- Load switch to activate or deactivate the actuators

Wissam Tedros

Wissam Tedros

Roald Lemmens

Roald Lemmens

Audrey Robinel

Audrey Robinel

Alex Martin

Alex Martin

shane.snipe

shane.snipe

Your concept with the 12 motor controller board with position and current feedback makes a lot of sense! Do you plan to sell it (maybe on tindie)? A lot of others could massively profit from such a board if it's easily available. Great project, keep up the good work :-)