The idea for an easy-to-manufacture water turbine came up during the development of WinDIY (a 3D printable wind turbine (more info here: https://hackaday.io/project/184849-windiy2-horizontal-axis-wind-turbine)).

The motives were actually the same.

Develop a turbine that can be easily manufactured with a 3D printer and assembled even by people who are not technically gifted.

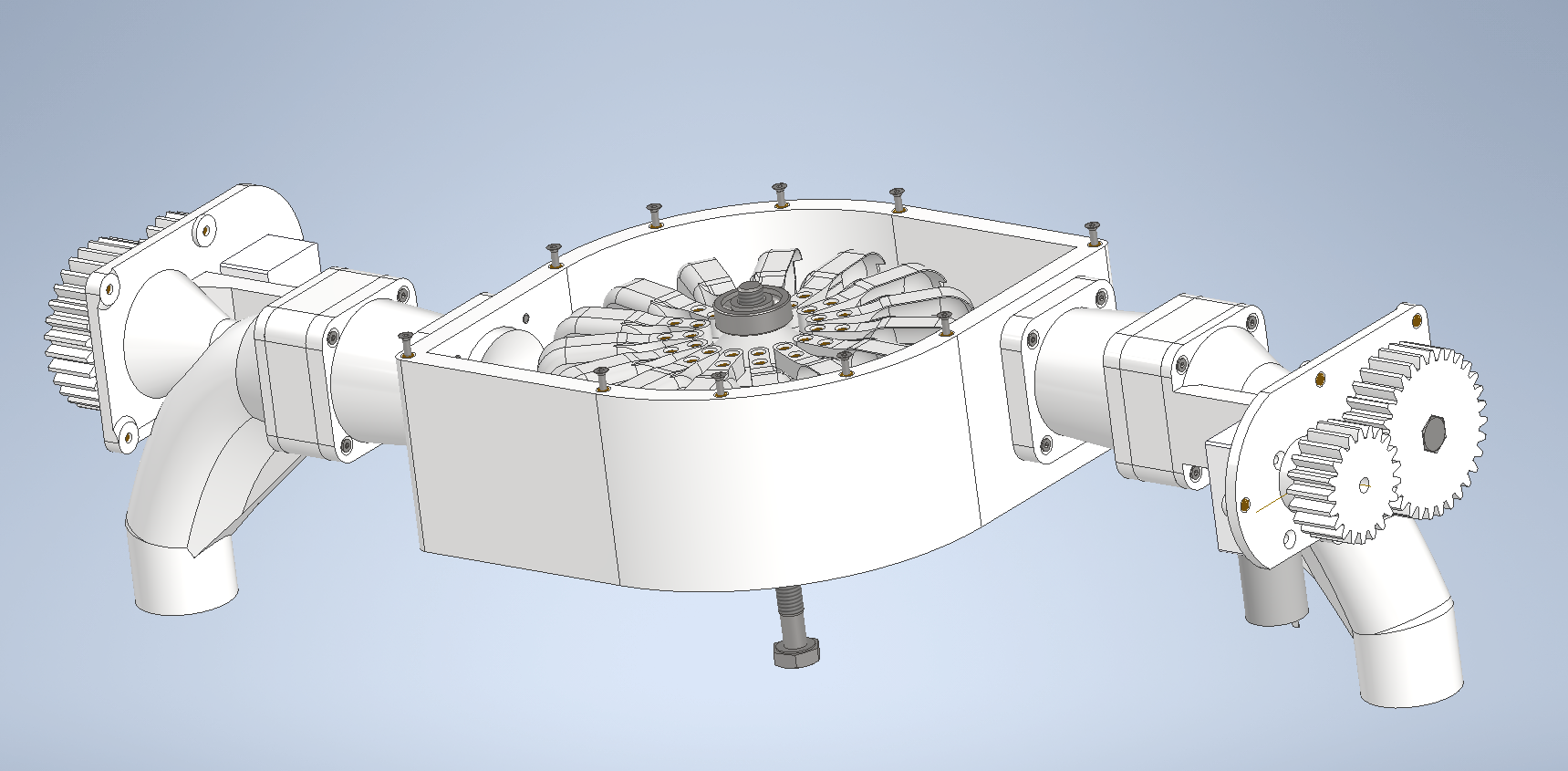

As a long-term goal, I would also like to be able to combine this turbine with WinDIY.

For example, you could use the excess energy from WinDIY to pump water to a higher level (model pump storage power plant).

In times without wind, this water can then be used with the 3D printed pelton turbine (I'm still missing a cool name :)) to generate energy from it.

Of course you can't generate outputs in the kW range with it, but a charged mobile phone or LED light at night can also make a big difference.

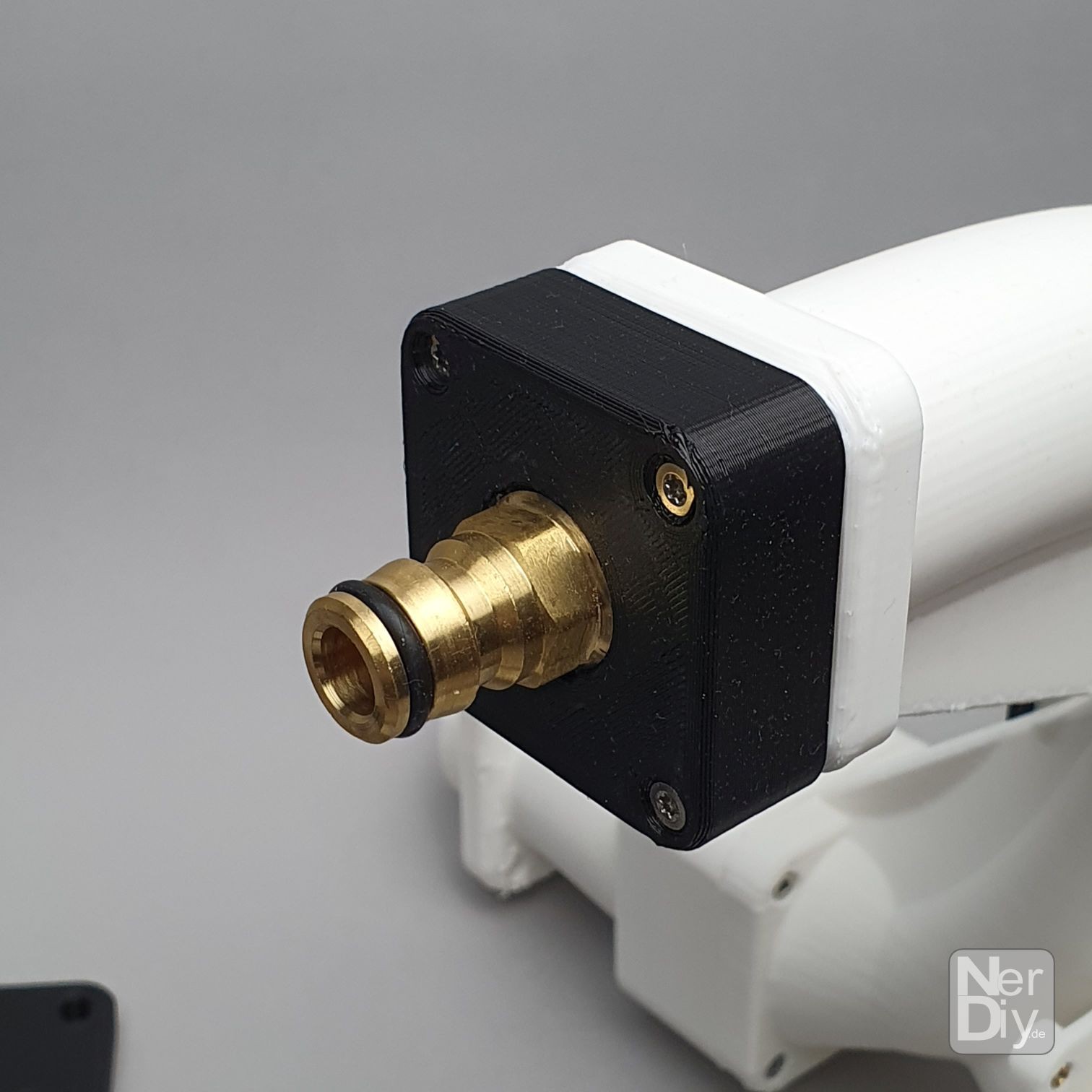

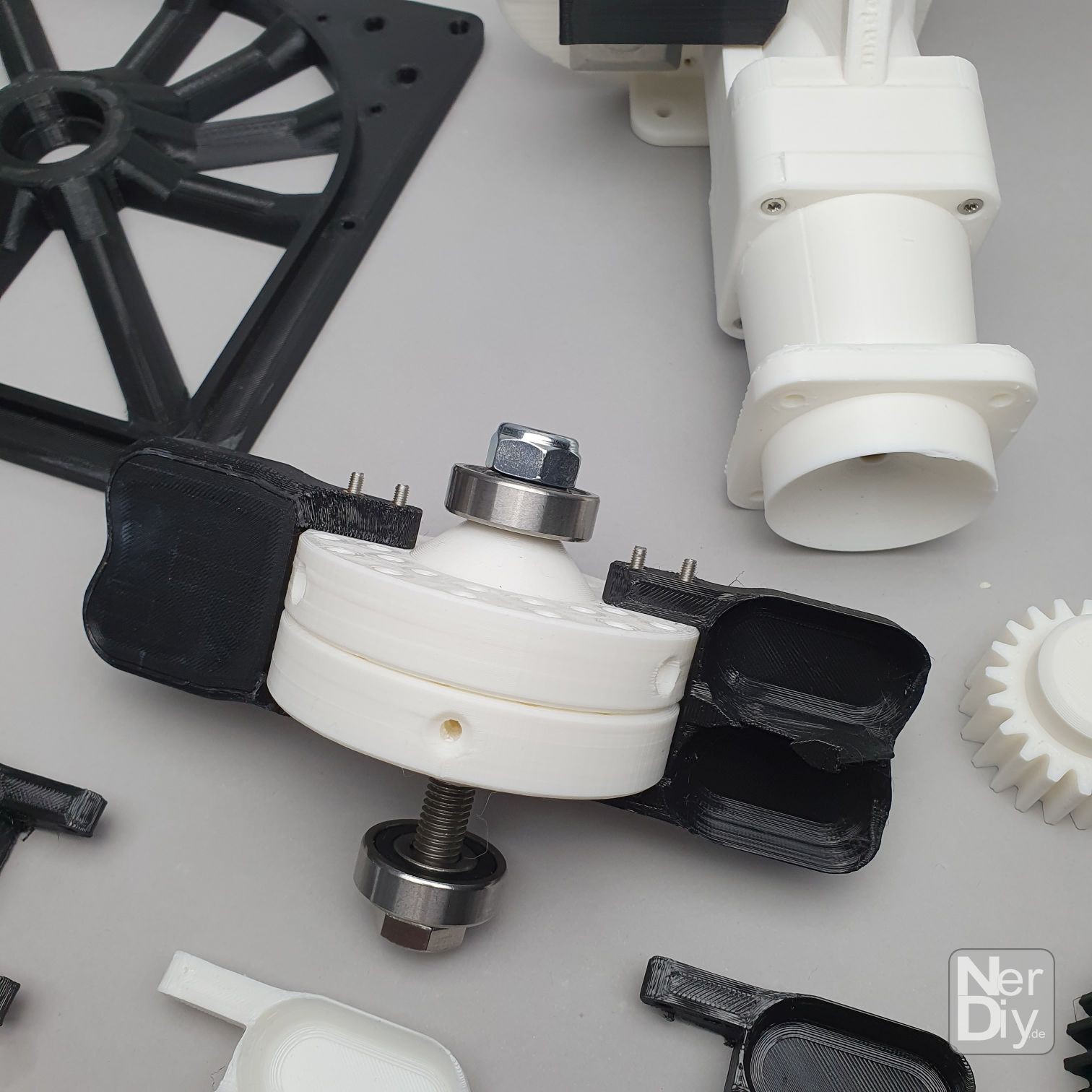

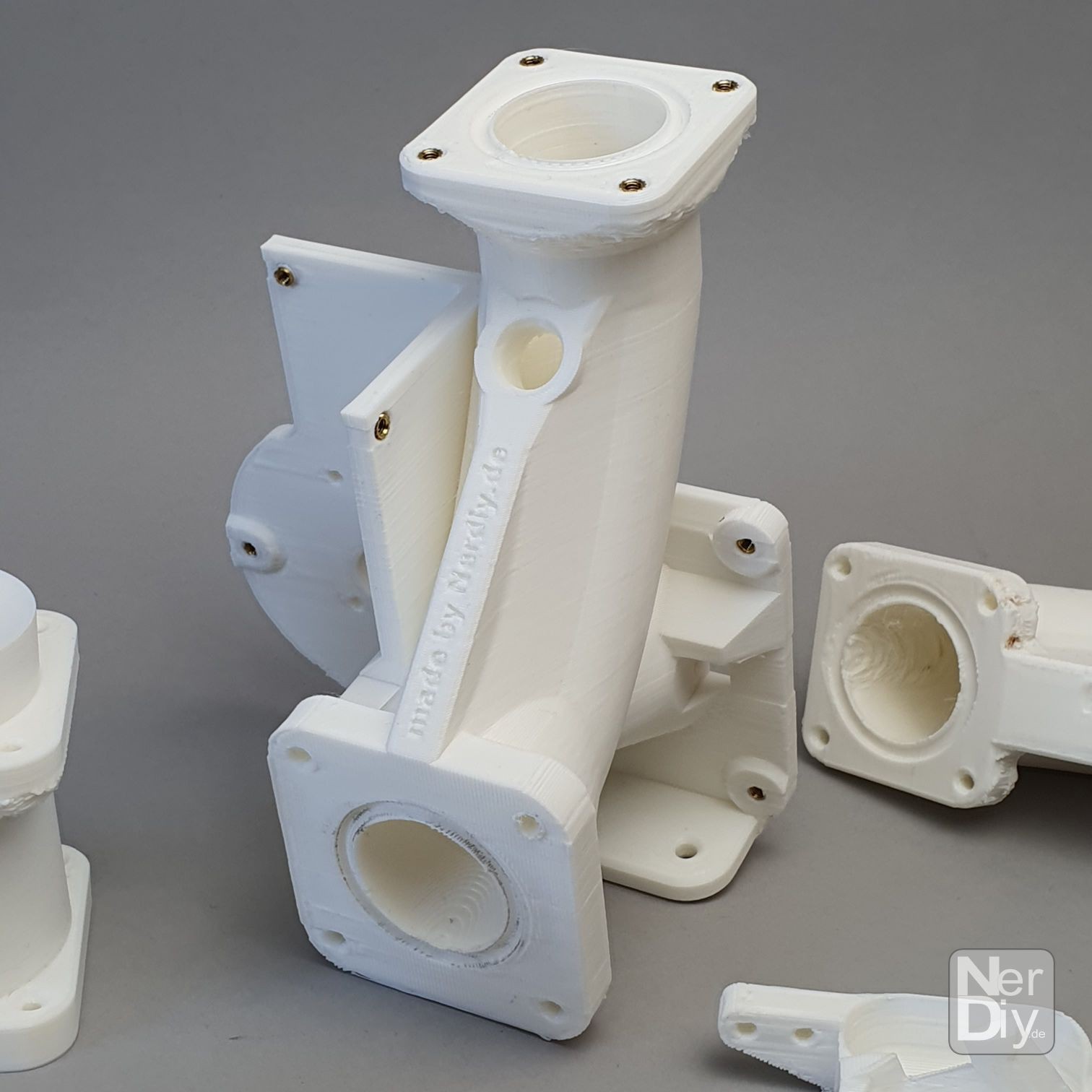

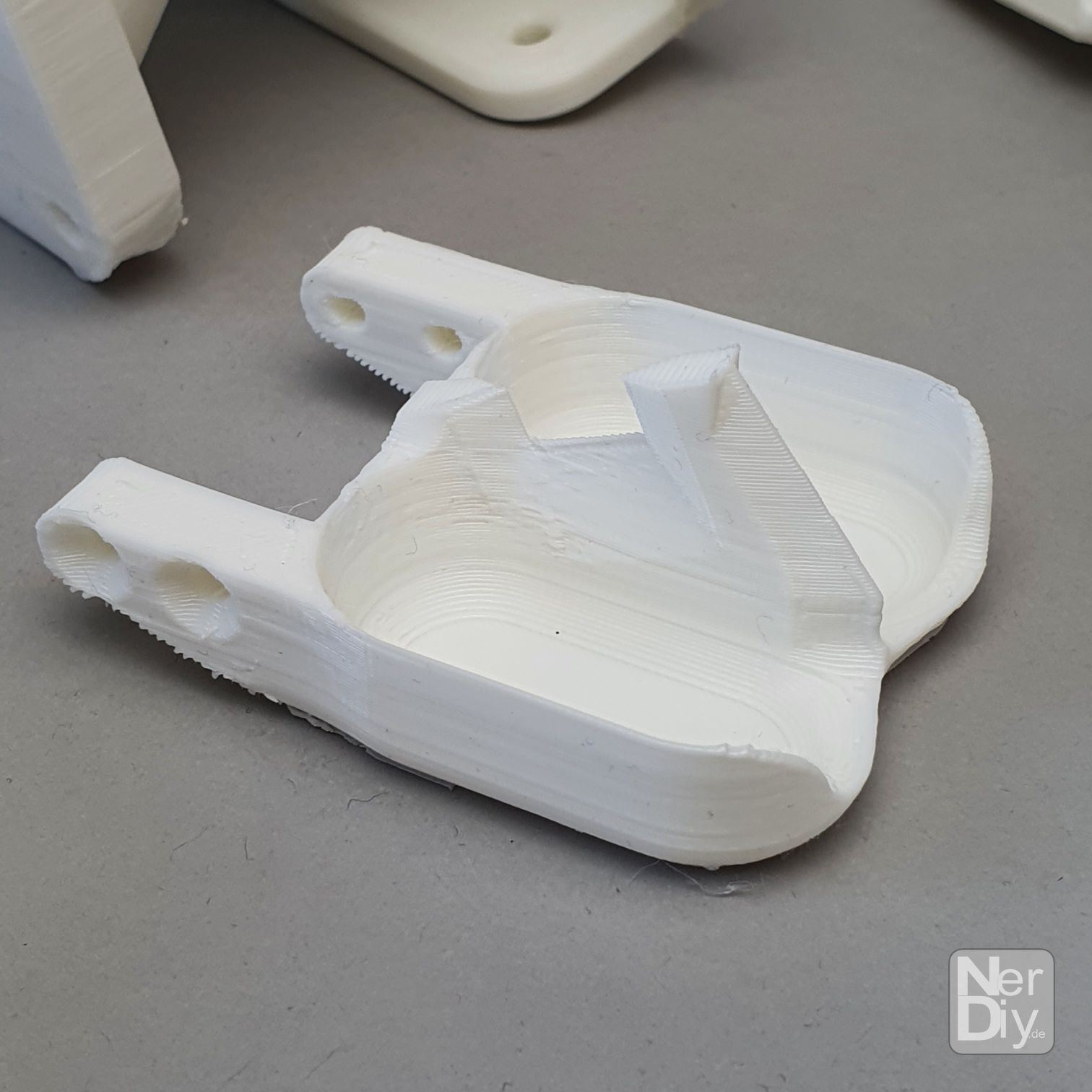

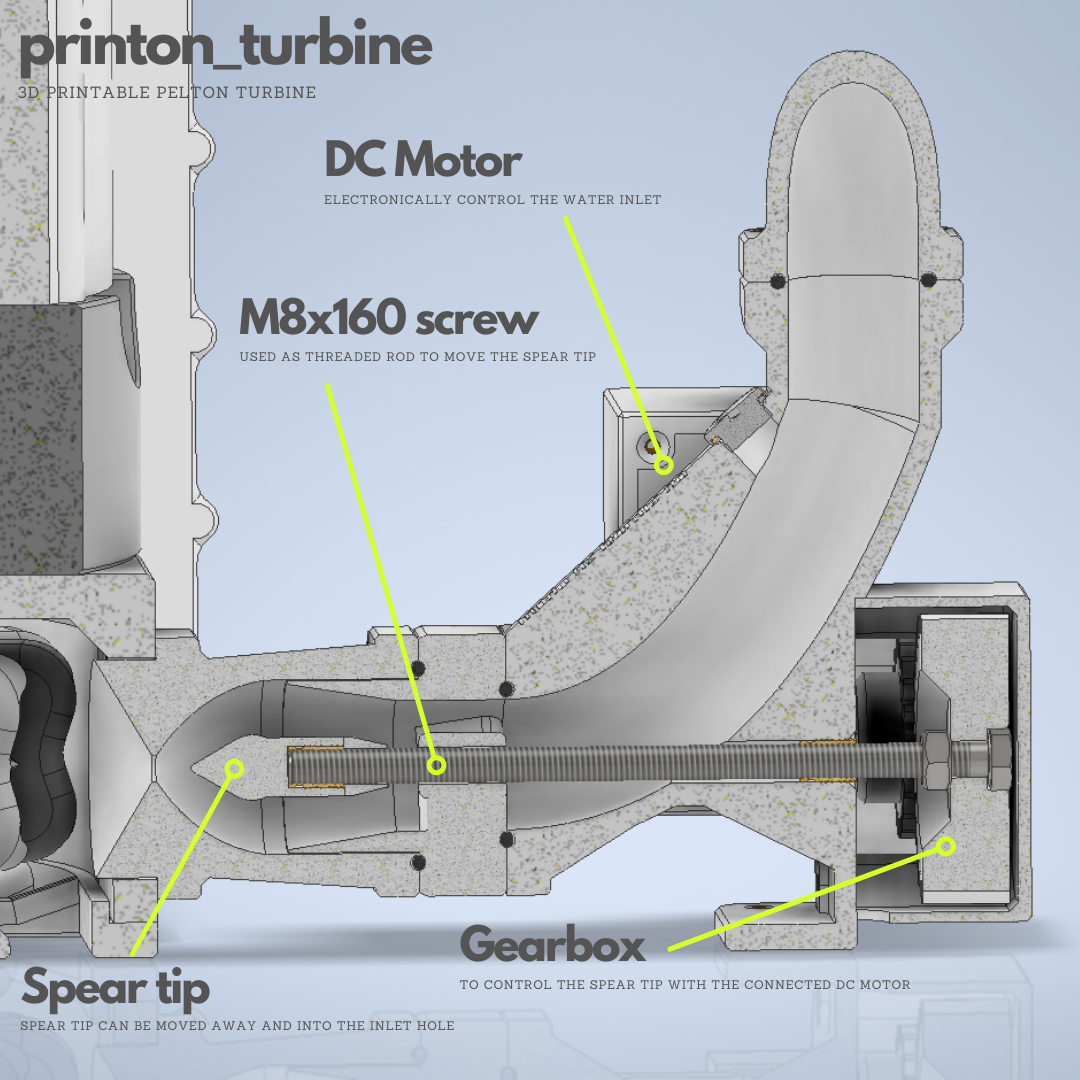

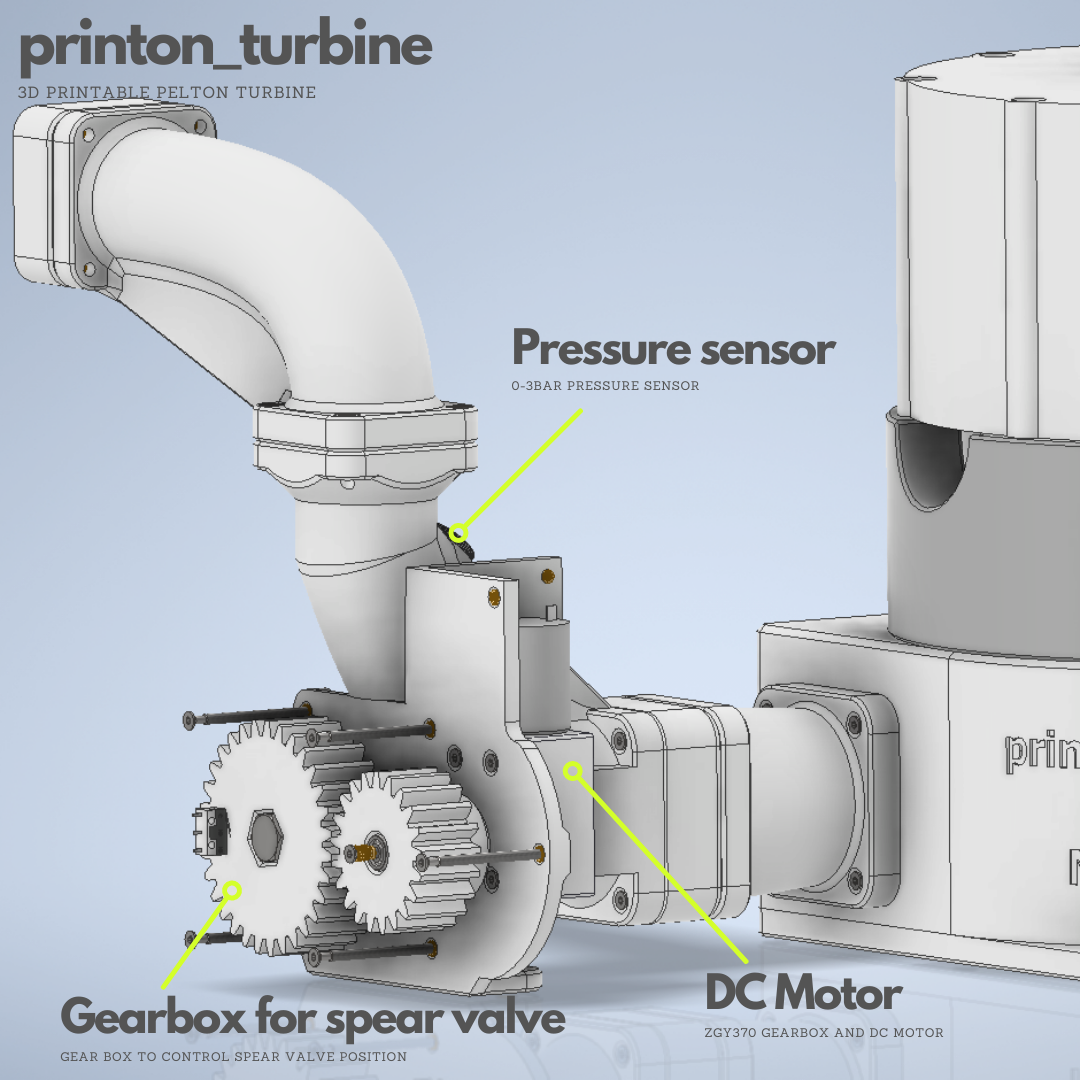

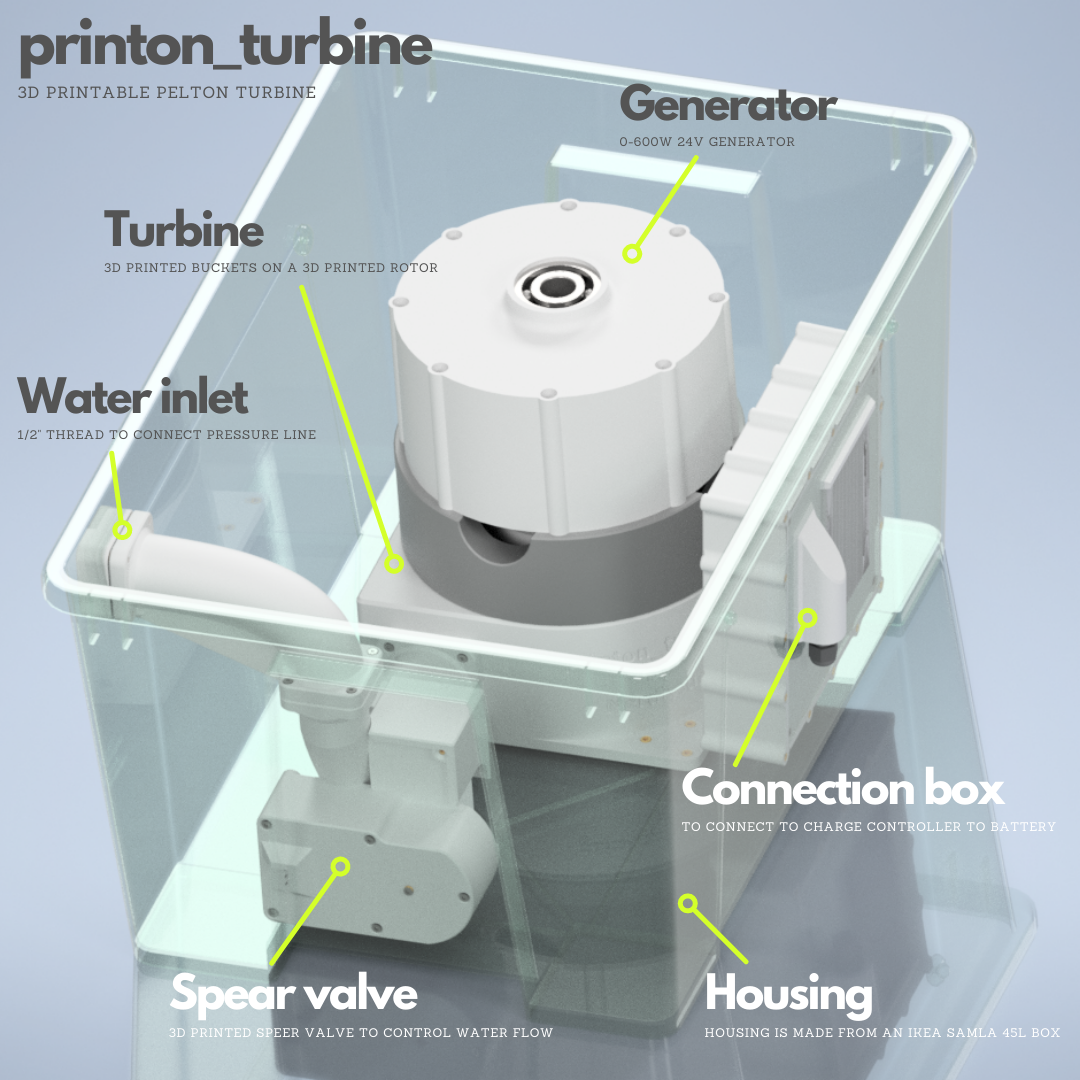

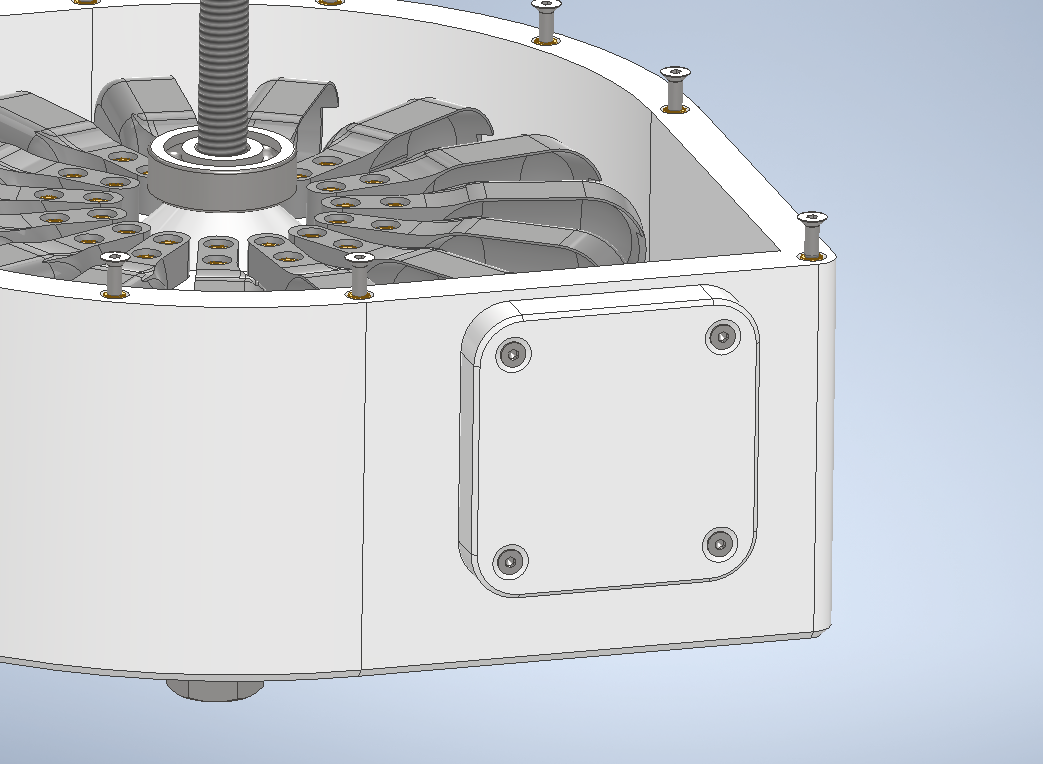

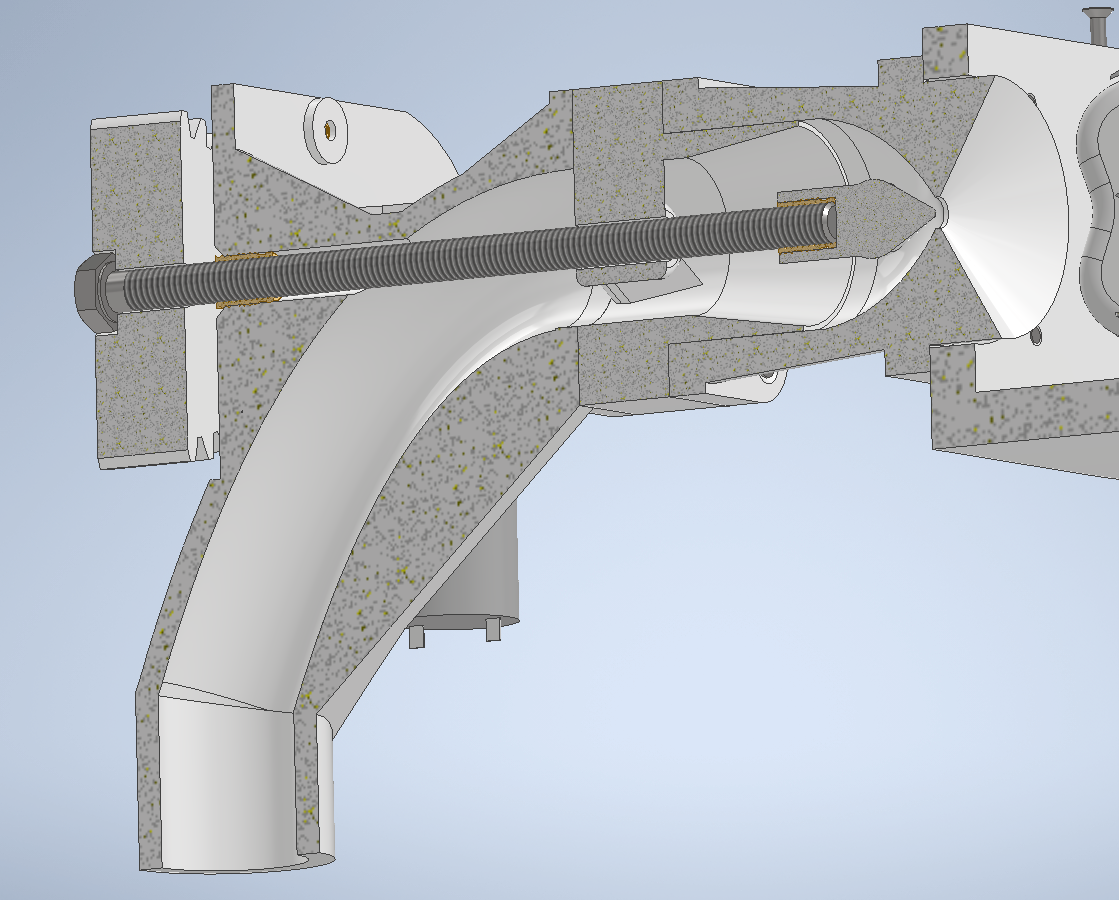

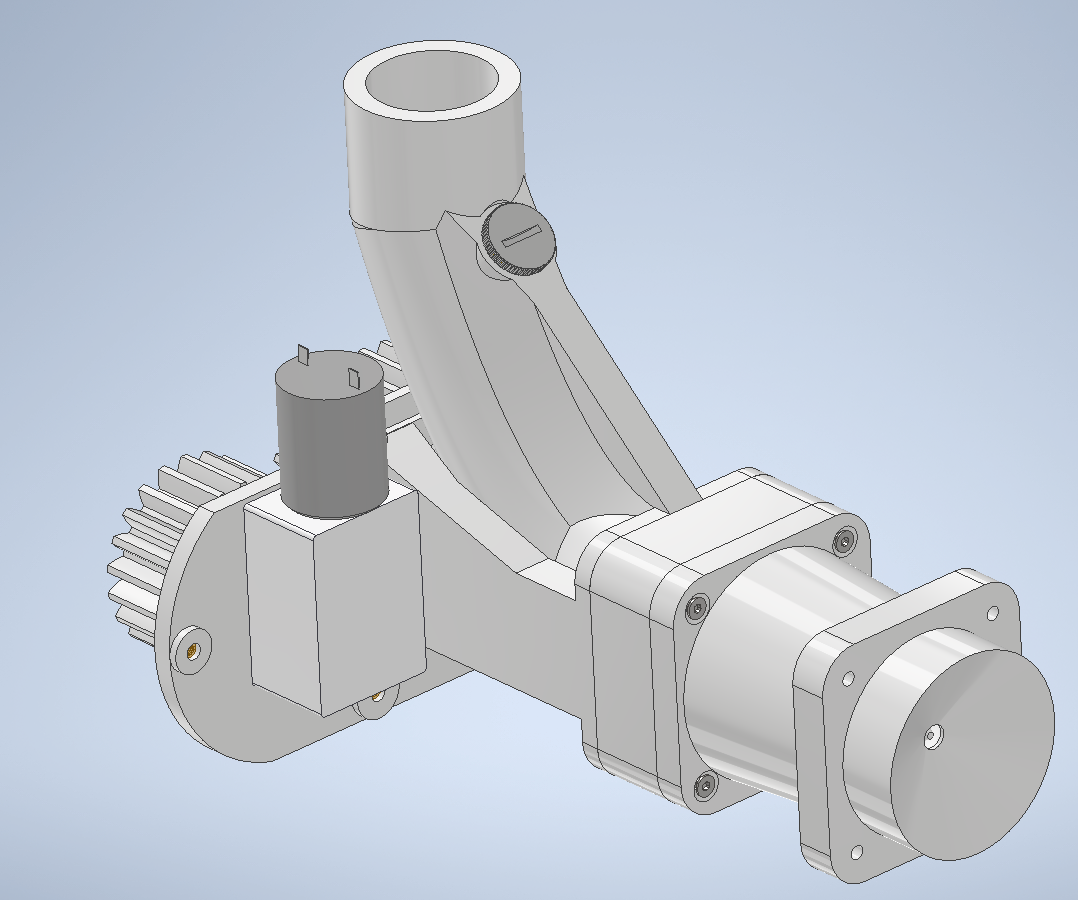

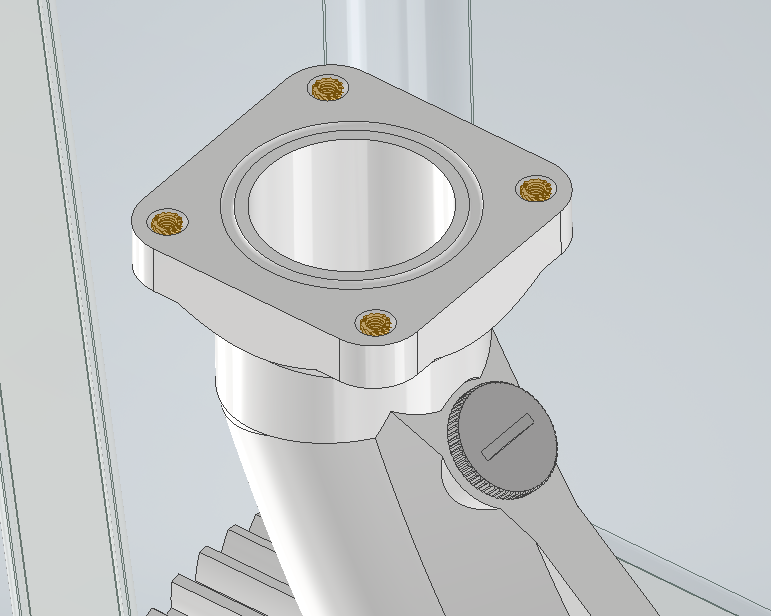

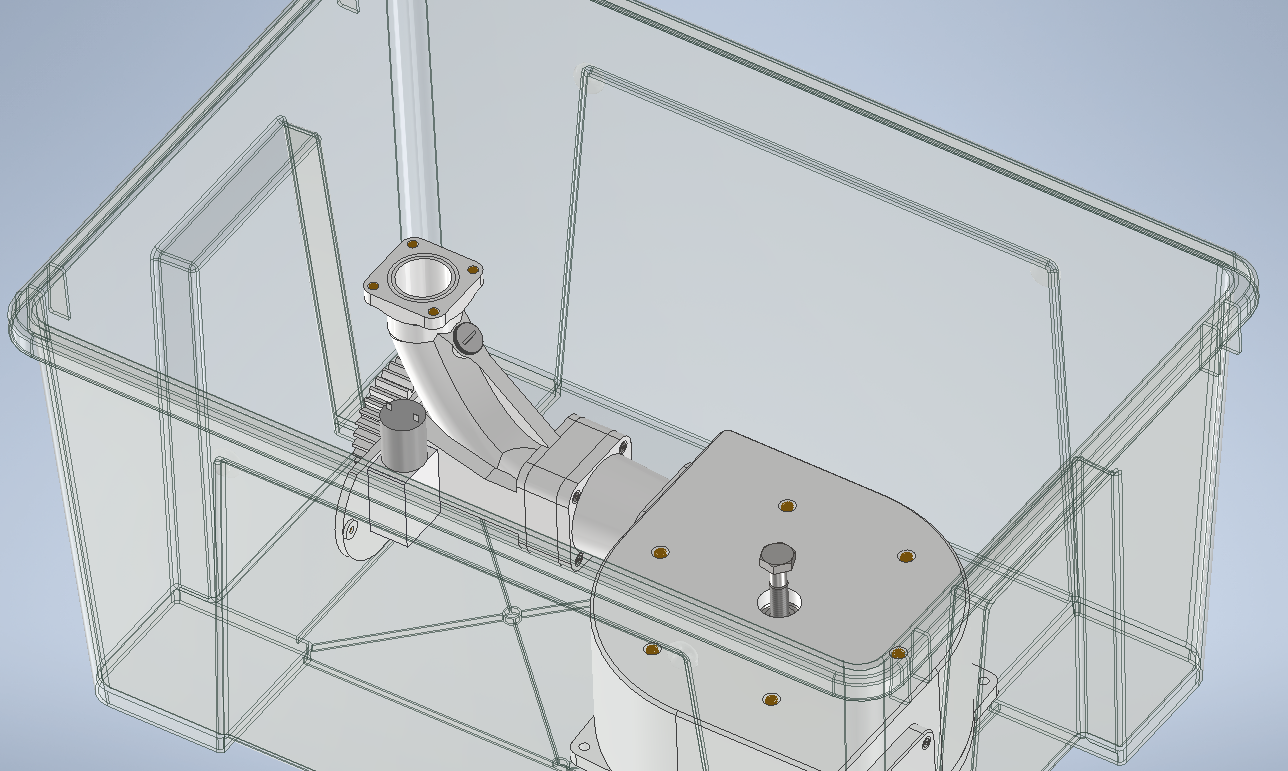

As a small side project I am also working on a 3D printable spear valve, which can be used to regulate the water flow.

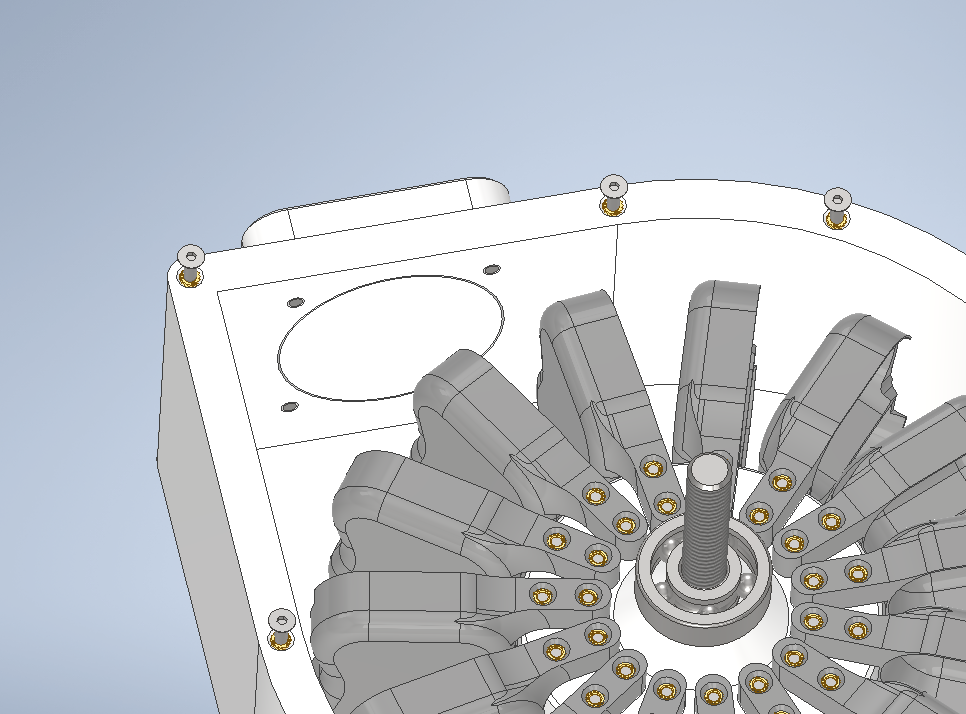

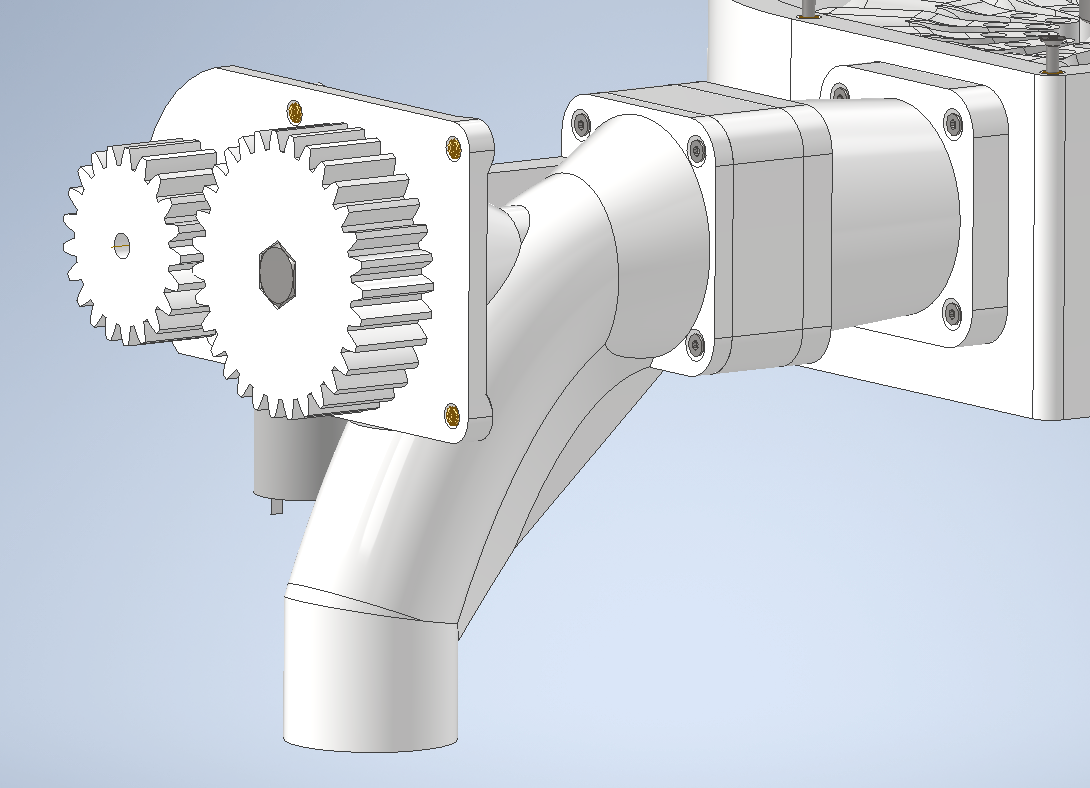

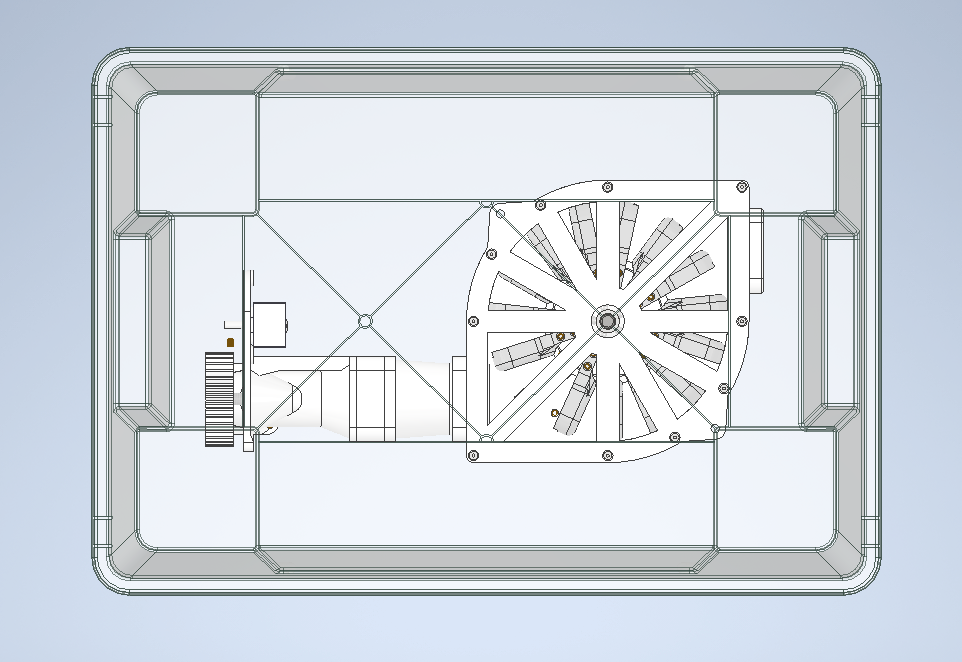

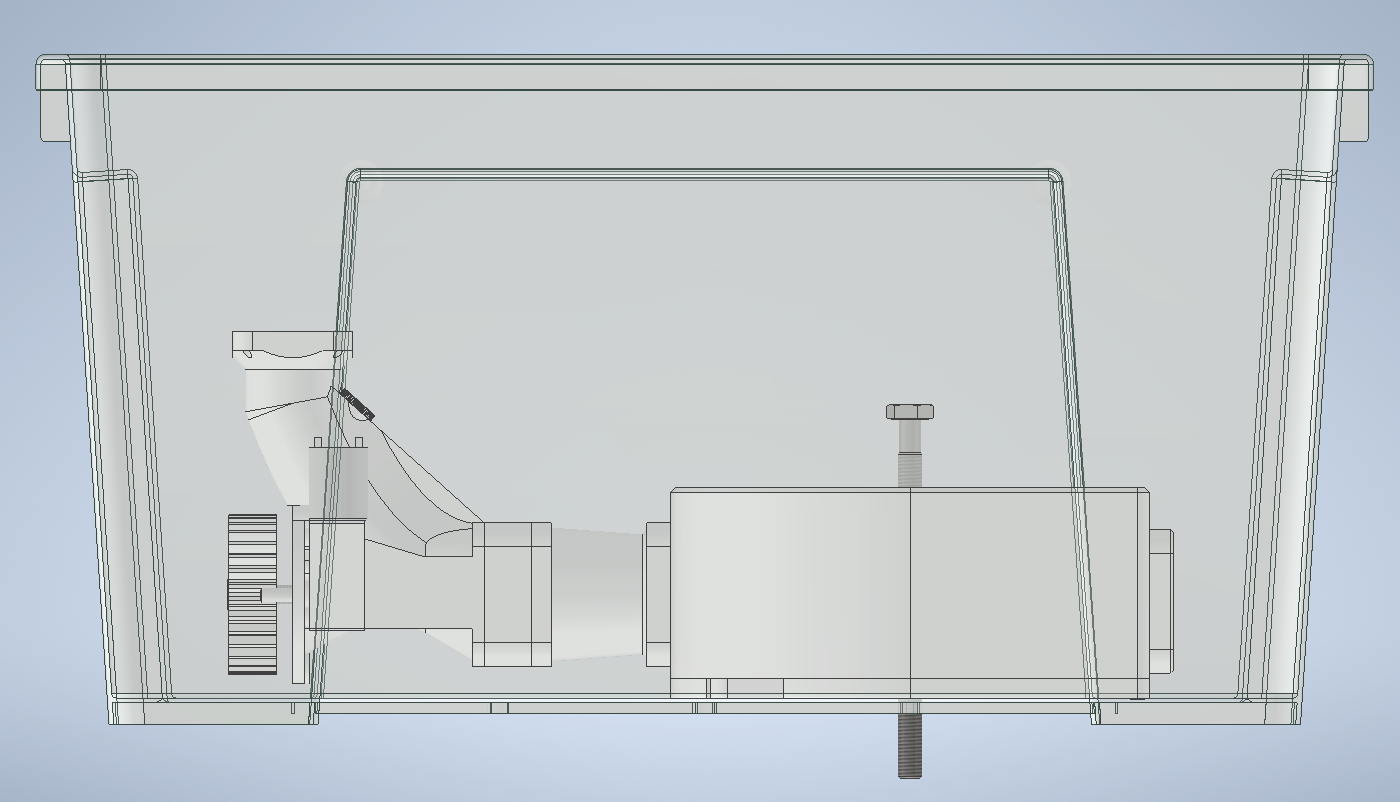

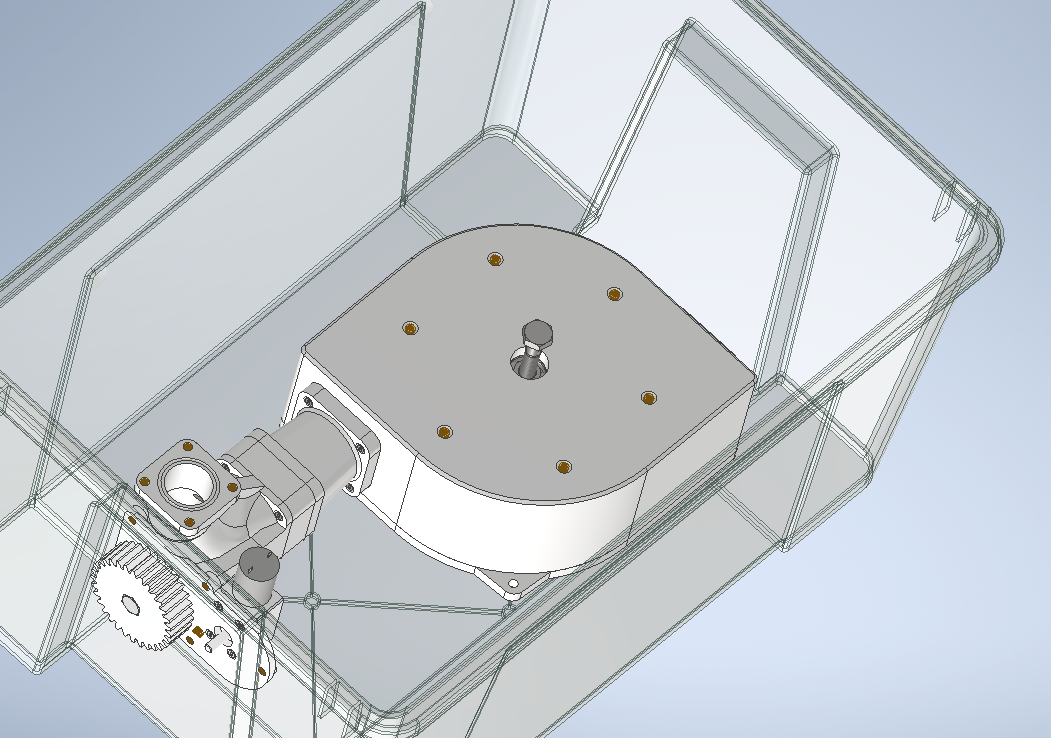

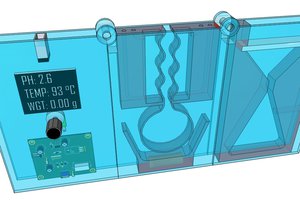

As you can see in the pictures/videos, the first plan is in place. But there is still a lot to be done. :)

Goals

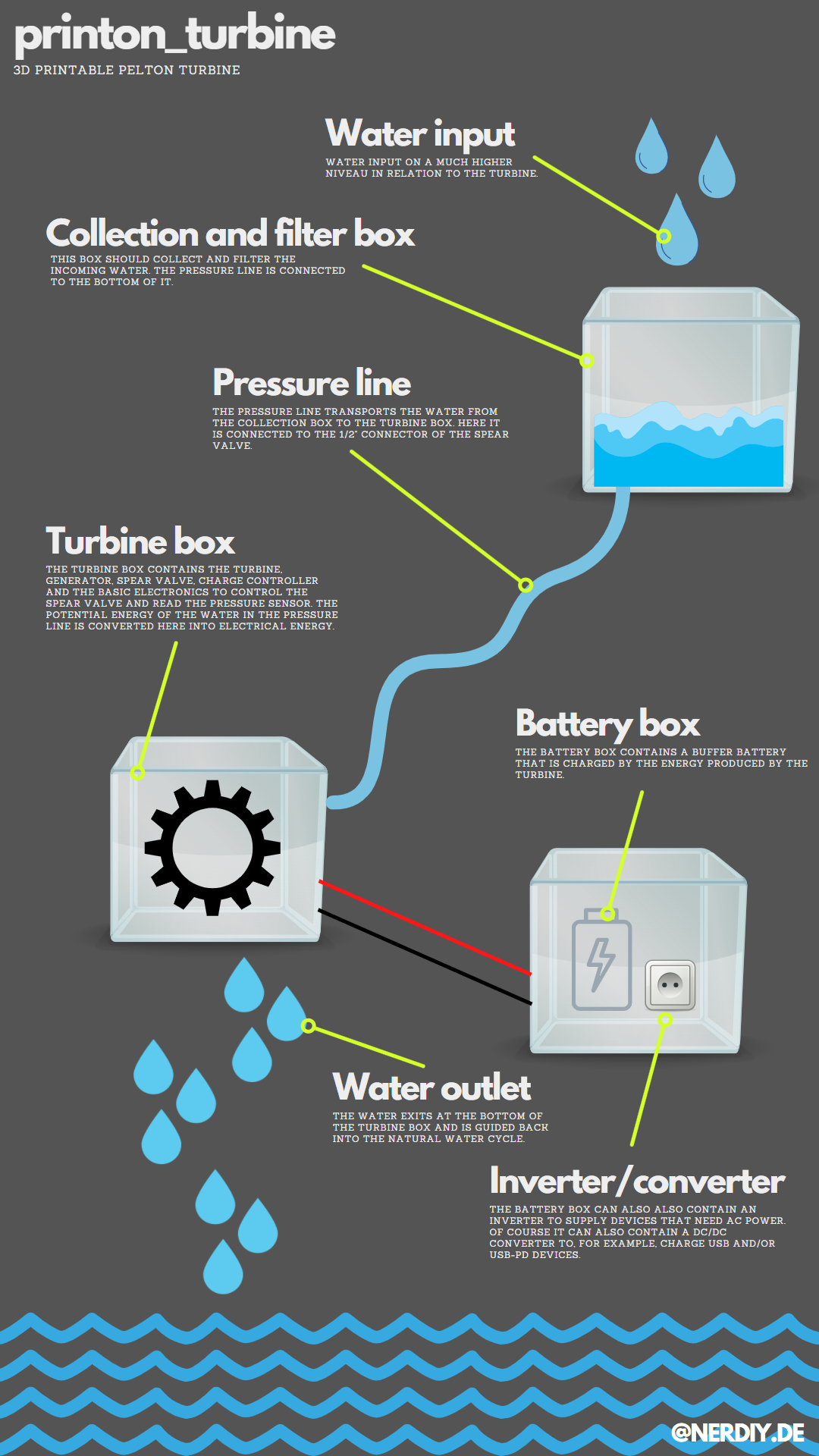

The basic idea is that with the help of the printon_turbine the manufacturing, assembly and installation of a renewable energy source powered by hydroelectric power is easy to realize even for beginners.

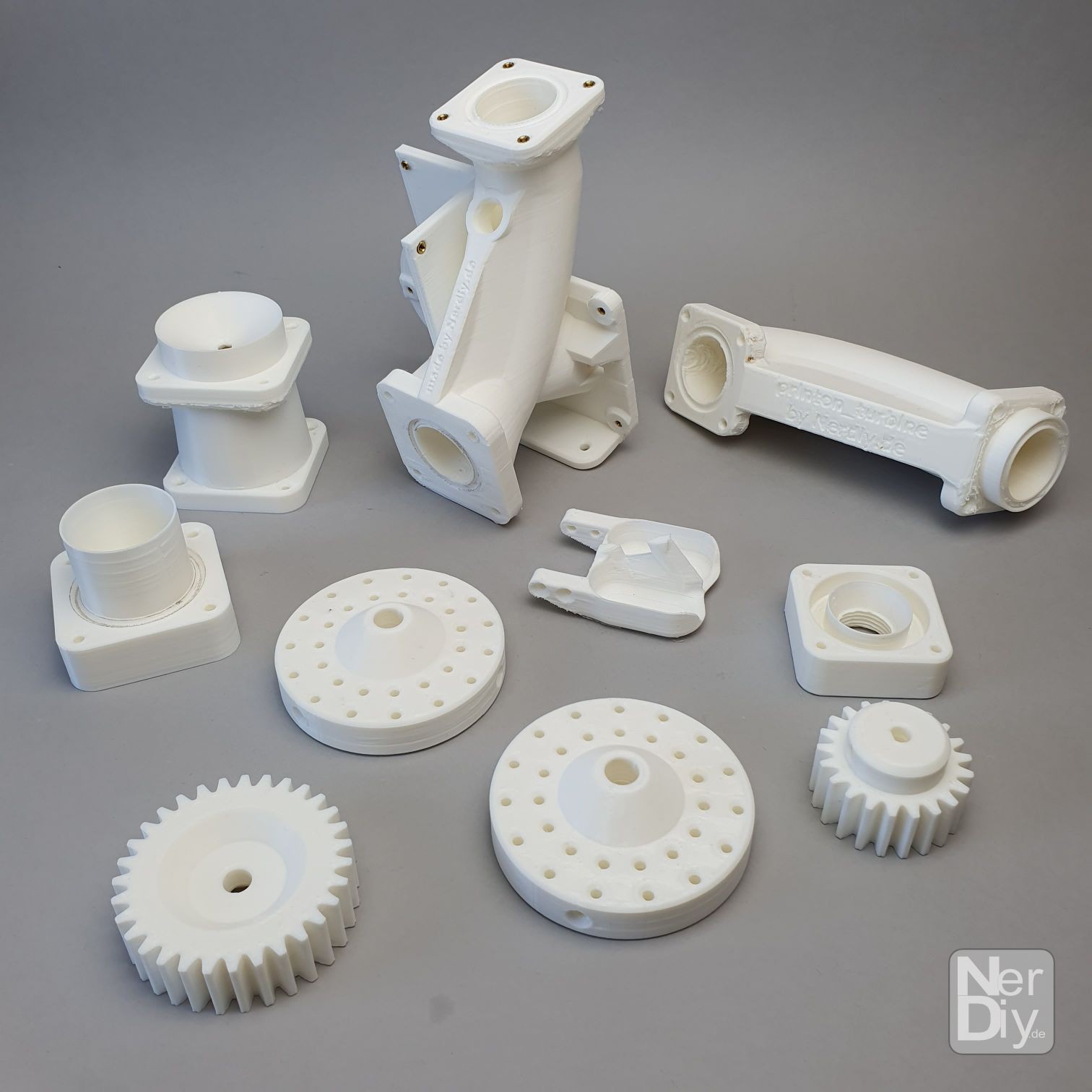

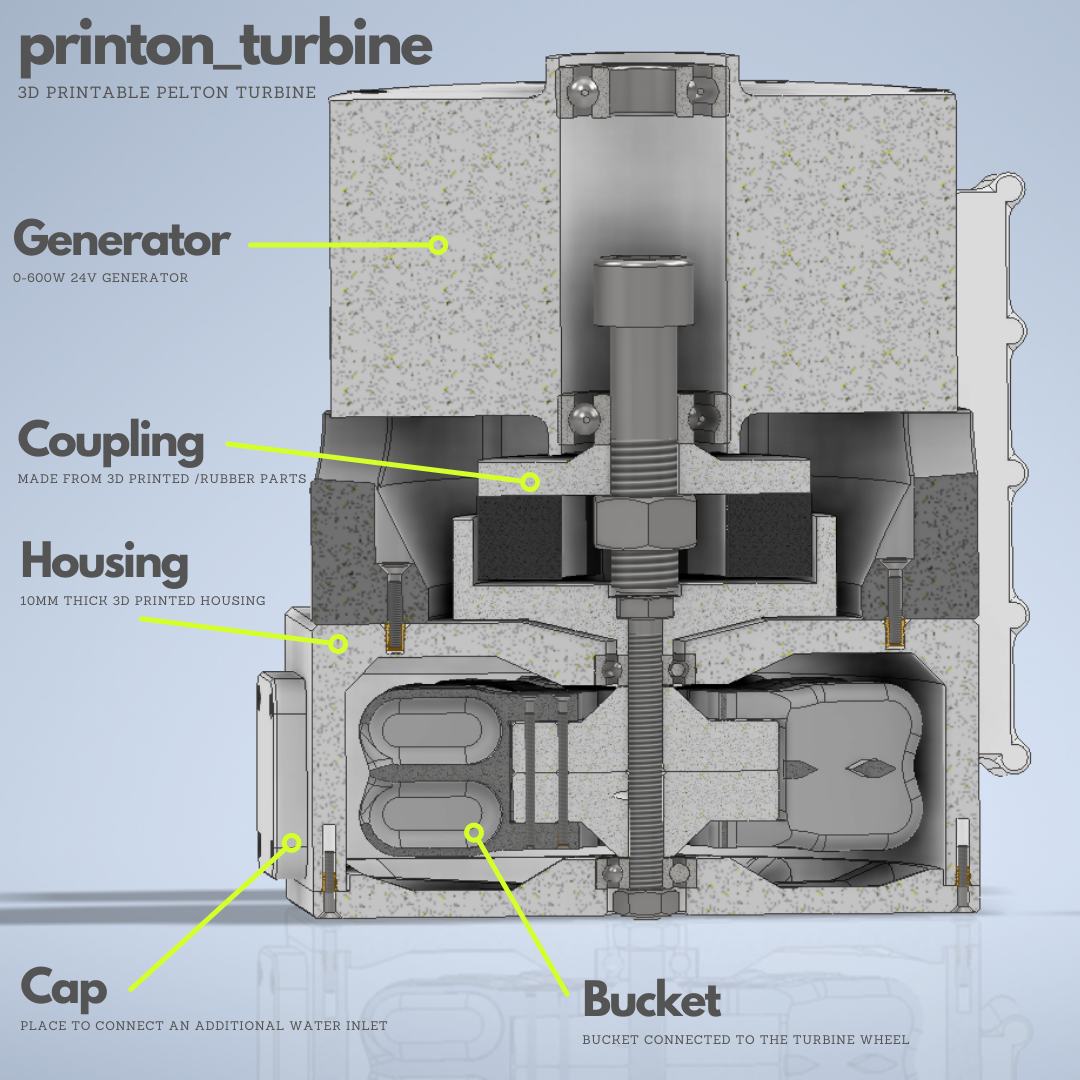

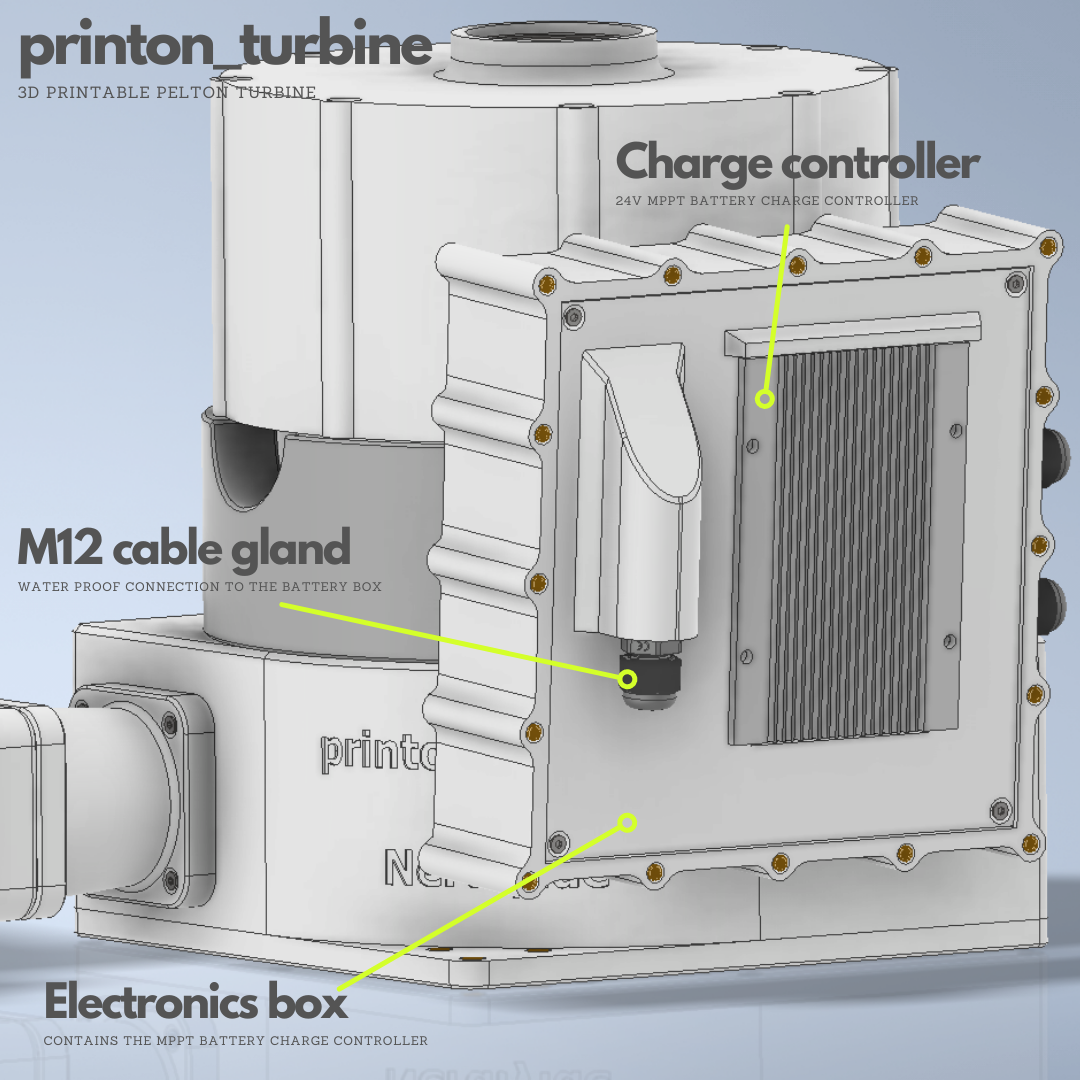

A large part of the parts should be able to be produced with a standard 3D printer. This means that the components do not have to be laboriously manufactured. They can easily be made on a 20x20x20 cm print bed of a standard 3D printer. As far as possible, the remaining parts should consist of standard mechanical parts that are readily available and, if possible, also reusable.

In the event of any damage to the system, it should be easy to reprint and replace the required parts.

In addition, the system should be as compact as possible and easy to transport. In this way, the system could be manufactured at a central location, assembled and then delivered to the location where it is actually needed. Here I think back to the scenario at the beginnings of the Corona period, when "face shields" were manufactured in many fablabs and then delivered to surrounding hospitals. You could do it in a similar way with the printon turbine: Wherever possible, it is manufactured and then delivered to where it is needed.

Scenarios

For all of the following application scenarios, an important structural or geographical requirement is necessary: A difference in height and sufficient water at the upper level.

The water at the higher level thus has potential energy, which is (with the help of the printon_turbine) first converted into kinetic energy and then (with the help of the generator) into electrical energy .

From my point of view the following possible usecases should be possible:

- The turbine is used as a permanently installed system where the water in the upper level is refilled by the natural water cycle. This mostly works in sufficient quantity in mountainous regions where the rained-off water runs down the slope in streams. Here it is easily possible to take some water from these streams to feed the printon_turbine.

- The turbine is used in a pump storage system. For this purpose, in energy-rich times (e.g. during the day when there is a lot of solar and/or wind energy available), water is pumped from the lower level to the upper one. As soon as little or no renewable energy is available, the water can be released from the upper level via the printon_turbine and usable electrical energy can be generated from it again.

- The turbine is used as an emergency power supply. For this the turbine could generate electrical energy using the water supply network. To do this, the turbine is connected to the water supply. Instead of using the water pressure resulting from the height difference between two water levels, the water pressure generated by pumps in the waterworks is used. Admittedly, this...

Fabian

Fabian

M. Bindhammer

M. Bindhammer

Md. Moniruzzaman

Md. Moniruzzaman

Michael Barton-Sweeney

Michael Barton-Sweeney

Peter Buckley

Peter Buckley

Fab, you make some seriously exciting things! The look is also very professional. How's the progress, any way I can contribute?