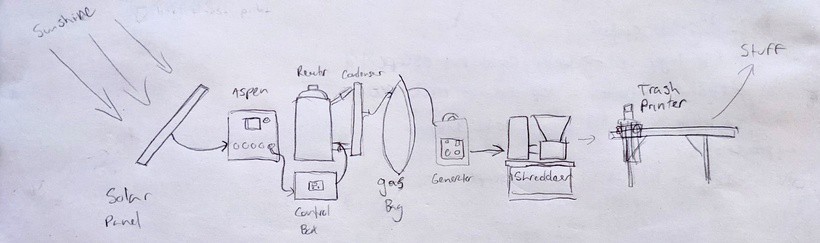

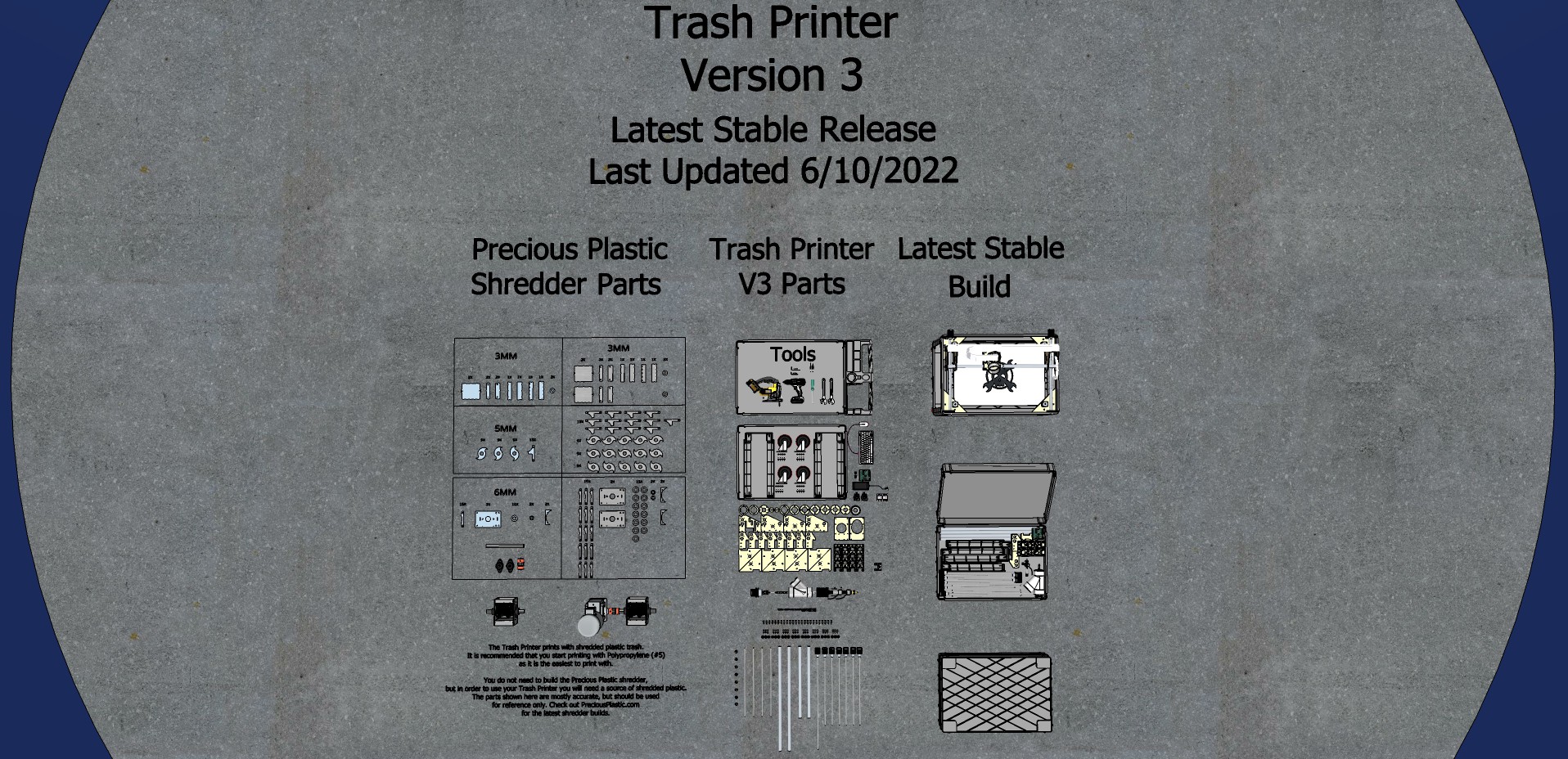

The Trash Printer was inspired by the Precious Plastic movement, a global, open-source, small-scale plastic recycling movement! It started with 4 open-source machines - a shredder, an extruder, an injection molder, and a compression oven. Since the original designs were published in 2013, a global network of makers has emerged, modifying, improving, and developing the original tools, and adding their own!

The Trash Printer is my small contribution to that global open-source effort. Precious Plastic is one of the most inspiring projects that I know of, and it’s changed the way I look at plastic. For my entire life, plastic was a material that I felt I had zero agency over. I didn’t get to decide what got made out of plastic, and I didn’t get to decide what happened to it after it was thrown away. It felt like all I could do was feel bad about it.

What I love about Precious Plastic is that it’s not about telling people what they shouldn’t do, or what the people in power should do, it’s about what we can do, right now, with our friends and the tools and materials we have around us.

None of the Precious Plastic machines are particularly revolutionary- the technology has existed at an industrial scale for decades. But that technology has always been large-scale, requiring huge facilities, tightly-held patents, highly-specialized skills, and lots and lots of money.

What Precious Plastic did that was revolutionary was take those basic machines and make them accessible to a much wider range of makers, lowering the barriers to entry, by making them smaller, cheaper, and fully open-source, so that people can get together with their friends, and actually DO SOMETHING about their plastic waste, instead of just feeling bad about it!

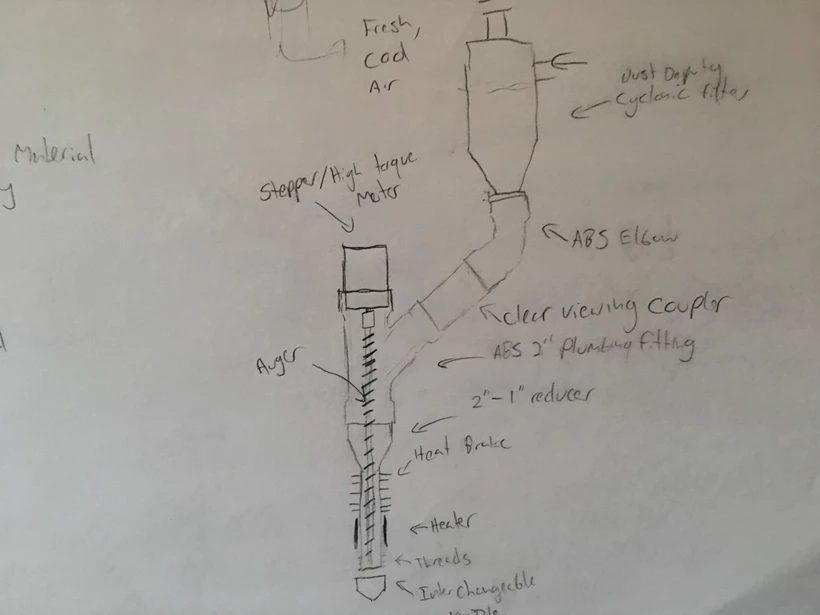

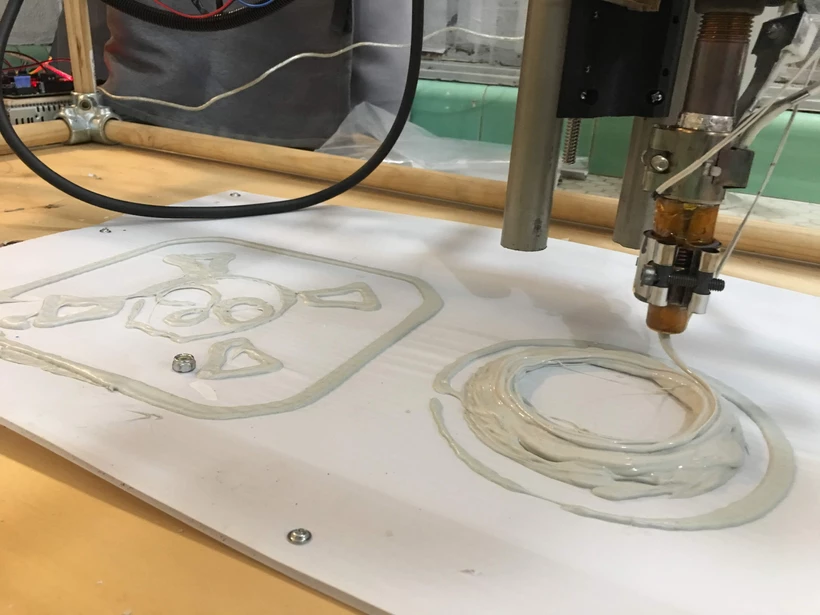

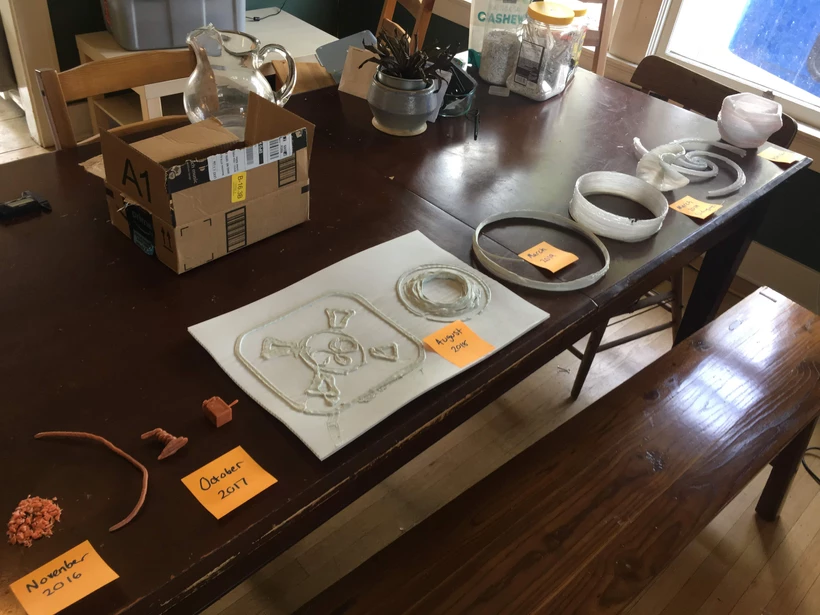

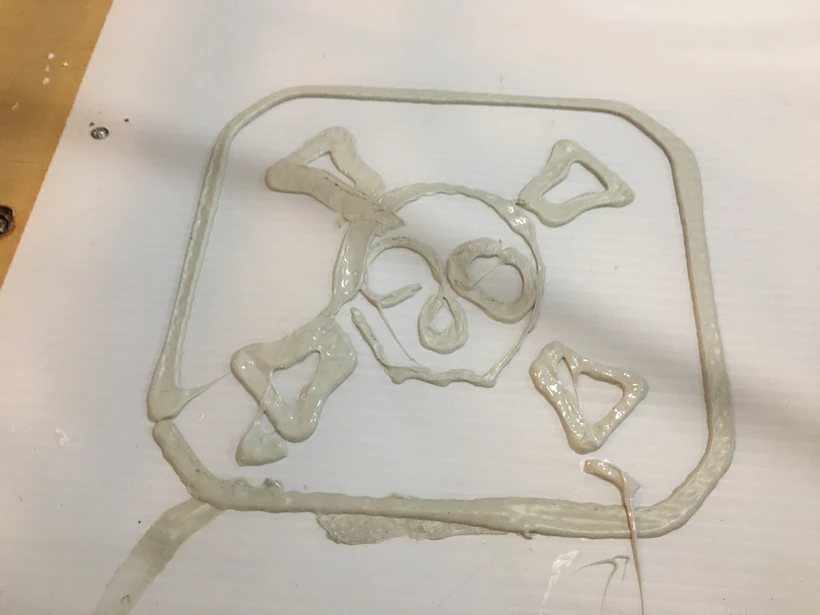

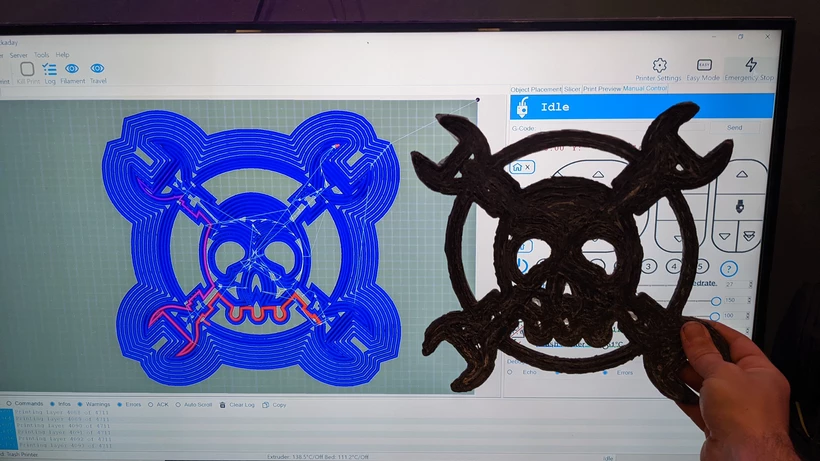

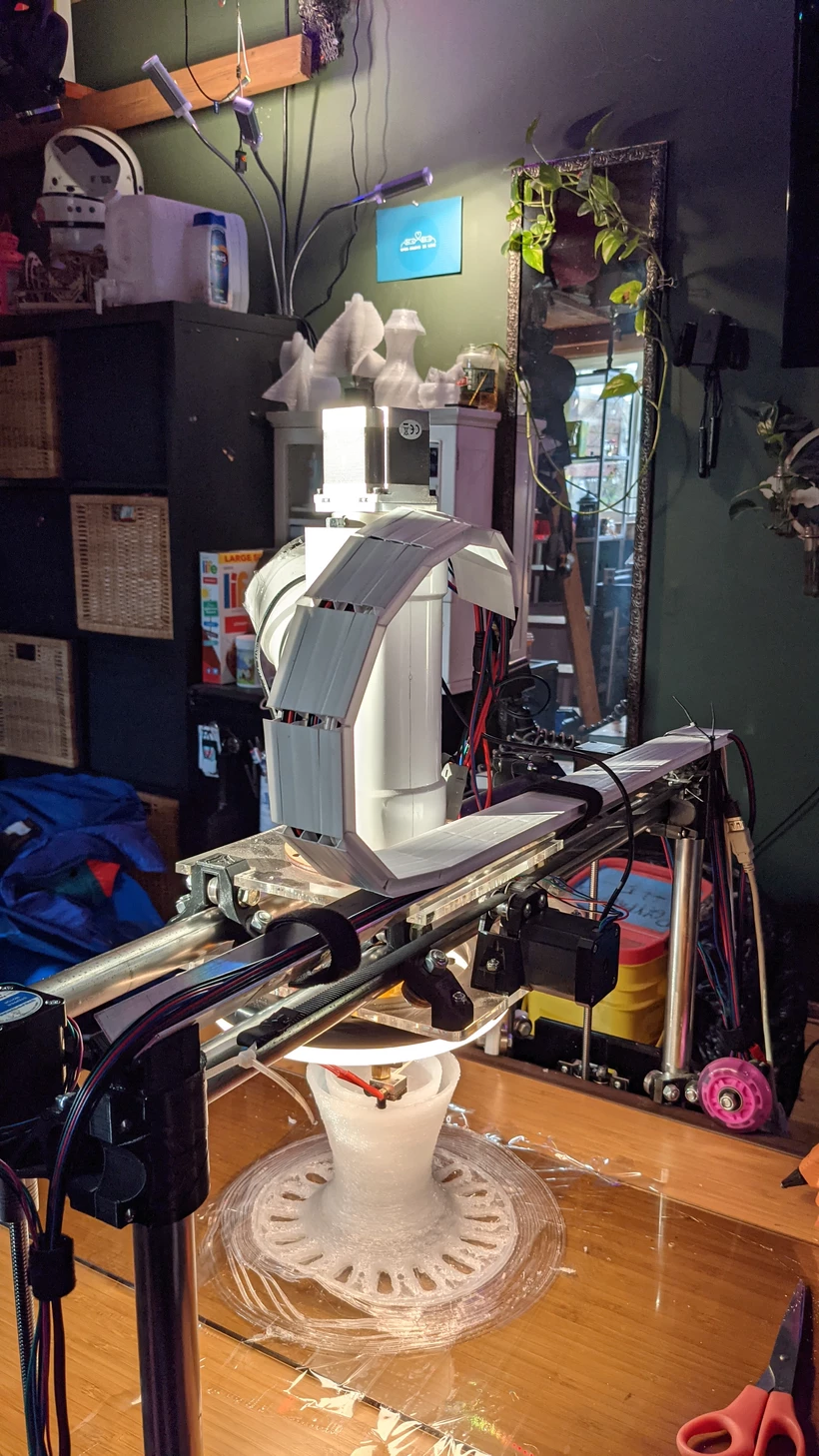

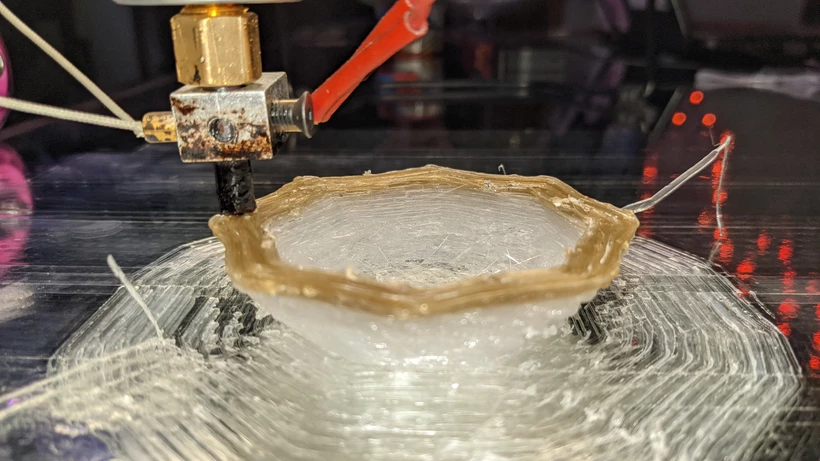

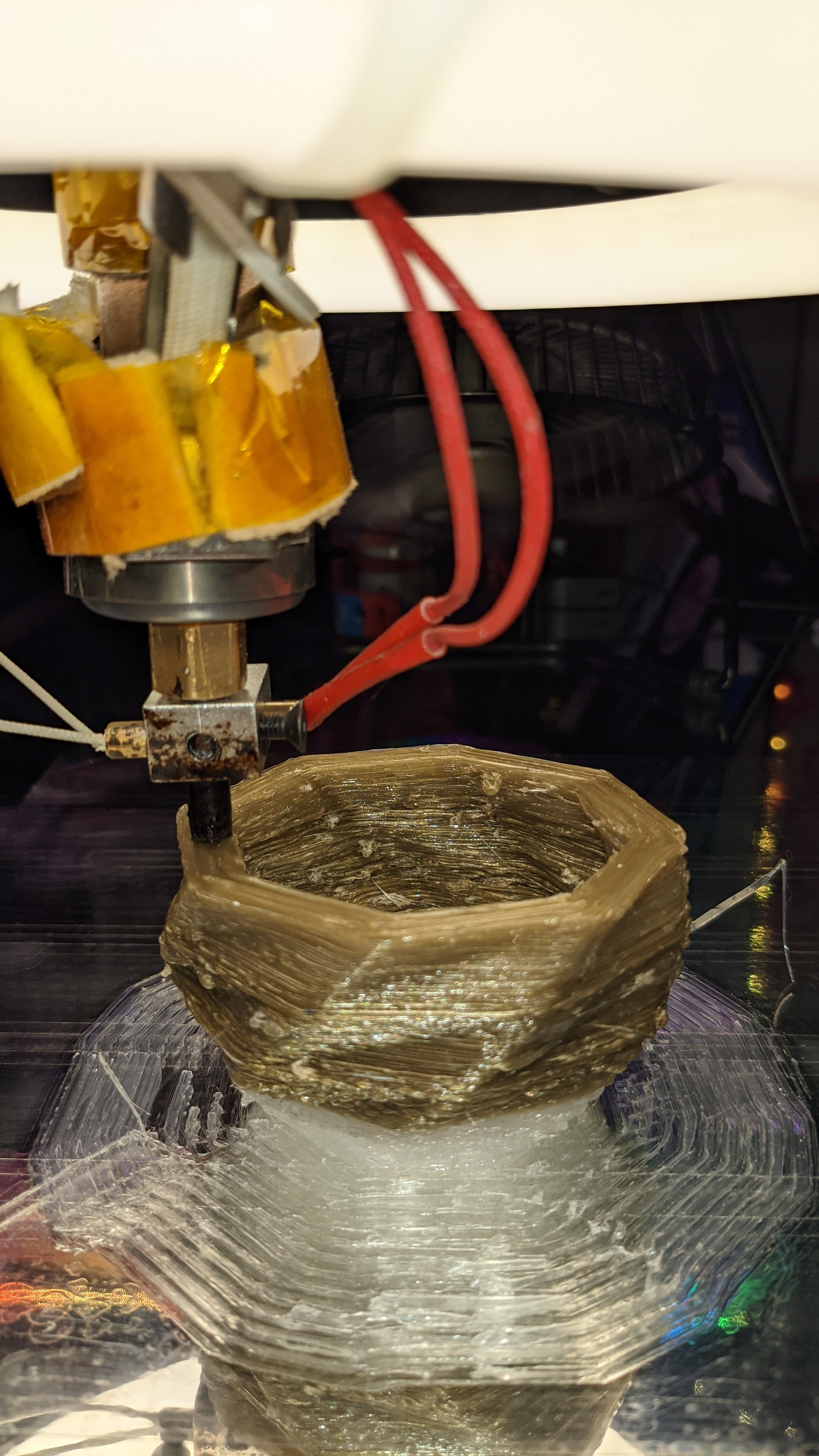

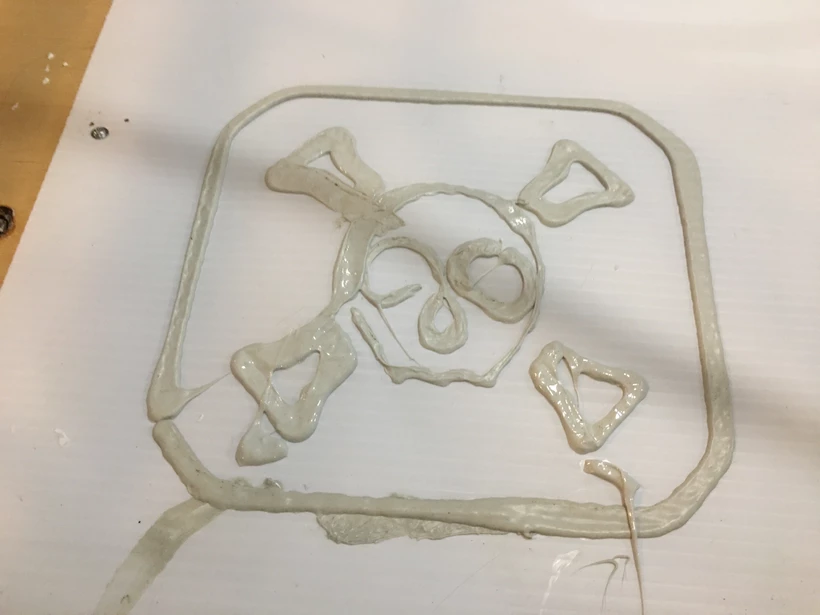

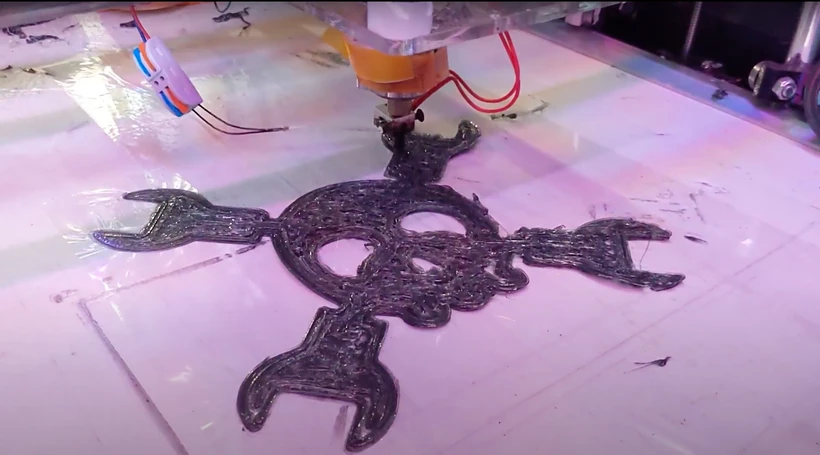

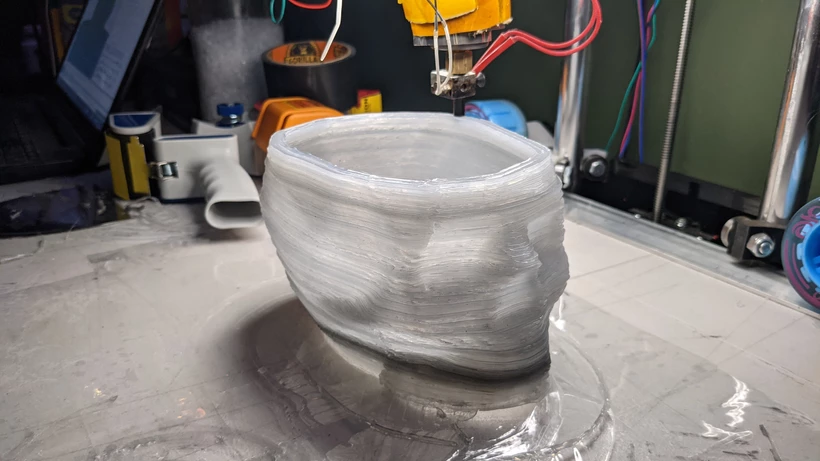

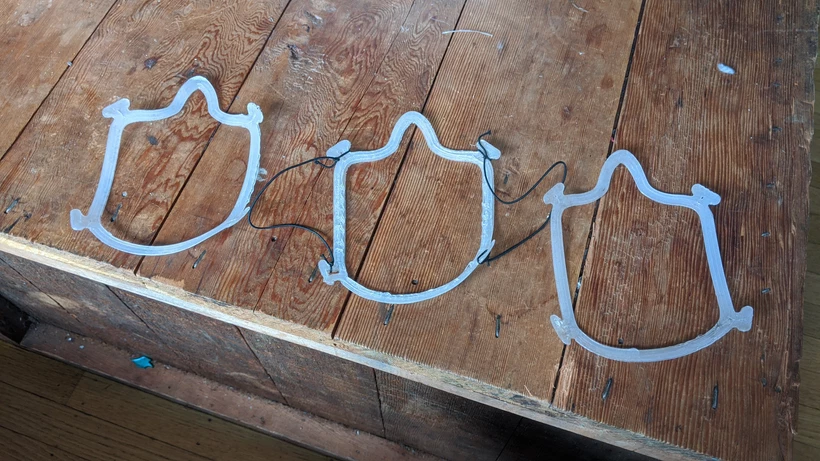

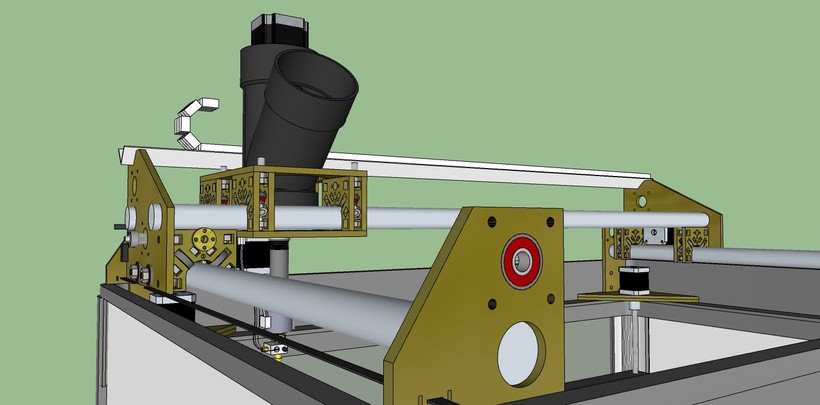

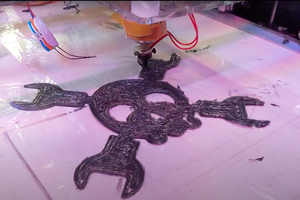

Like the other Precious Plastic Machines, the Trash Printer isn’t a particularly revolutionary machine. It’s certainly not the first or only pellet/flake extruder or large format printer - I was originally inspired by the RichRap extruder, and the SeeMeCNC Part Daddy, which showed me that printing from flakes instead of filament was possible.

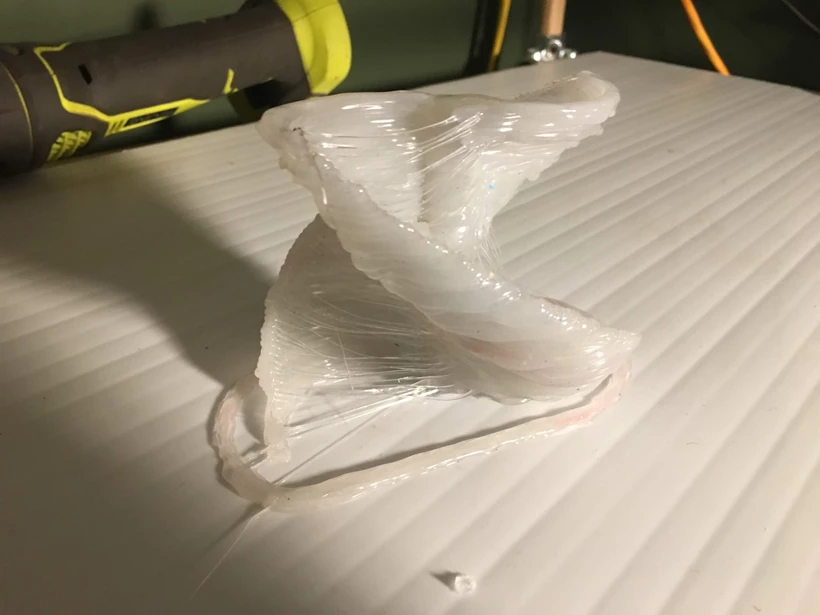

It’s also not the only printer to print with recycled plastic. The PullStruder and PolyFormer Plus can print high-detail parts using recycled PET (#1), and the enormous Bloft MK2 (also inspired by Precious Plastic) can print huge parts! I've always wanted print a whole surfboard out of plastic trash!

When you're up against a challenge as big as global plastic waste, there really isn’t such a thing as competition. The “competition” is the plastic waste problem itself. The waste problem is distributed, and it requires equally distributed solutions, not one single machine or one idea.

Every new open-source tool we can add to our toolkit expands what YOU and YOUR FRIENDS can do with YOUR trash, and ultimately, that's what Precious Plastic is all about. It’s about what YOU can do about it. The Precious Plastic machines were the first plastic recycling tools that were simple and well-documented enough to make me go, “Hey, I could do that!”

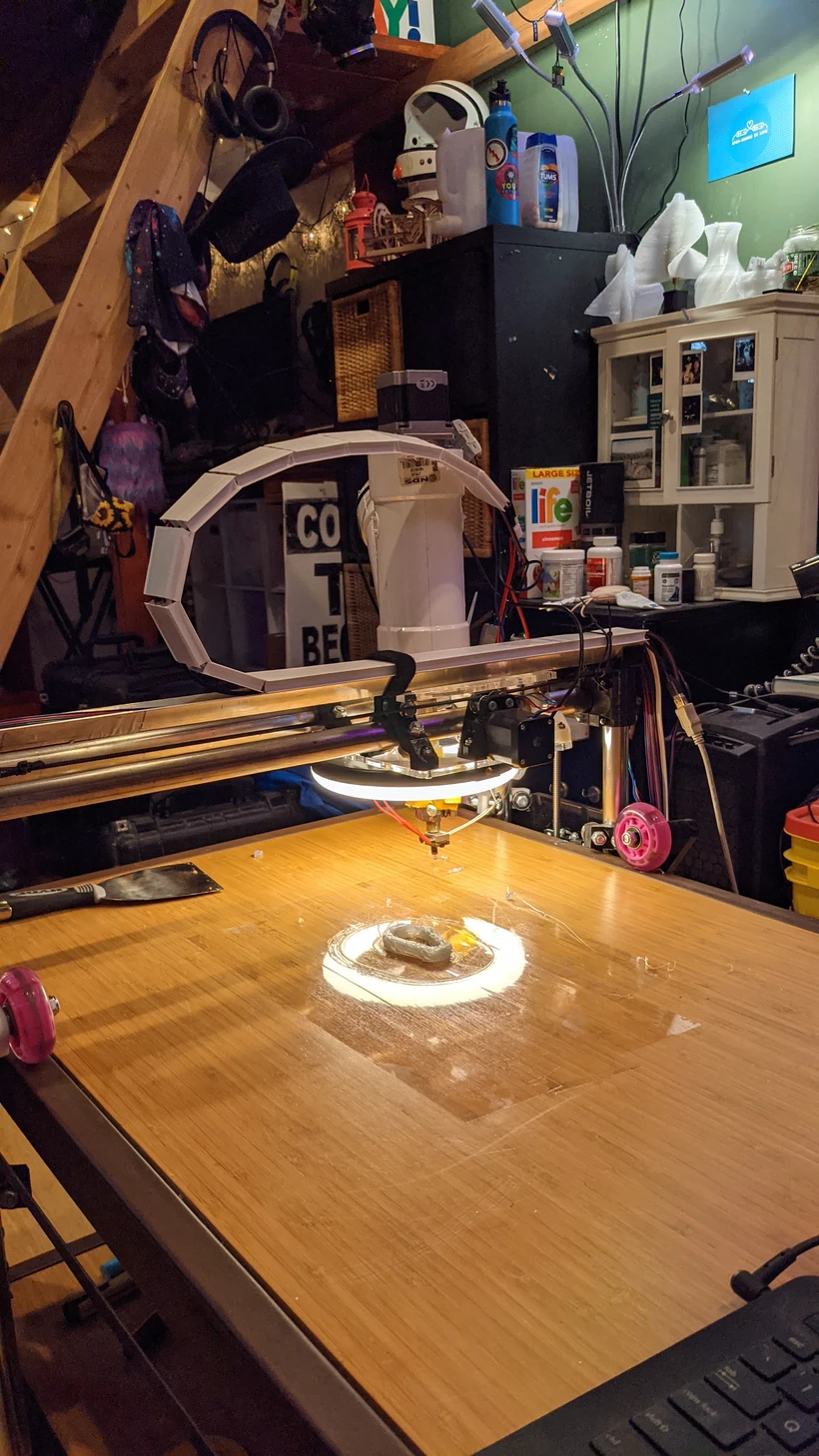

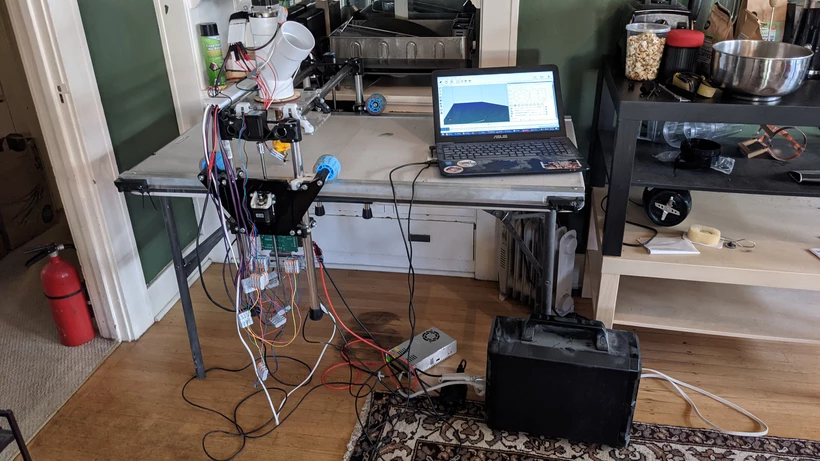

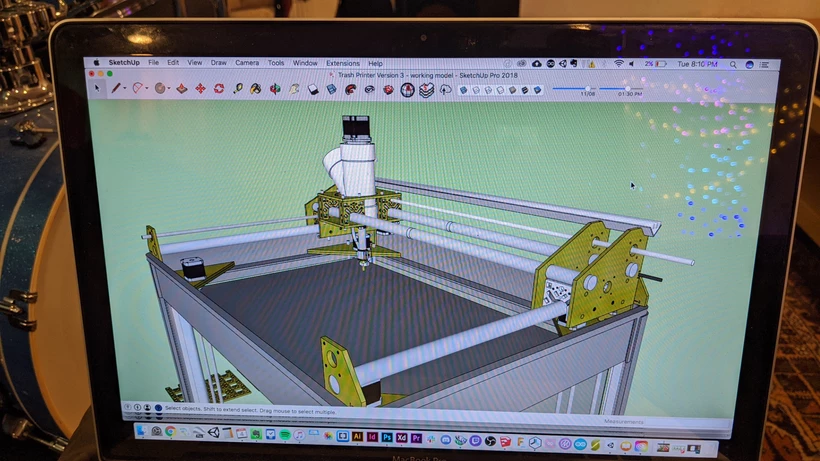

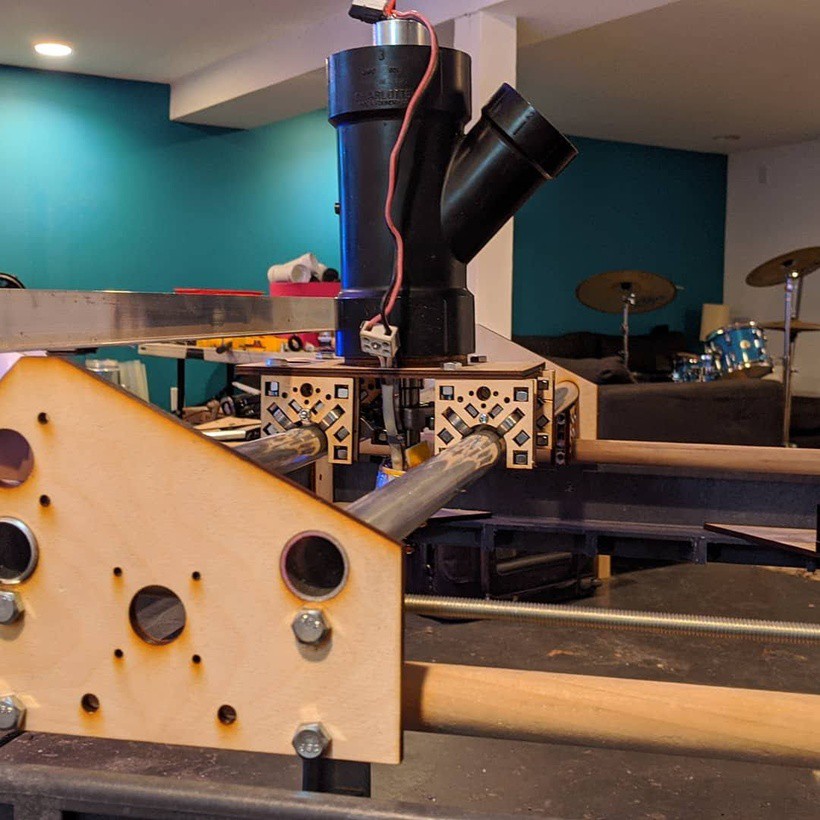

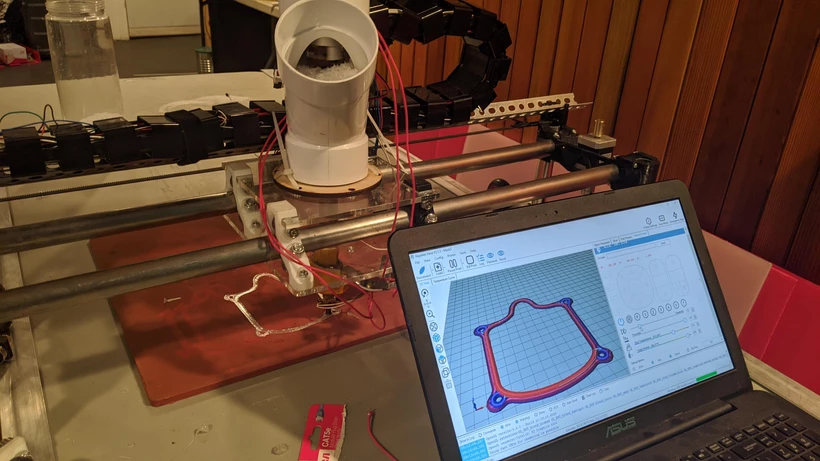

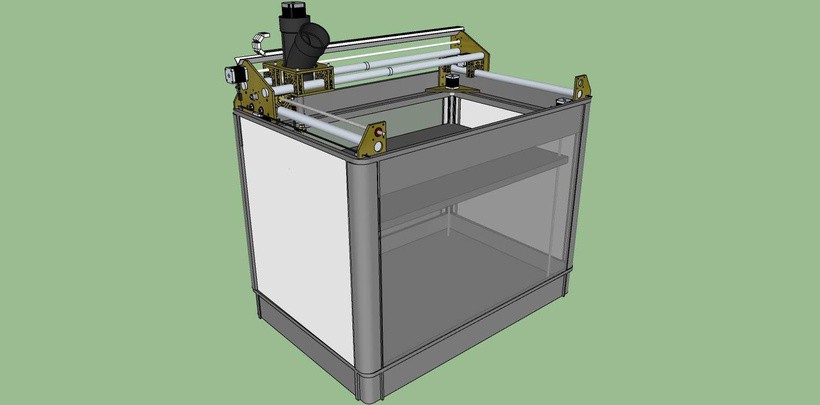

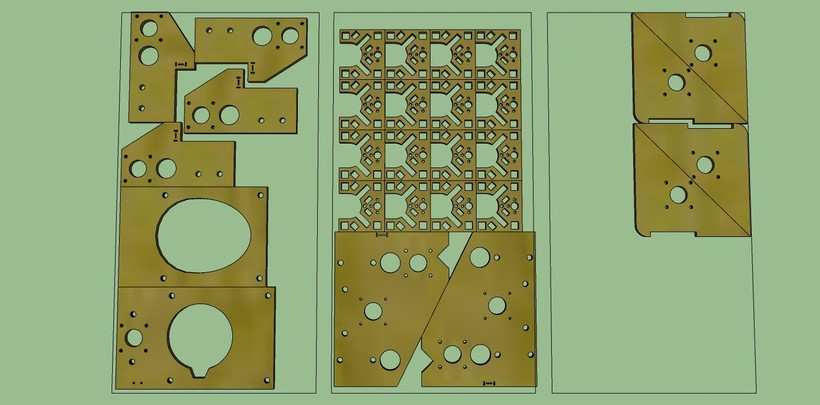

My deepest hope is that the Trash Printer might do the same for you. My primary design goal for this entire project has always been to make the Trash Printer as easy as possible to build, requiring the simplest tools, the most widely available parts, for the least amount of money possible.

I’m not a 3D printing expert, and the Trash Printer was the first 3D printer that I ever built. If you are a 3D printing expert, you can probably tell.

When I first started building the Trash Printer, I knew nothing about how 3D printers worked, and "3D printer people" seemed to possess some magical, mystical, deeply technical knowledge that felt far beyond my understanding.

I didn’t know what I didn’t know, and didn’t know where to start. I didn’t even know what questions to ask. They would say things like, “all you have to do is flash Marlin onto a RAMPS,...

Read more » Sam Smith

Sam Smith

Patrick

Patrick

Atte Linna

Atte Linna