I'm living in a flat without balcony on the second floor. I'm not allowed to modify the building stock, like drilling holes into exterior walls. Nonetheless, I want to use solar energy to cover the base load of my flat.

I need to solve two problems:

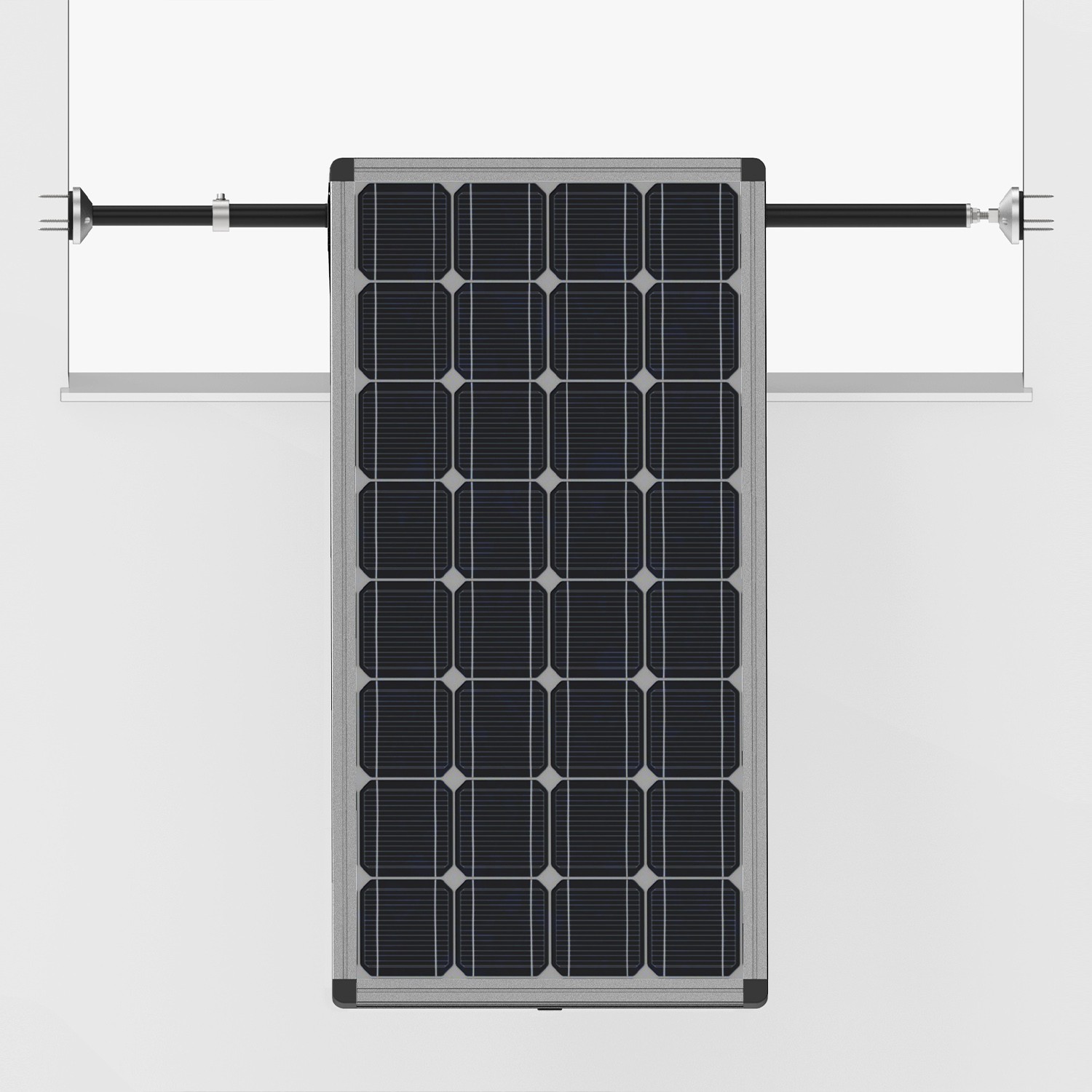

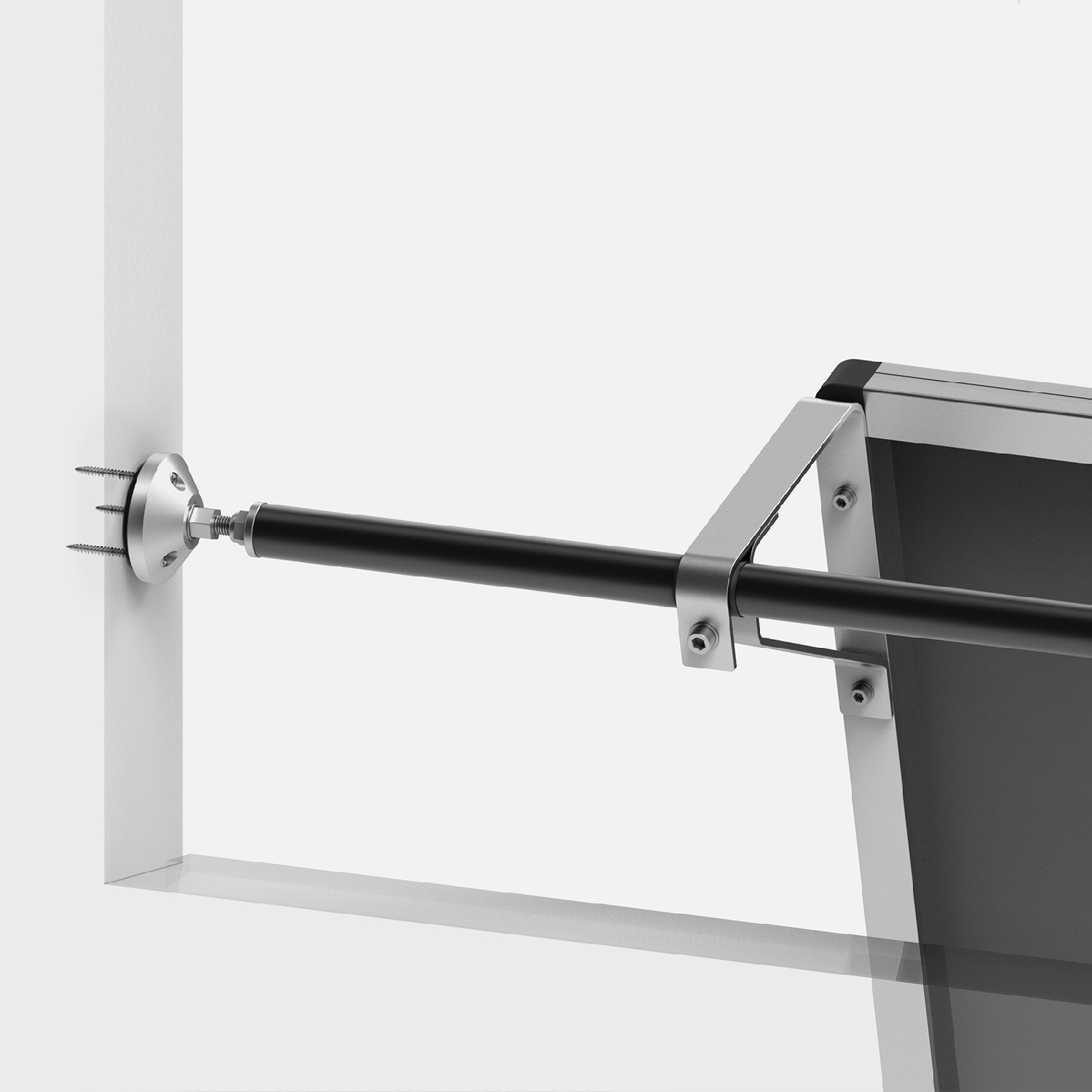

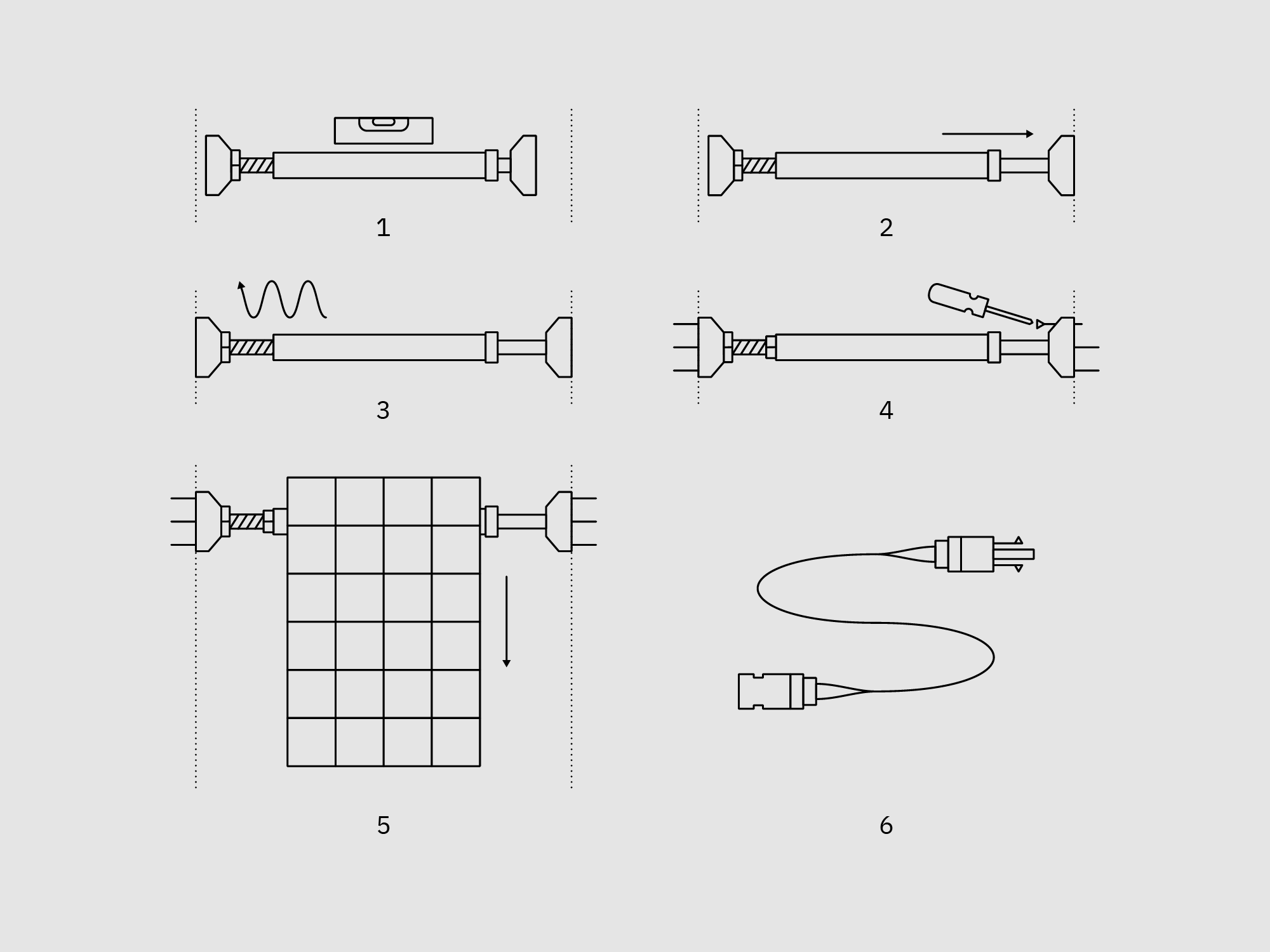

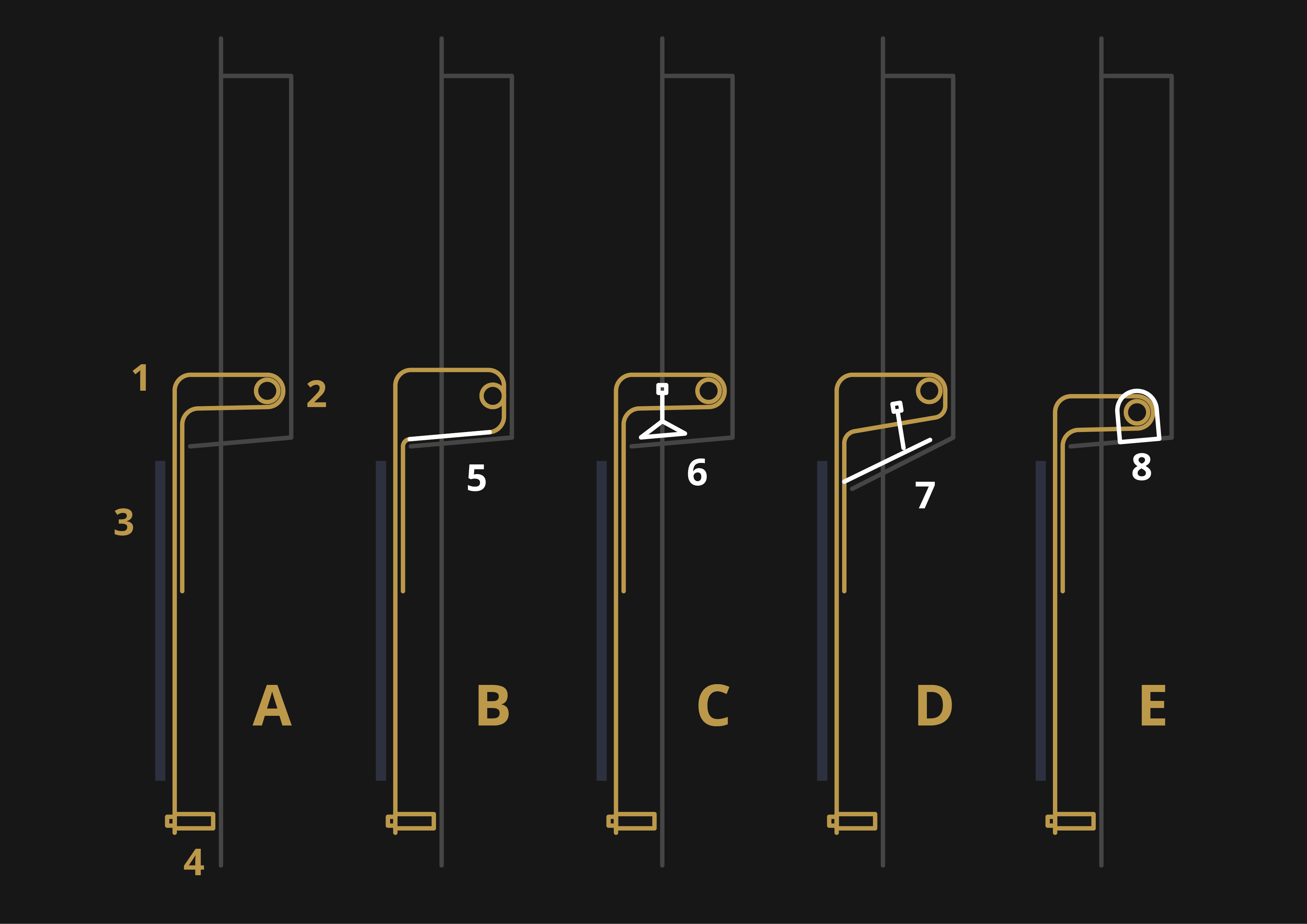

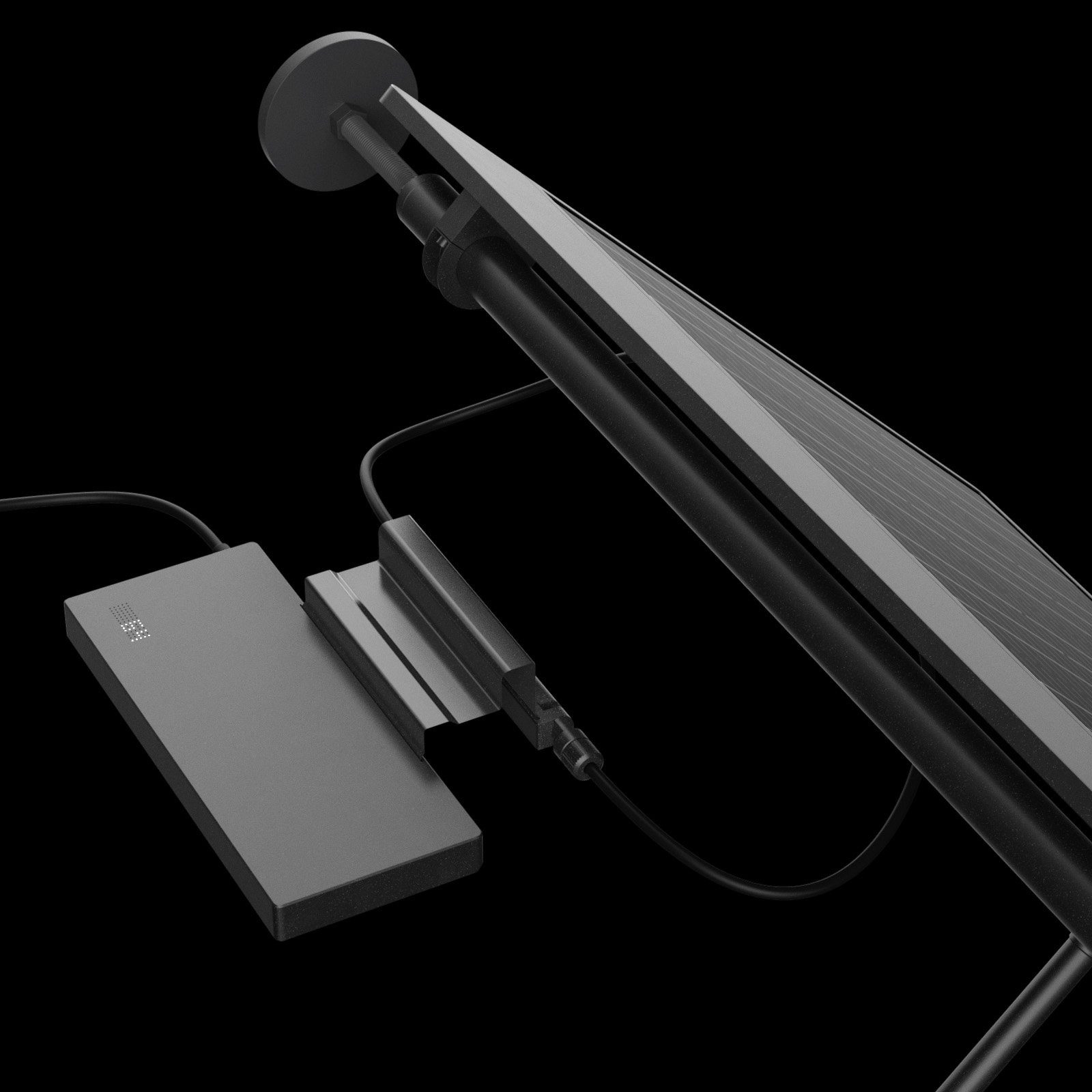

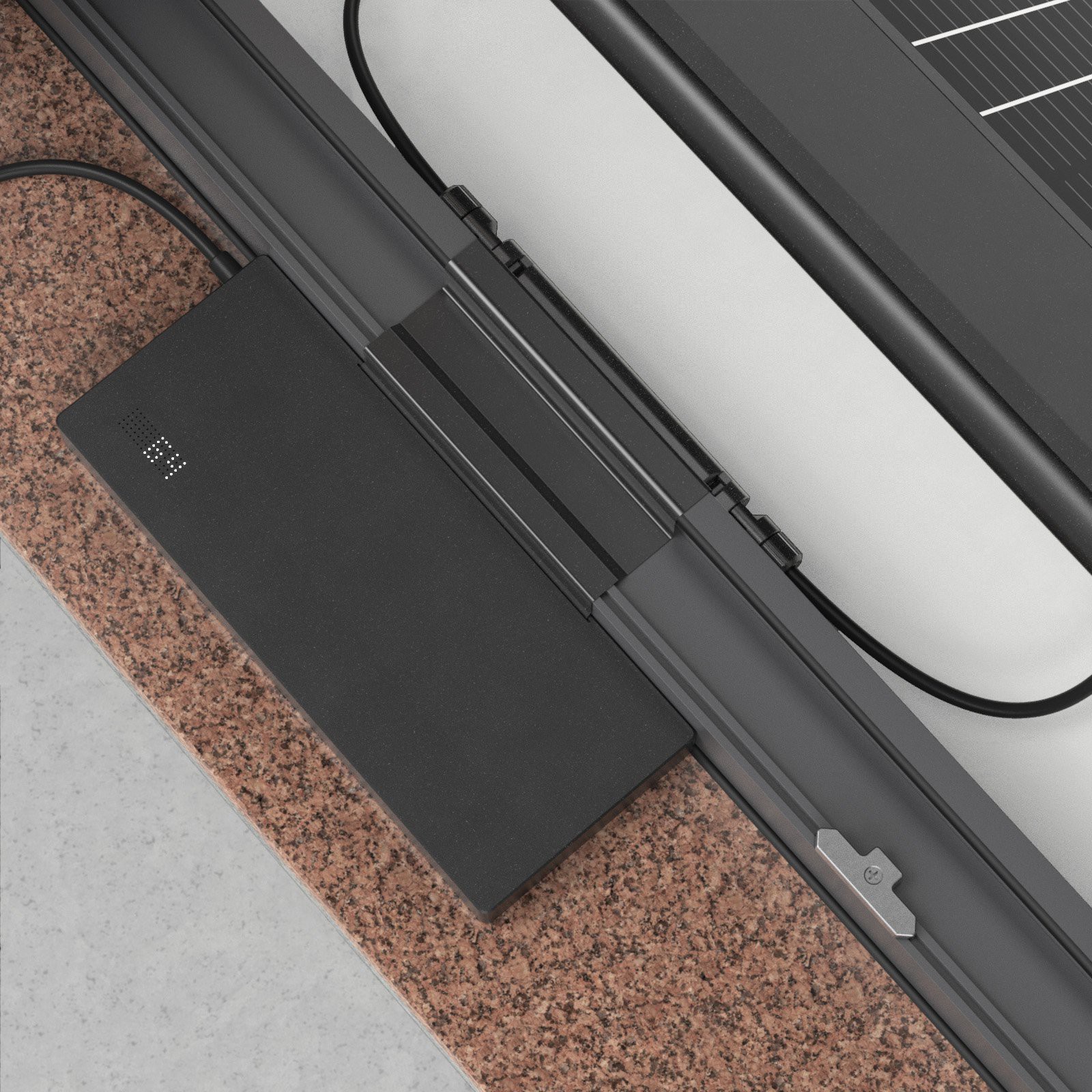

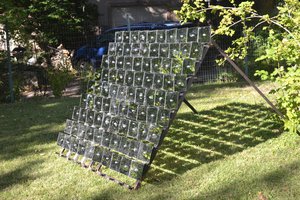

- Mounting a solar panel outside of my window without modifying the building

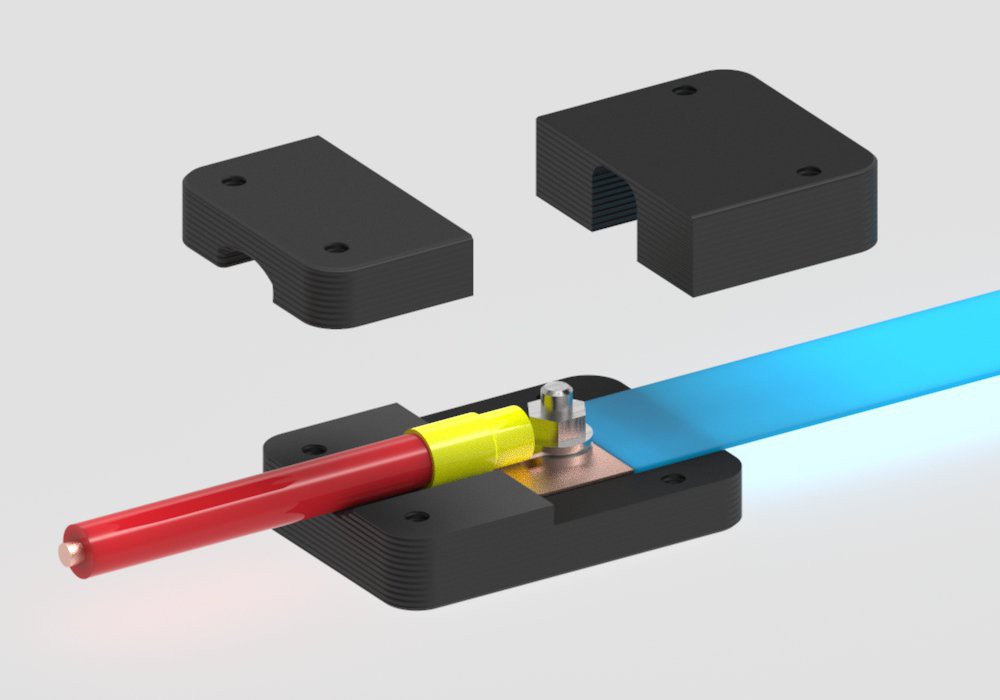

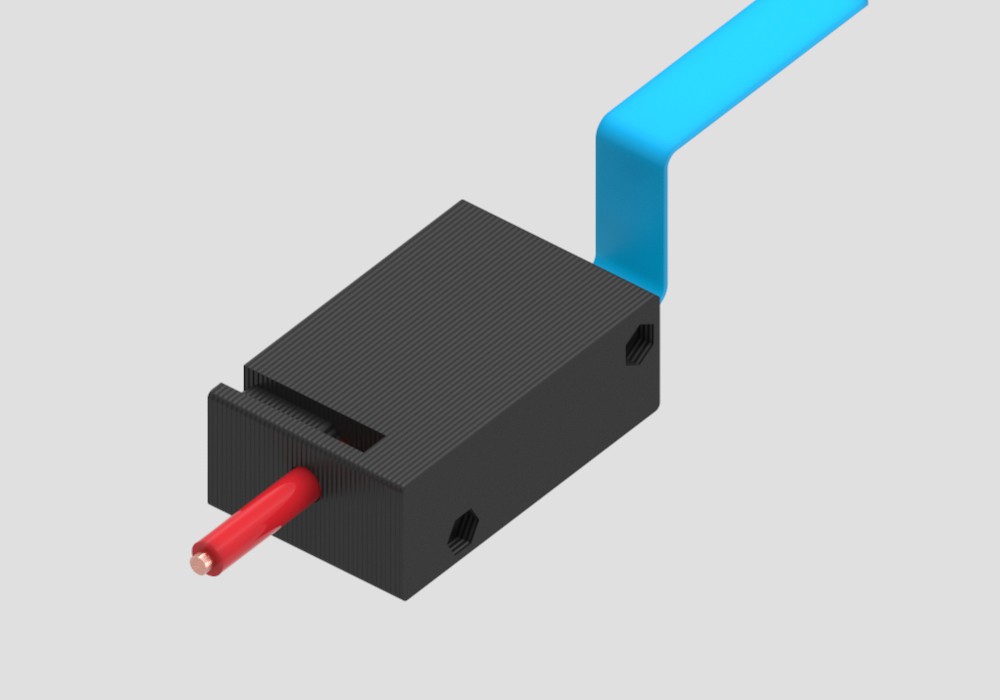

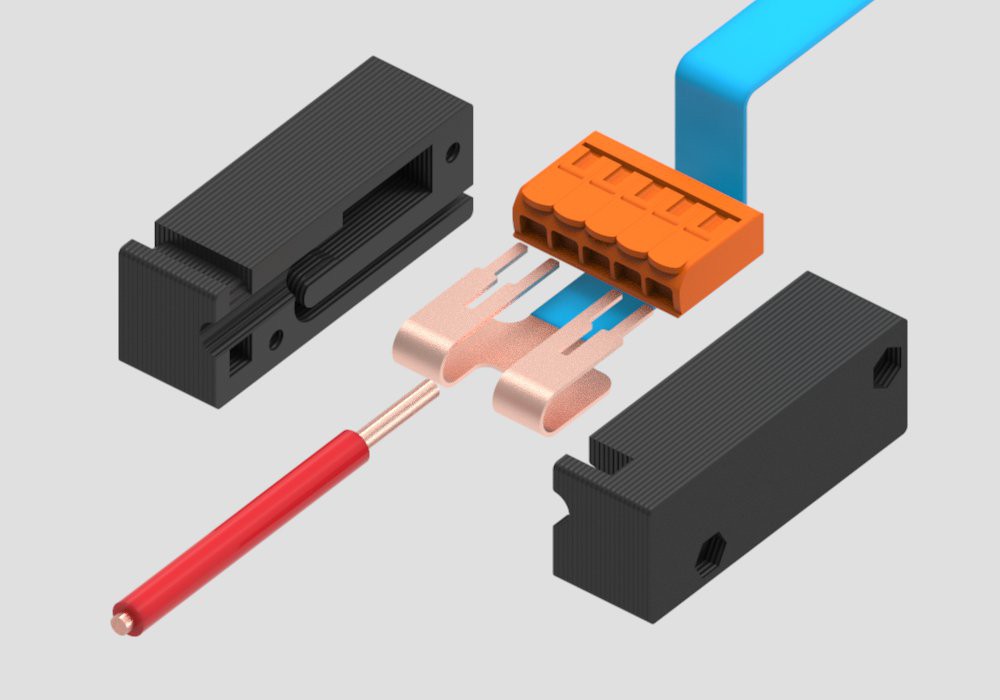

- Getting the power into my flat

ATTENTION: Please contact me if you want to produce any of my ideas commercially. A previous approach was conceived while working at my university and is protected by them.

My goal is to find a design that is uncomplicated to build or adapt as a hobbyist, but suitable for mass production, at least in principle. Making it reliable and safe is a priority.

Please note that I am not an expert and all these quite untested ideas could be very dangerous to use. The whole contraption could fall and damage people and property. The cabling could be a fire hazard. Please only take inspiration form this project if you know what you are doing, since I have to reject any responsibility for any problems these concepts cause at this point.

Window mount for solar panels

Searching for a way to mount solar panels in my flat without modifying the building stock.

Joris Wegner

Joris Wegner

wkpsahl

wkpsahl

Andrea Console

Andrea Console

Maximiliano Palay

Maximiliano Palay

Vijay

Vijay