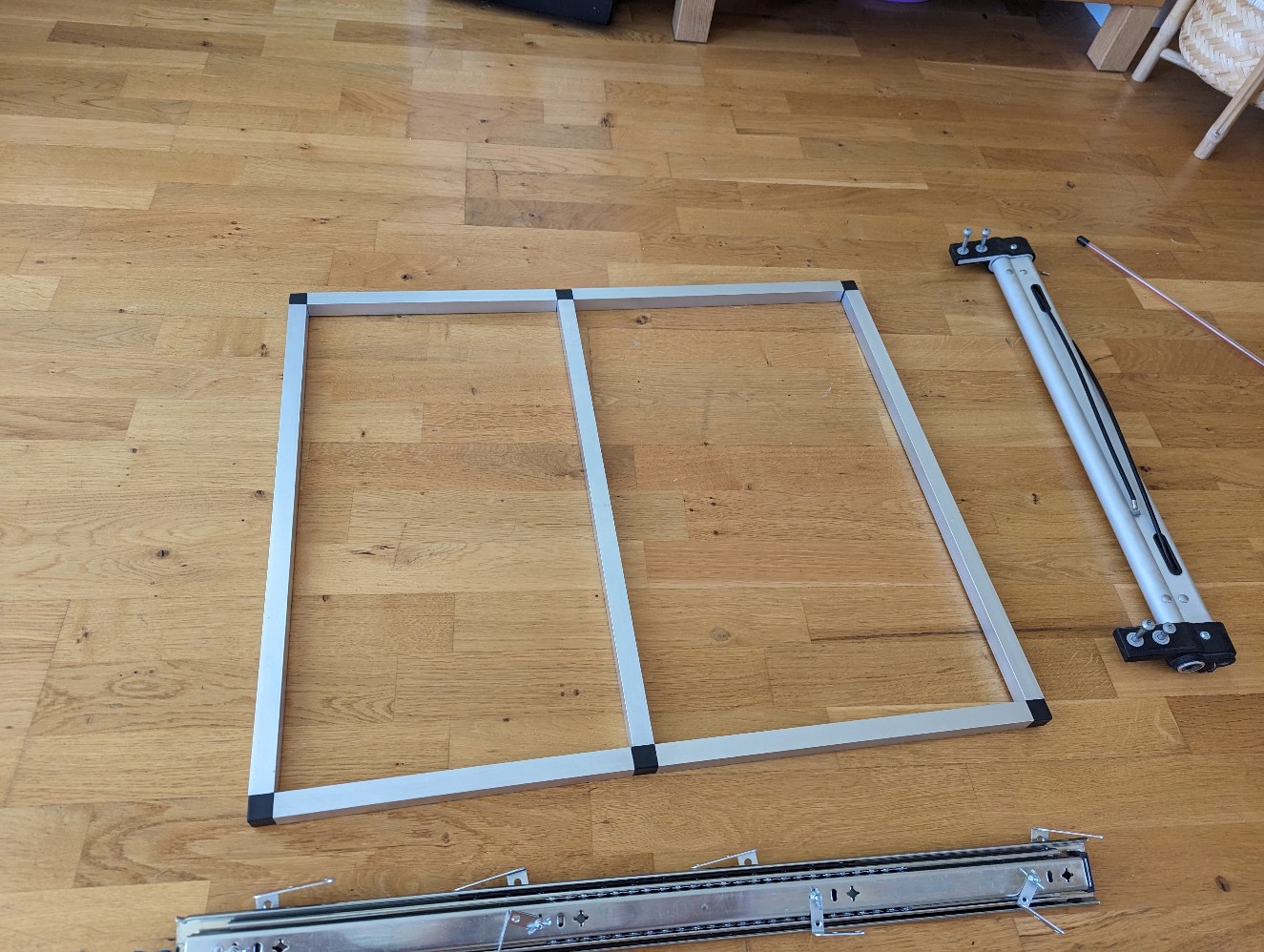

Some design goals:

- Hard shell, last wagons I made used a tent.

- Good looking, aiming for a Citroën HY Van look.

- Sleep area to be ready really fast, e.g. just a few thing folded out.

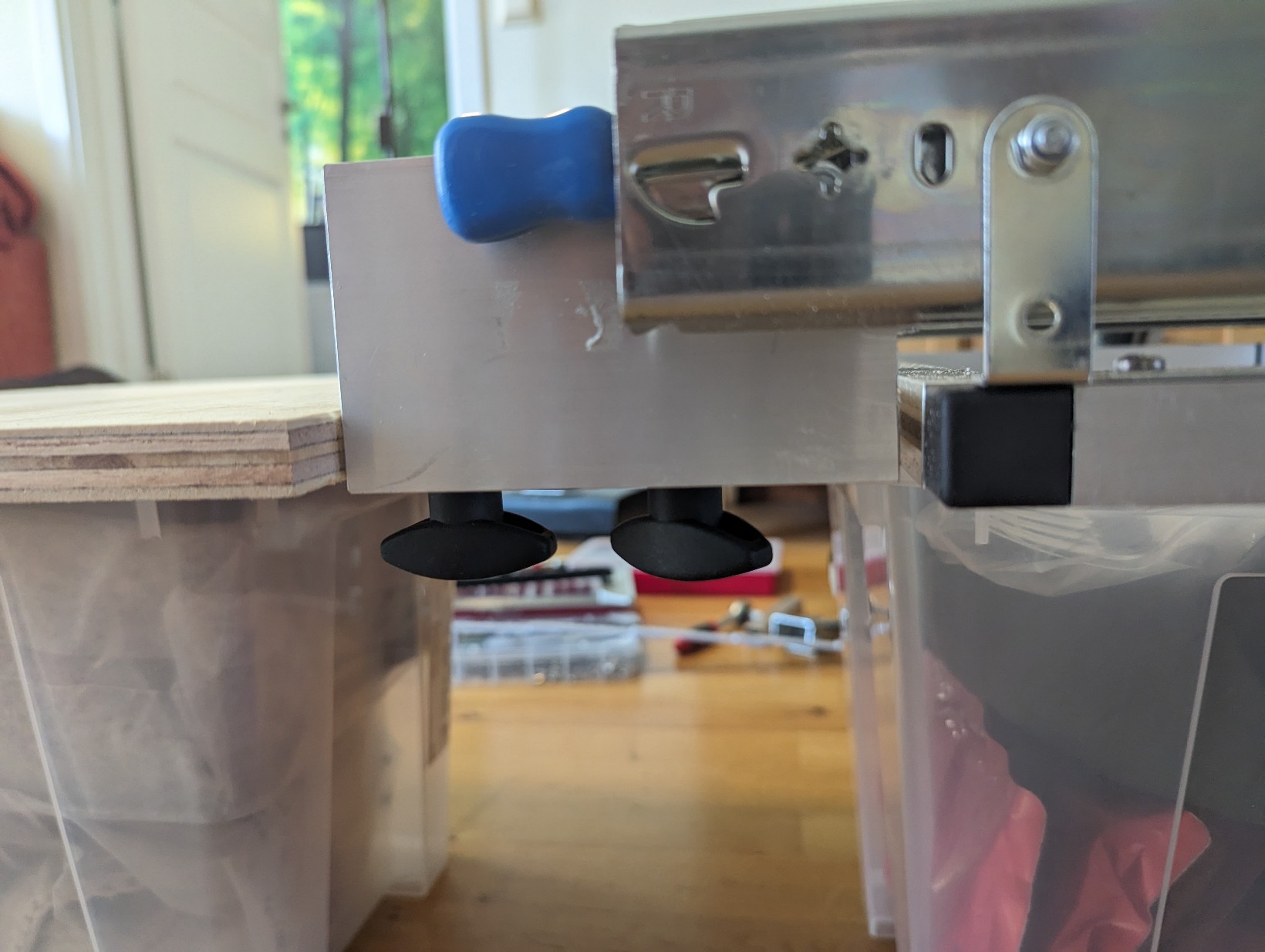

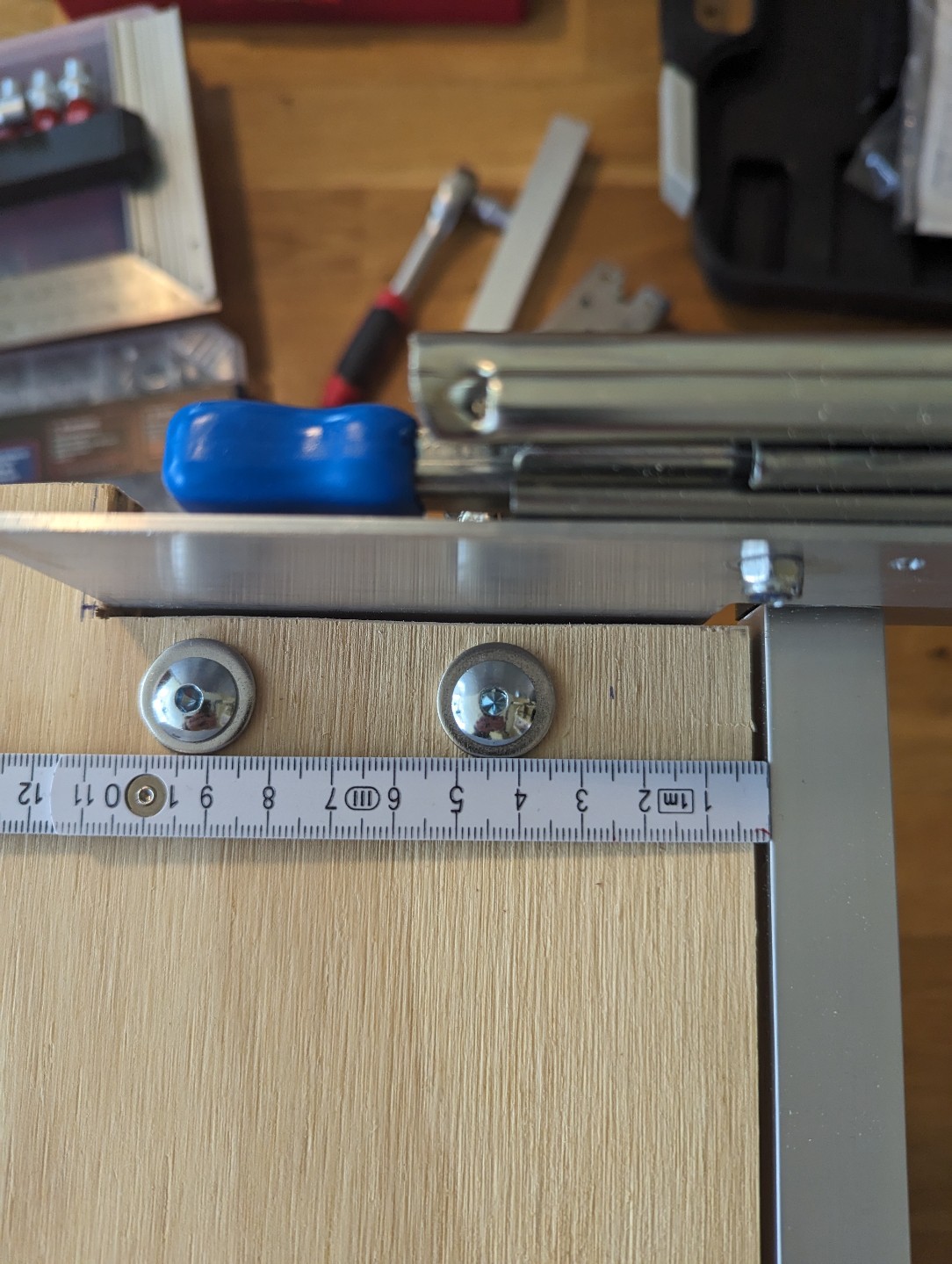

- Kind of easy or at least possible to take apart for transportation by train/car

- Lightweight as possible but not to expensive, tried to use PVC and Aluminum where possible

- My aim is that this should be possible to build in my apartment with no strange tools, because of this some stuff get a bit more expensive and not optimal but I don't have a garage space and tried to keep it kind of over all cheep e.g. not buying expensive tools.

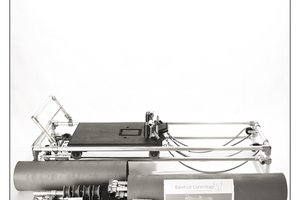

Goal idea is to make it look "kind of close" to this mockup I made in a FreeCAD. To simplify the design Ill remove all bendy/roundish stuff and adopt the sizes to my wagon. As the time of writing this there is still some work needed to reach the end goal so it will be interesting also for me to see hos it turns out.

Zingo Andersen

Zingo Andersen

Jan

Jan

joseph

joseph

David Tucker

David Tucker