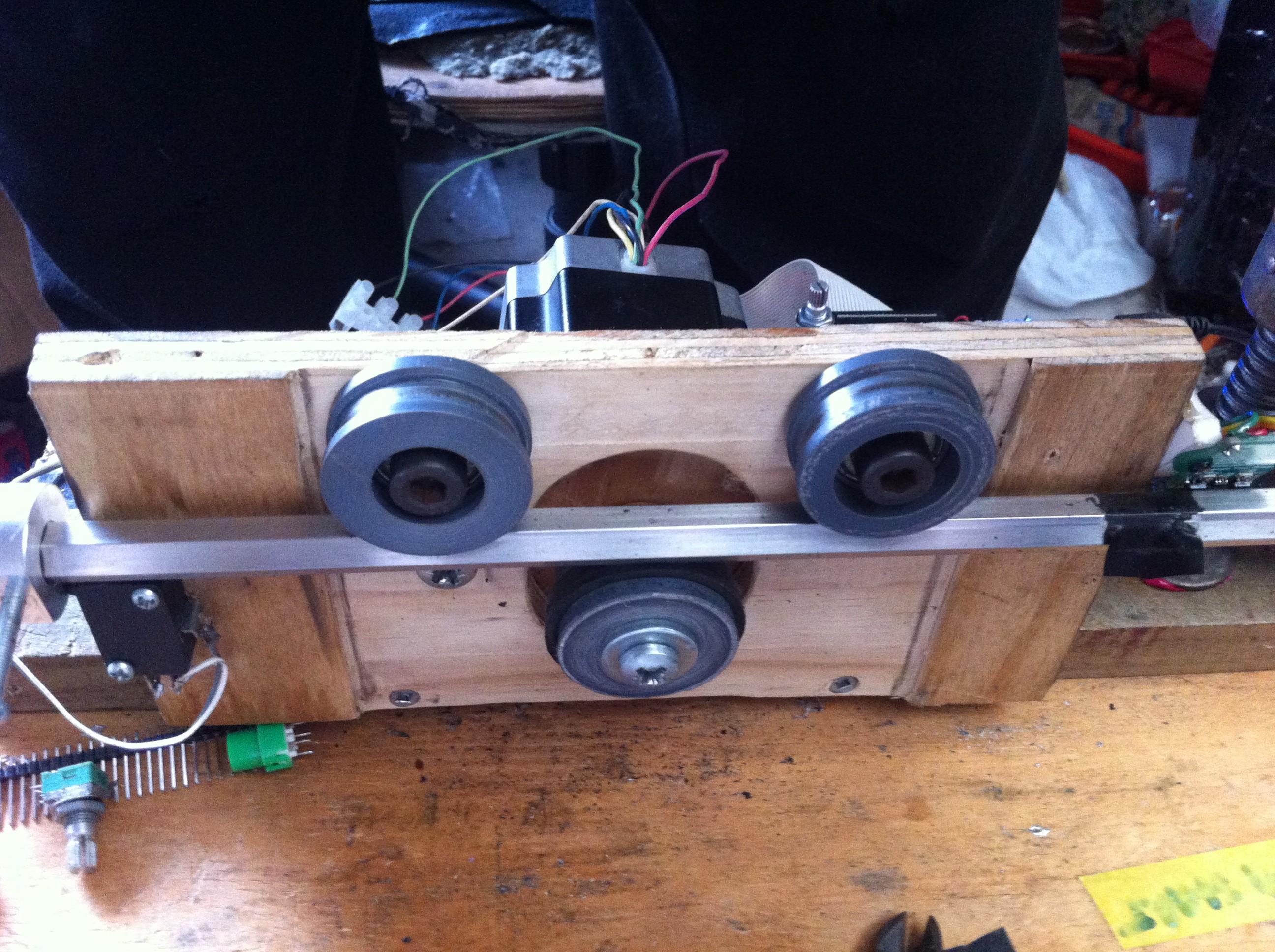

The first part of the project was to look at what kind of motor to use, having built a few CNC machines in the past I opted to use a Stepper Motor as this would allow me to change speed and direction quickly as well as create a programmed step arrangement..

The concept was to make something that could be programmed allowing the user to set how long they would like the stoke to be and the possibility of altering the stroke length on the fly.

By hitting the program button the user can extend and retract the shaft by hand and save up to 40 moves that will repeat over and over when played back.

Boris van Galvin

Boris van Galvin

Aaed Musa

Aaed Musa

Daren Schwenke

Daren Schwenke

shlonkin

shlonkin

Joseph Eoff

Joseph Eoff