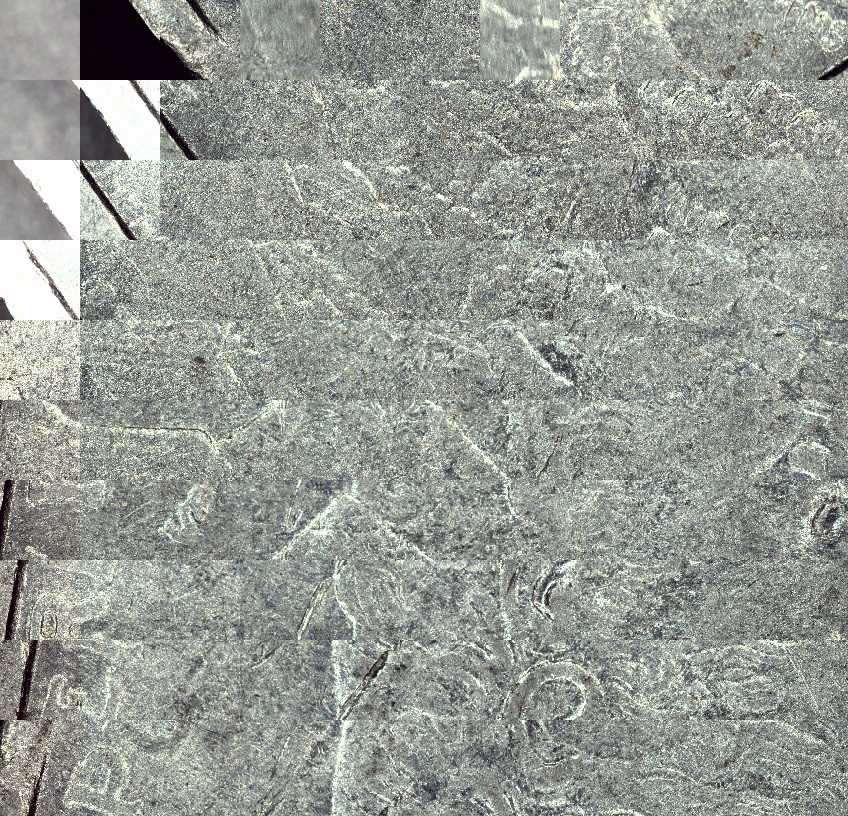

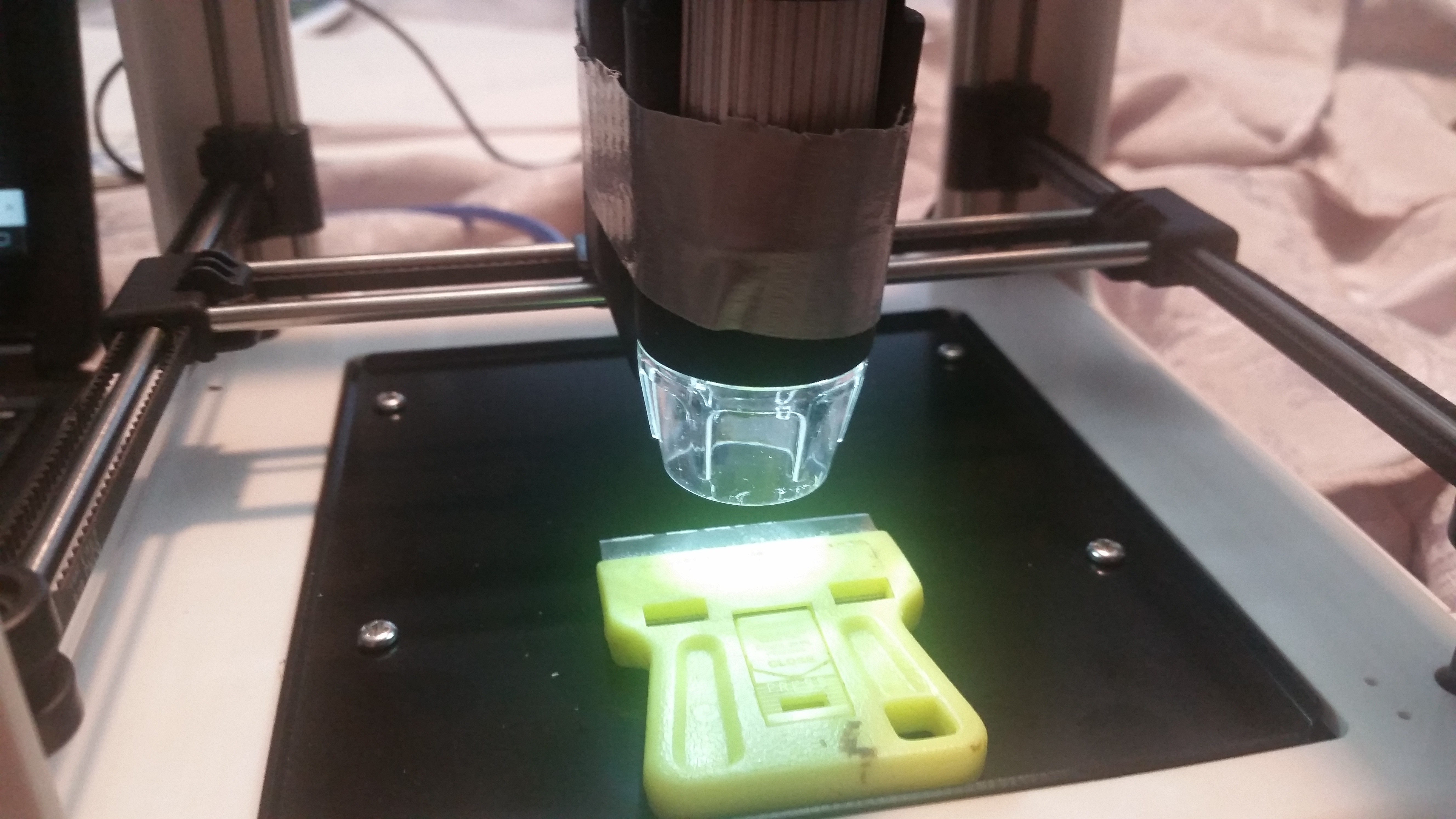

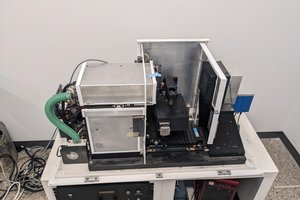

A couple of years ago, I broke my first 3D printer during a replacement of the fan. Up in smoke the mainboard went, never to turn on again --- until now. Life has been breathed into it again in the form of a Raspberry pi 4, some easy drivers, some extra motors, and an unholy amount of jumper cables, hot glue, and some other stuff.

Main components:

1: Old Flashforge finder --- the one with the matte surface finish, external power supply, and LED mounted in the front. The new model has a smooth surface finish and LED mounted onto the extruder assembly, but has the same mechanical guts.

2: Raspberry pi 4 (1 gb) ram. I have also used a raspi 3 with this and an older ladybug, but the 4 has a much higher framerate with USB cameras, which is nice. I use it like a desktop with a monitor/keyboard/mouse, but there's no reason you couldn't go headless.

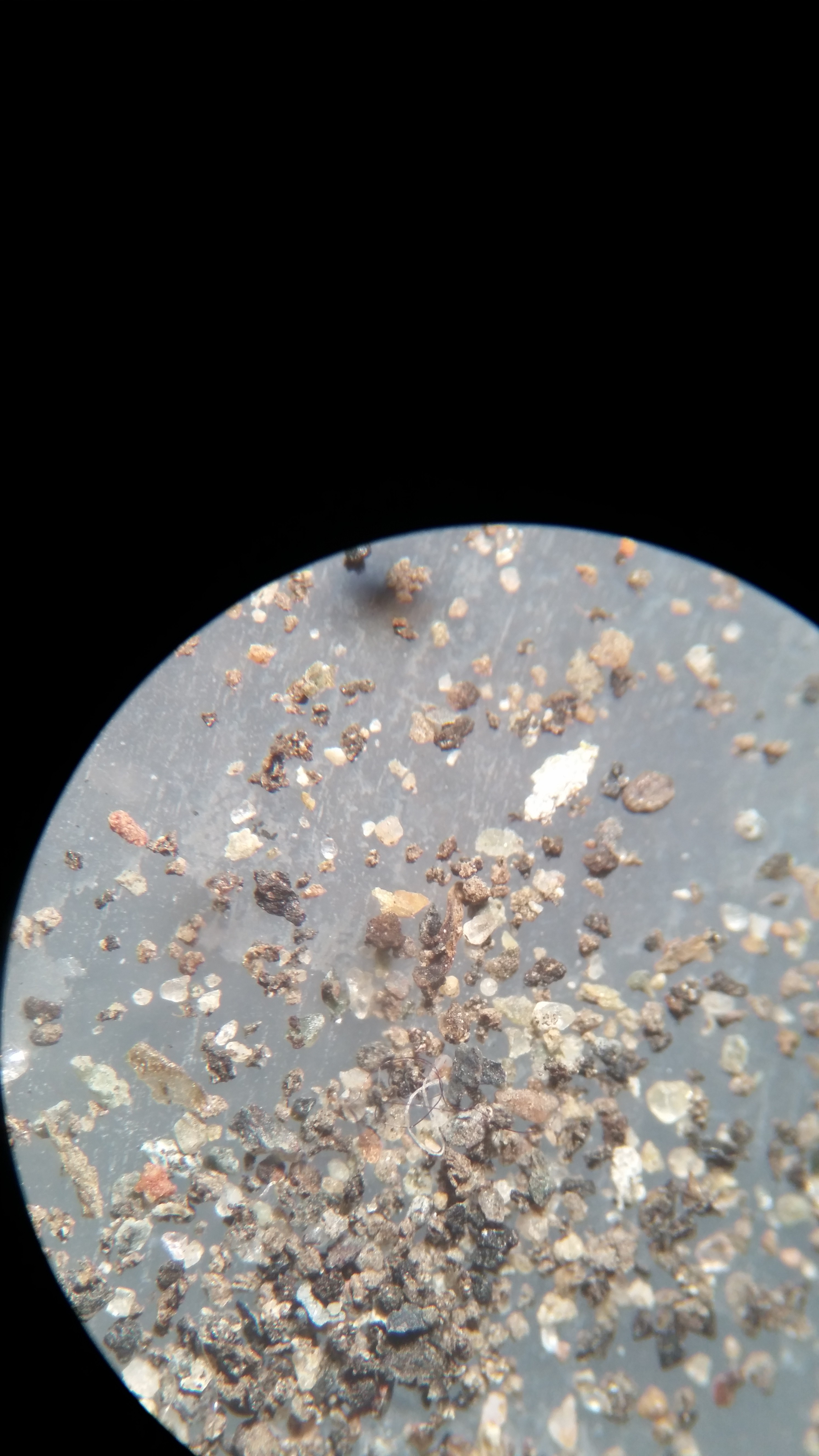

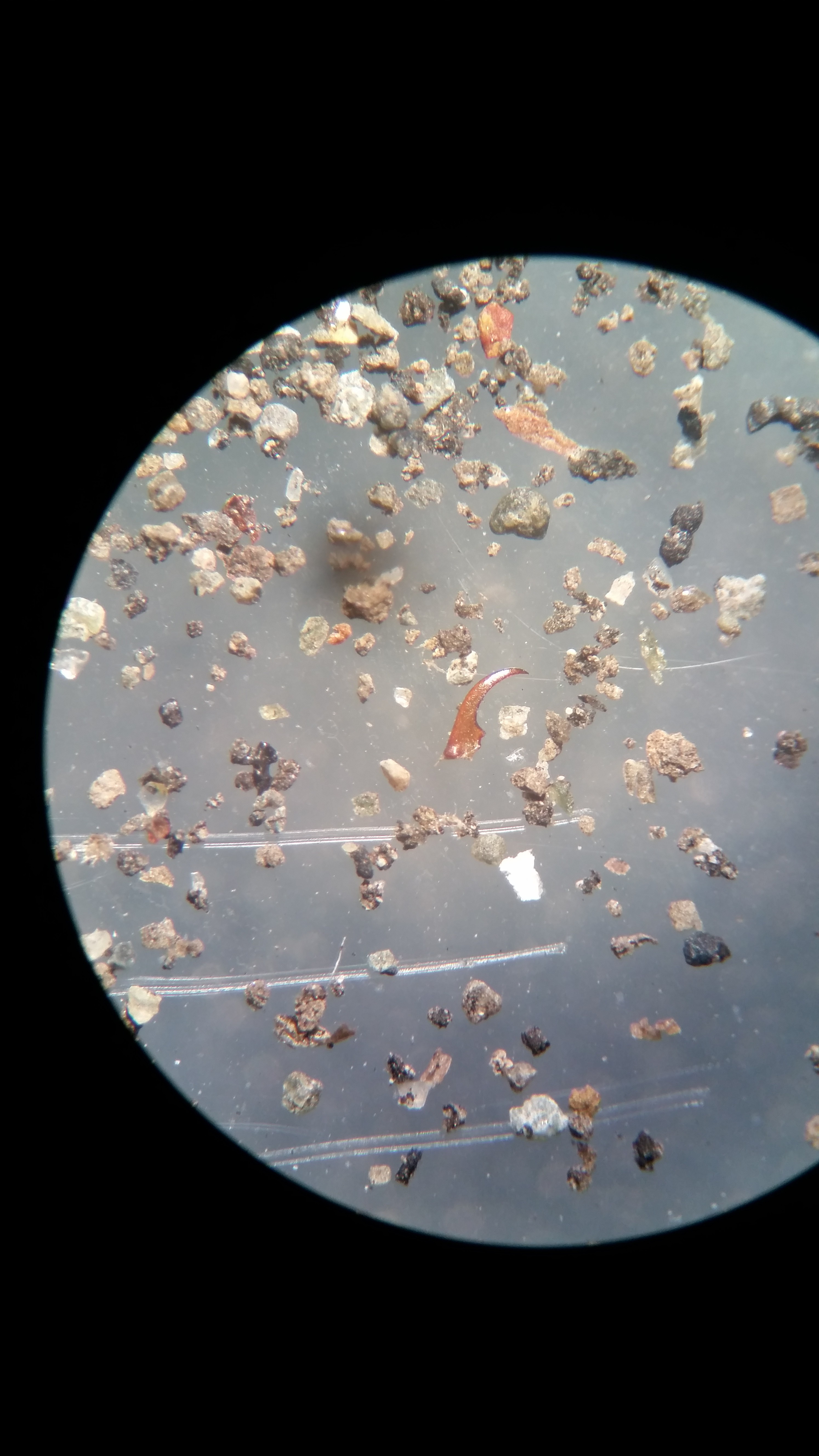

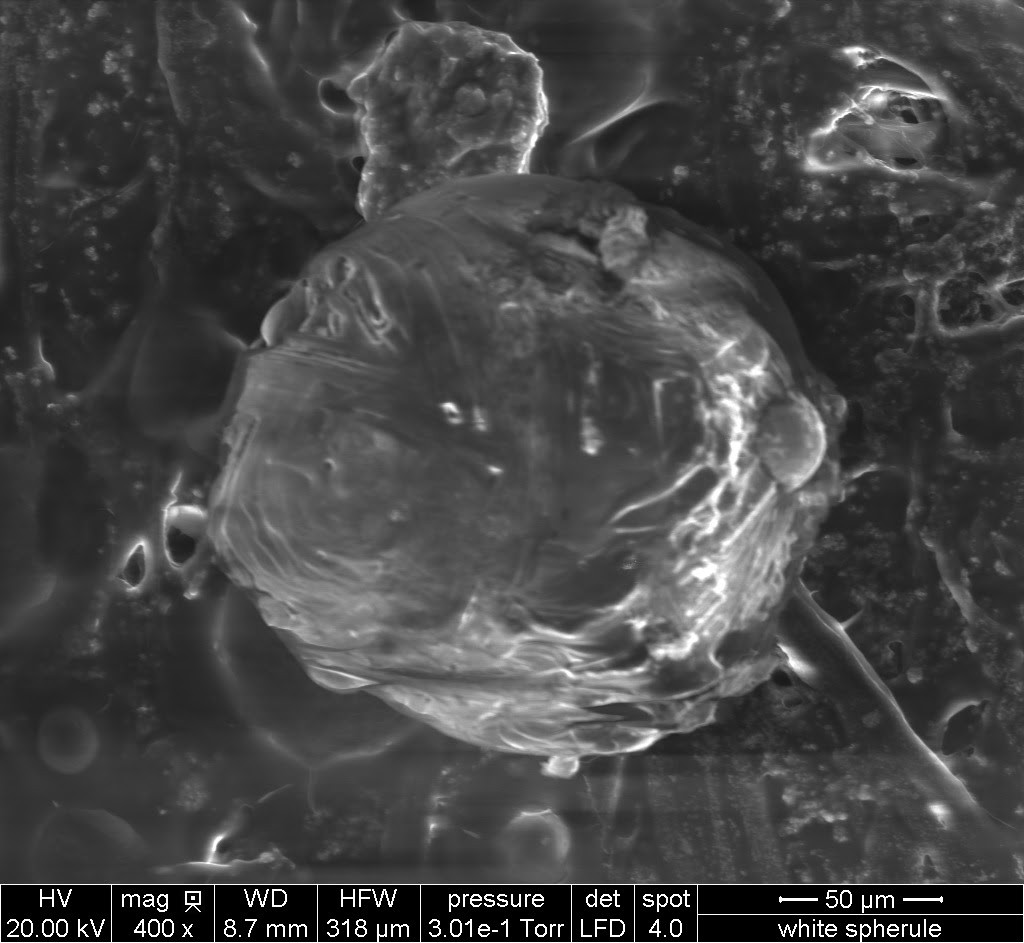

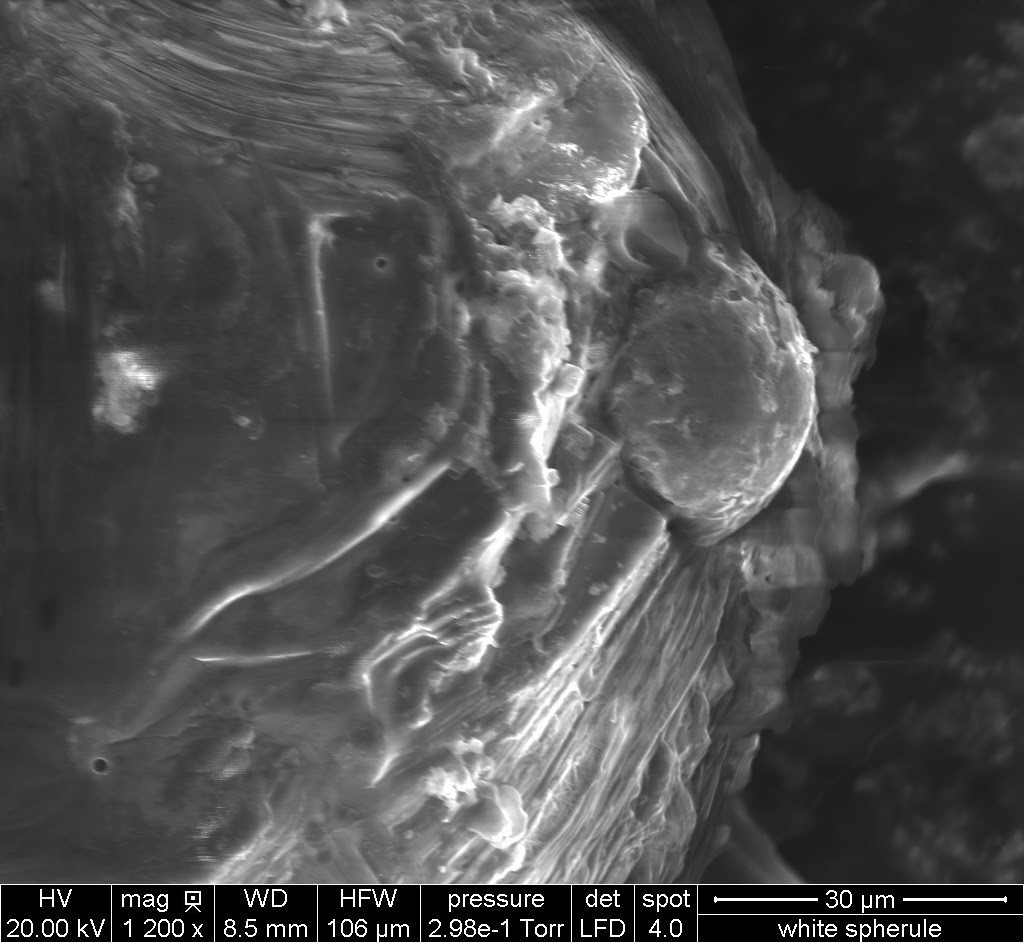

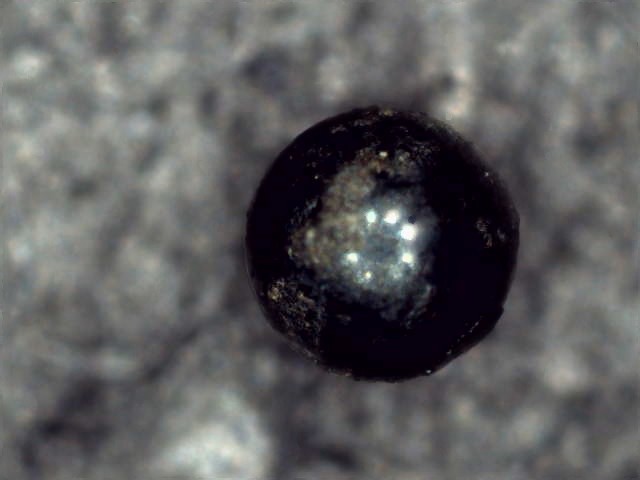

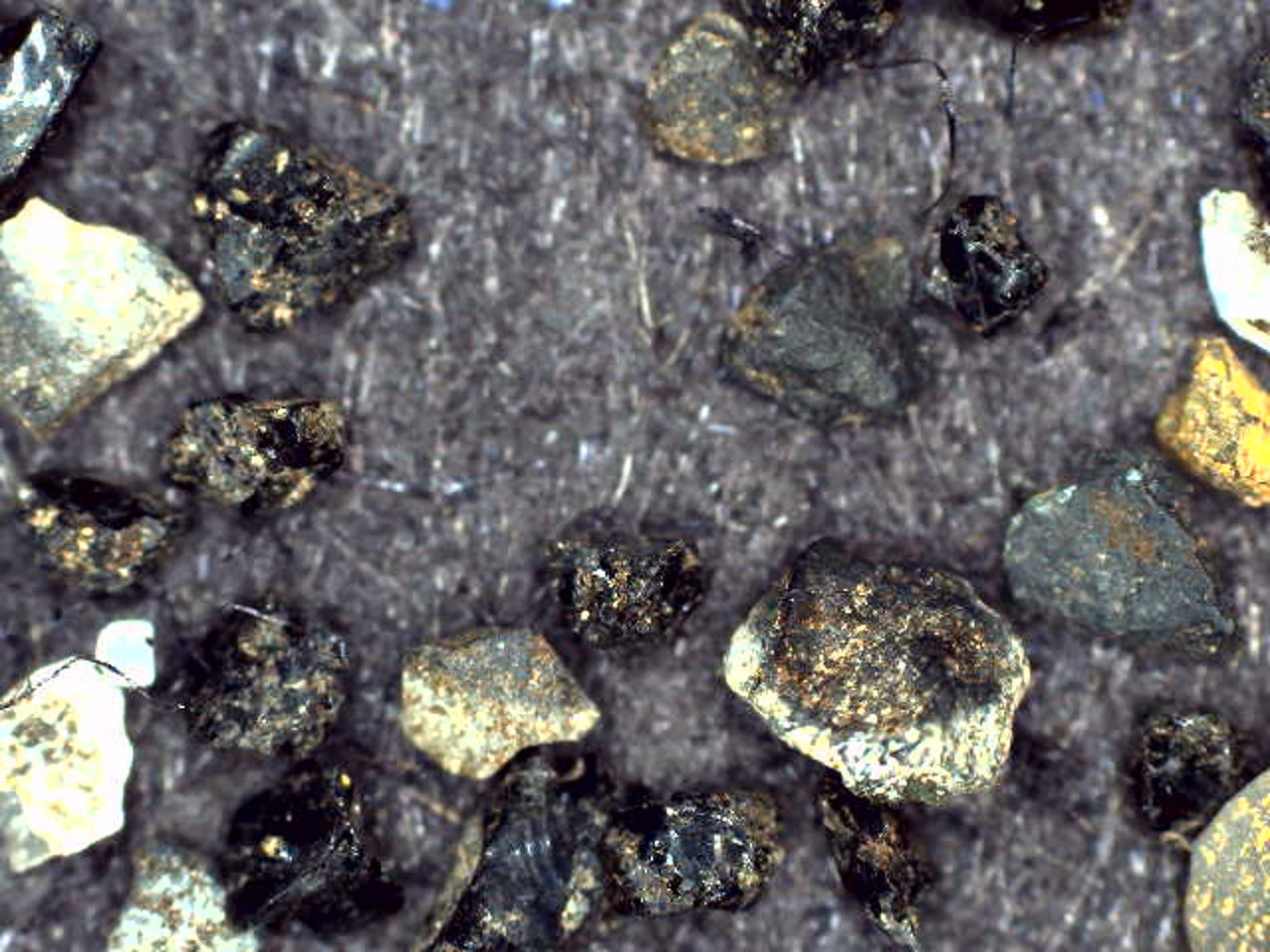

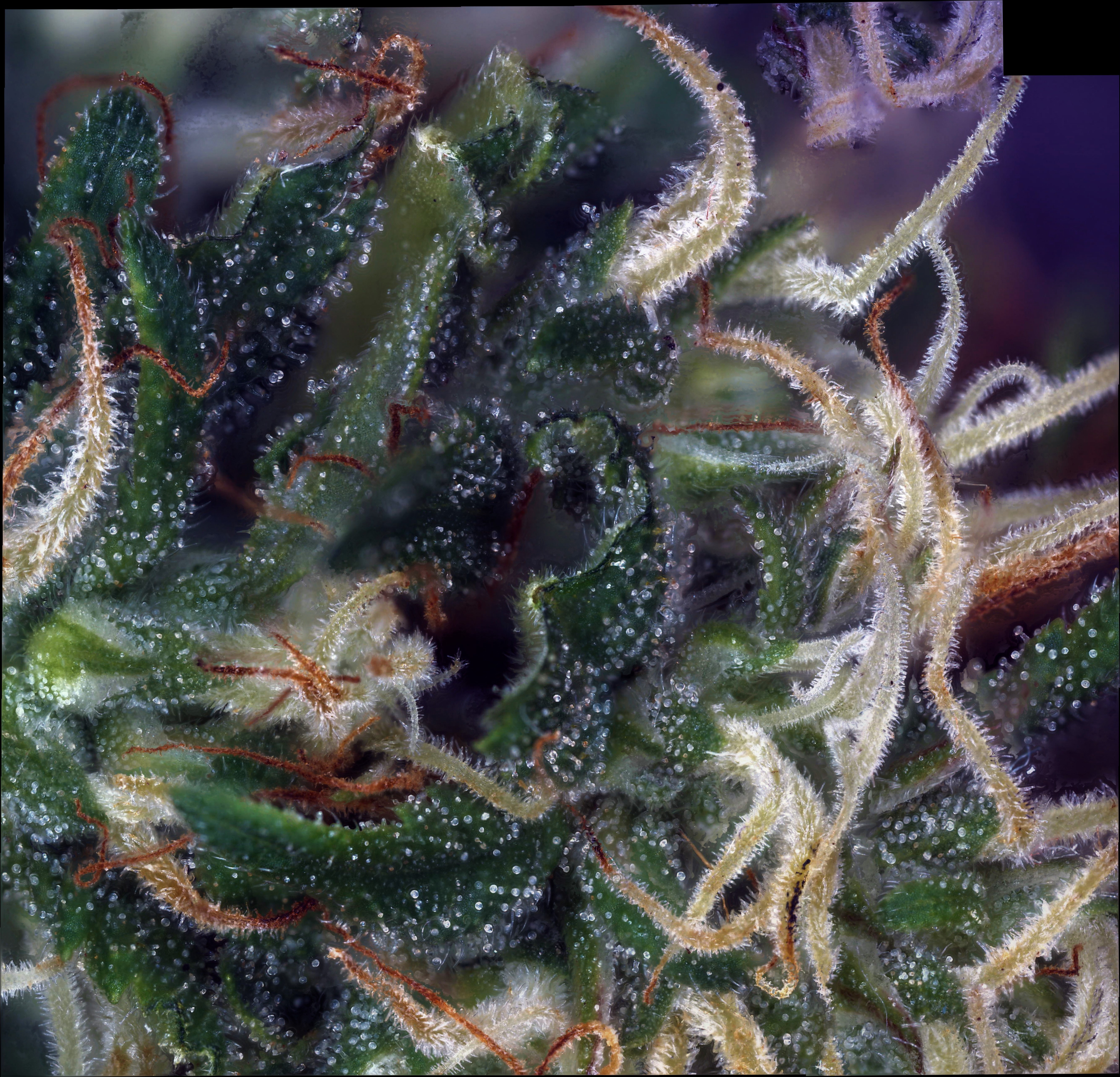

3: USB microscope: By happy coincidence, the generic ones in the style of dinolite (or the genuine article) fit neatly into the hole in the original extruder assembly.

4: I'm used to Easydrivers, but standard a4988/drv8825 drivers or whatever should work fine, especially for motors of this size.

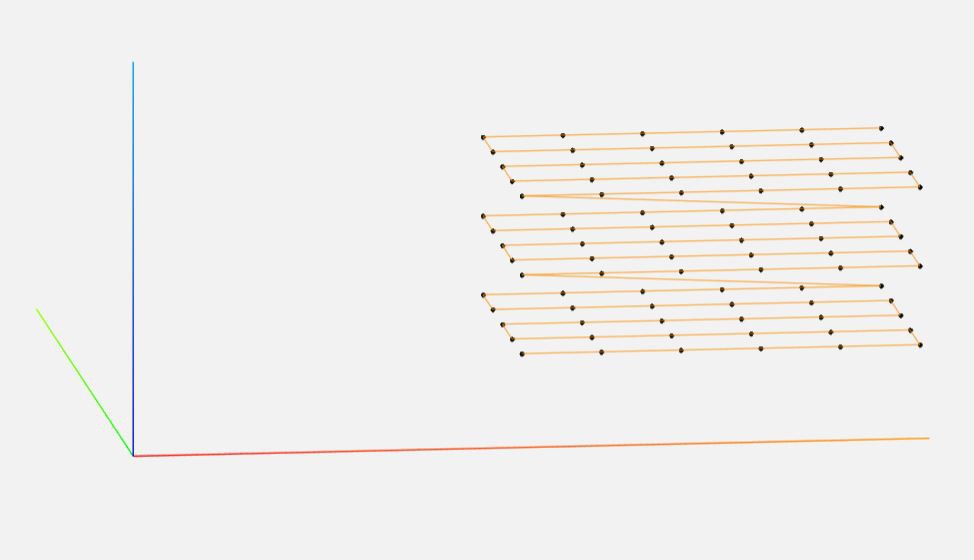

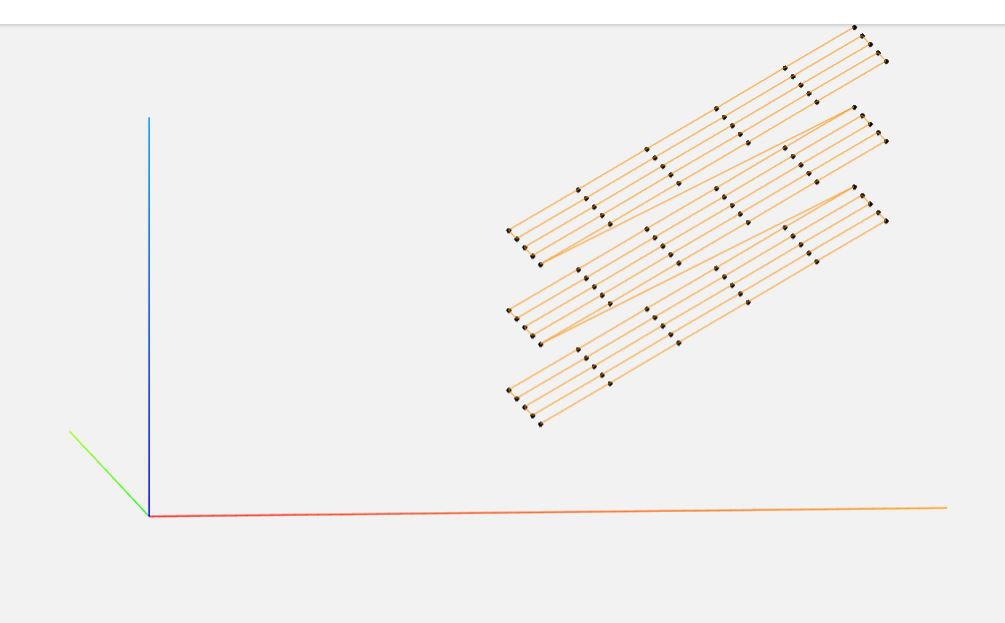

5: Extra motors (optional). At the very least, you should make use of the extruder motor to add a fourth axis. But you can go really crazy and go for a fifth or more.

6: Misc: An older 20v laptop power supply, wireless selfie module for taking picture with a phone, breadboard, wires, beeper.

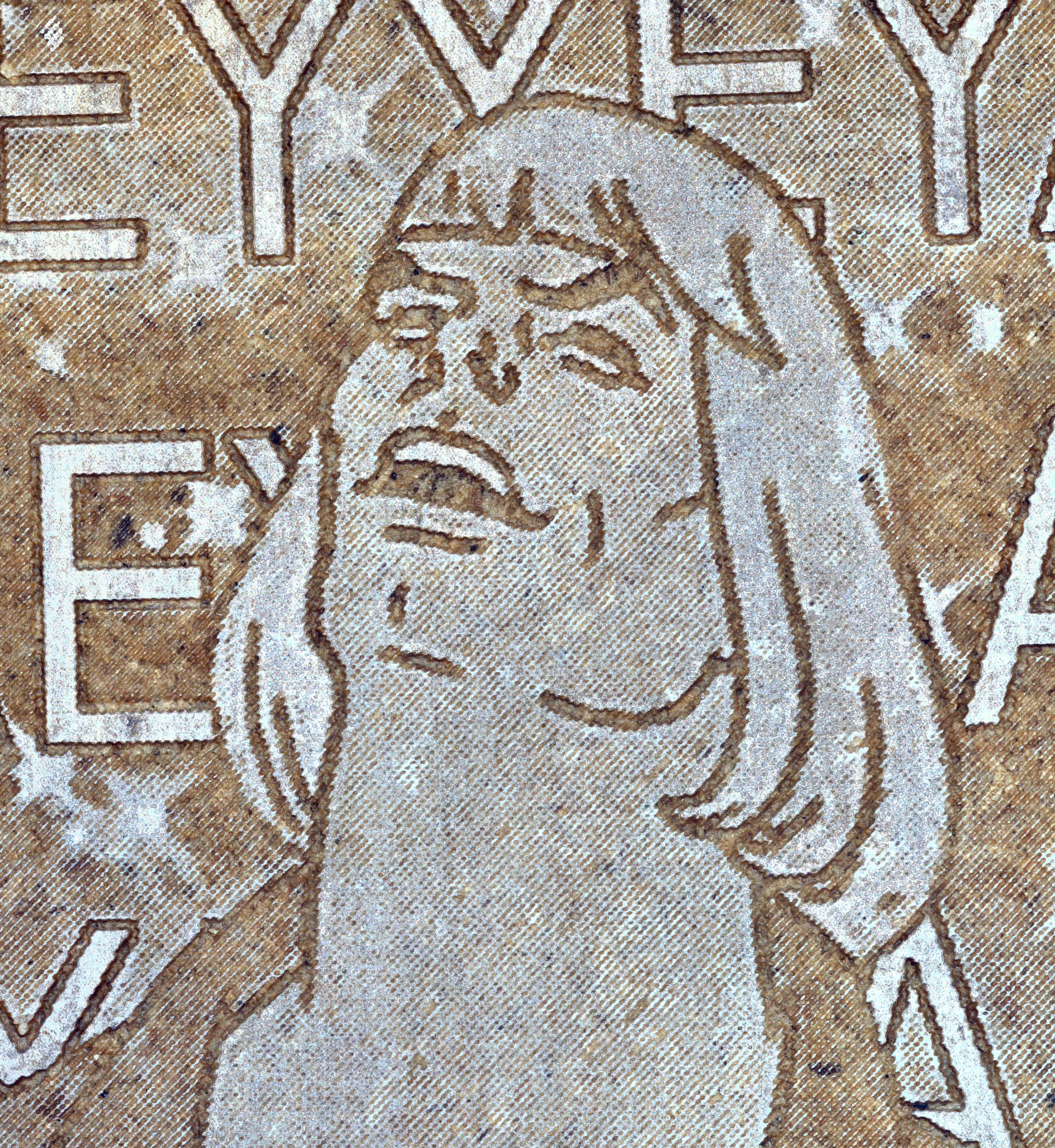

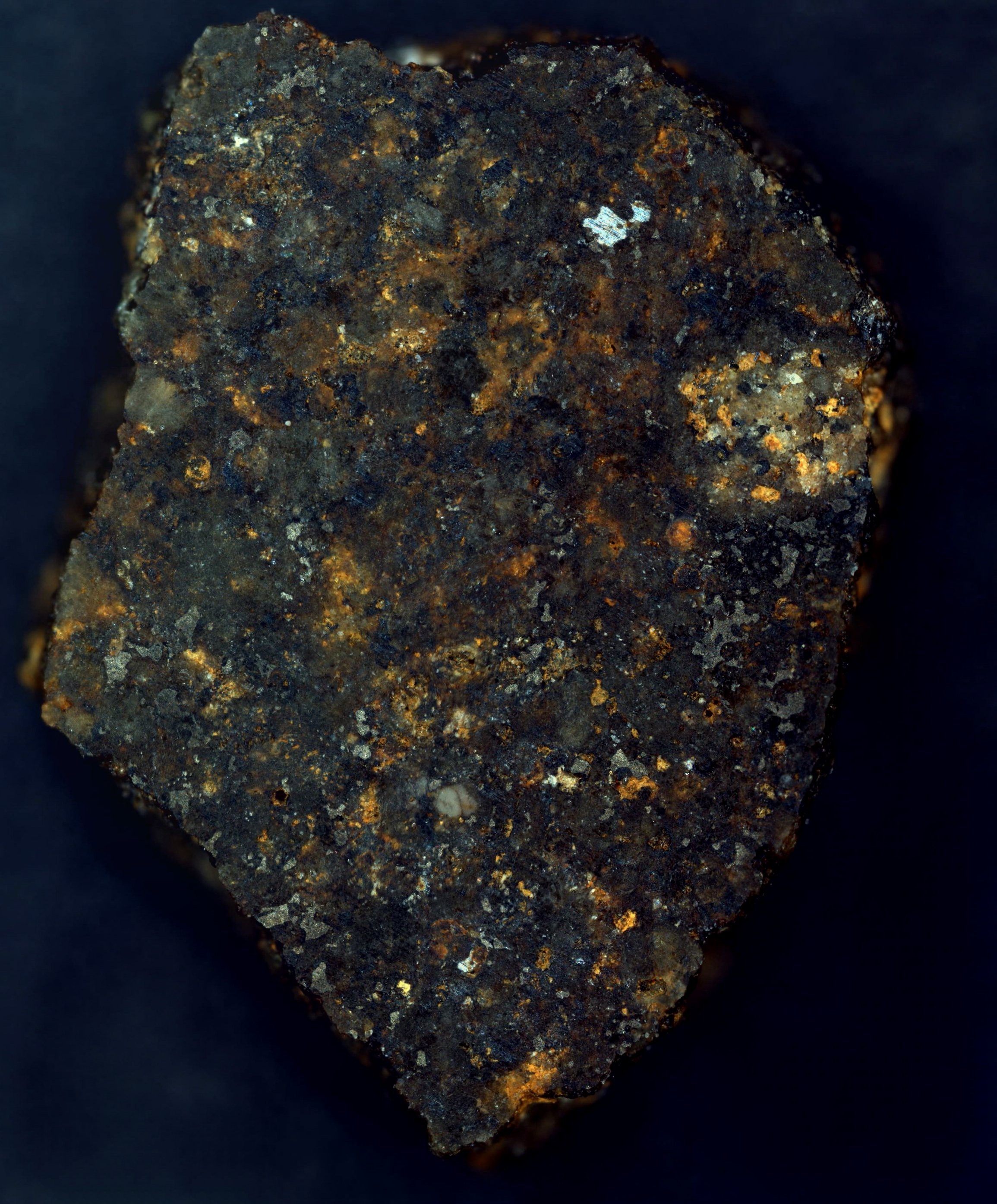

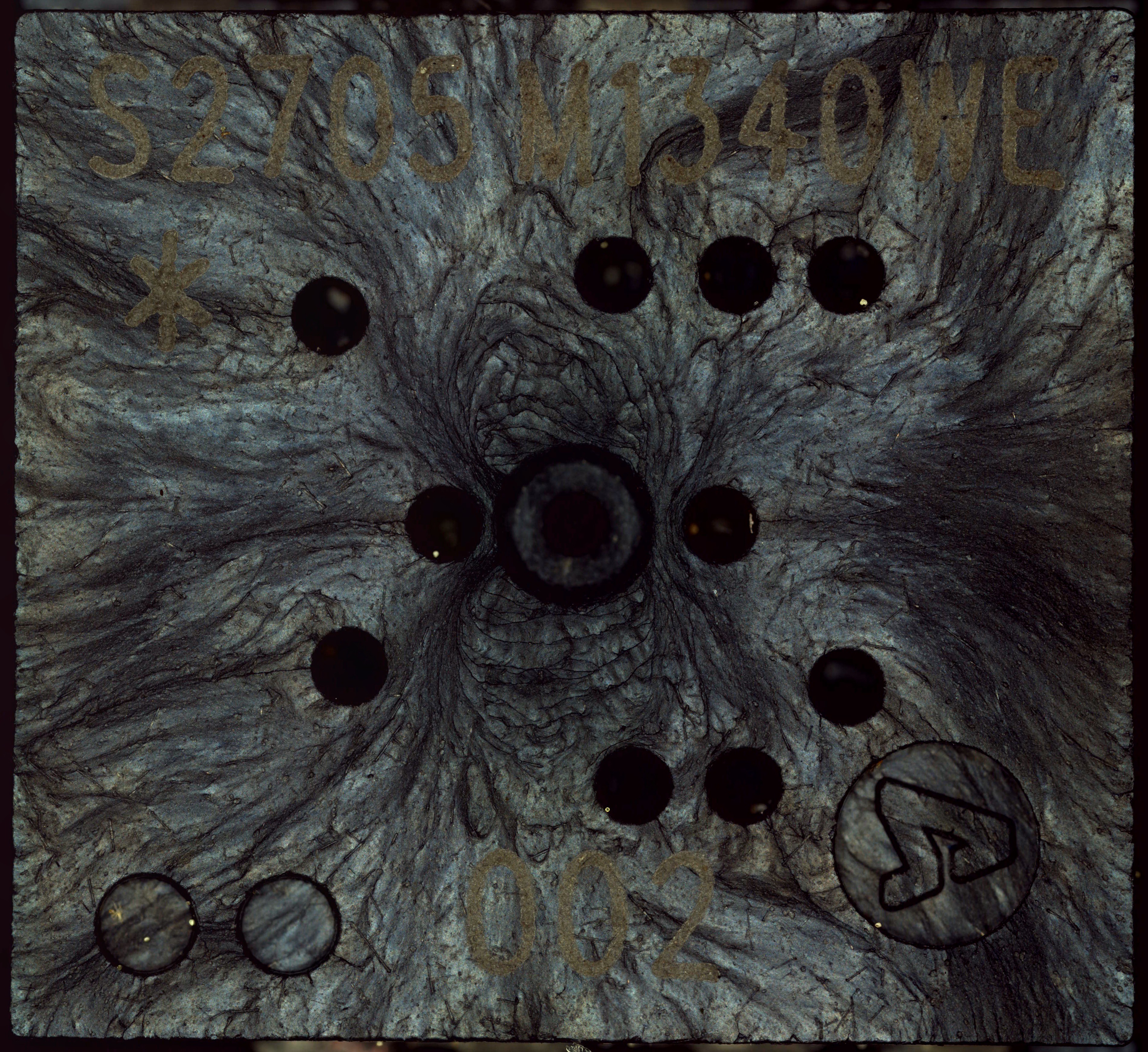

Scanning is done on a single python file in the Pi, with most post-processing done on a main computer using commercial software as well as some custom utils.

Ahron Wayne

Ahron Wayne

Morning.Star

Morning.Star

Kevin Kadooka

Kevin Kadooka

Stephen Holdaway

Stephen Holdaway

so cool it reminds me of a confocal microscope like this I made a scanning laser microscope - YouTube

is this what type of system being built here? plz forgive my ignorance.

I really looking for a way to scan objects to cad accurately on the small scall

thanks