20181108 : project reboot !

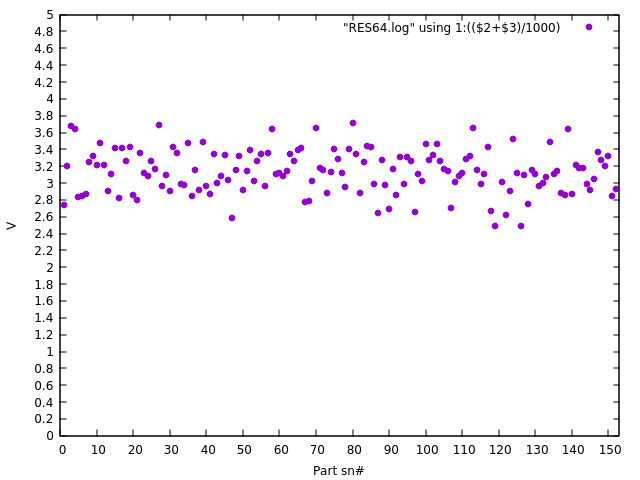

The text below is a bit outdated but the purpose is still the same: test relays. However I only measure the hysteresis voltages now.

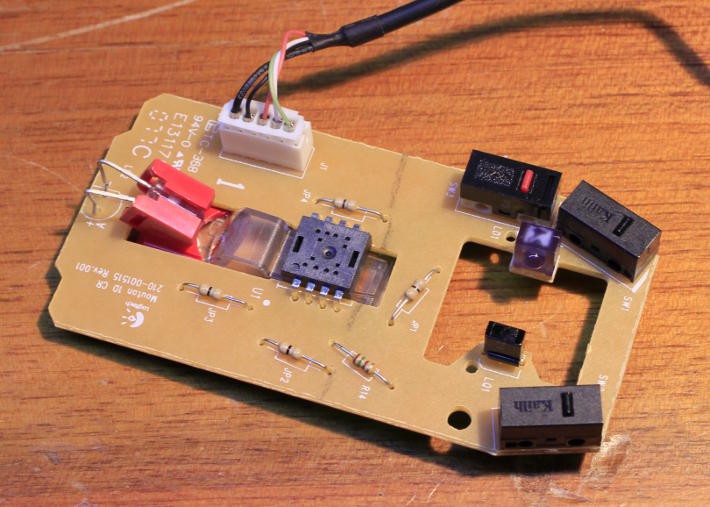

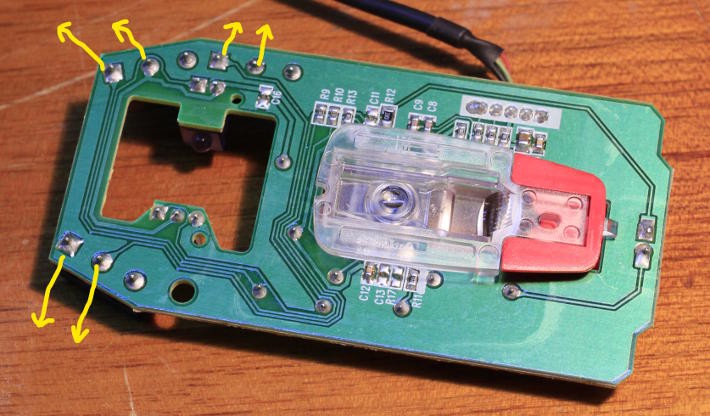

2020-02-04 : The hacked mouse and the SCPI lab PSU are among the many features of this video of the testing procedure :-)

Old version :

The РЭС15 are low-voltage small-signal relays built in Soviet Russia, brought to us by the magic of eBay. I use a certain quantity in #AMBAP: A Modest Bitslice Architecture Proposal and #SPDT16: 16-bits arithmetic unit with relays

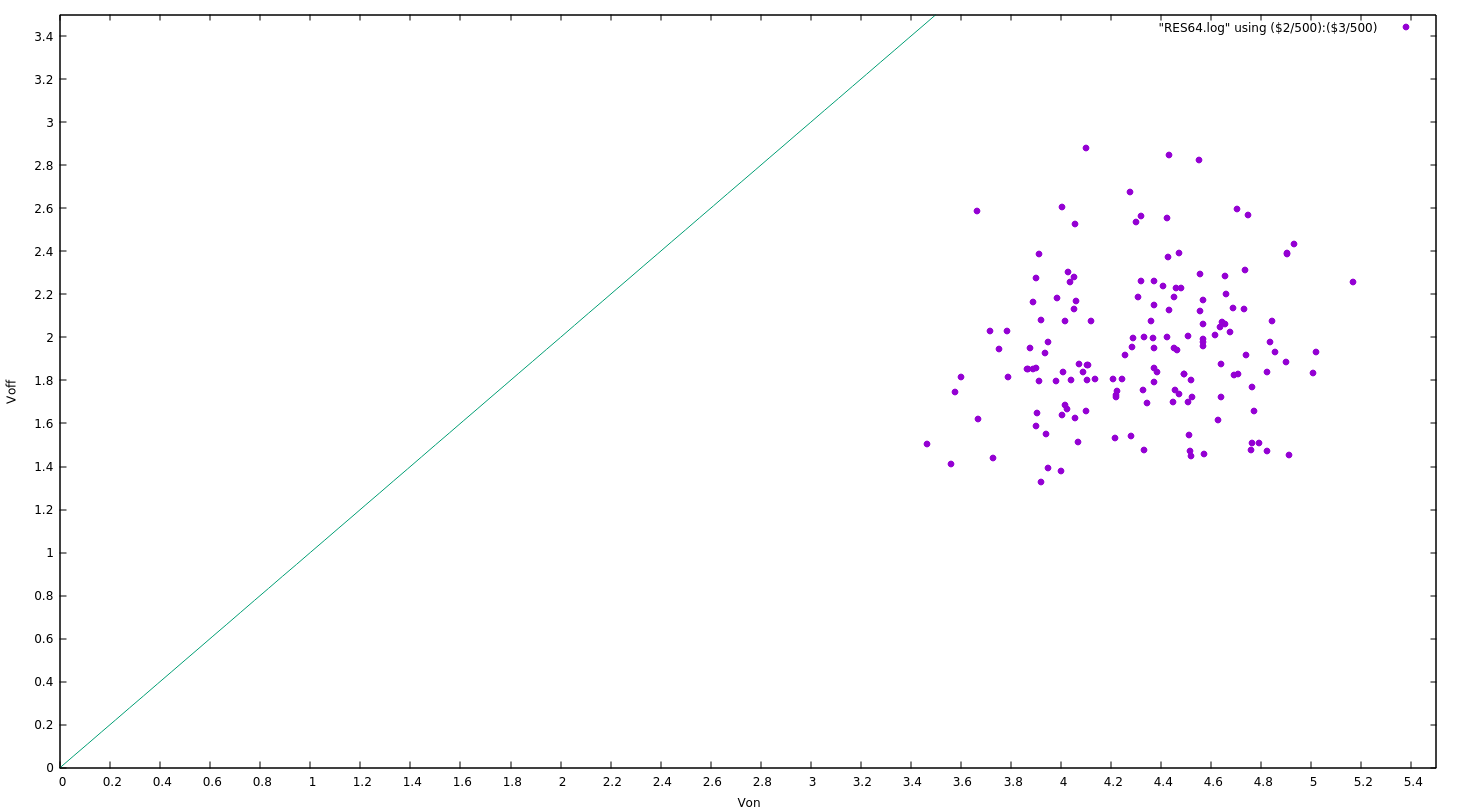

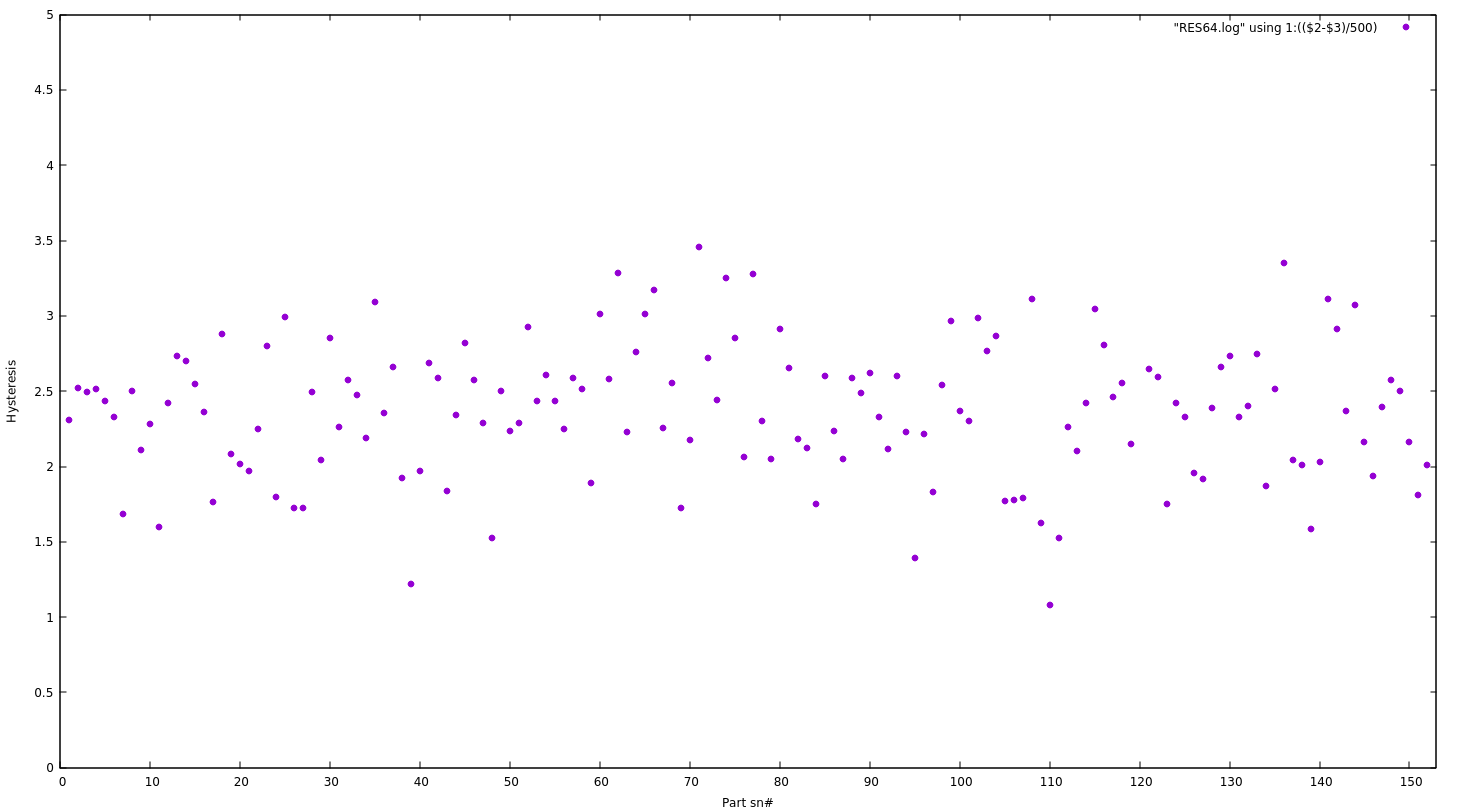

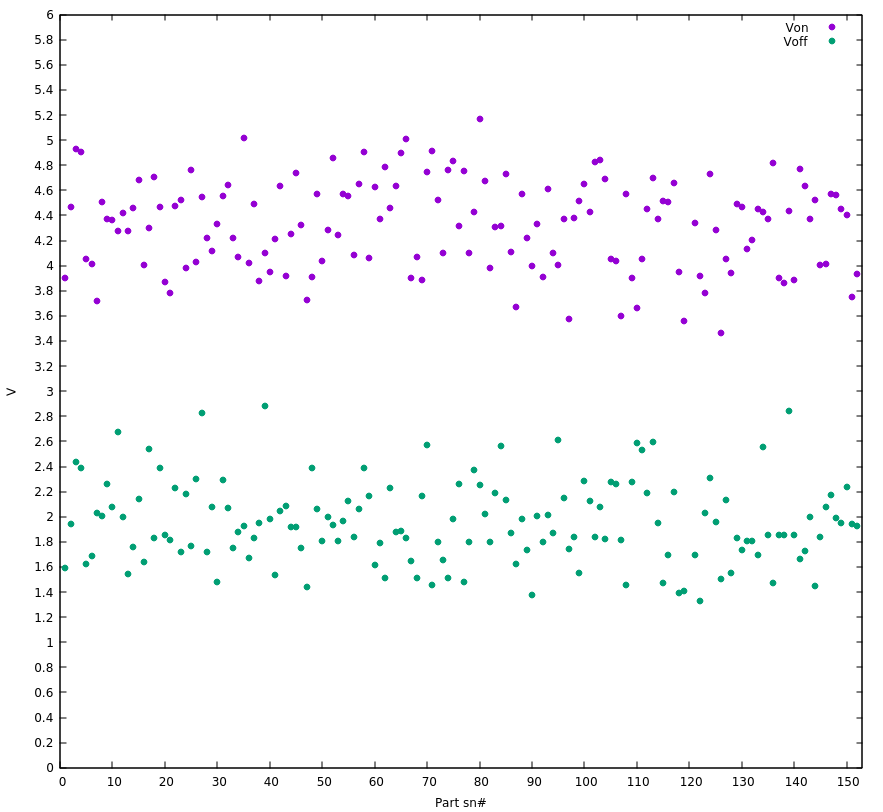

In another page (Pre-Biased, or Hysteresis Relay Logic) I gather some measurements and find some outsiders that diverge about 20%. In practice, this can be enough to destabilize the circuit, particularly the latch bits that rely on magnetic hysteresis.

@matseng has designed his own relay timing analyser: #ReTest - Relay timing tester which I'm not able to replicate and doesn't provide me with data I need (such as coil voltages and currents).

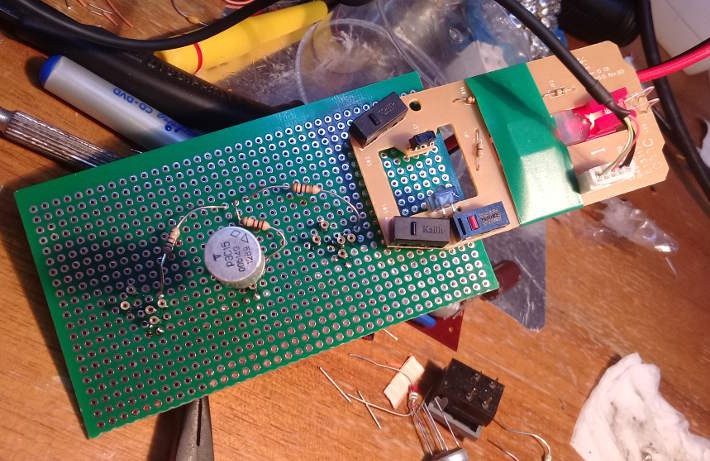

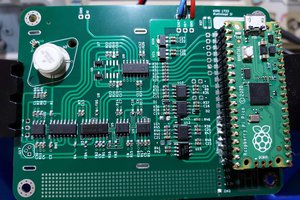

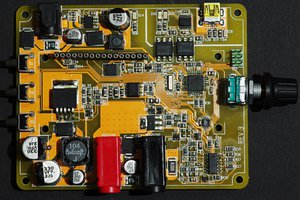

I'm more comfortable with the Raspberry Pi (first generations) and this project is a good opportunity to play with some 74HC parts, precision current generators and other funky analog and digital circuits...

Logs:

1. Sampling

2. SPI Interface

3. Programmable current generator

4. Reboot !

5. Relevant datapoints

6. Got mouse.

7. And the PSU (bis)

8. First automated ramps

9. Relay labelling

10. Increase the resolution again...

11. Mouse button handling in C

12. Changes for the RES-64

13. No more FP23, use sed !

14. More mouse buttons handling in C

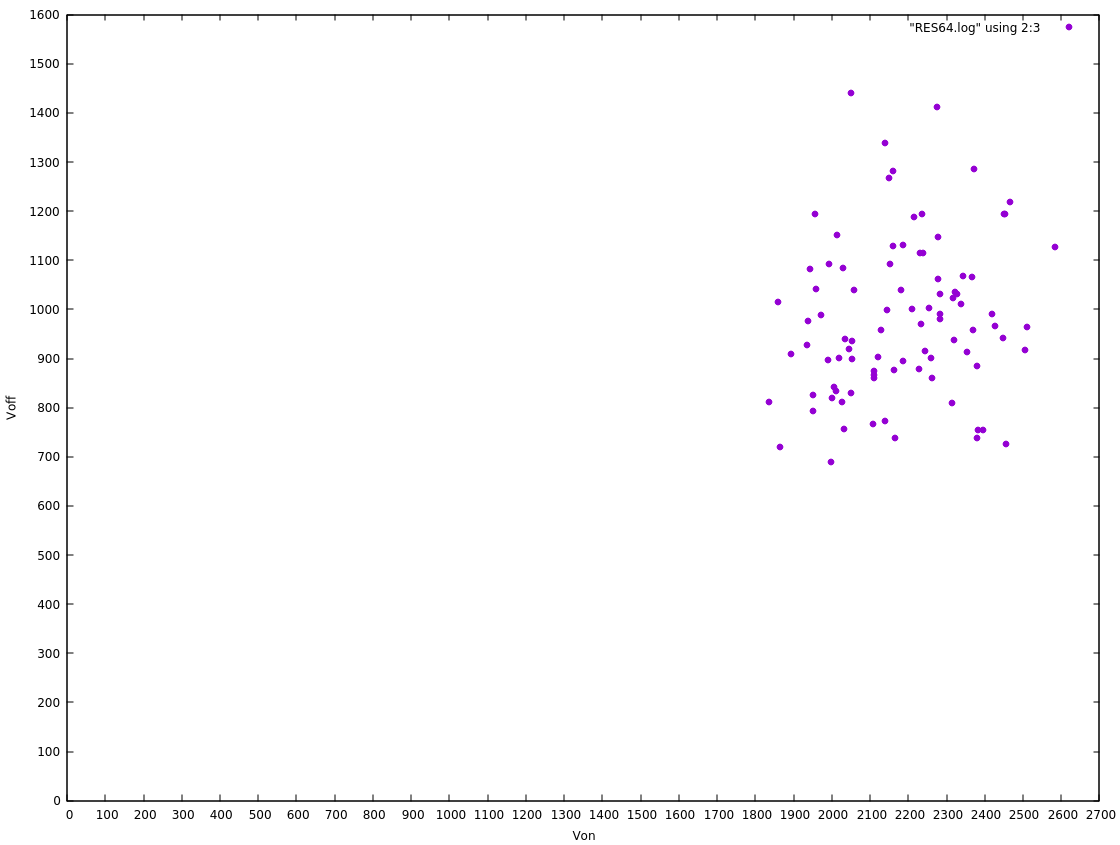

15. First plots

.

Yann Guidon / YGDES

Yann Guidon / YGDES

Jithin

Jithin

NNNI

NNNI

Oh ! a cute little page about the РЭС15 :-D

http://www.155la3.ru/res15.htm