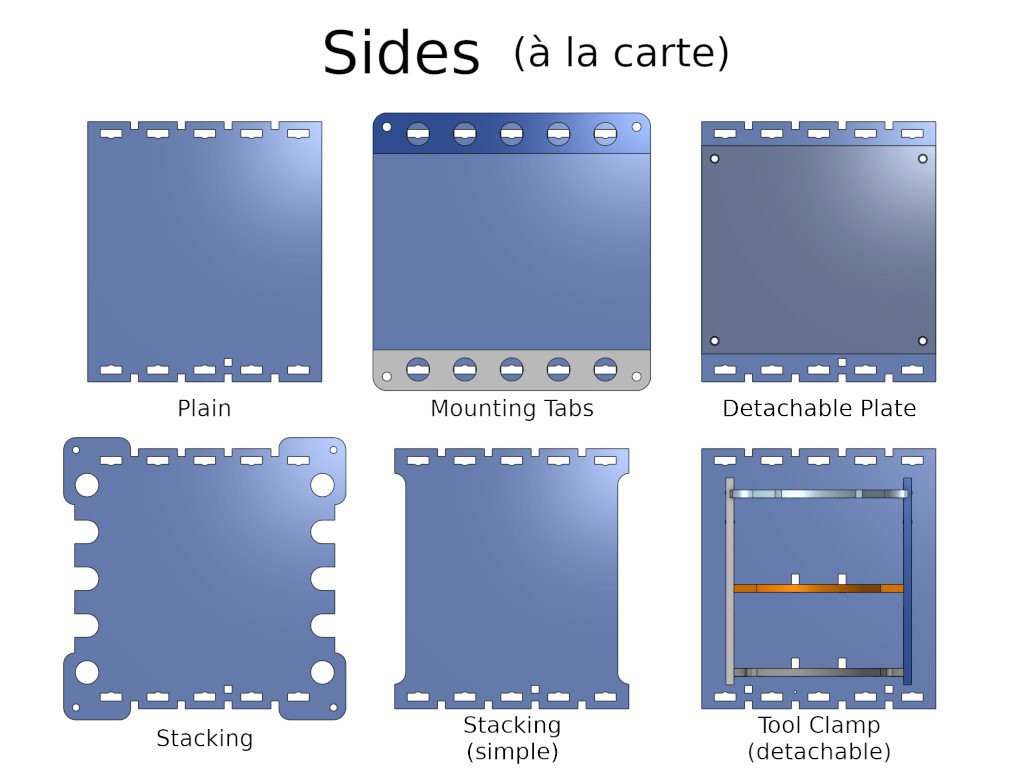

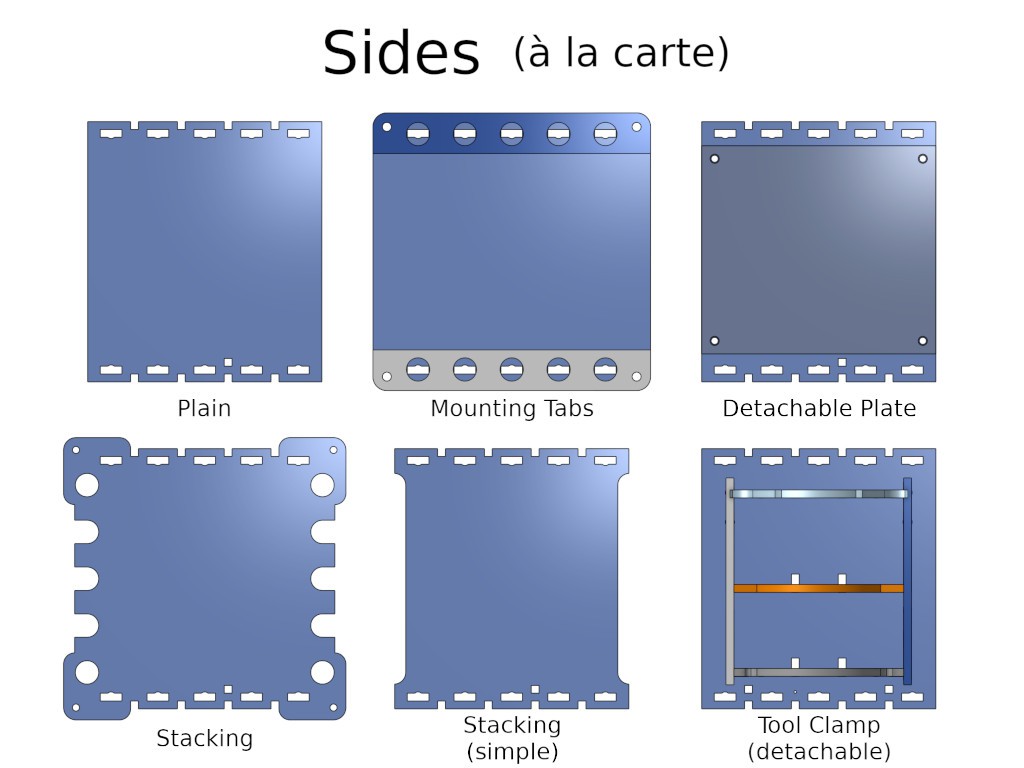

(25 May update: side options)

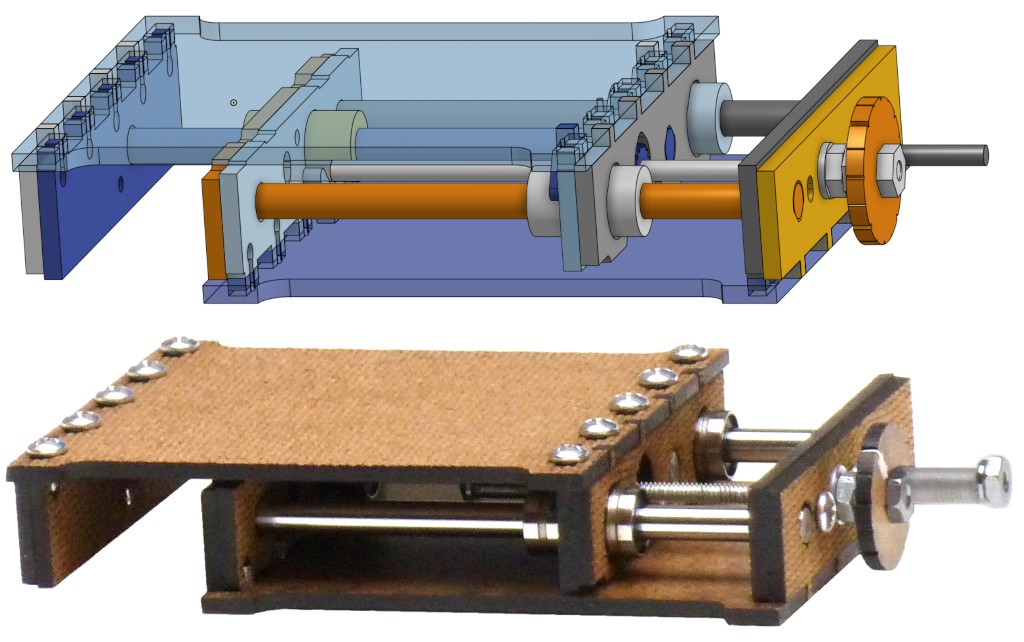

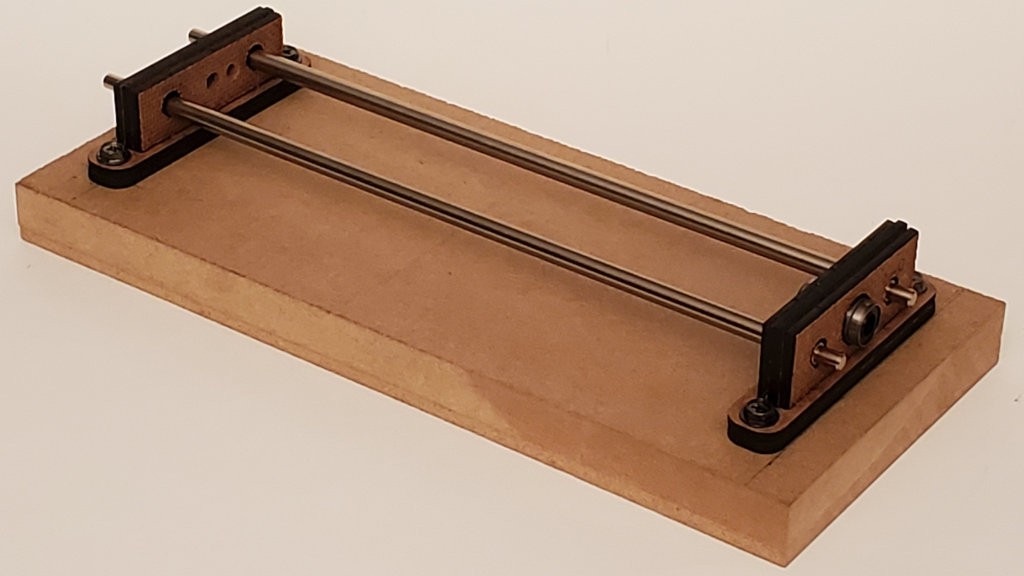

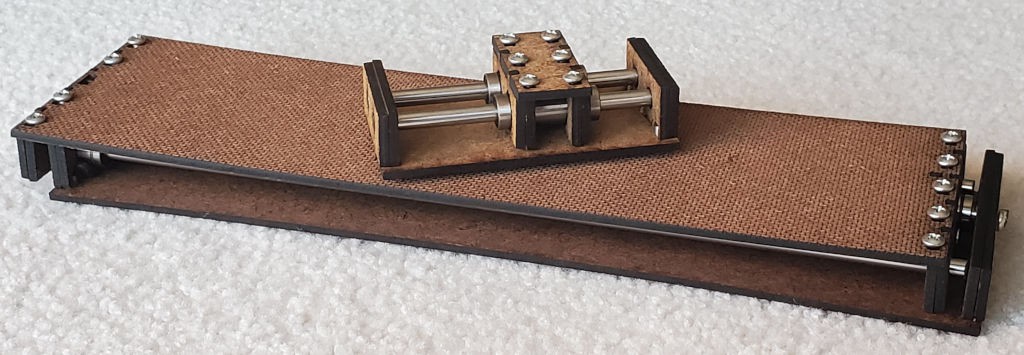

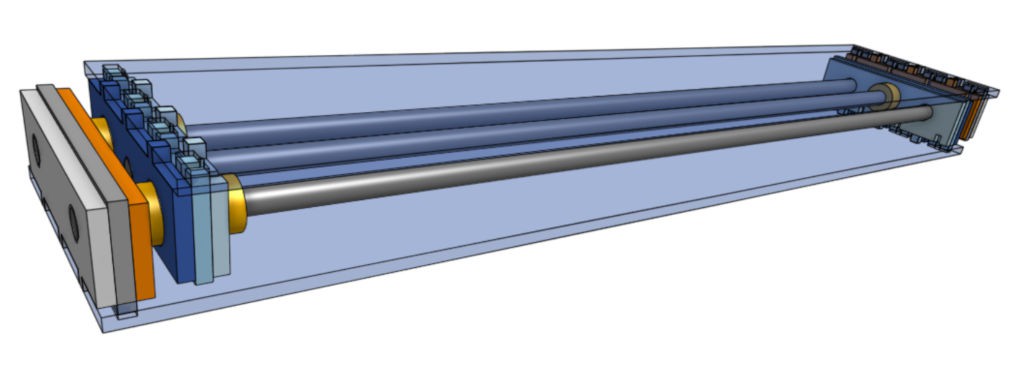

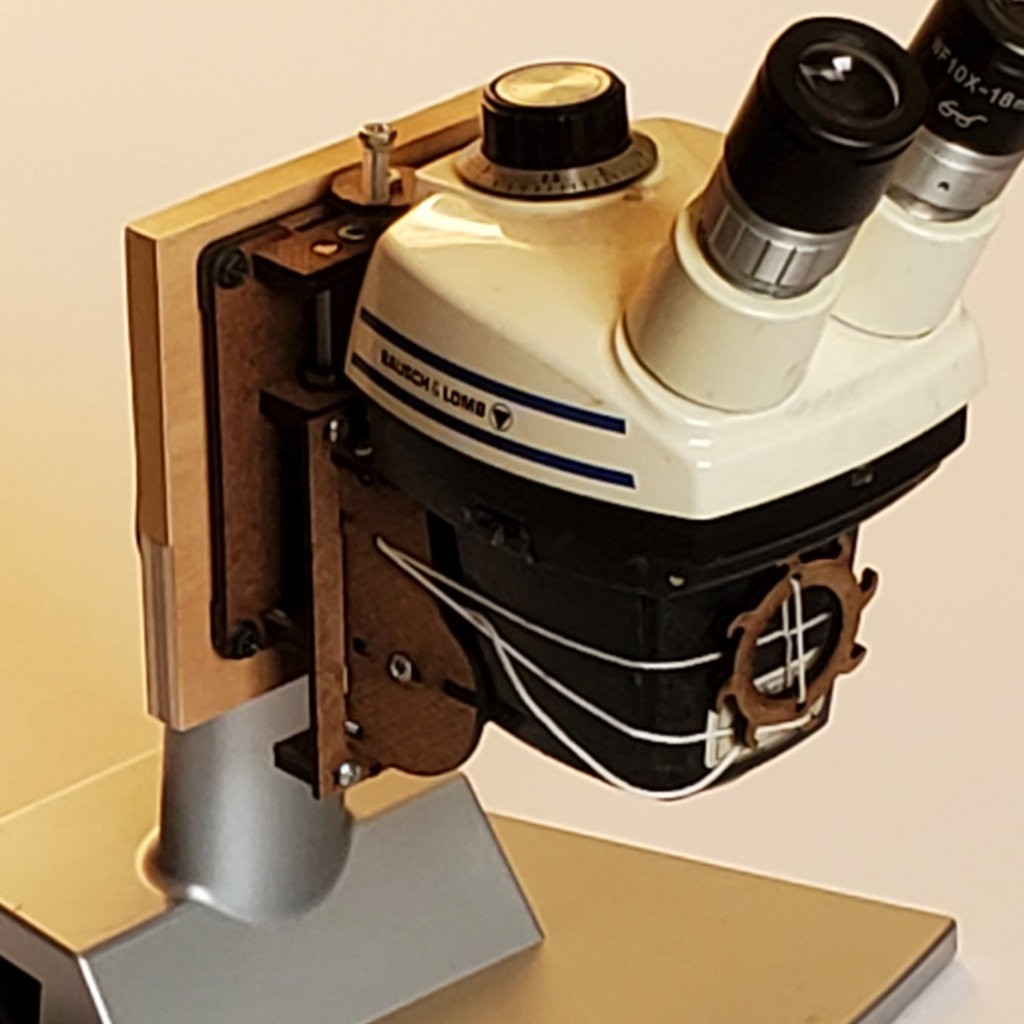

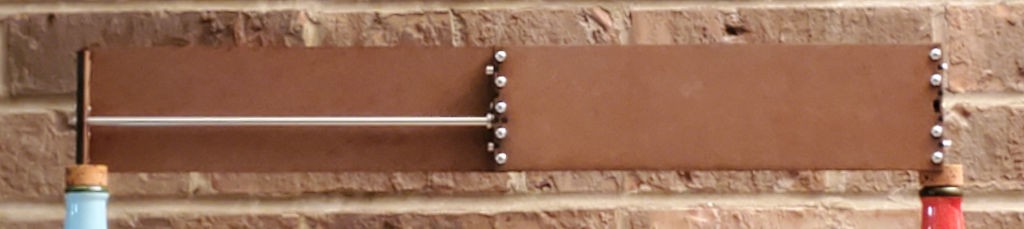

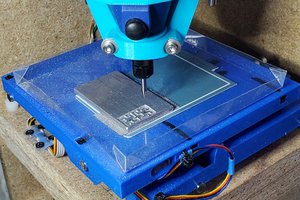

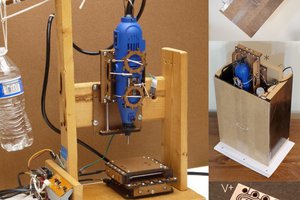

This very low cost linear slide design does most of the work of my #Minamil project - a “minimal CNC mill”. I hope this rendition of a single isolated unit will serve two purposes:

- Share this idea as a concrete, ready-to-use example

- Isolate and simplify the hard part of describing how to make a Minamil-like machine

Maybe you can use this to reduce the entry cost of some other project!

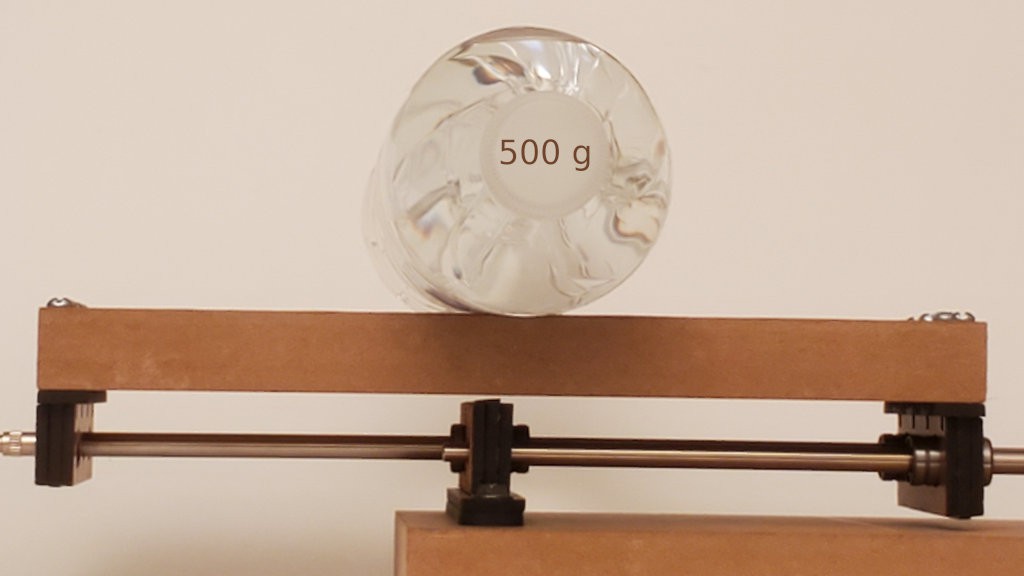

Video showing load carrying capacity and repeatability (>10 kg, <10 μm):

If you want to try one of these (or three) for yourself, check out detailed build instructions over at Instructables.

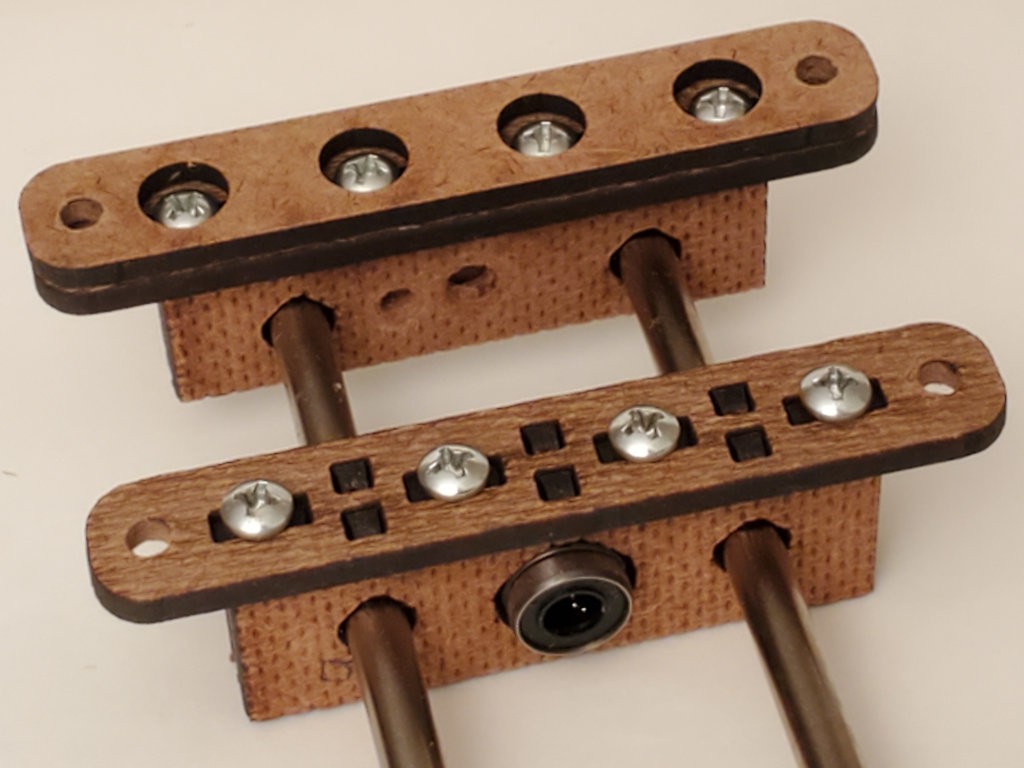

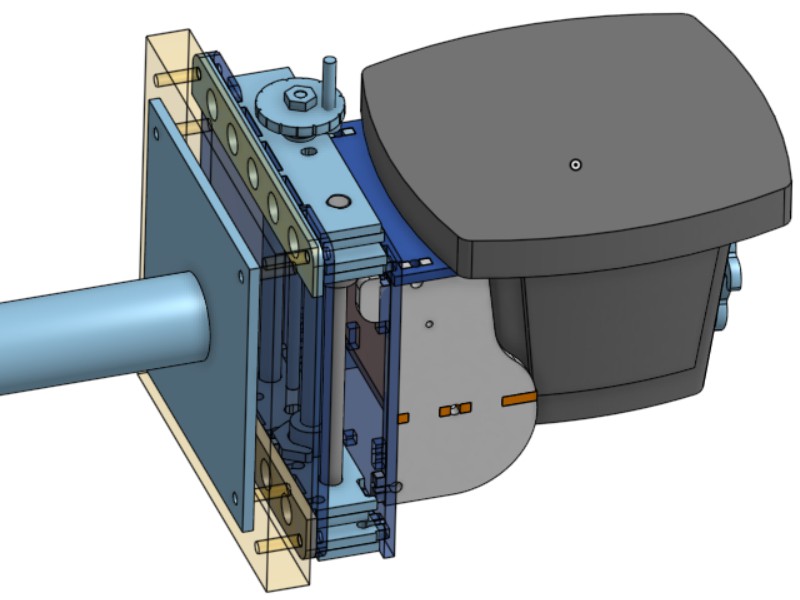

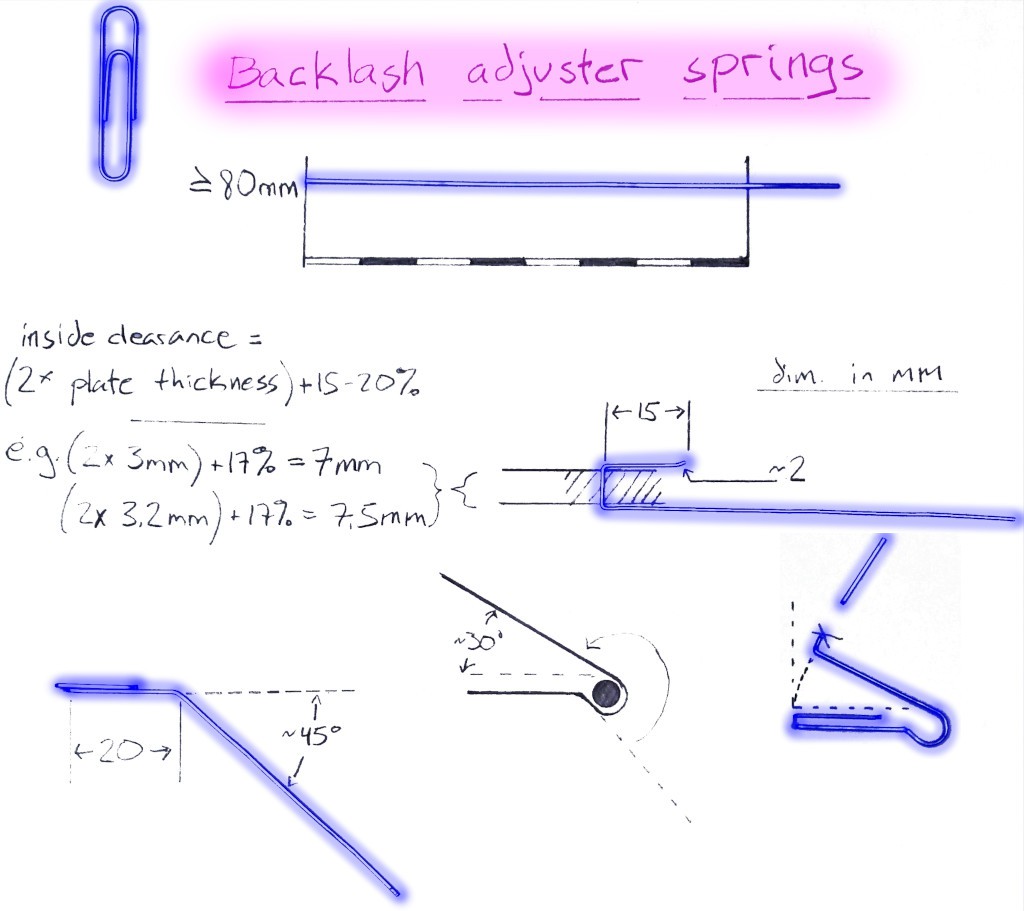

The CAD model is configurable for:

- material thickness

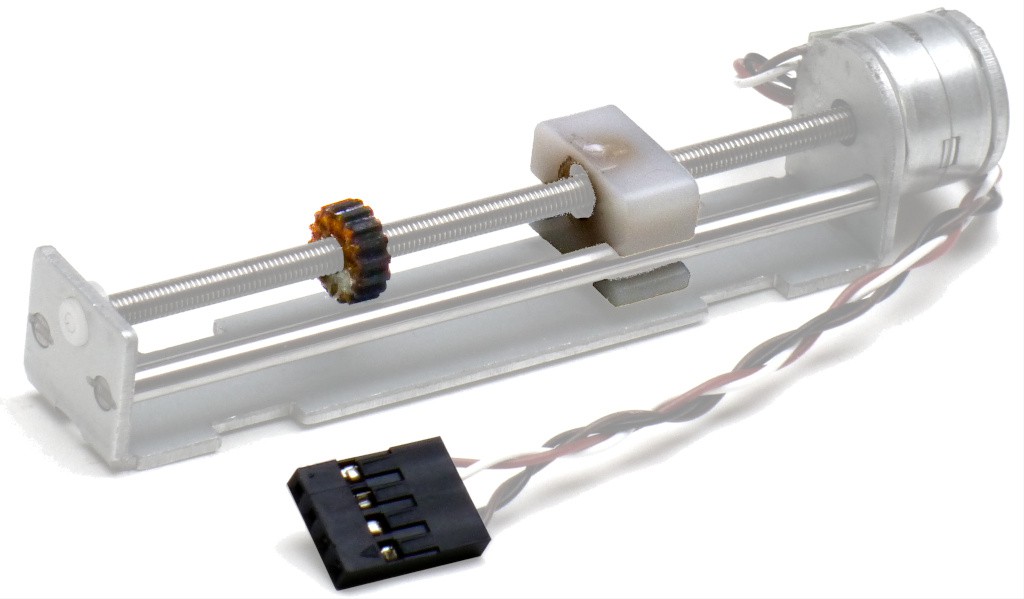

- handwheel or stepper drive

- driving/driven side

- application option, selectable for each side:

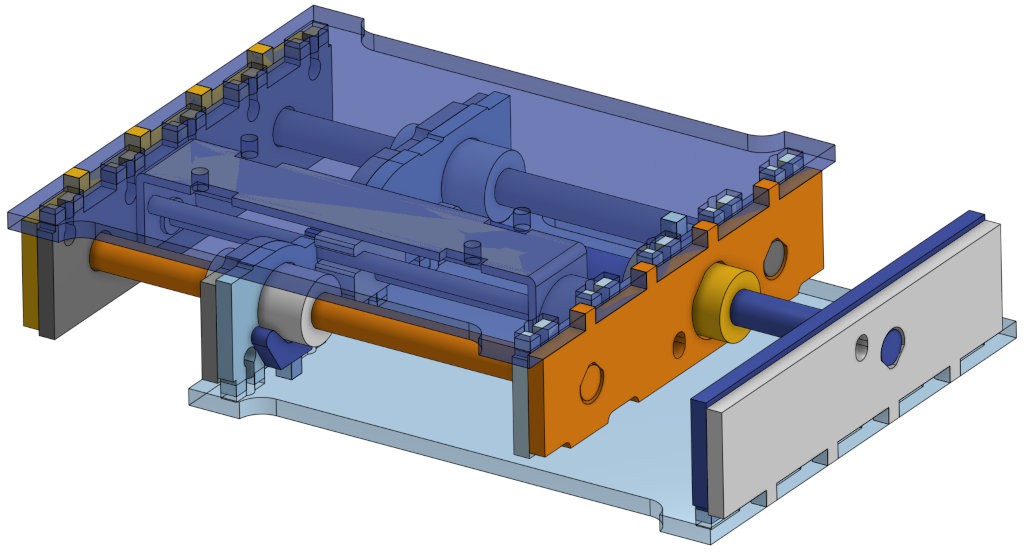

A couple of example configurations:

handwheel drive • heavy load configuration

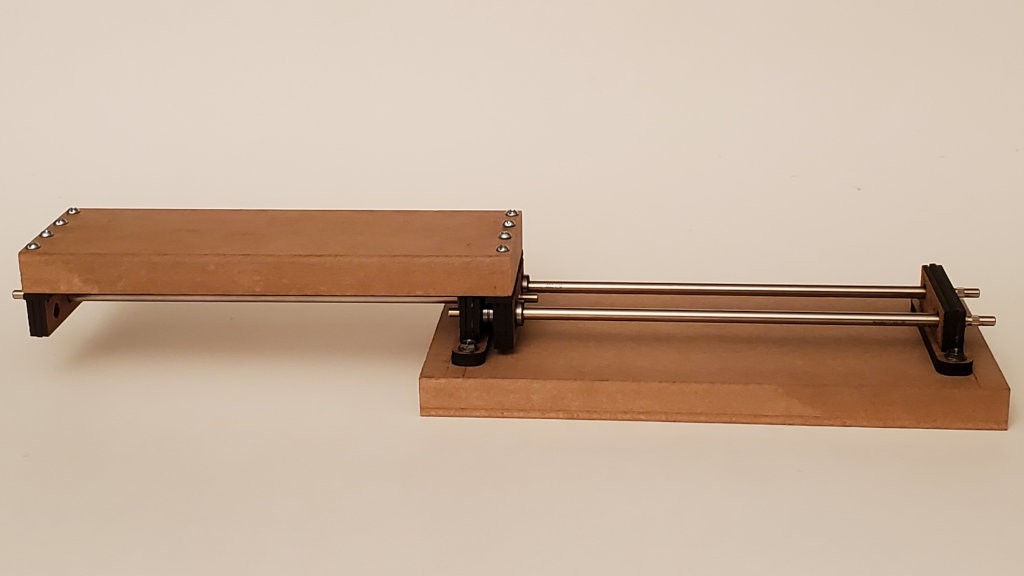

stepper motor drive • fixed point-of-action configuration

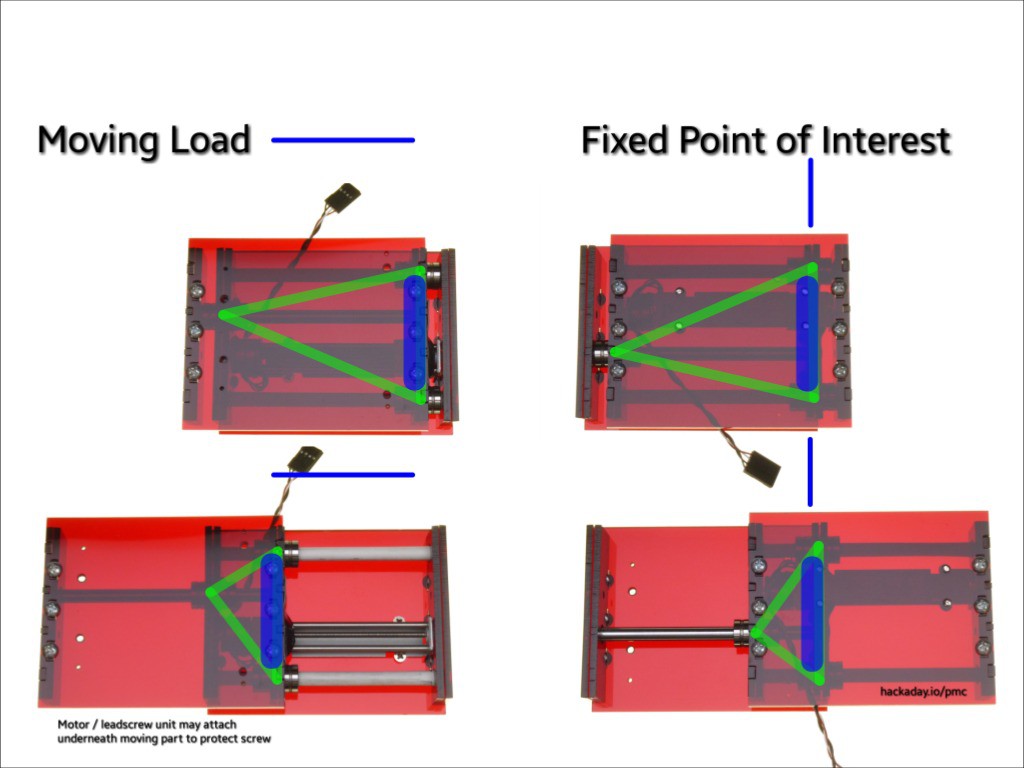

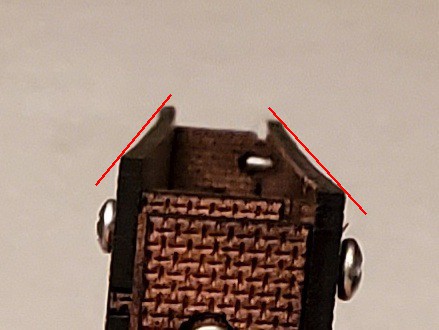

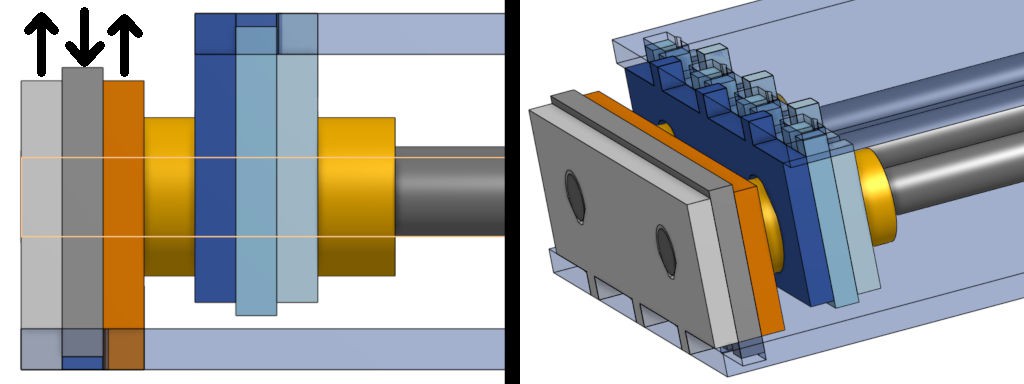

The moving load/fixed PoI distinction illustrated:

Where this comes from, and i̶s̶ slowly g̶e̶t̶t̶i̶n̶g̶ got back to:

#Minamil: a minimal CNC mill. And friends.

But HaD.io projects can include instructions...

Why send traffic elsewhere instead of writing instructions here in sunny HaD? Because the longish 'ible was a mess until it was done and I didn't find how to save unpublished instructions-in-progress here.

Paul McClay

Paul McClay

Ted

Ted

Pretty cool design with the extending table, I have never seen that before. It surely has some drawbacks, but it solves the problem of linear slides wasting lots of space.