(update: counterweight delete)

CNC Kitchen video - thanks Stefan!

Even though the Minamil is minimalistic, the part quality Paul can achieve with it blew me away!

Hackaday.com writeup - thanks Bryan Cockfield!

Hackaday Podcast 136 - thank you @Mike Szczys & @Elliot Williams for the kind comments!

"I'm frankly shocked by the quality of the parts coming out of this" 11:54

Hackaday Prize 2021 finalist! - thank you judges!

(mocking the style of over-hyped package labeling, in case that got lost in translation)

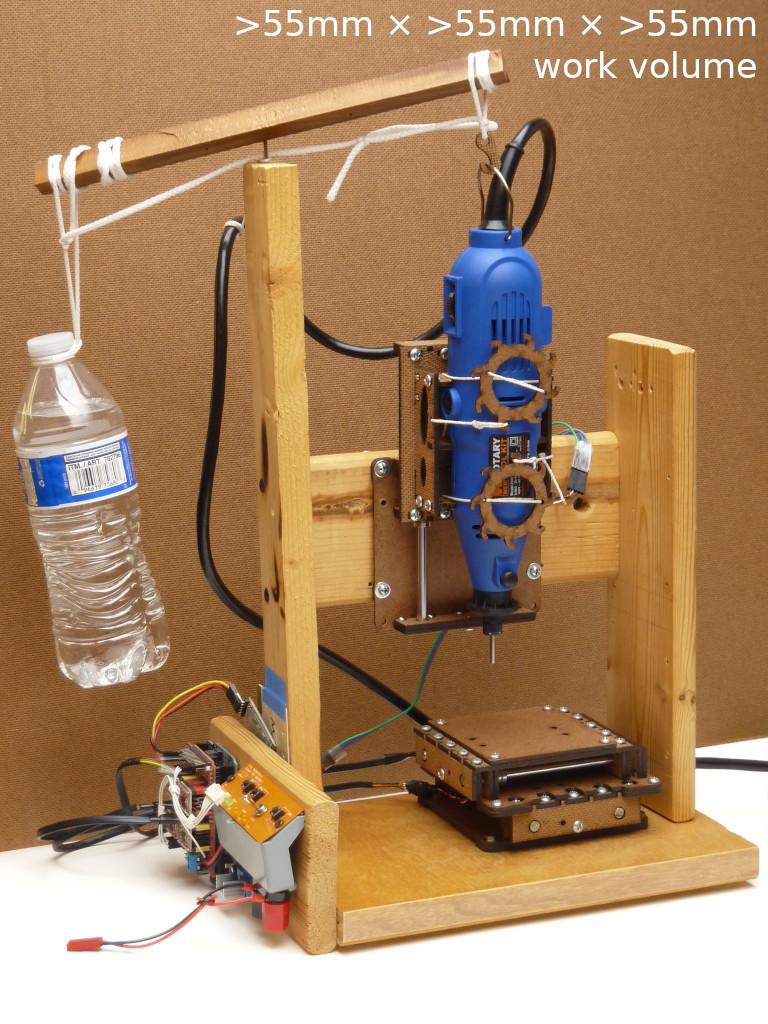

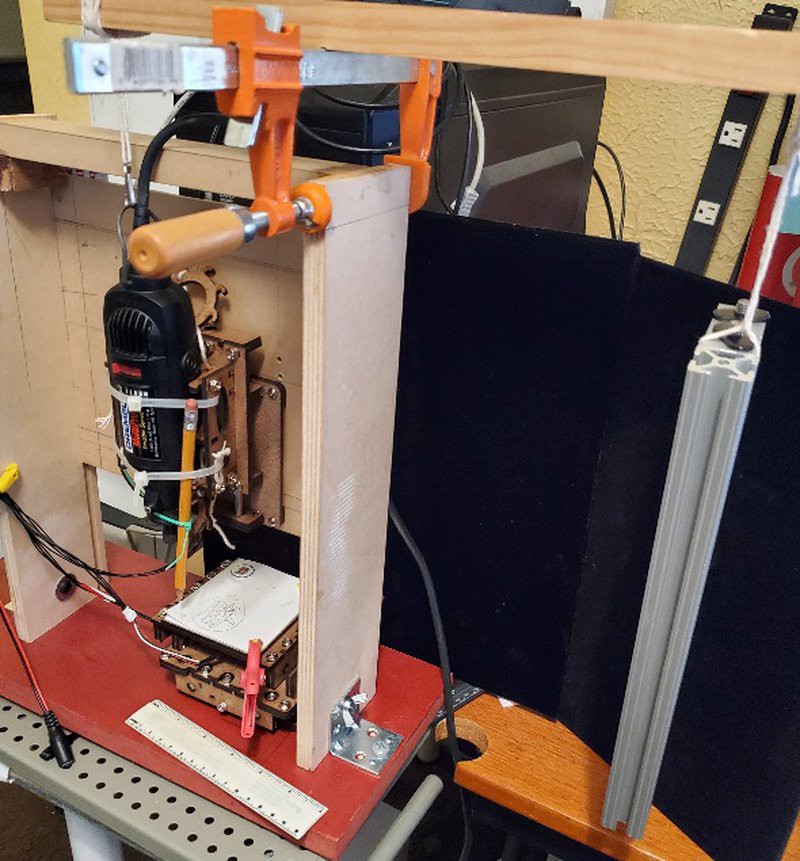

Many of the photos and videos here show a big counterweight rigged off the side of the little machine. But nevermind. That's now "legacy product". Because the new Z axis does better with less. Yay for maximizing minimality!

This little CNC mill works well enough to produce an eye-candy demo video:

(that's a "new" (June 2022) demo vid; here's the first eye candy demo)

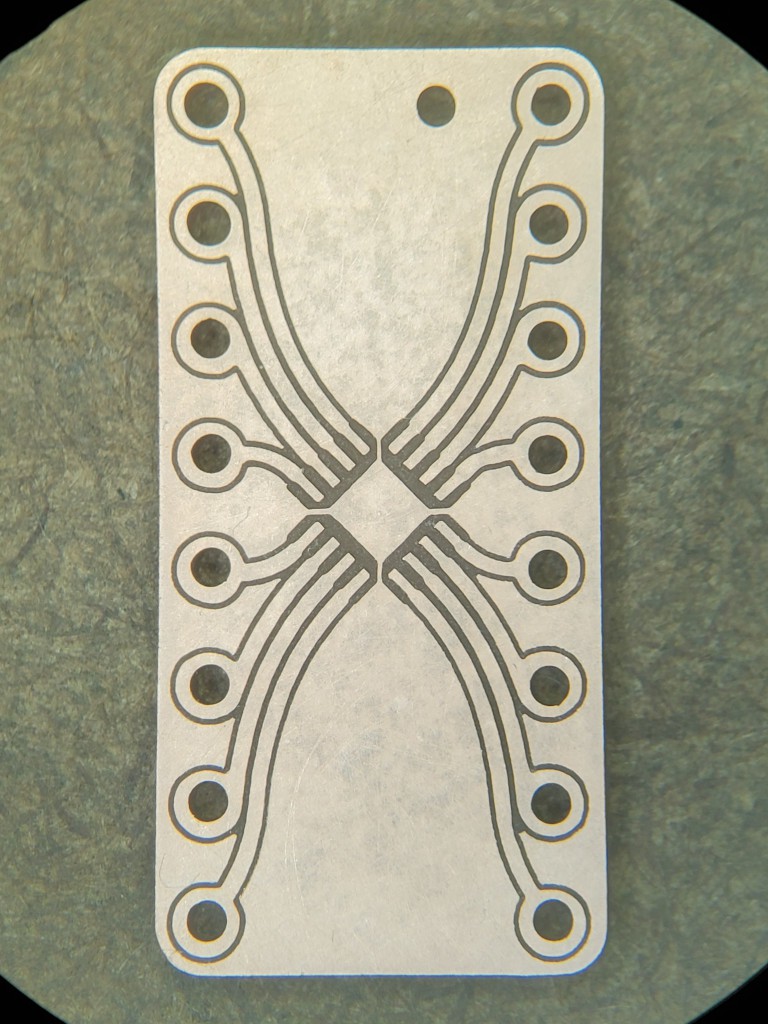

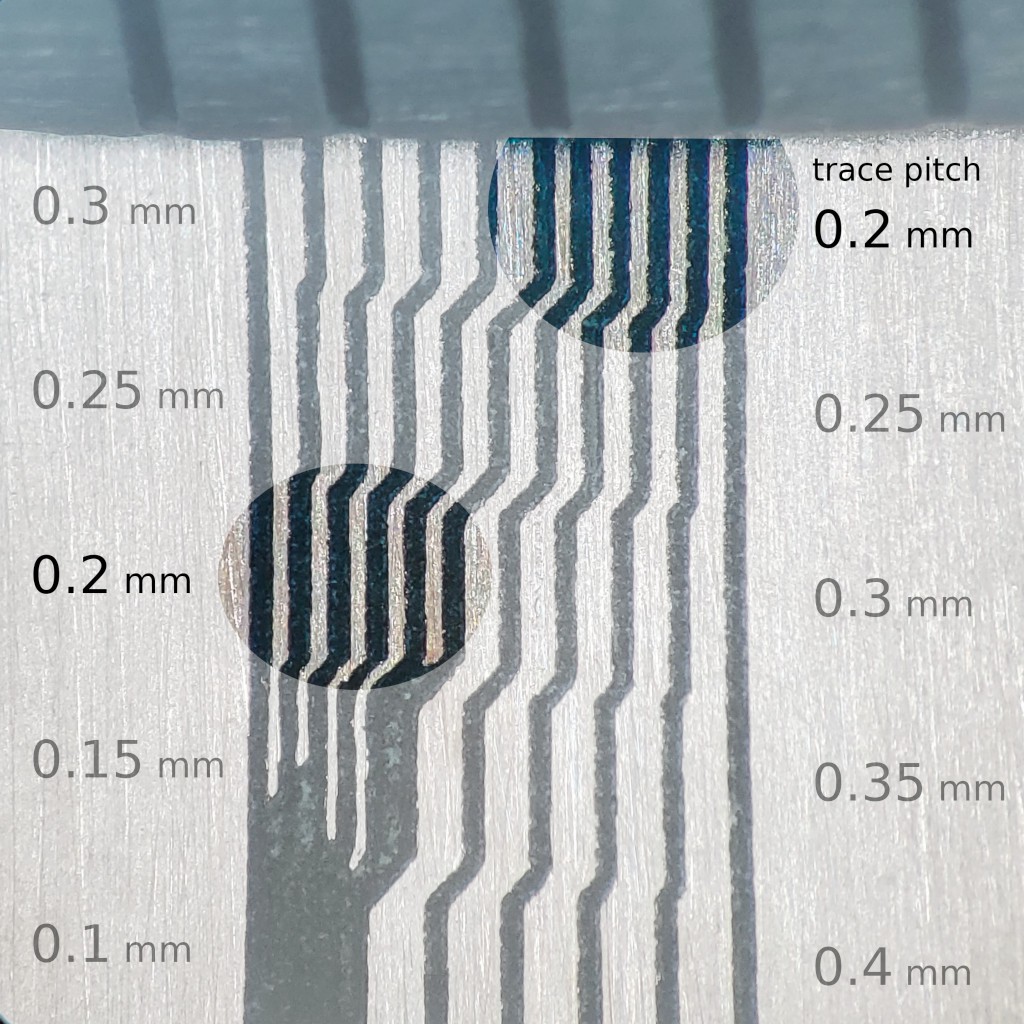

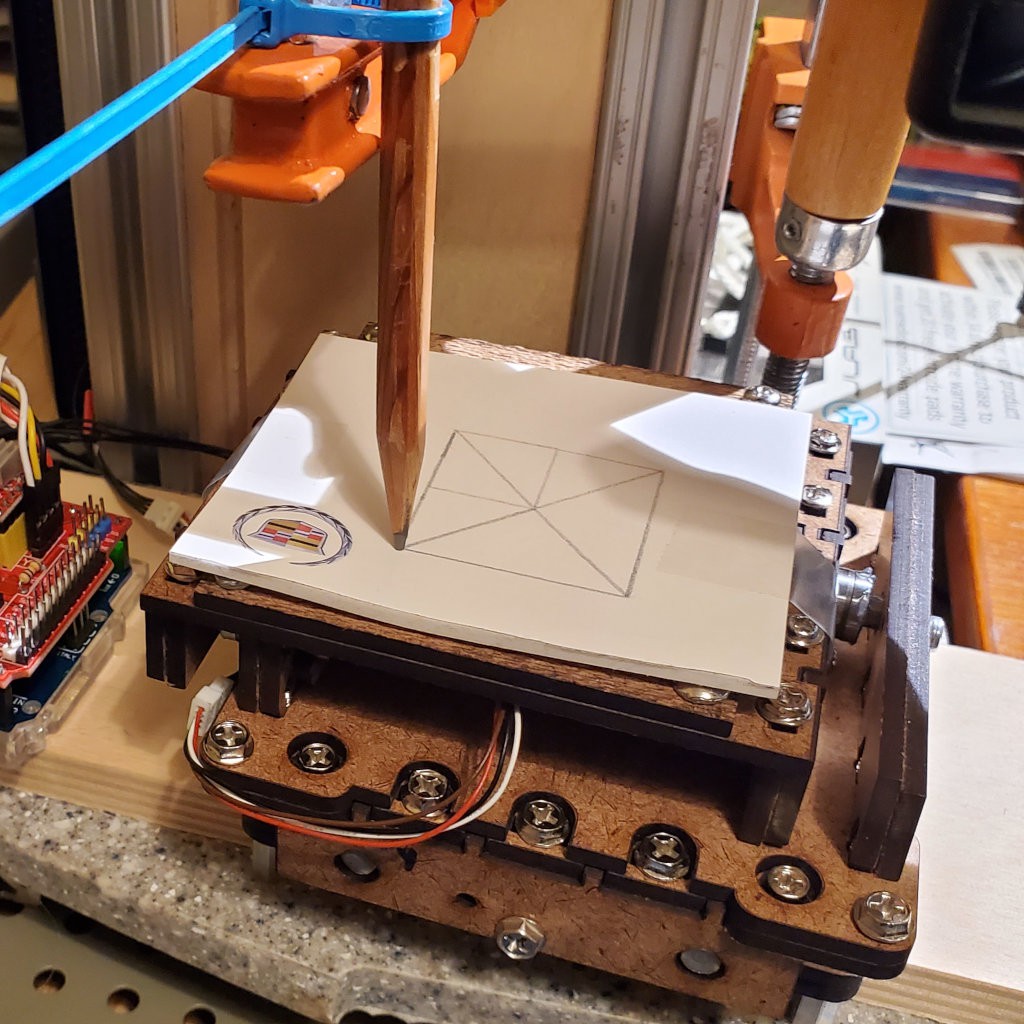

...and mill fine-pitch circuit board traces:

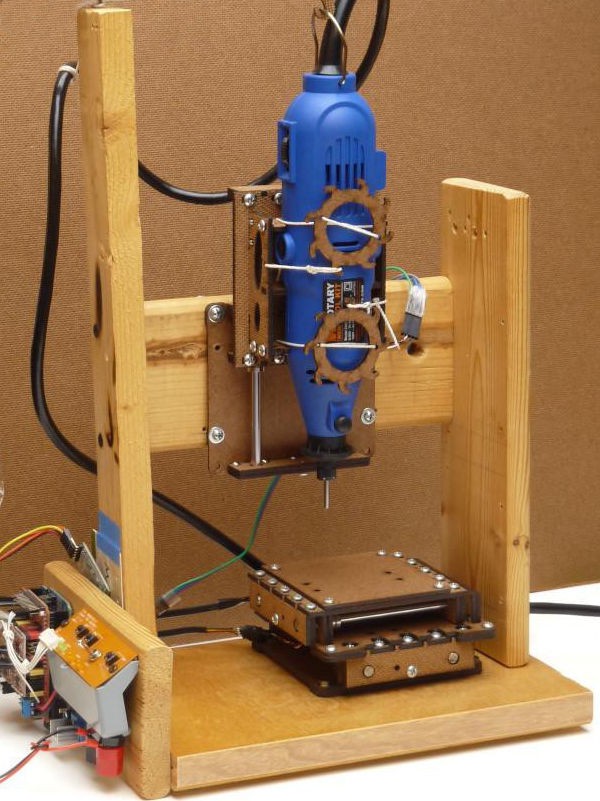

What little CNC mill?

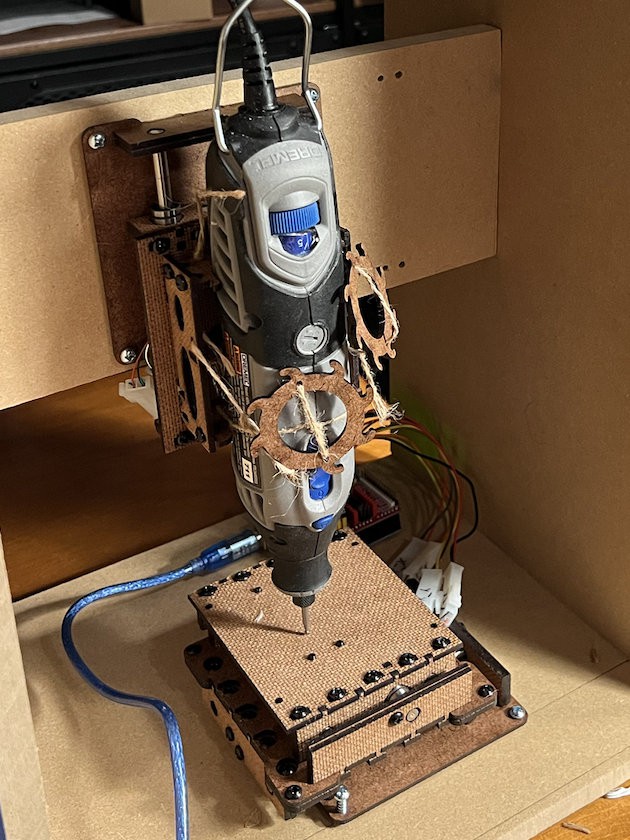

Minamil: a minimal CNC mill

First there was #CDCNC, a highly-constrained just-barely-functional one-off toy built by improvisation with found junk and simple tools.

Here I'm developing an idea that came from thinking about whether or not there is any space between a dumb stunt like CDCNC and a commercially (i.e. efficiently) produced entry level CNC mill/router. Early results seem encouraging.

In contrast to CDCNC, this is about reproducibility from a simple BoM, economical access to laser cutting, and instructions for building your own sub-mini CNC mill.

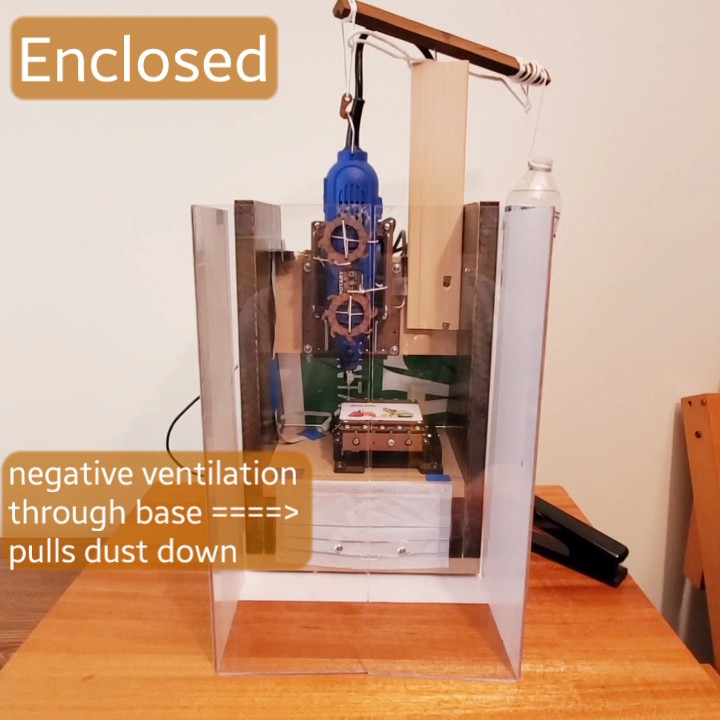

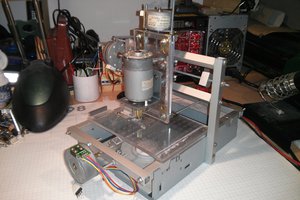

Next there may be #"Desk Accessory" CNC Milling Machine. For progress in that direction, with not much more effort in the frame+enclosure department:

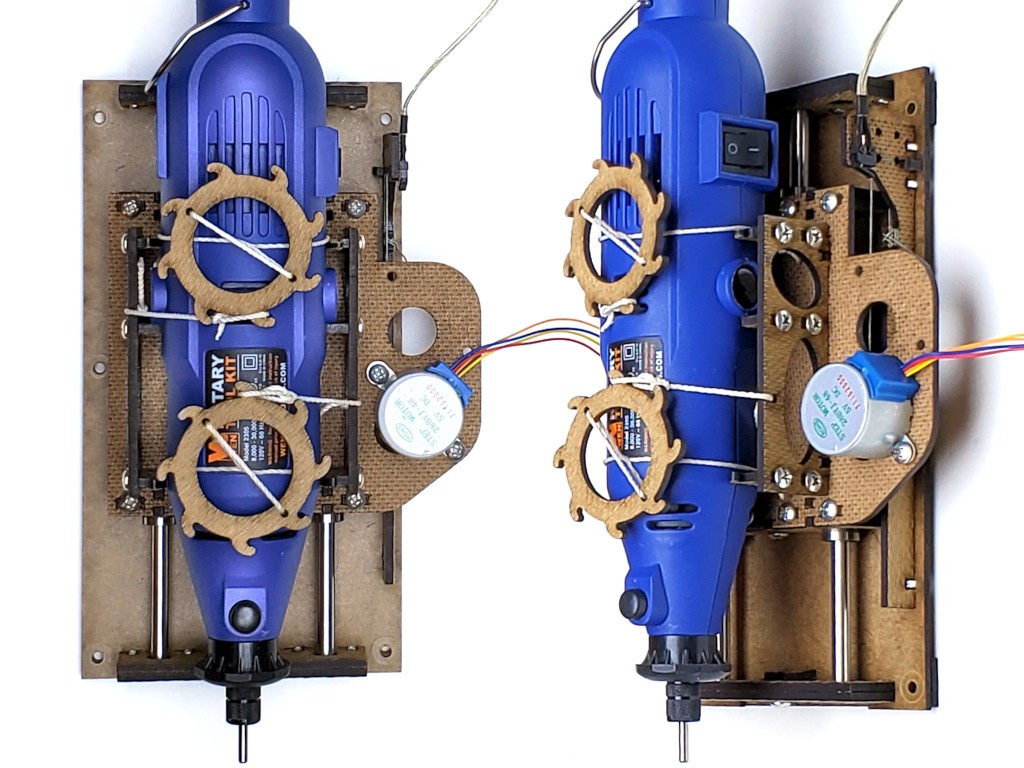

(different Z axis in those two pics - part of [what used to be but isn't anymore] the not-quite-so-minimal "and friends" part of the project title that I haven't written much about yet)

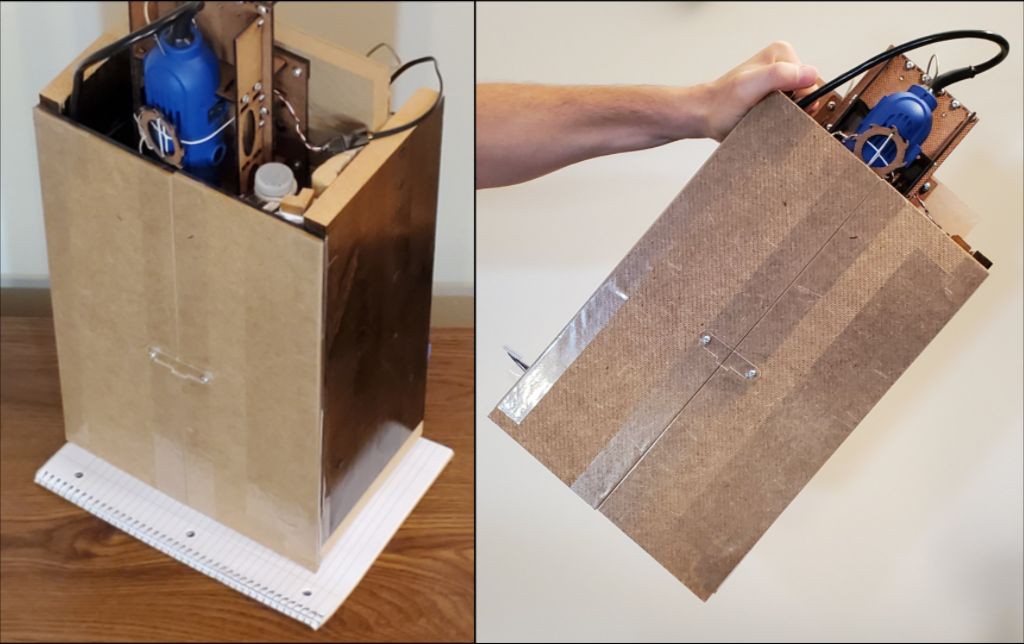

Telescoping axes allow the enclosure to fold up smaller when parked and expand for operation:

Selected Log Entries

- Build!

- Parts source / cost notes

- milling PCB (so... MCB?)

- milling aluminum

- material removal rate (MRR) in acrylic

- uh oh... unexpected trouble with self-locking leadscrews

- how it works (could use some updates re later learning)

- compact & convenient packaging

- building blocks: the slide sub-project

- trying intentional interference -- which has worked so far

- first assembly (the eye-candy video)

- first part

- first try with XY & Z

- HaDPrize 2021 Challenge 3: not selected 😞

- HaDPrize 2021 Challenge 5: selected 🙂

Paul McClay

Paul McClay

charliex

charliex

Stefan Lochbrunner

Stefan Lochbrunner

Hahah... The 'faux' ad, and I 'm thinking 'counterweight' ? And then I see the counterweight. Made me laugh, thank you.