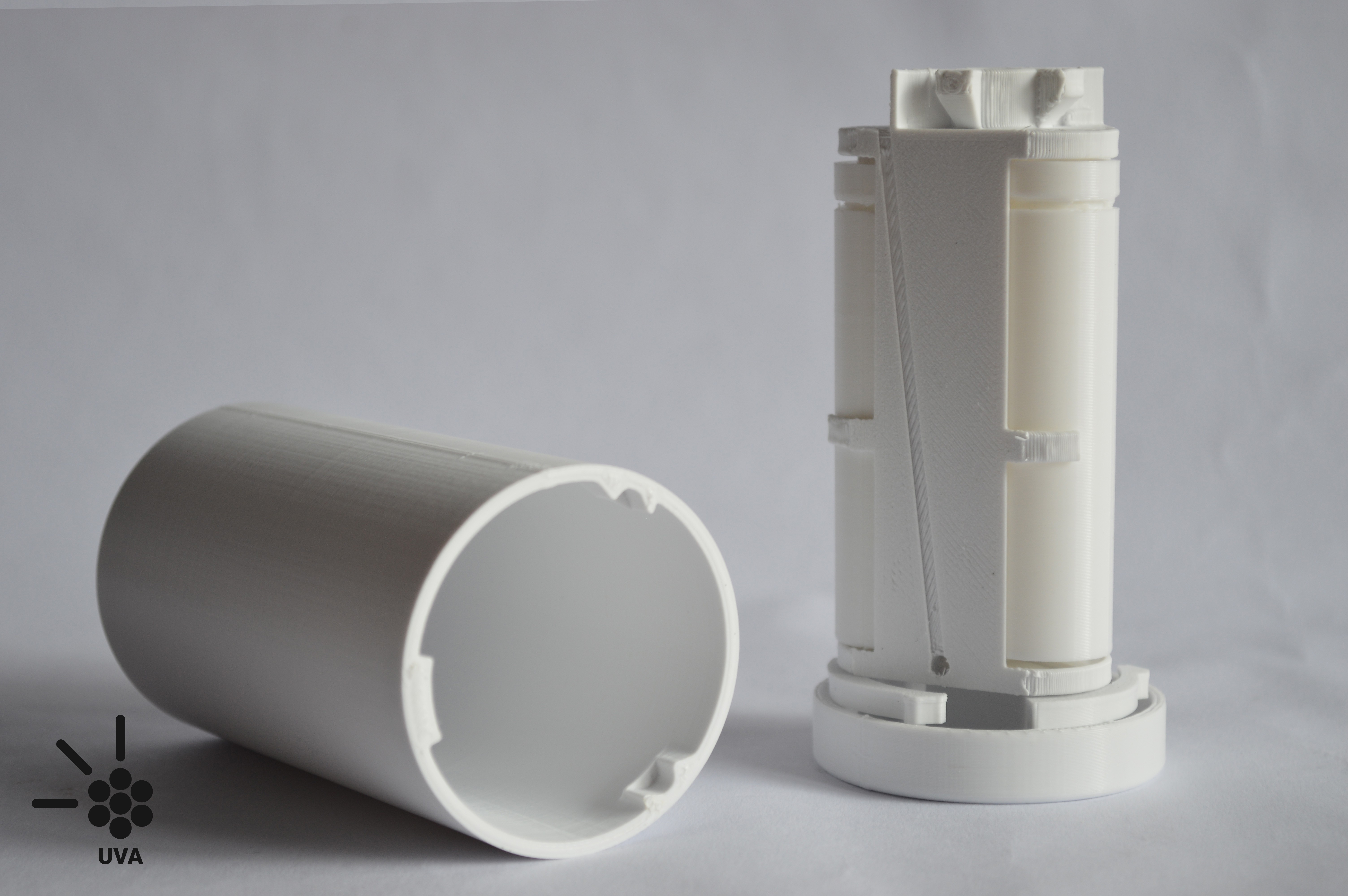

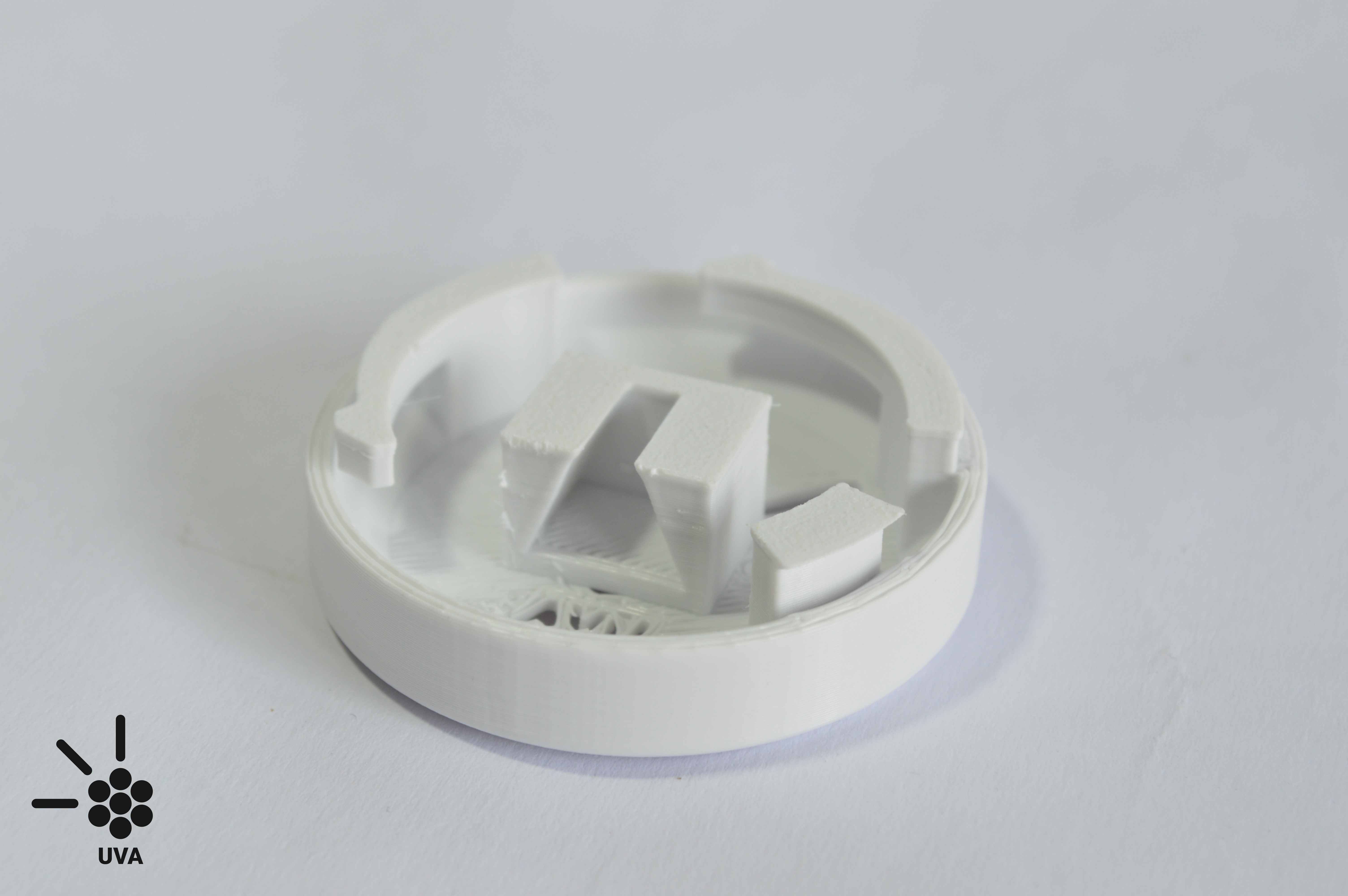

Fabrication and Assembly Manuals:

FABRICATION and ASSEMBLY MANUAL

Source Code and Fabrication Files:

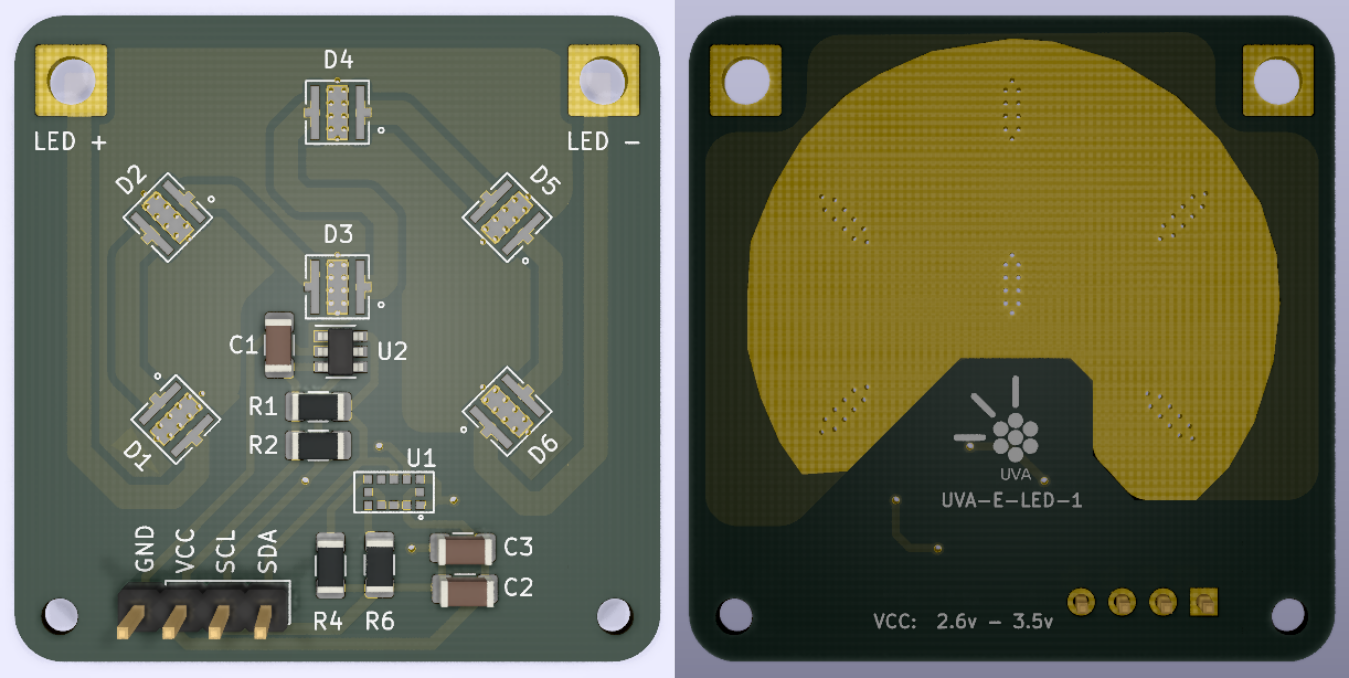

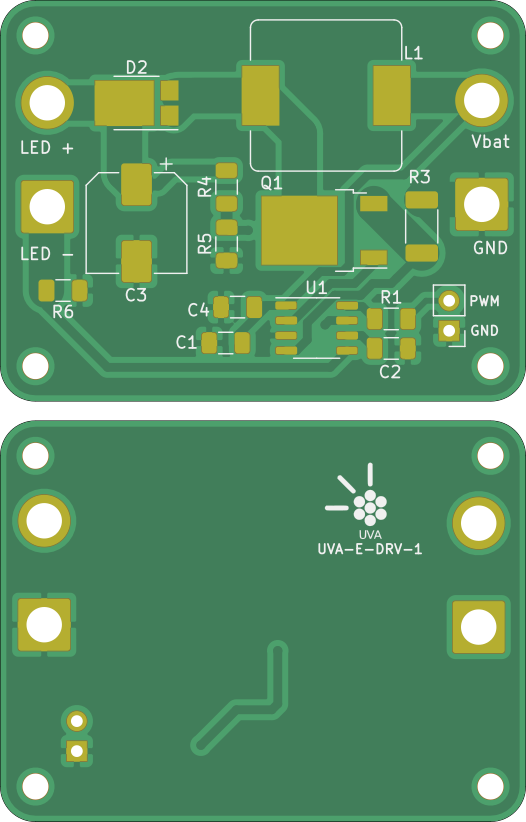

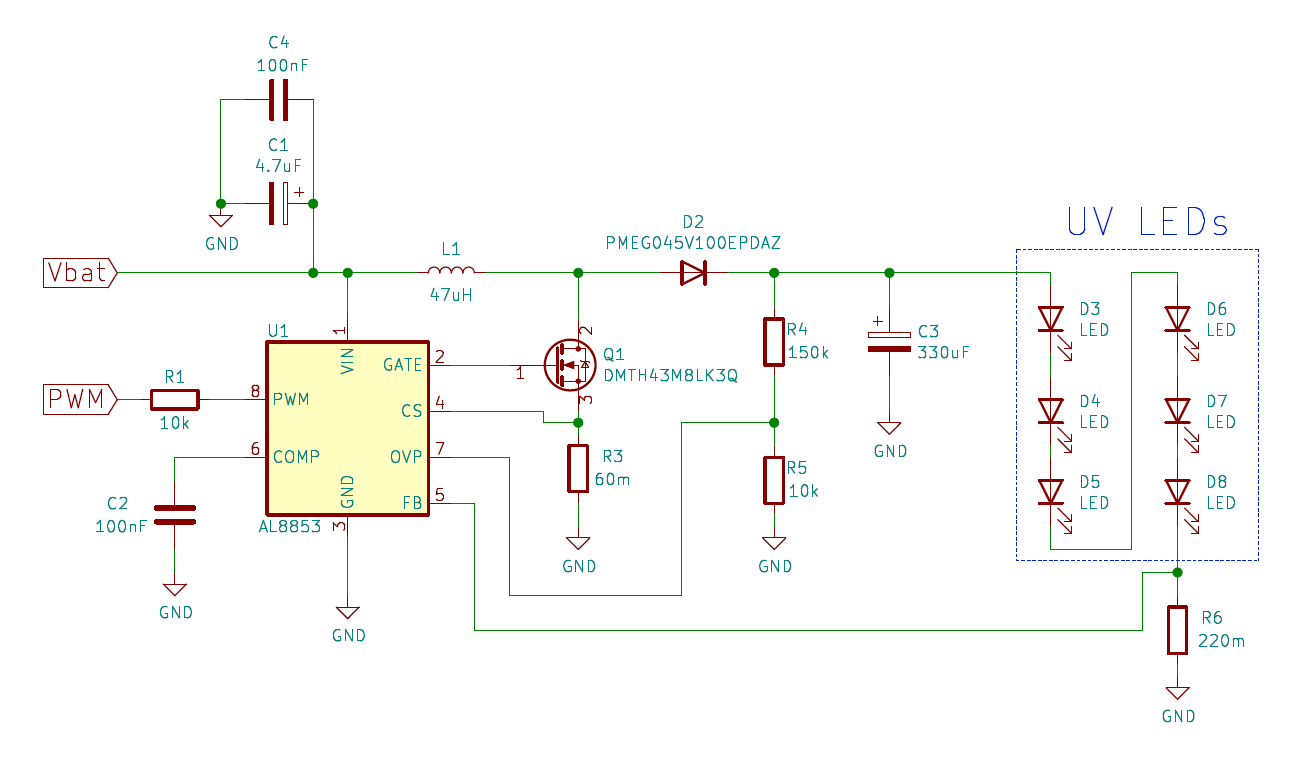

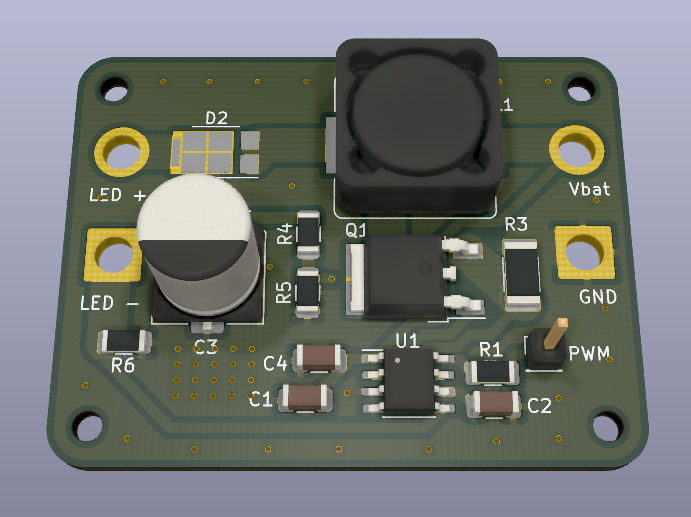

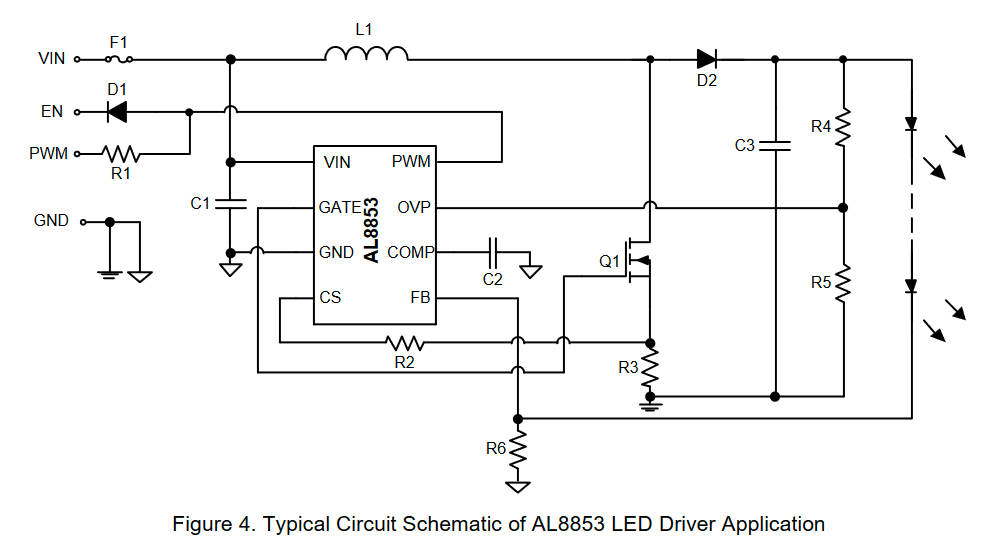

https://github.com/SaidAlvarado/UVA---High-power-ultraviolet-flashlight

Risk assessment Report:

UVA Project - Risk Analysis Report - English Version

UVA Project - Risk Analysis Report - Spanish Version

Licenses

All the hardware components of this project are licensed under a Creative Commons license

UVA by Said Alvarado, Miguel Fernandez is licensed under a Creative Commons Attribution 4.0 International License.

All the firmware of he project is licensed under the MIT license.

Copyright © 2020 Said Alvarado and Miguel Fernandez

Permission is hereby granted, free of charge, to any person obtaining a copy of this software and associated documentation files (the “Software”), to deal in the Software without restriction, including without limitation the rights to use, copy, modify, merge, publish, distribute, sublicense, and/or sell copies of the Software, and to permit persons to whom the Software is furnished to do so, subject to the following conditions:

The above copyright notice and this permission notice shall be included in all copies or substantial portions of the Software.

THE SOFTWARE IS PROVIDED “AS IS”, WITHOUT WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO THE WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND NONINFRINGEMENT. IN NO EVENT SHALL THE AUTHORS OR COPYRIGHT HOLDERS BE LIABLE FOR ANY CLAIM, DAMAGES OR OTHER LIABILITY, WHETHER IN AN ACTION OF CONTRACT, TORT OR OTHERWISE, ARISING FROM, OUT OF OR IN CONNECTION WITH THE SOFTWARE OR THE USE OR OTHER DEALINGS IN THE SOFTWARE.

Said Alvarado Marin

Said Alvarado Marin

Jakub Kaderka

Jakub Kaderka

Gorky

Gorky

Scott Clandinin

Scott Clandinin

Jana Marie

Jana Marie

Big fan of the Risk Analysis Report. It has been fun to watch project progress.