Summary

Last year I designed the first iteration of an open source computed tomography (CT) scanner. It was a lot of fun to design, having many atypical design problems in it, from the mechanical design of the rotary gantry to pairing an appropriate radioisotope source with a modified extra-sensitive radiation sensor. Something about it being essentially a radioactive desktop Stargate that lets you see inside of things also seems to get people very excited, and so I've received an eclectic bunch of e-mails asking about the scanner from folks as diverse as radiology professors and biomedical folks to makers to those hoping I'd open up Dr. Jansen's back-alley CT scans to have a look at some strange bump they have (please go see your doctor!).

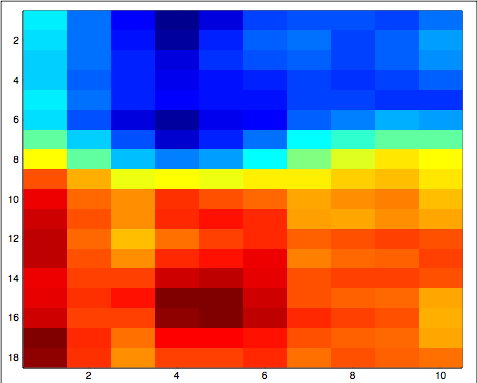

But I feel that for all the excitement, to quote Feynman, that first open CT design feels a bit like a dog that walks on two legs — it's not that it does it well, it's that it does it at all that gets people excited. It's essentially a working model of the first generation of CT scanners, but with a much weaker source, and so it takes a very long time to get even a single slice of an image. I've been wondering what it would take to move the idea of a desktop CT scanner from a proof of concept into something that does the job well, or at least substantially better.

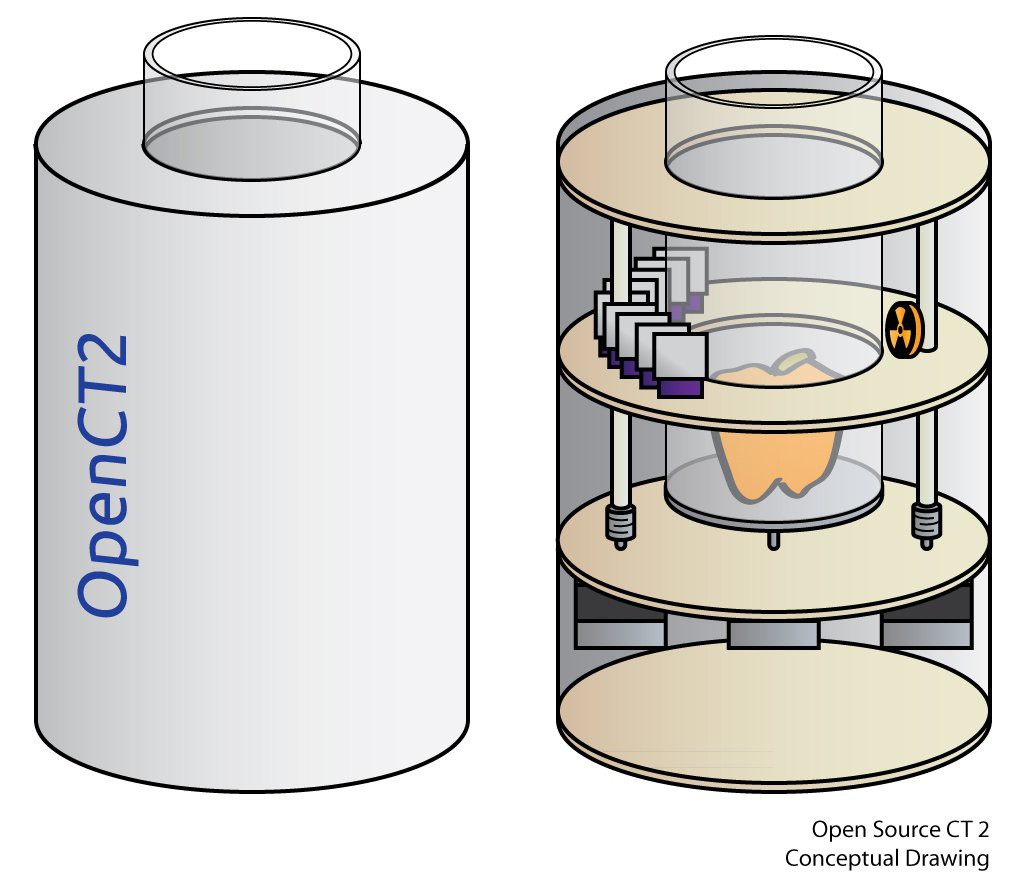

OpenCT2

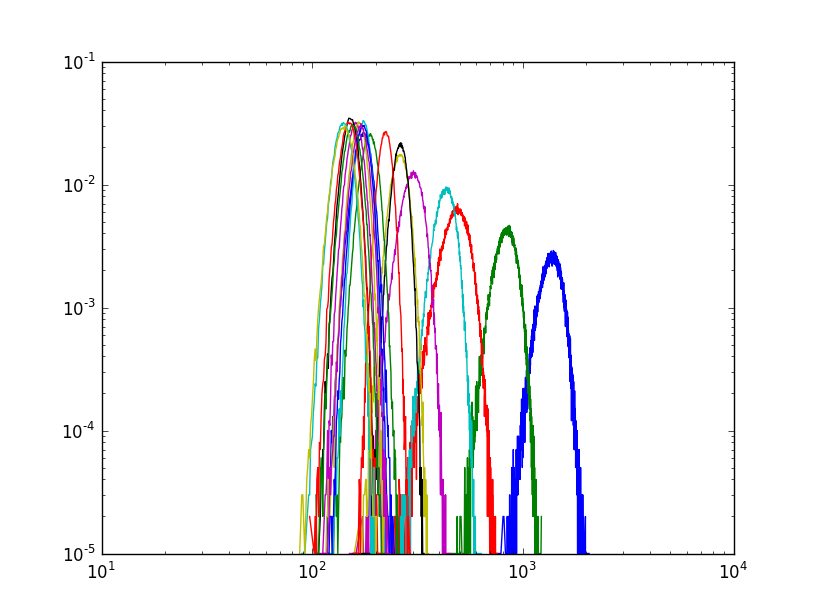

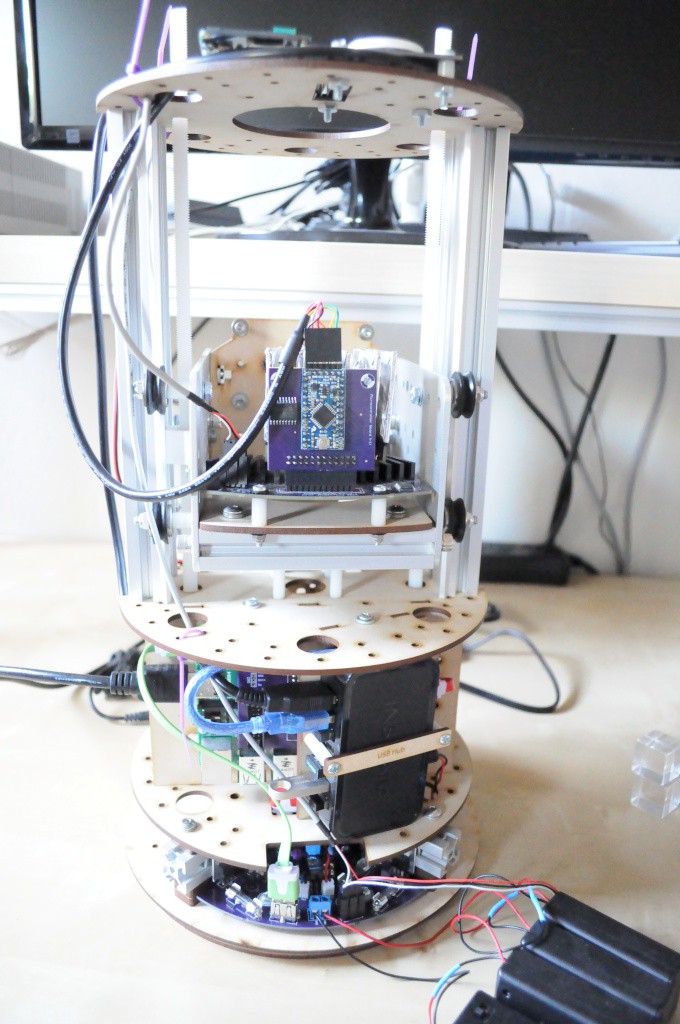

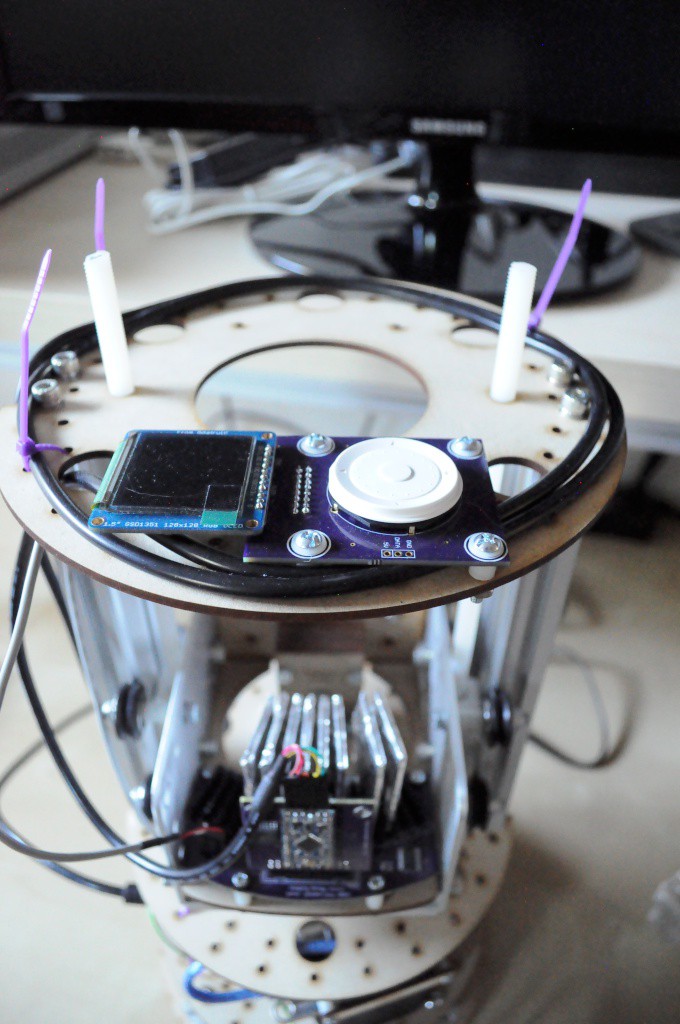

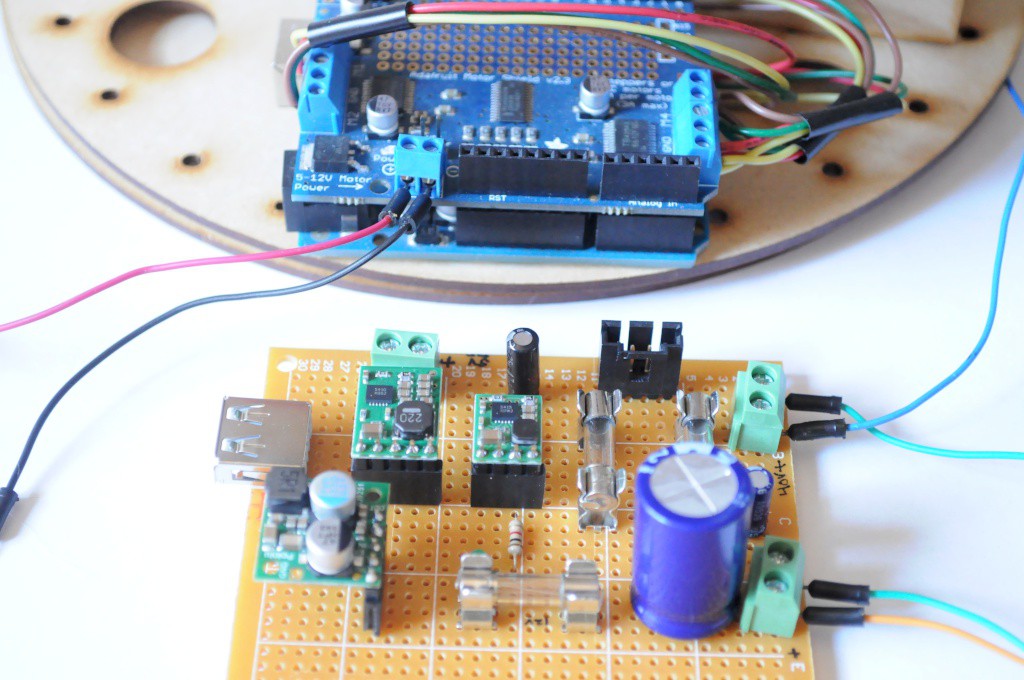

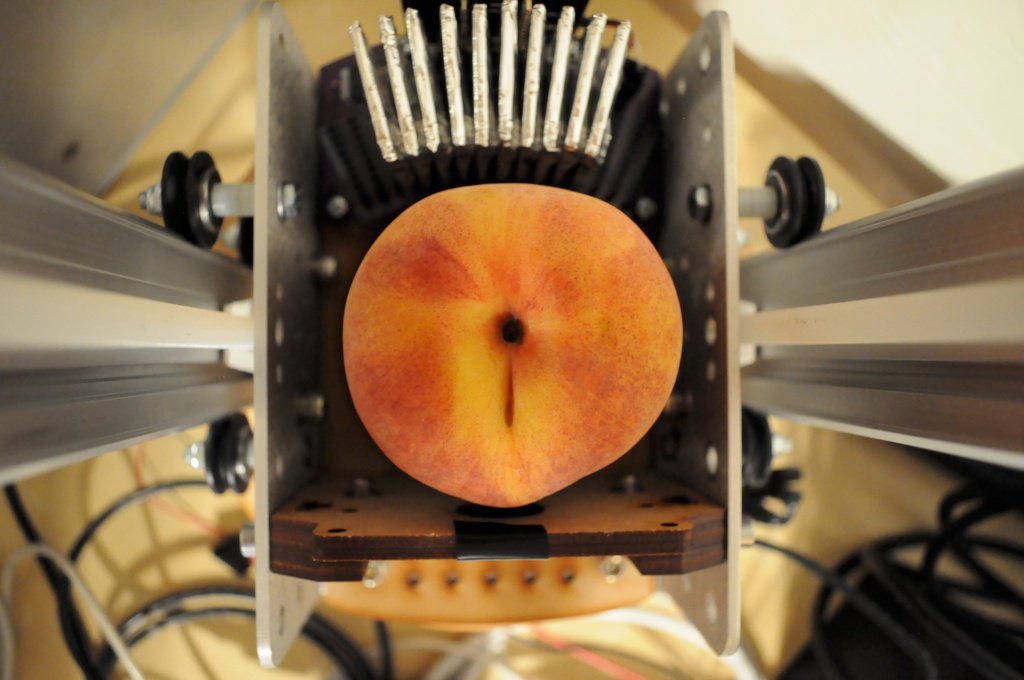

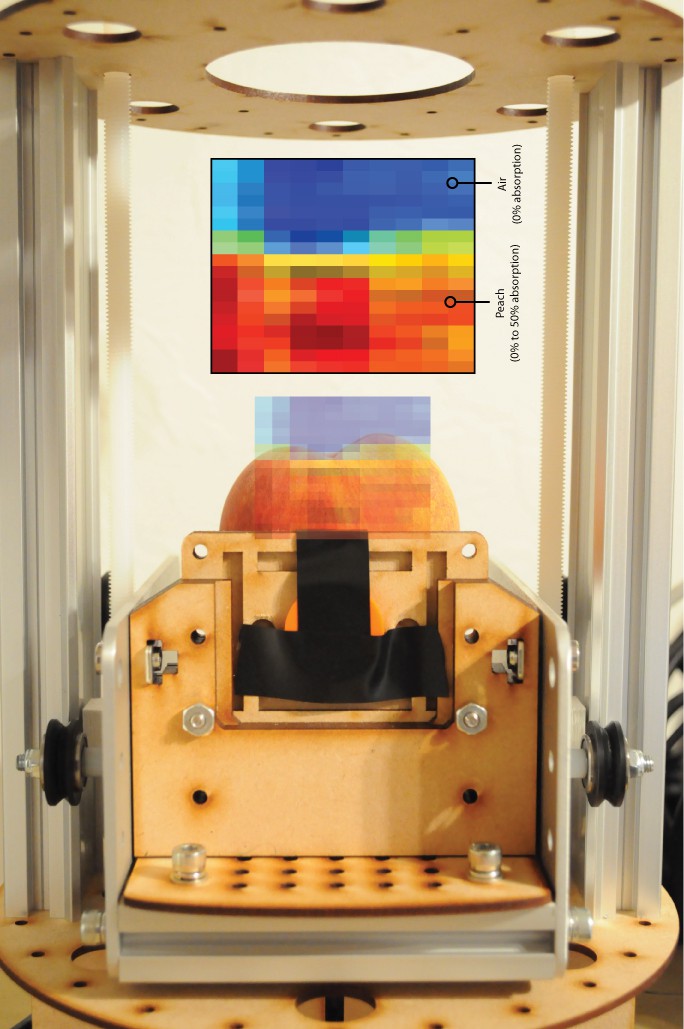

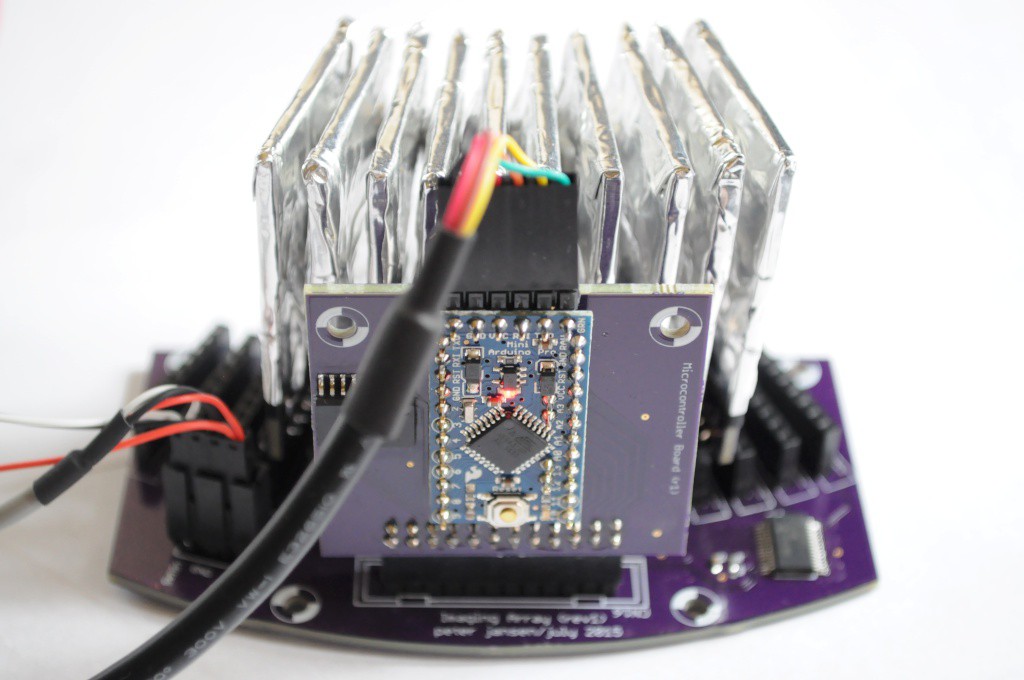

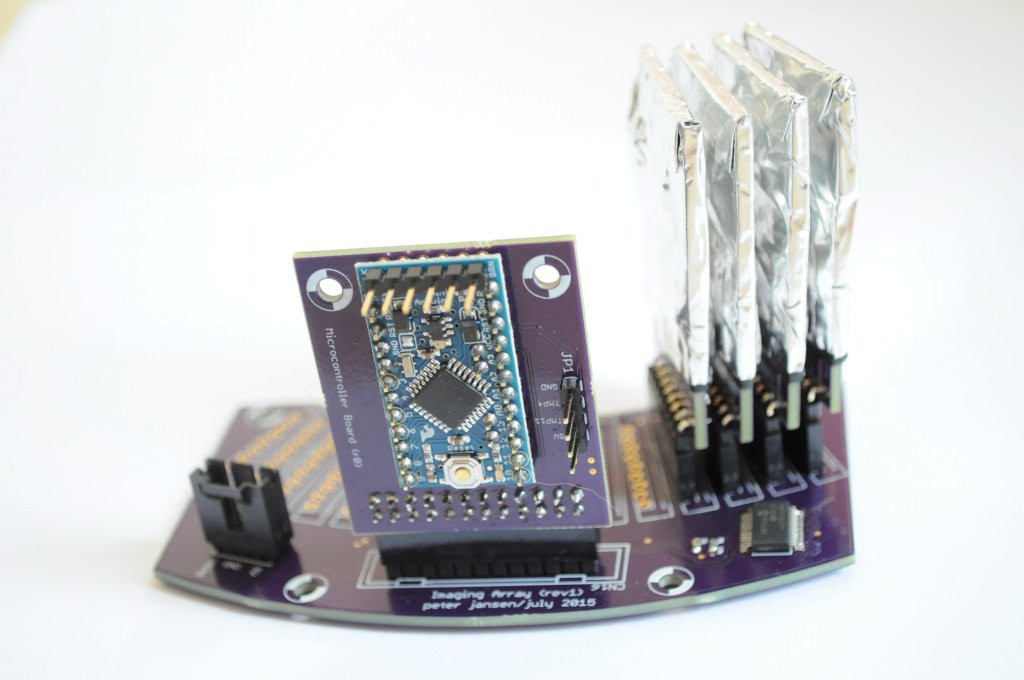

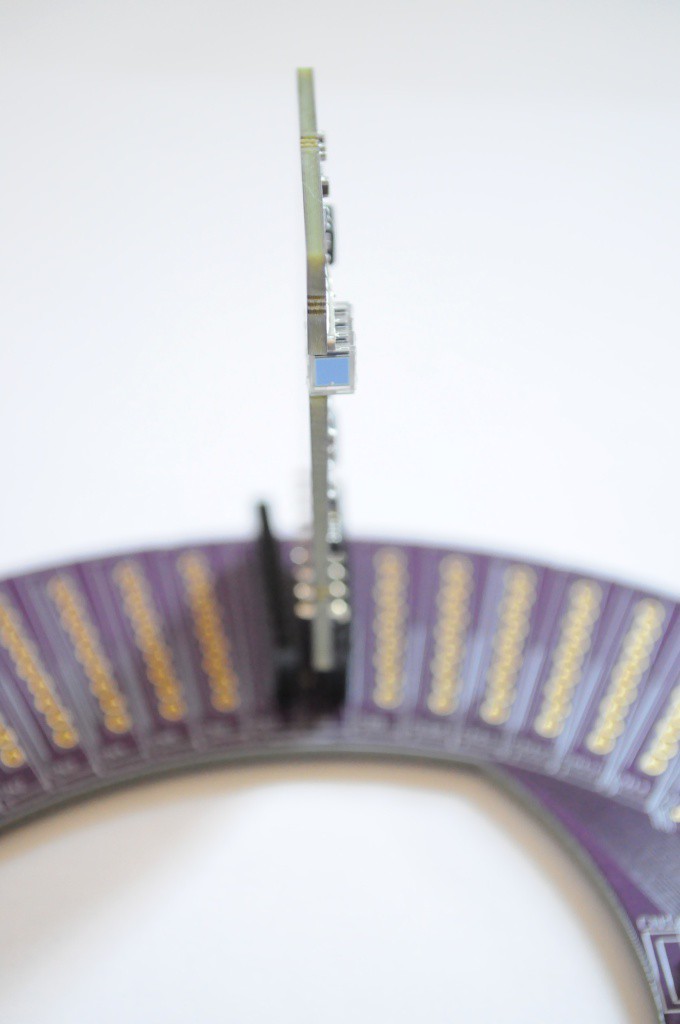

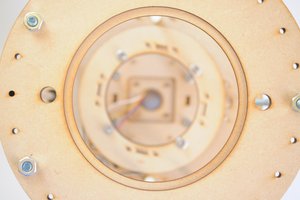

The OpenCT2 is my attempt to move the design much closer to the tomographic systems in use today, and make a complete third generation desktop CT scanner that uses a large parallel array of detectors. This should decrease the acquisition time substantially, acquiring low-resolution images on the order of an hour, and tomographic scan times on the order of a day.

Design Goals and Constraints

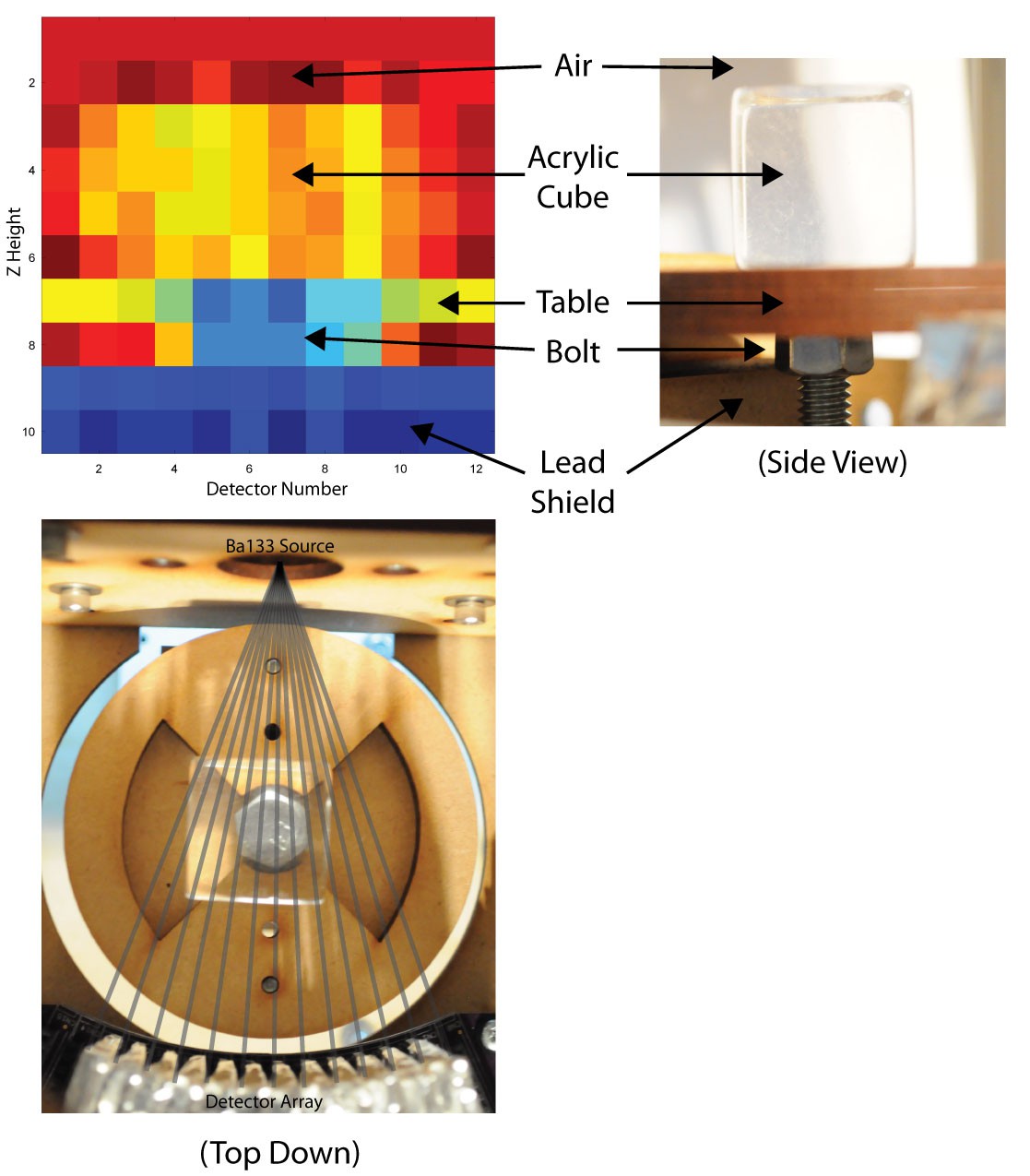

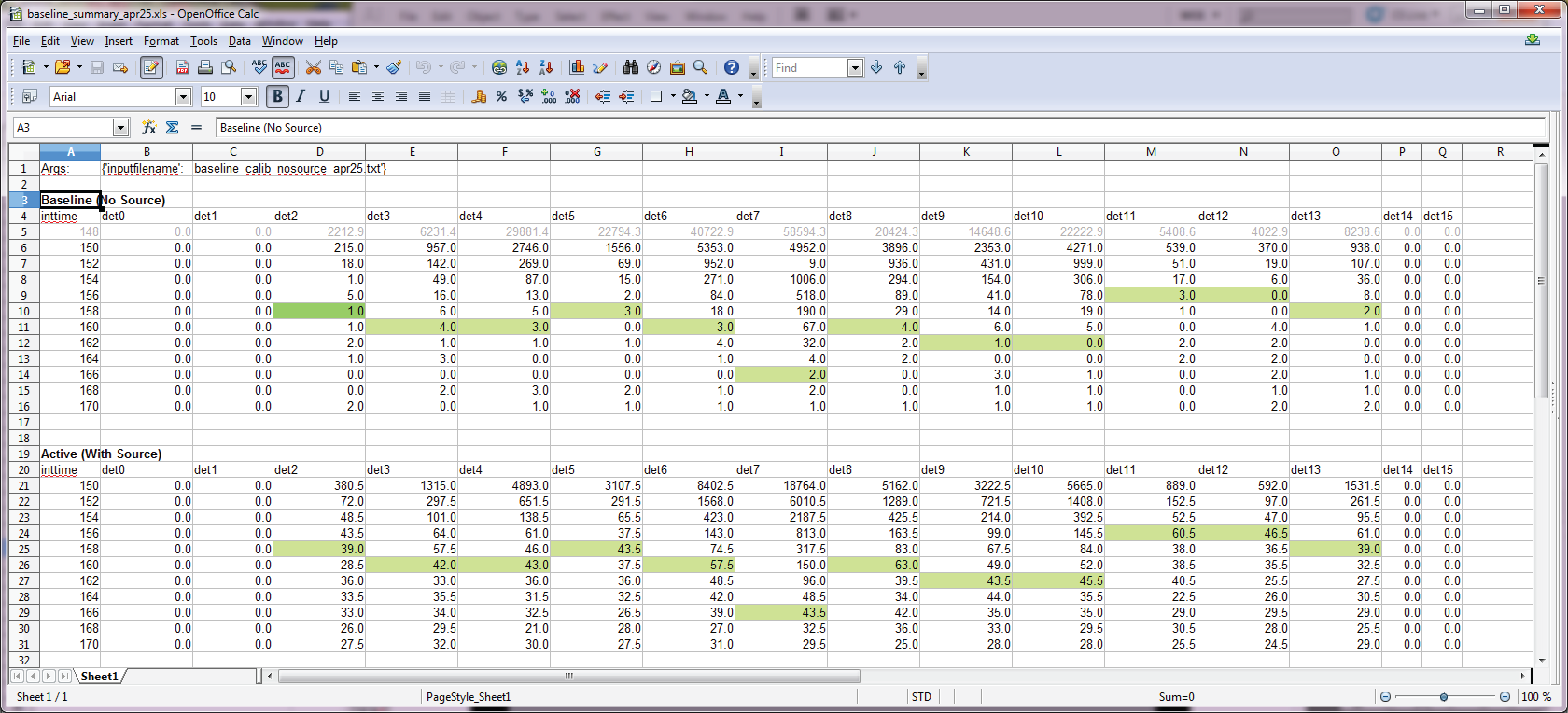

- Extremely low intensity source: Instead of using an x-ray tube, for safety the system is designed to use a low-intensity radioisotope source. The 10uCi Barium-133 source used with this system is the most intense radioisotope source that one can purchase without a license in the US. This constraint makes the design much safer than using an x-ray tube, but it's also the major limiting factor in acquisition time -- because the source is of such a low intensity, the acquisition times are essentially bound by the shot noise associated with photon counting. For those professionals extremely well trained in radiographic safety, with appropriate lab facilities and comfortable modifying open designs, it should in principle be possible to mount a small x-ray tube in the design, decreasing scan times from the order of a day to a few minutes.

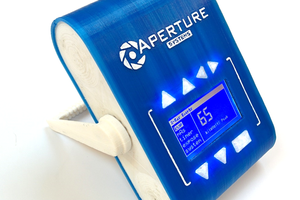

- Compact, and in it for the long haul: The design should be small, self-contained, and attractively fit on the edge of ones desk. The scan times are limited by physics and safety.

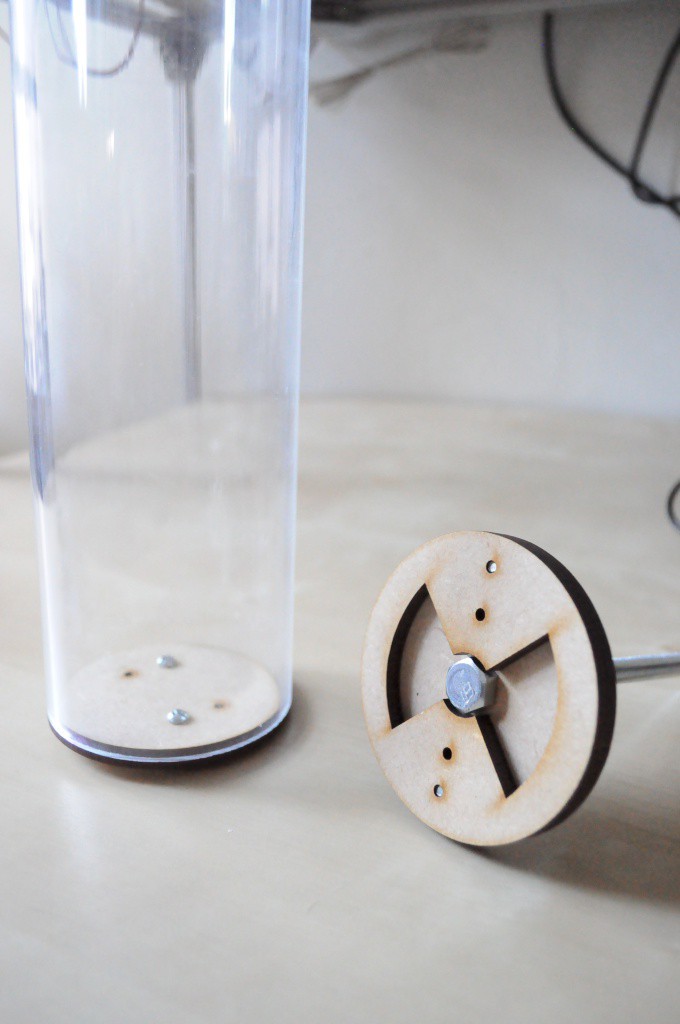

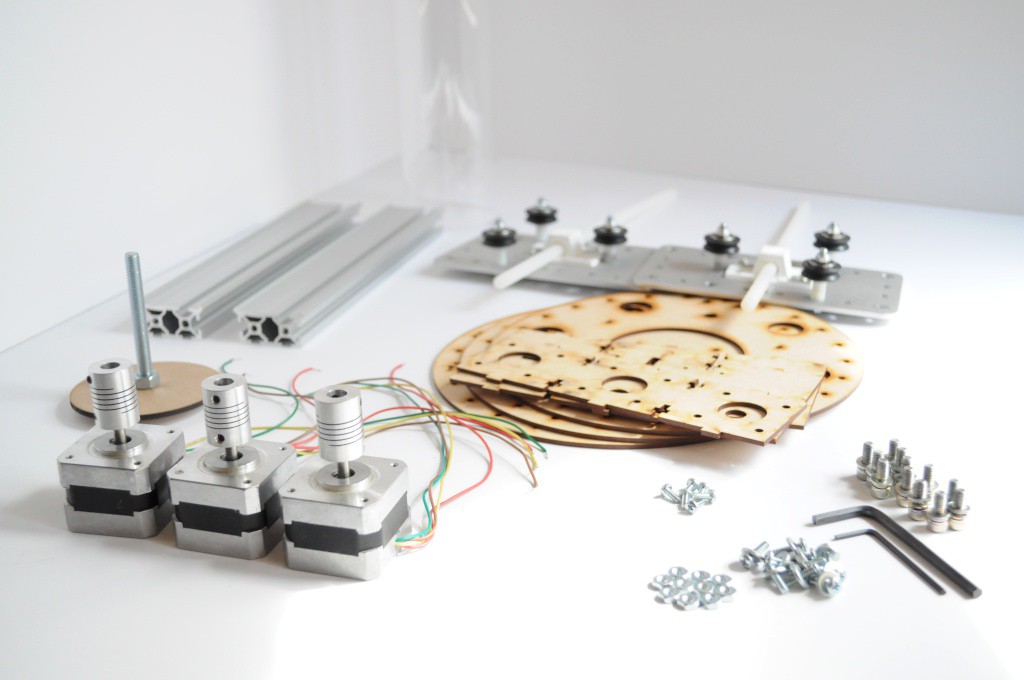

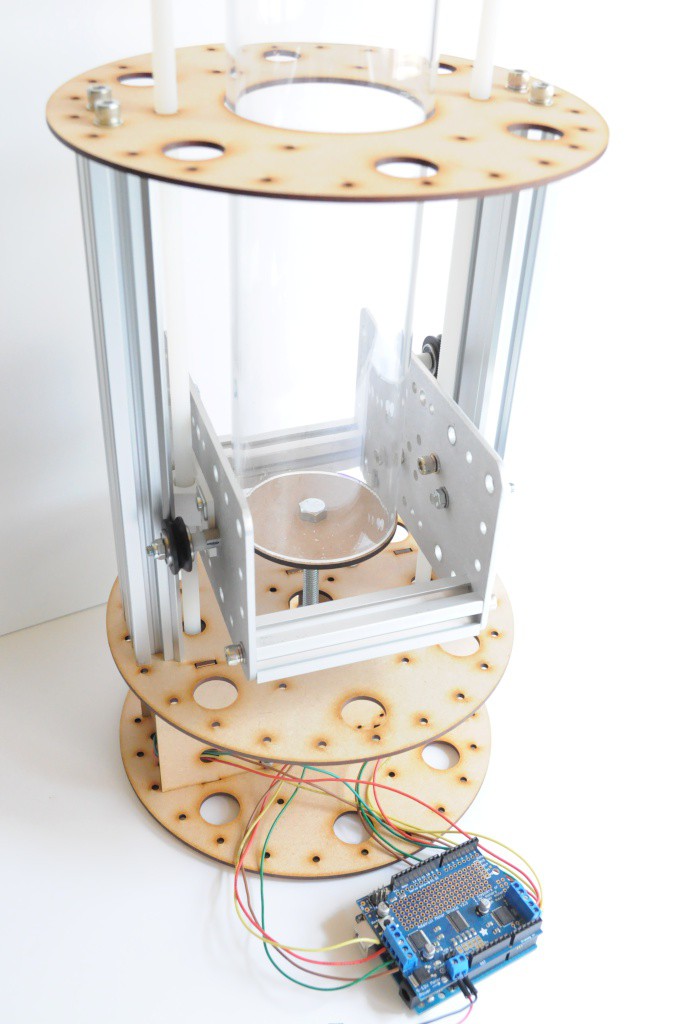

- Mechanically simple: The tomographic platform is designed to make use of a simple rotating sample tube and single linear axis, instead of a complex rotating gantry.

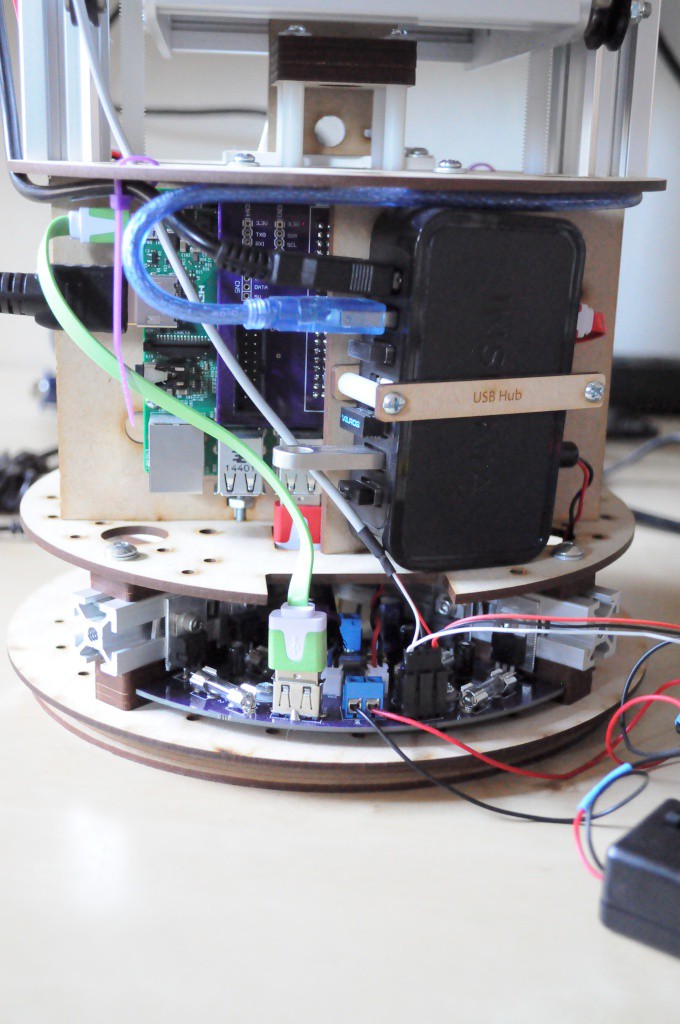

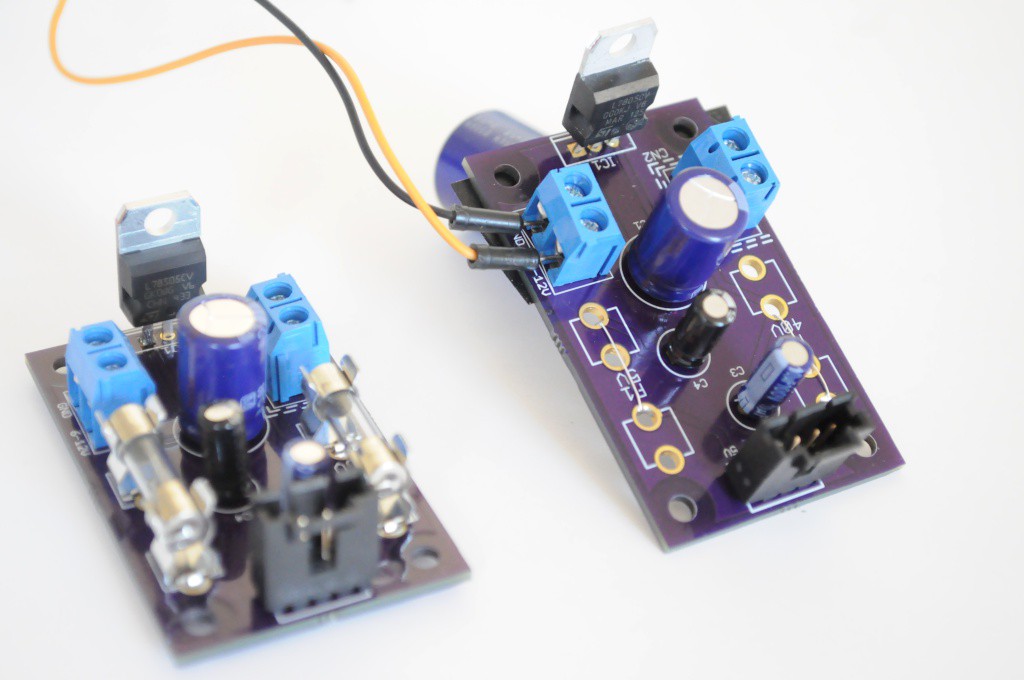

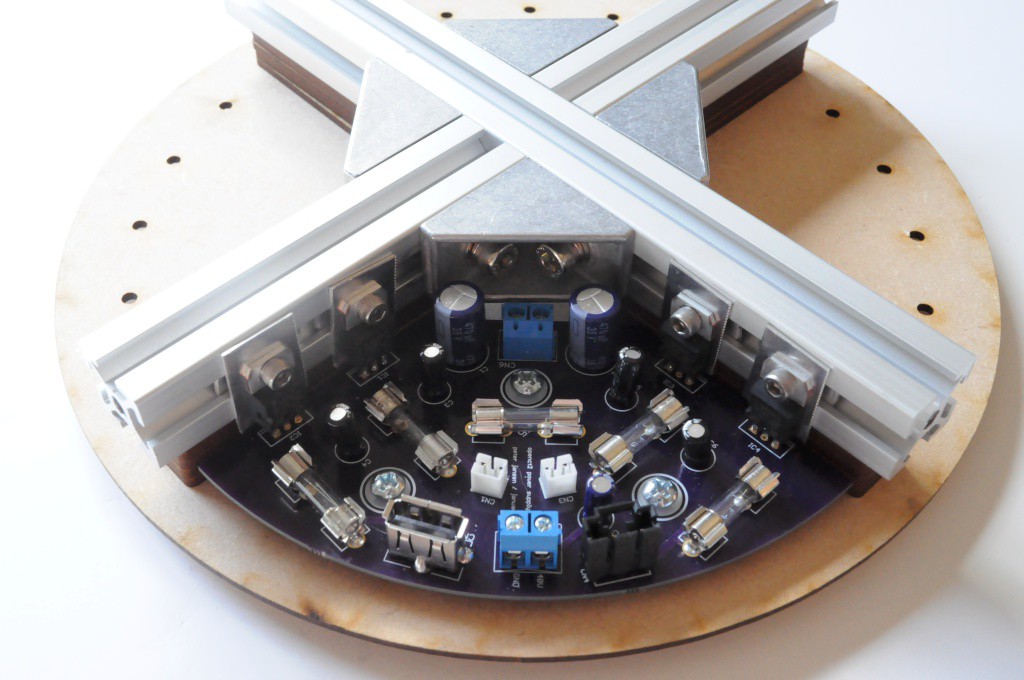

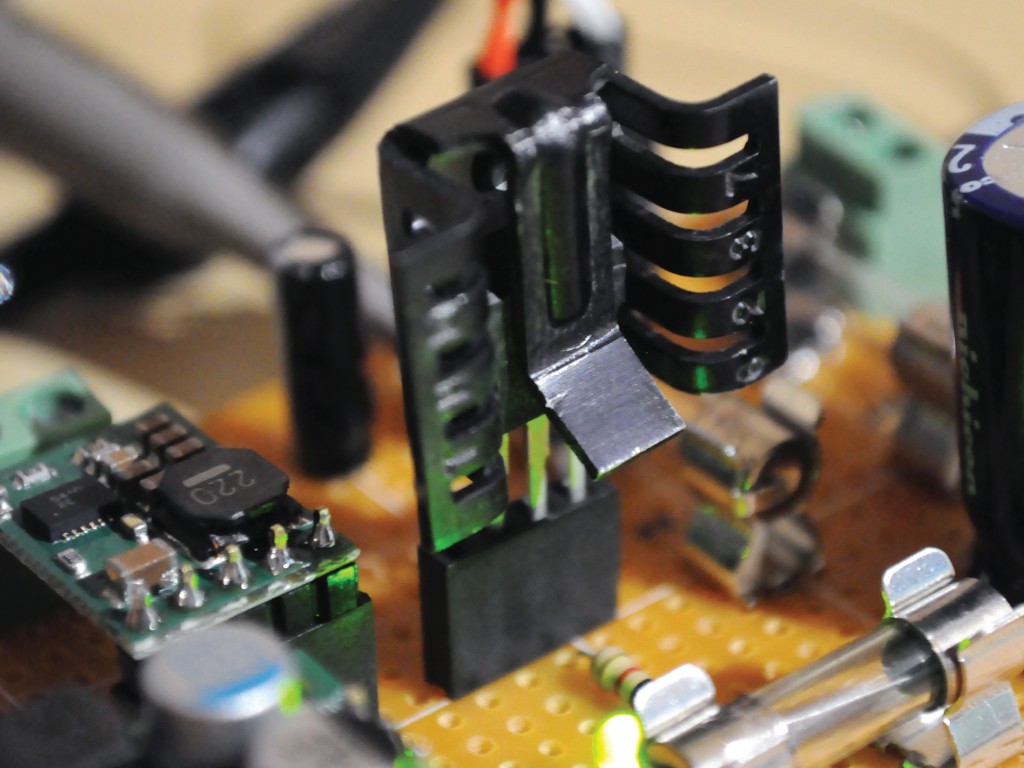

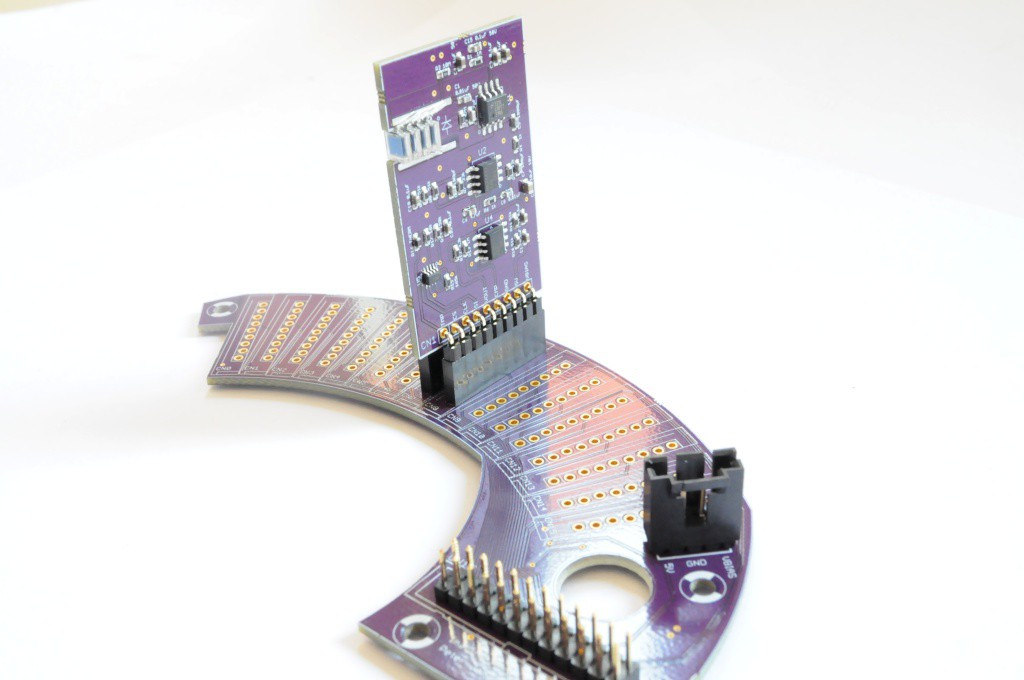

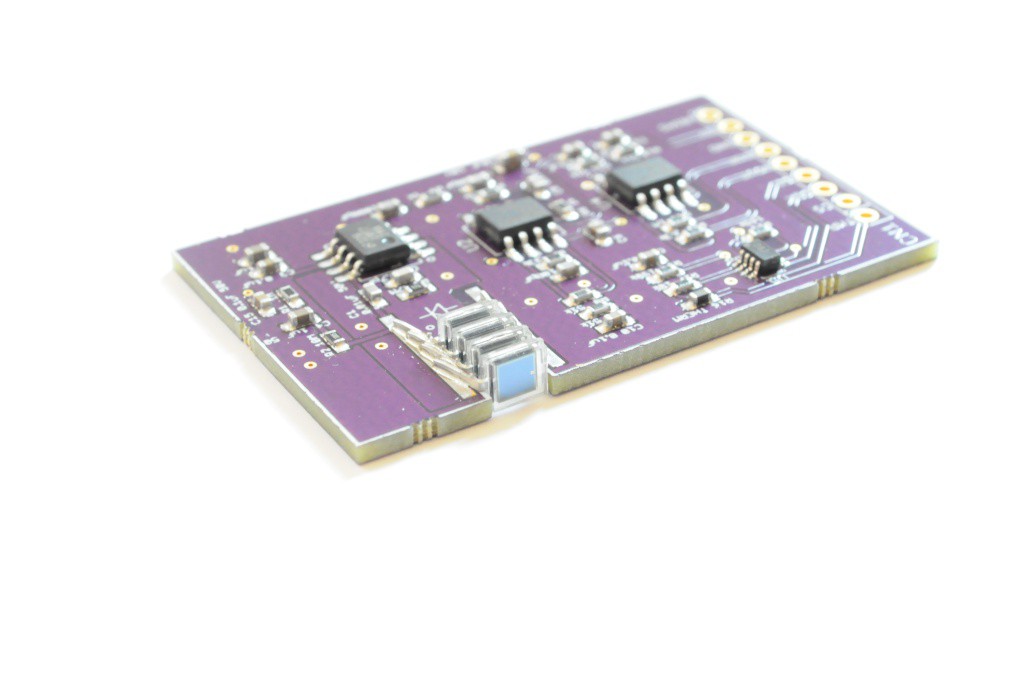

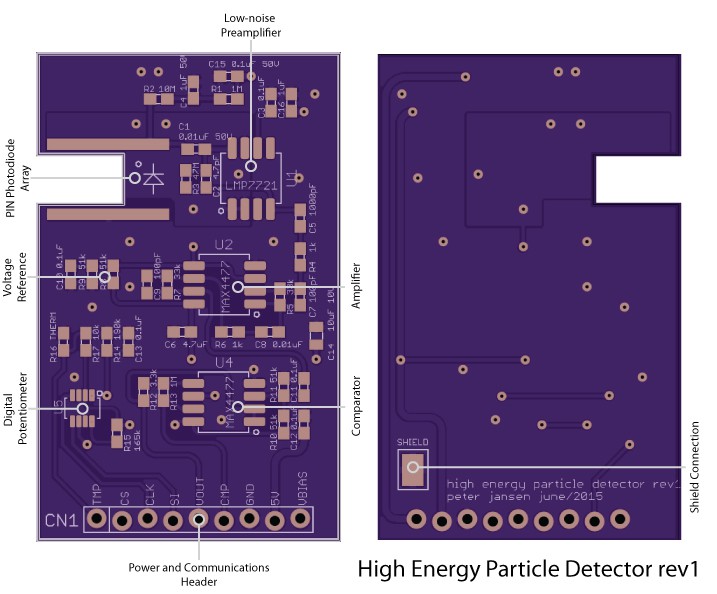

- Modular: The three main components of the system (radiation sensors, imaging array, and tomographic platform) are modular -- so whether you're simply looking for a design for an inexpensive high-energy particle detector, or a tomographic platform to mount your infrared or terahertz system upon, there's something for scientists and engineers of many interests.

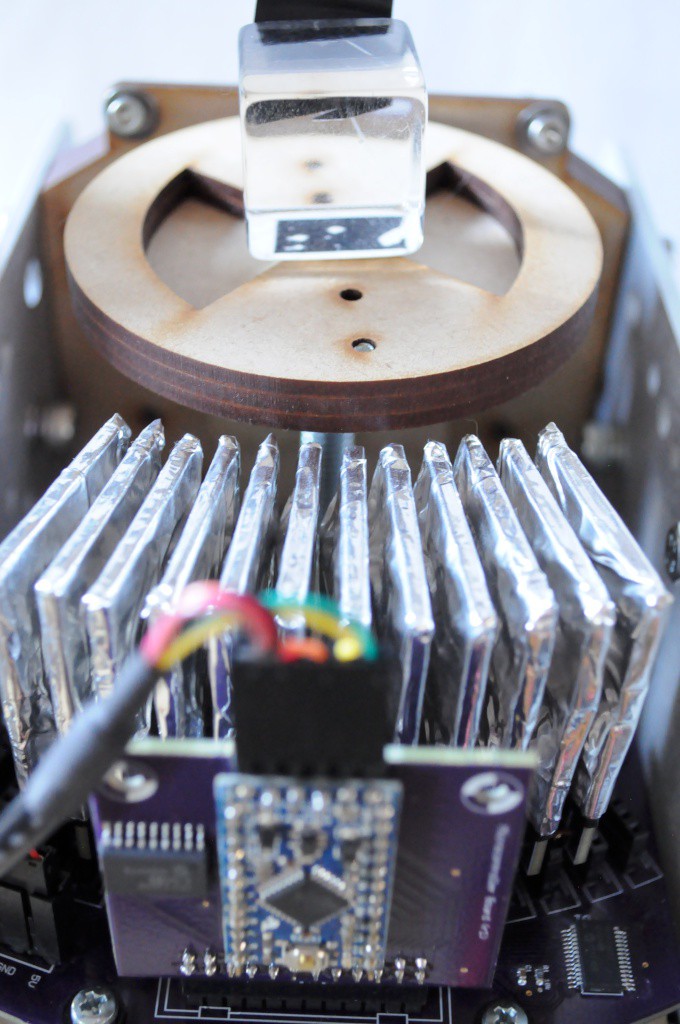

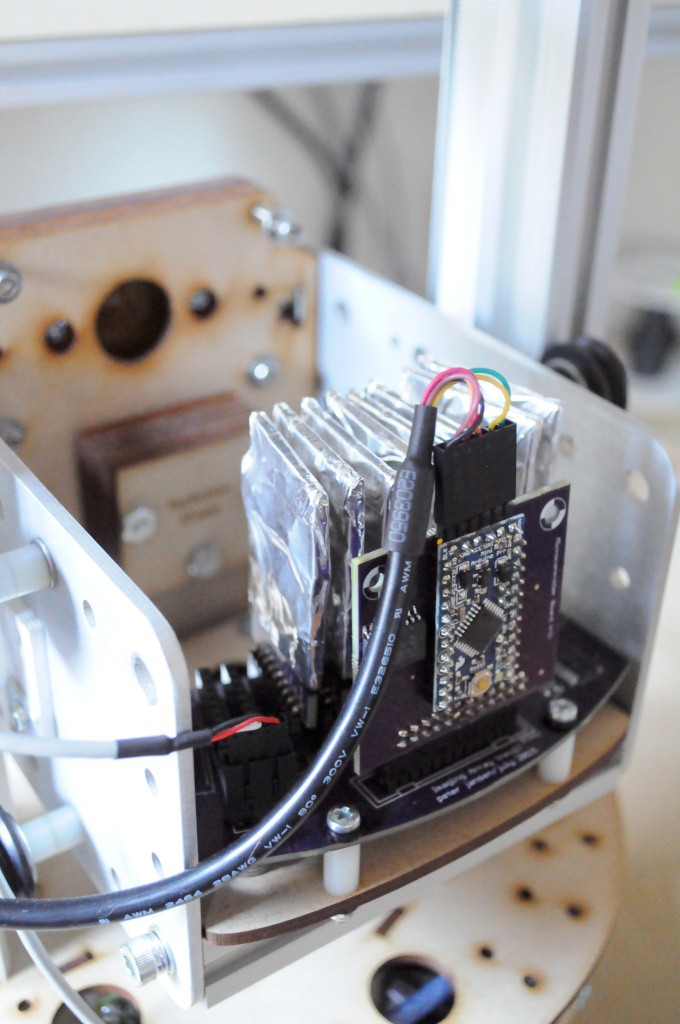

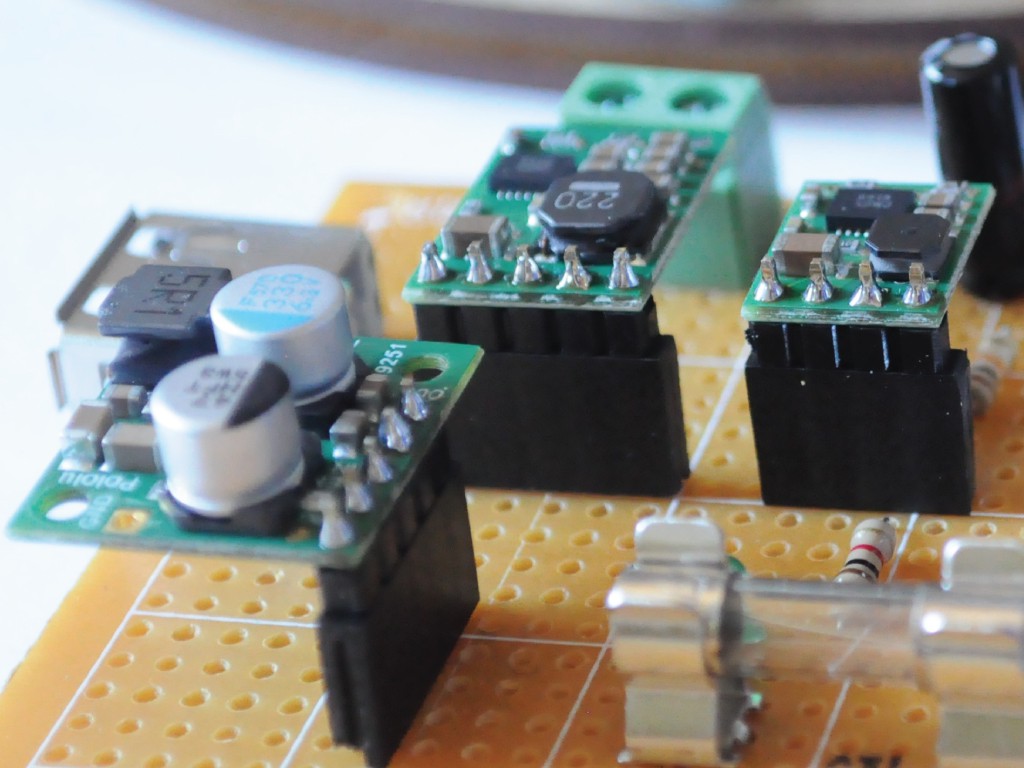

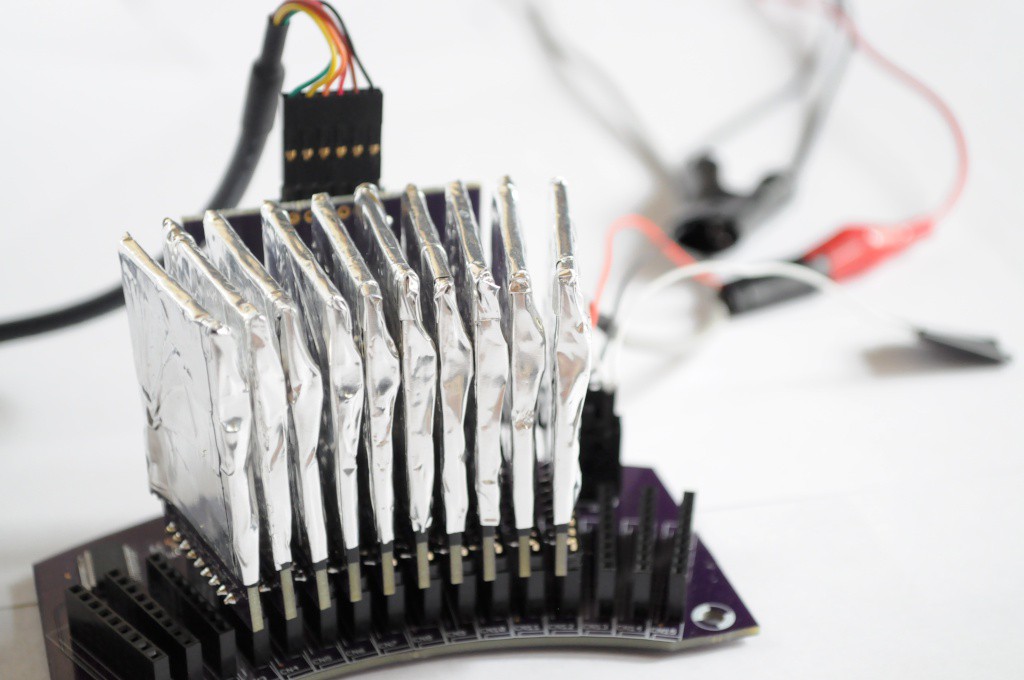

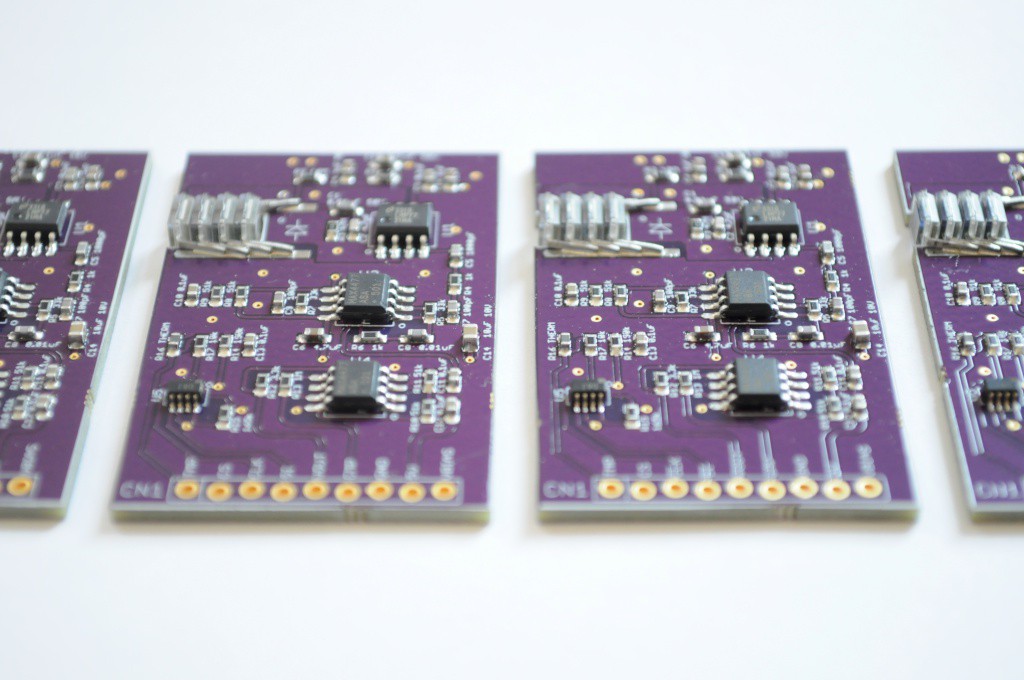

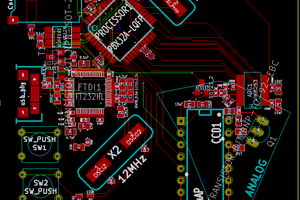

- Easy to assemble: The system is being designed to be capable of being assembled by a keen undergraduate with modest surface mount assembly skills. The modular detectors generally make use of SOIC ICs and 0603 passives. To make the tomographic platform as general as possible, it's designed to be assembled using largely off-the-shelf components, and basic through-hole soldering skills.

Contributions

The project has three main contributions:

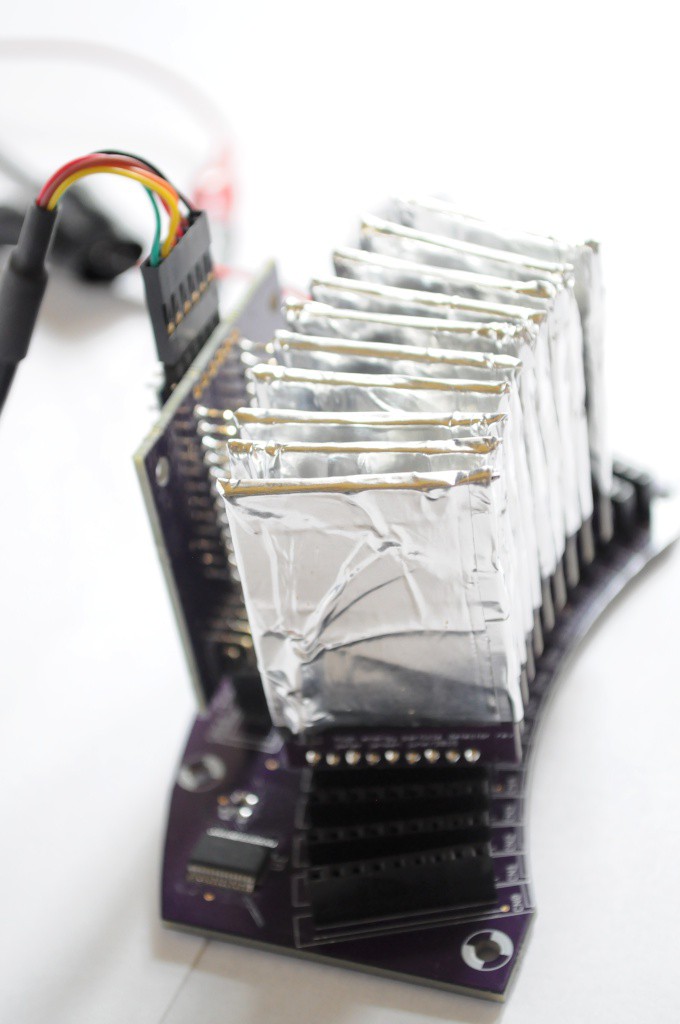

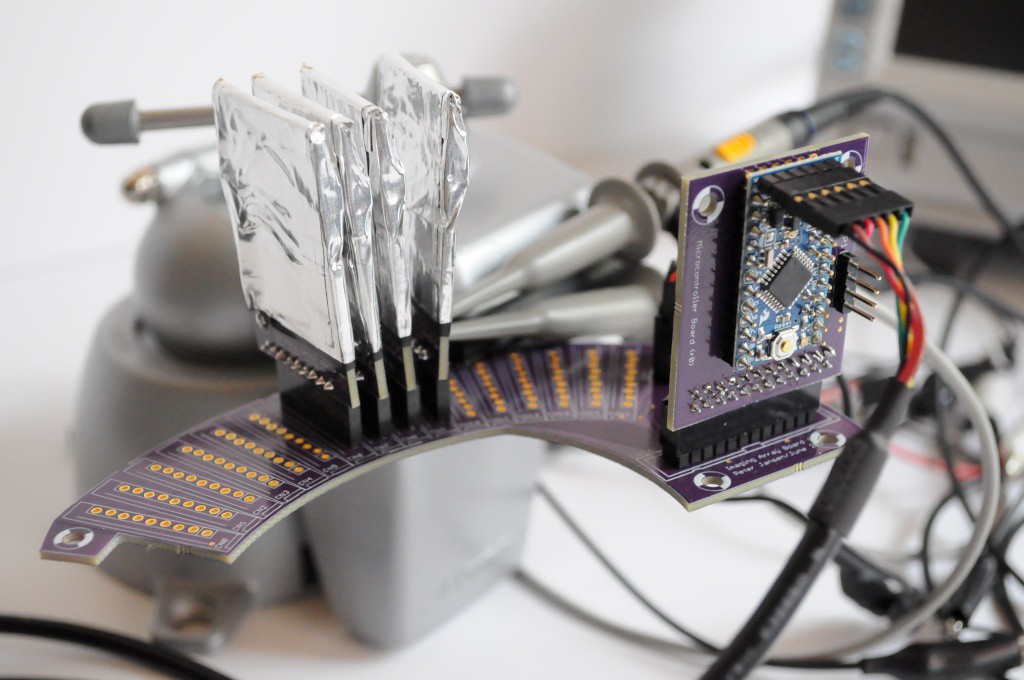

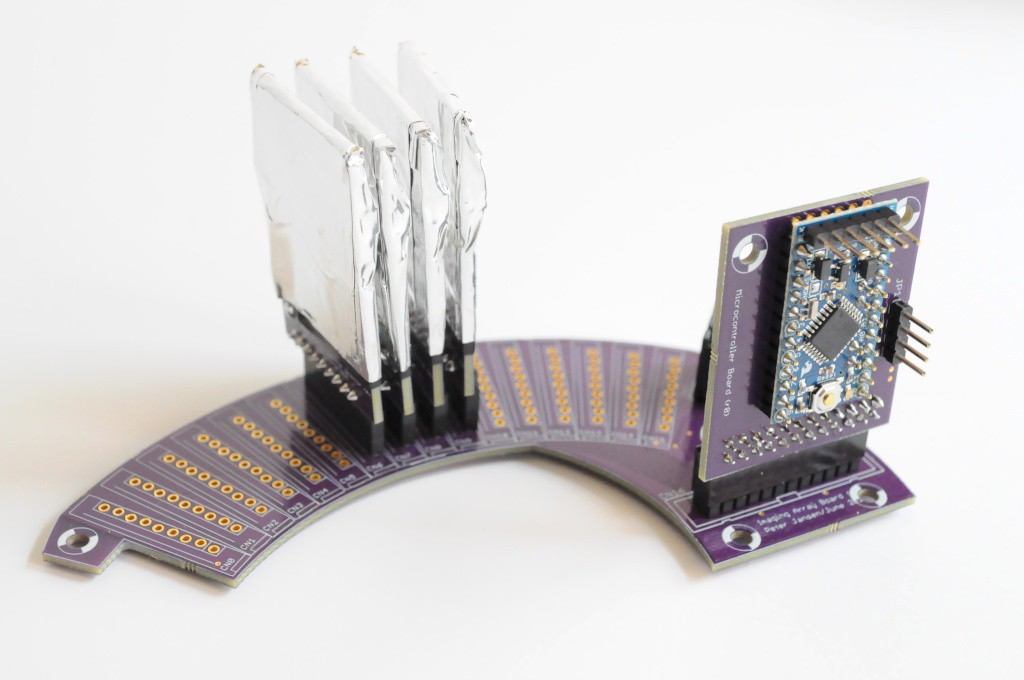

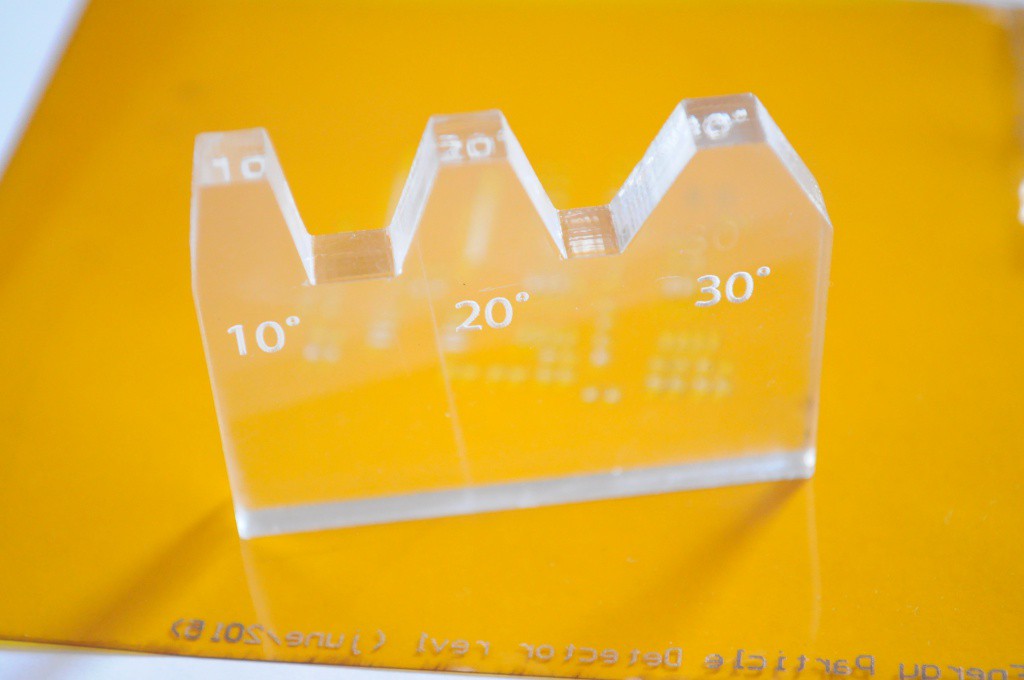

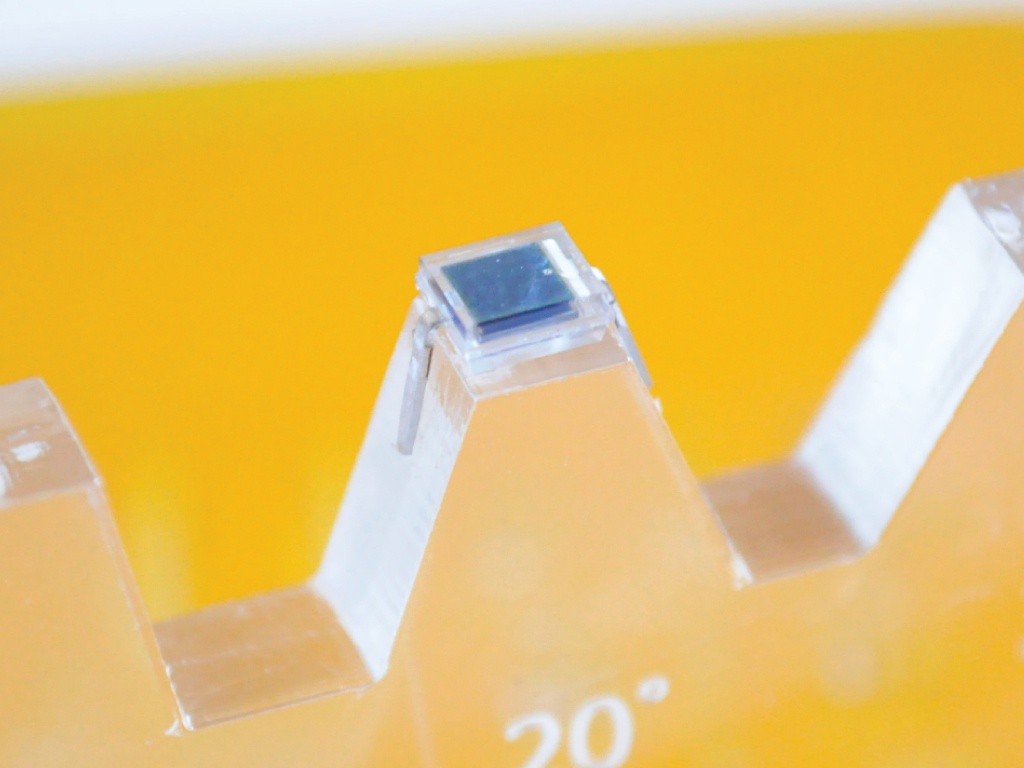

- An inexpensive modular radiation sensor suitable for low-resolution spatial imaging (nearing completion). These modules have pixel sizes of about 2.5mm square (7.5mm^2 area), and are designed to be placed in close proximity to form one dimensional imaging arrays. The single-quantity BOM for...

peter jansen

peter jansen

Adam Munich

Adam Munich

any update on the c00l CT prototype?