3D Printed Robot Actuator

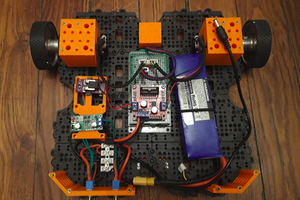

A high speed and high torque robotic actuator using low-cost brushless motors, custom controller, 3D printed parts and bearings.

A high speed and high torque robotic actuator using low-cost brushless motors, custom controller, 3D printed parts and bearings.

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

Leg.zipRepaired Pack and go file for SEA legx-zip-compressed - 28.52 MB - 04/24/2019 at 16:48 |

|

|

WS3.cywrk.Archive02.zipPSOC4 Project files Hardware and software (code) files More CAN comms and move instructionsx-zip-compressed - 1.76 MB - 10/23/2018 at 16:28 |

|

|

tail.zipFull Tail CAD Files Inventor Pack and Gox-zip-compressed - 21.73 MB - 10/21/2018 at 17:40 |

|

|

6807_tail.stpFull Tail Step Filesstp - 3.93 MB - 10/21/2018 at 16:28 |

|

|

6908_LEG.stpFull Leg (with SAE) Step filesstp - 5.83 MB - 10/21/2018 at 16:23 |

|

41:1 Dual Disk, Single stage

27mm x 102dia QM4208 motor, 6809 Bearing

Before Cycloidal Gearboxes, I research Concentric Magneti Gearboxes.

I made an improvement on the current design by drastically reducing the flux path length and hence increasing the torque handling ability.

standard flux path

New flux path

1x Brushless motor with extended shaft (6mm Silver Steel)

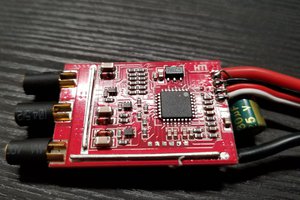

1x Custom Brushless Controller Board

2x AS5147 Absolute Position Boards

2x 6mm x 2.5mm Diametric Neodymium Magnet

12x 3D printed parts

16x 5x8x2.5 bearings

2x 6809 Bearings

5x 12x18x4

1x 6x10x3

8x 3mm dia x 30mm Silver Steel shaft

26 (or 13) 3/32" x 28mm Silver Steel shaft

26 (or 13) 1/8" x 16mm Brass tube (thin wall)

24x M3 bolts

10x M2 Bolts

3x PZT screws

1x M6 thin wall washer

1x 2mm dia x 11mm Silver Steel shaft

Suppliers

Favorite Makers

Create an account to leave a comment. Already have an account? Log In.

This looks super awesome! There's a group of roboticists that would love to hang out with you on the ODrive Discord: https://discord.gg/J9bG3dH

Swing by if you have some time to chat!

Thanks Oskar. I just joined your ODrive Discord, but remember I'm on Australia time.

This looks amazing. I always considered cycloidal gears to be just too tricky to make into actuators for joints, but seems like you have done a great job. Also seems like they are very strong and quick joints. Look forward to seeing future progressions. The quadroped construction you have looks really interesting.

Thanks Dan. I was surprised it worked so well. The first 10 prototypes were tricky but now they are made quite quickly. Cutting the silver steel rods and the brass tube still takes time. ABS is not the right material to make the cycloidal gears with. I sure other filaments would have better mechanical properties. I am using ABS because I can't get other materials to print well on my cheap 3D printer.

I've been watching your project for a while, as cost is a huge factor in how I design robots. Things start to add up when you have 20ish joints. Do you have a problem with backlash? All of the tooth gearboxes I 3D printed were very bad.

I have a couple of methods for dealing with backlash, but unfortunately there is still a bit. The cost savings across an entire platform justify me programming strategically to mitigate those effects. But I can't pretend that backlash is not an issue. I can imagine you have zero back lash on those gears?

have you considered casting the parts out of urethane or nylon? both have lubricating qualities and are much stronger than the pla or abs. I wonder if a outer casing and lube grease might make the mechanism more quite

You might want to think about using Dowel Pins for the drive pins instead of silver steel. They're available in lots of diameters and lengths.

Josh, I would like to try casting but it doesn't seem to easy. I was thinking to 3D printed Nylon. I haven't added any grease to the gears yet. The final actuator will be fully sealed (outer housing to be added later).

Drew, I didn't know about Dowel pin, thanks for the tip.

This is really great. I wonder, do you have any problems with heating/cooling of the motors? The quadcopter motors are made to work in a pretty fast stream of air, I wonder how they work without that for cooling.

I have not run the motors for more than a minute at a time and I am limiting the power to 60W. They are a bit warm, but I can still touch the stator, (about 50degC). Cooling will be required as the project progresses. I had though of water cooling around the stator with some red die in clear tubing so it looks like blood running through the quadruped's body.

Become a member to follow this project and never miss any updates

Christopher Xu

Christopher Xu

matop

matop

Petar Crnjak

Petar Crnjak

Anthrobotics

Anthrobotics

@Dan DWRobotics I do have a little bit of backlash, but it is hardly noticeable. The teeth of ABS cycloidal gear acts like a mini spring, so the back increases a bit with increase load. As you said the software can compensate for this. Backlash was the main reason I started to look into my own actuator design. I made a little biped with RC servos and my own servo amplifiers. The servo backlash was terrible.