Project Roadmap:

- Port PCB designs to KiCad

- CPU board:

- Complete!

- Memory Board:

- Complete!

- SIO board:

- Complete!

- PIO board:

- In progress

- Front Panel:

- Not started

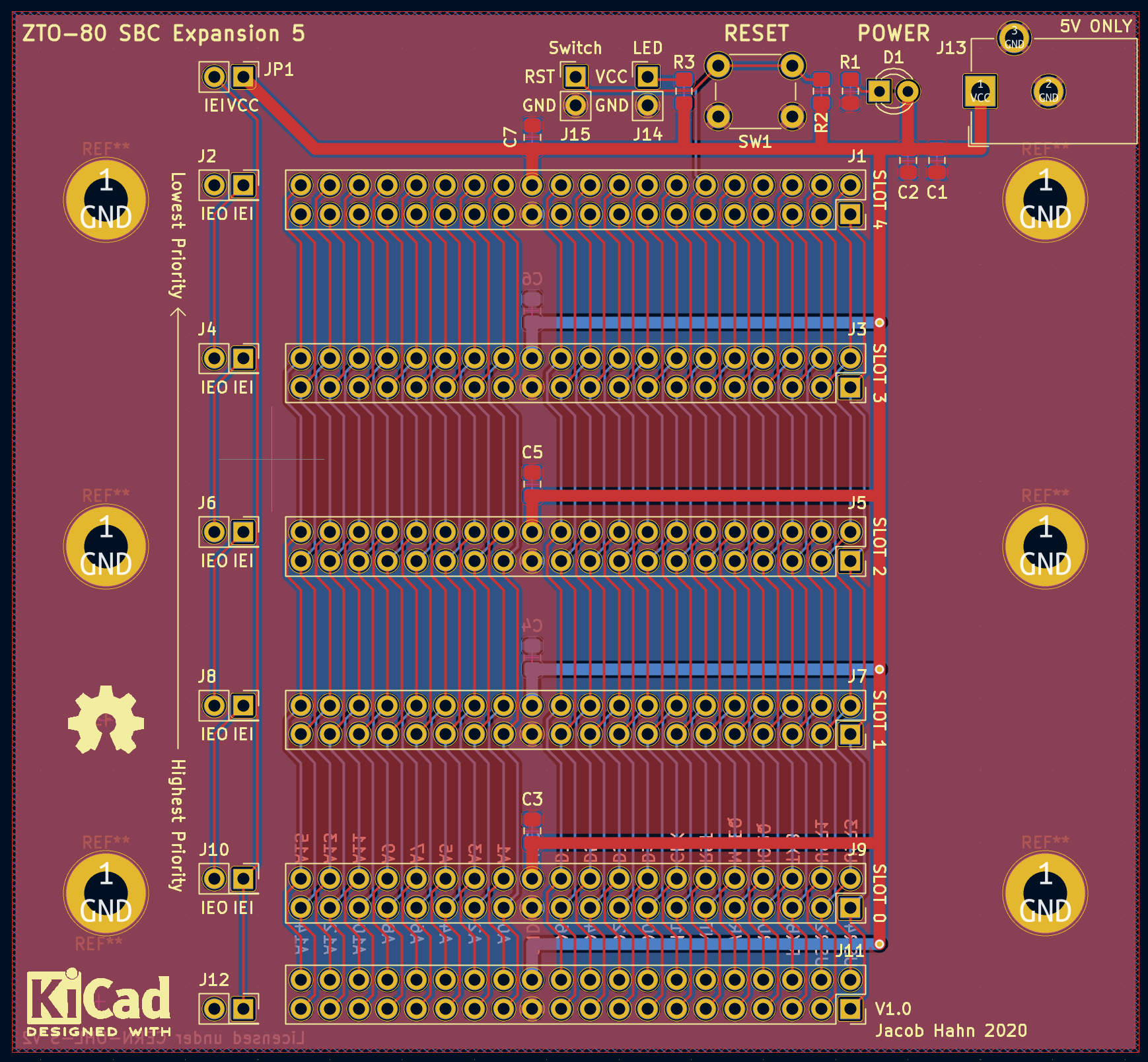

- Backplane 5:

- Complete!

- SBC:

- Complete!

- CPU board:

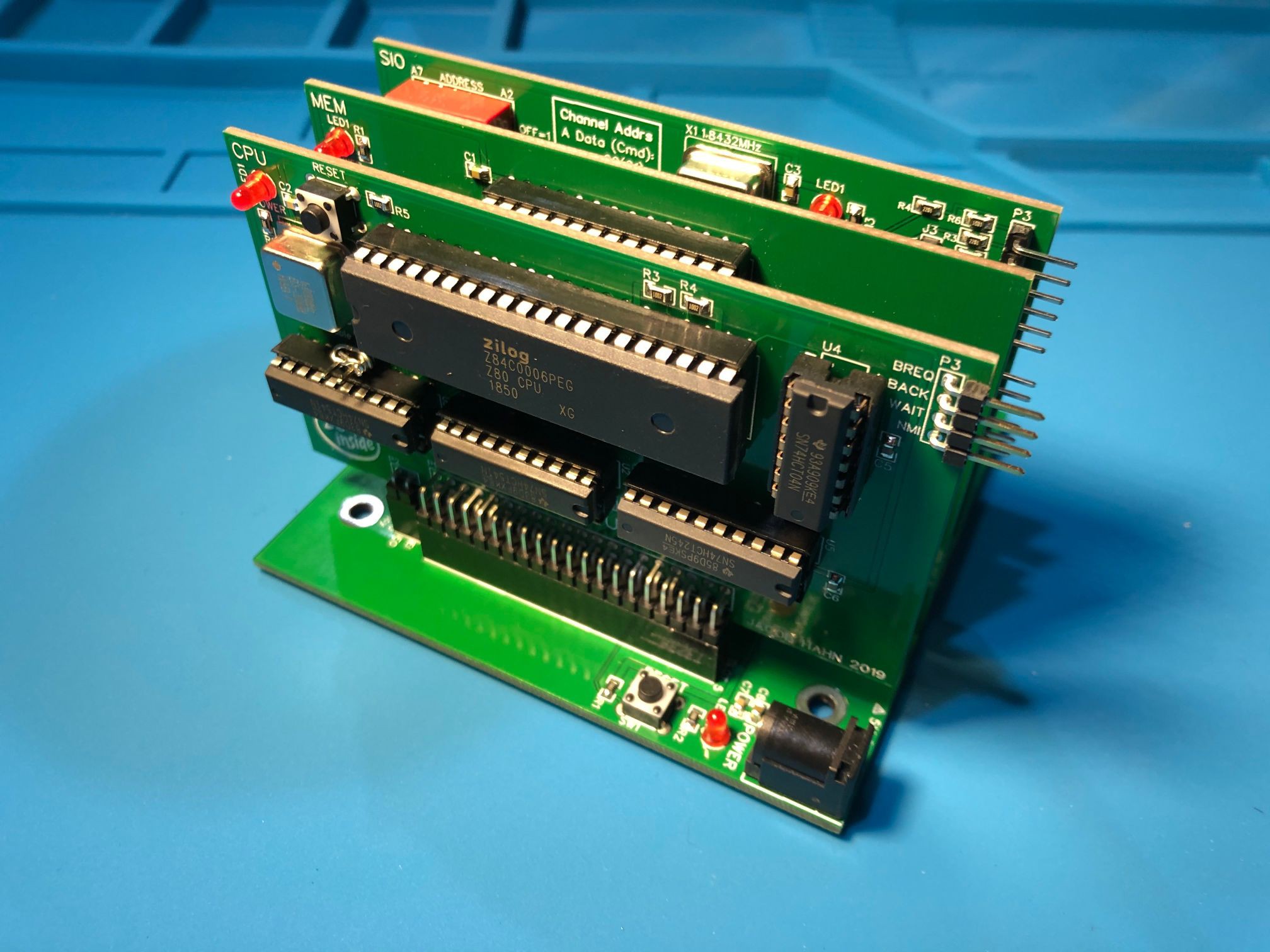

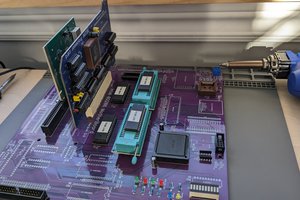

ZTO-80 Modular System Features:

- Custom bus built for the Z80 family and beyond

- Pre-designed backplane, CPU, memory, SIO, PIO, CTC, and other boards

- Nearly infinite potential for customization and expansion

- Built using off-the-shelf parts

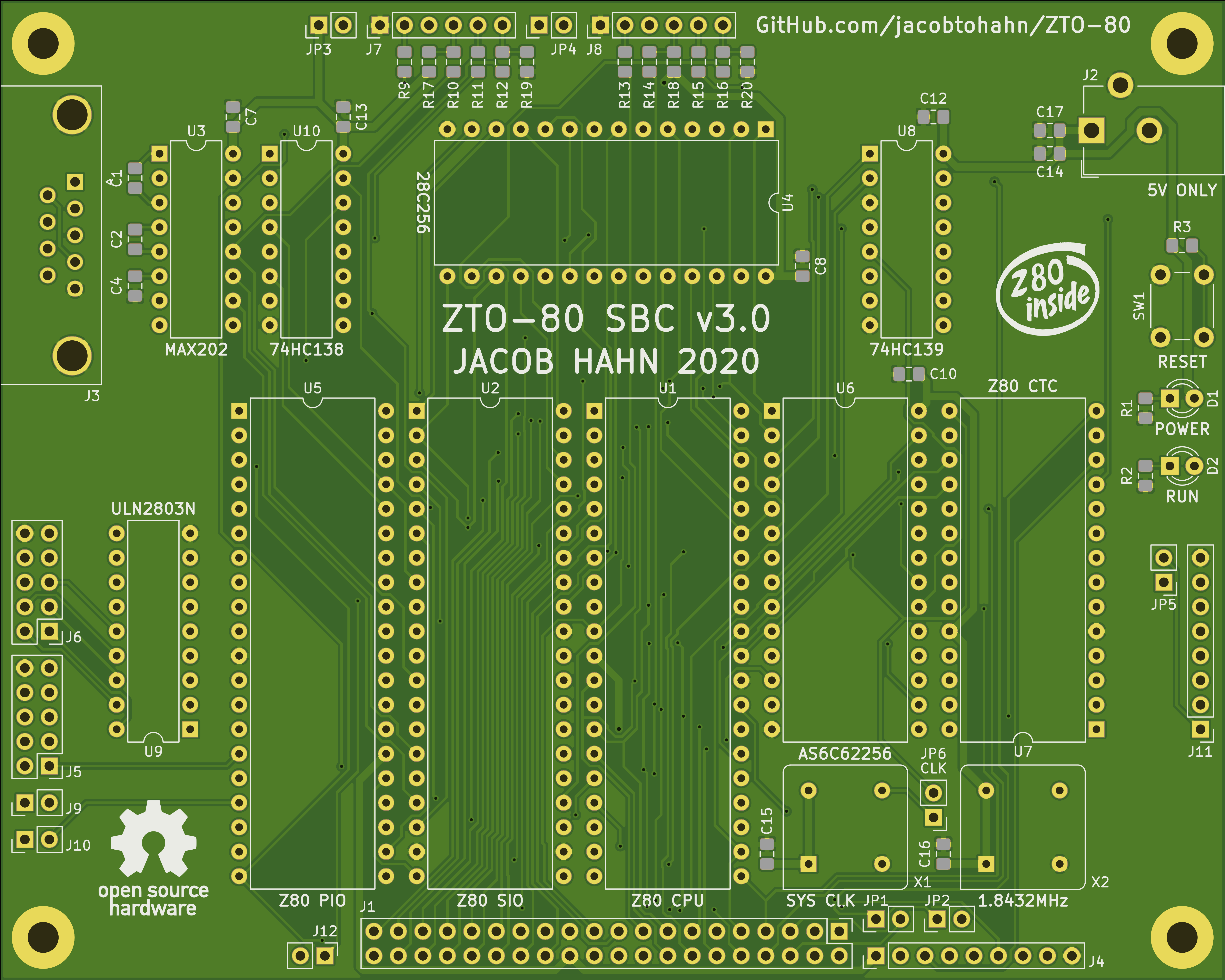

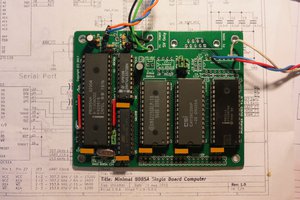

ZTO-80 SBC Features:

- 8MHz Z80 processor

- 32K of ROM, from $0000 to $7FFF

- 32K of RAM, from $8000 to $FFFF

- Z80 SIO (DART) controlling two TTL serial ports

- Z80 PIO controlling two channels, one connected through a darlington transistor array

- Z80 CTC with four software-programmable timer/counter circuits

- Modified NASCOM BASIC (Microsoft BASIC) interpreter

- Bus expansion header

- Open-source hardware!

IC selection:

The heart of the ZTO-80 System is the Z80 CPU, first designed by Zilog in 1975.

The ZTO-80 SBC is designed around hardware that would have been available during the 1980s, with only a few exceptions. Despite this, however, all of the hardware to create the SBC is still manufactured and readily available, including the entire Z80 family and the 74xx family. As of writing, every part can be found on Digikey. They can be expensive, so I have found that eBay is a good option to find chips for lower prices. However, you do need to be careful about fake and counterfeit chips. There is a BOM for the SBC in the GitHub repository, but most of the part numbers are silkscreened onto the board or can be found in the schematics.

Important hardware info:

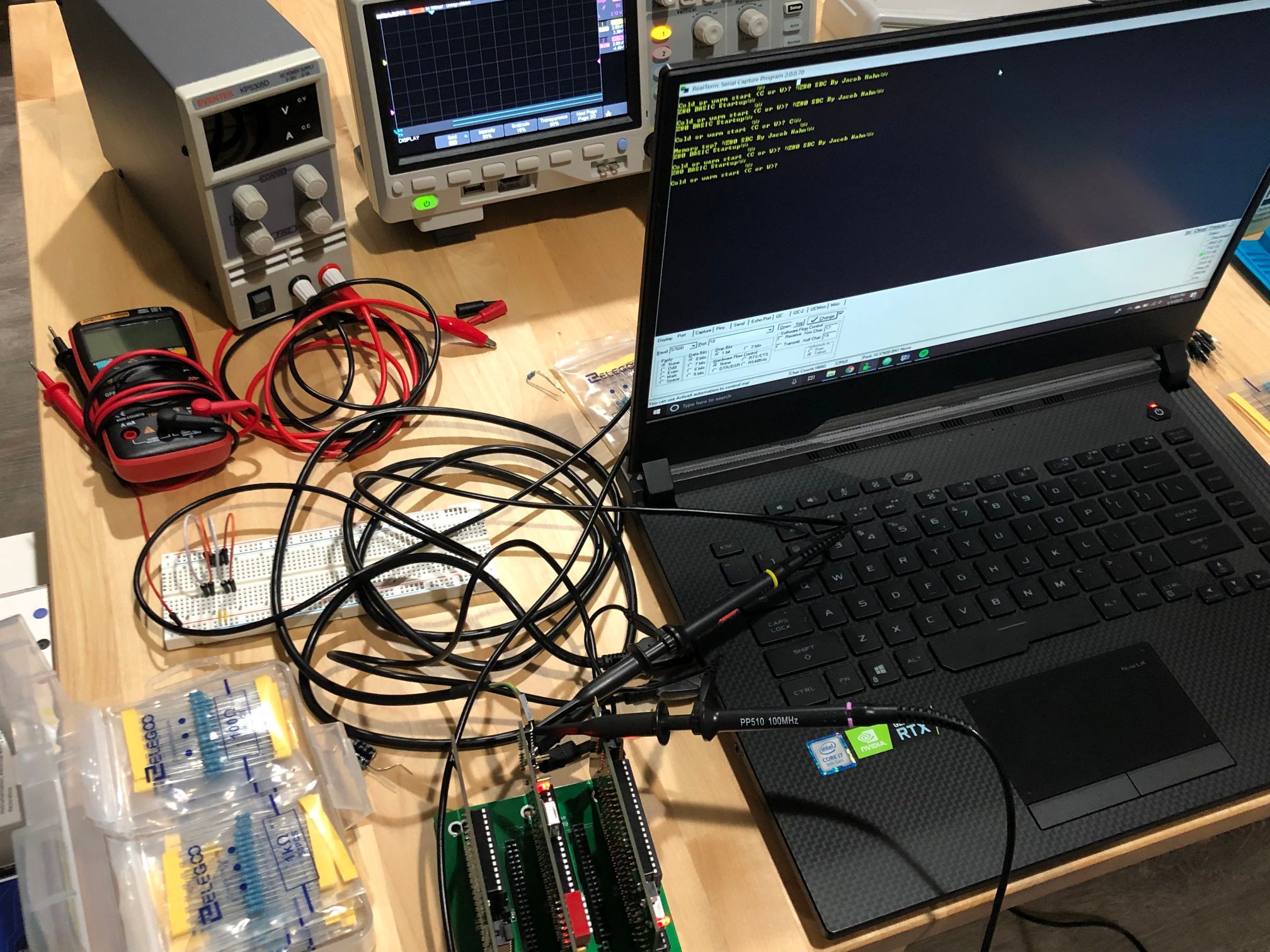

The term "ZTO-80" refers to the project as a whole. Usually, to clarify which part I am talking about, I'll say either "ZTO-80 SBC," "ZTO-80 Bus," or "ZTO-80 Modular System."

Note that the power input for the SBC is 5V only and is not regulated on the board. Anything higher than 5.5V can damage or destroy some ICs! On the SBC or backplane, power is provided through a 5.5mm barrel jack. I choose to use a cable such as this one so that I can use a USB port or AC adapter as a power source. On the modular system SIO card, either serial port can be used to provide power to the whole system, which is useful as it means that you only need one cable to use a minimal system. It is very important to only connect one power source at a time. I recommend removing the serial power jumpers from any port not being used to receive power so that it is difficult to accidentally connect multiple power sources at once.

Although my system is designed to use a CMOS Z80 SIO/0, the older Z80 DART will still work due to its compatible pinout. It is a TTL IC, but it seems to still work fine in a CMOS system from my tests with it.

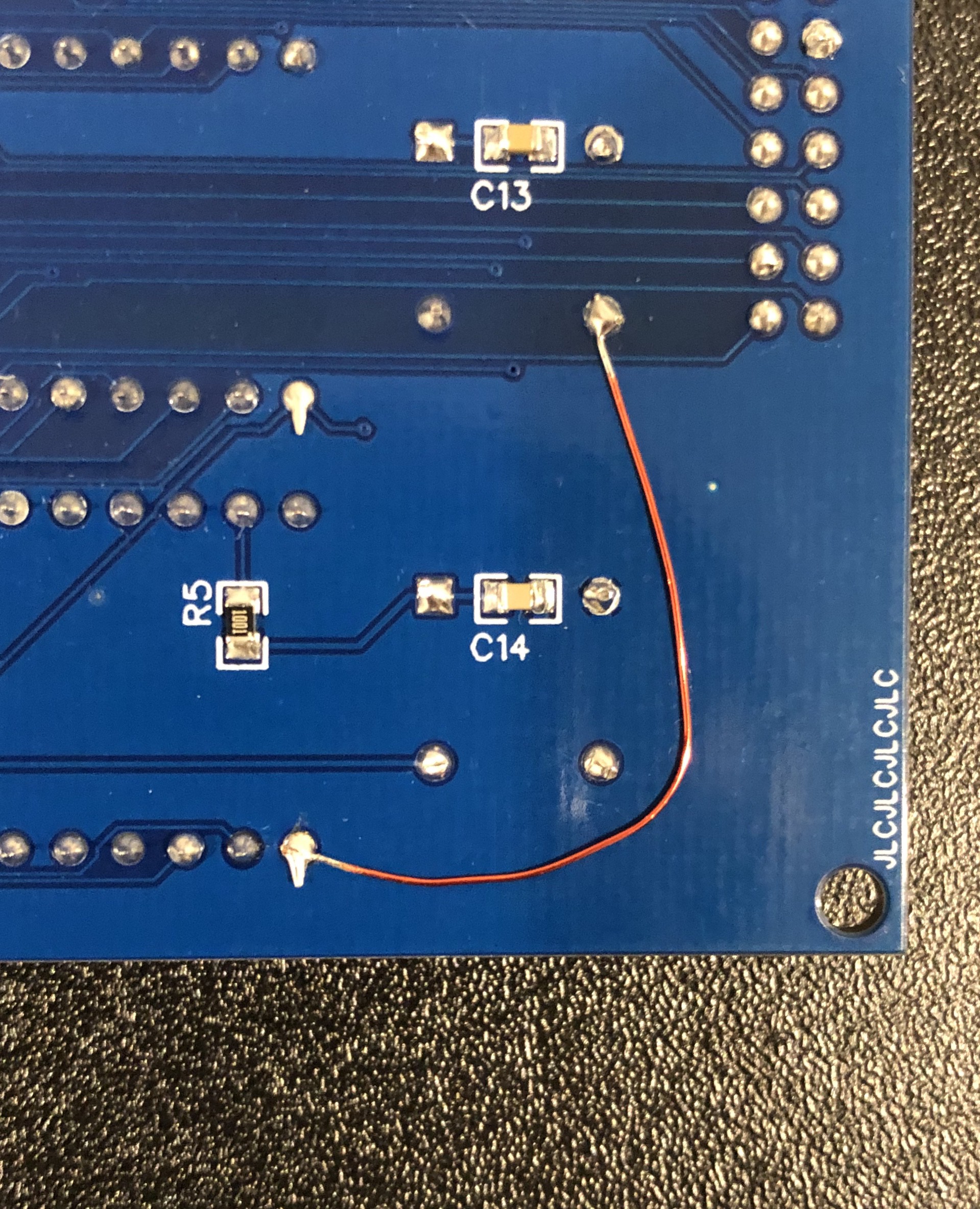

I have taken the time to create schematics and PCBs for this project. They can be found at the GitHub link on this project page. At the beginning of the year, I migrated from using EasyEDA to KiCad. I am in the process of redesigning all of my designs with KiCad. Most boards are complete, but it will take a little longer to finish the remaining designs. The boards have 0805 SMD passives, but they are large enough to easily solder even without magnification. You can also find plenty of SMD soldering tutorials online, including a quick one for passives made by me here.

I currently don't sell modular system PCBs, but you can have them ordered through JLCPCB or any other fabrication service. An order of 5 of the SBCs (excluding shipping) costs $8 from JLCPCB, and 5 boards of any ZTO-80 module type costs $4.

I sell the latest version (v3.1) of the ZTO-80 SBC on my Tindie page here. You can also find the Tindie banner for the product at the top of the page. Thank you for supporting the project!

Ideas for the future:

- CP/M capability

- A new SBC would have to be designed and I would have to create a new memory module.

- An external keyboard/video board to allow standalone...

Jacob Hahn

Jacob Hahn

Dominic Emond-Belanger

Dominic Emond-Belanger

Dean Netherton

Dean Netherton

Ken Yap

Ken Yap

Nicolò

Nicolò

this is a such a nice straightforward design! shame on me for not auditing the board *before* i had it made though.. i found out the hard way the v2.1 board you have up has the tx pin (TXA232) on the dsub disconnected, and the data out from the max202 (TXA).. tied to vcc.